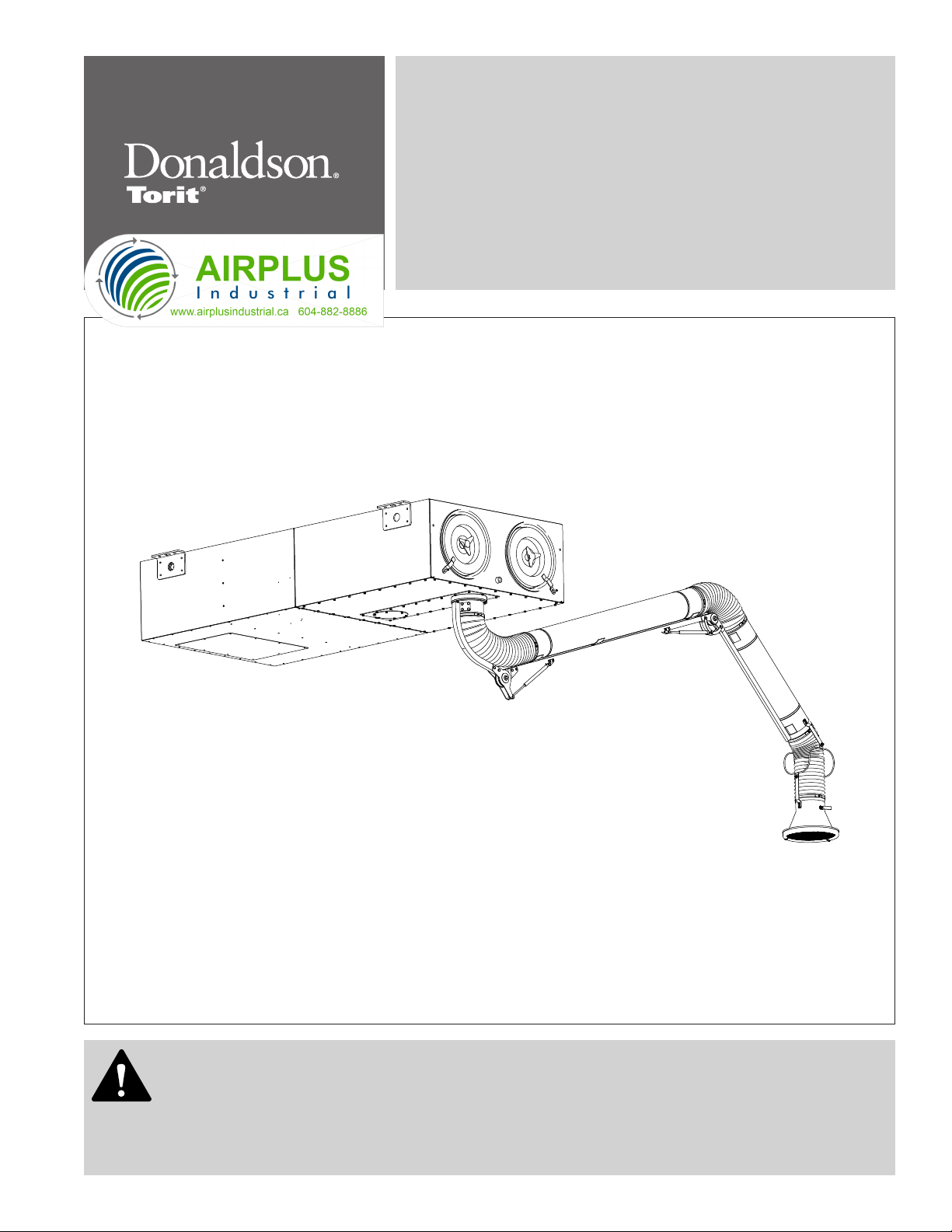

Trunk 2000,T-2000

4

Inspection on Arrival

1. Inspect collector upon delivery.

2. Report any damage to the delivery carrier.

3. Request a written inspection report from the Claims

Inspector to substantiate any damage claim.

4. File claims with the delivery carrier.

5. Compare collector received with description of

product ordered.

6. Report incomplete shipments to the delivery carrier

and your Donaldson Torit representative.

7. Remove crates and shipping straps. Remove loose

components and accessory packages before lifting

collector from truck.

8. Check for hardware that may have loosened during

shipping.

9. Use caution removing temporary covers.

Installation Codes and Procedures

Codes may regulate recirculating

filtered air in your facility.

Consult with the appropriate authorities

having jurisdiction to ensure compliance

with all national and local codes regarding

recirculating filtered air.

Safe and efficient operation of the collector depends on

proper installation.

Authorities with jurisdiction should be consulted

before installing to verify local codes and installation

procedures. In the absence of such codes, install

collector according to the National Electric Code,

NFPA No. 70-latest edition and NFPA 91 (NFPA 654 if

combustible dust is present).

A qualified installation and service agent must complete

installation and service of this equipment.

All shipping materials, including shipping covers, must

be removed from the collector prior to or during collector

installation.

Failure to remove shipping

materials from the collector will

compromise collector performance.

Inspect collector to ensure all hardware is properly

installed and tight prior to operating collector.

Installation

Use proper equipment and adopt

all safety precautions needed for

servicing equipment.

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Turn compressed air supply OFF, bleed and

lock out lines before performing service or

maintenance work.

Site selection must account for

wind, seismic zone, and other

load conditions when selecting the location for

collectors.

Codes may regulate acceptable locations for

installing dust collectors. Consult with the

appropriate authorities having jurisdiction to

ensure compliance with all national and local

codes regarding dust collector installation.

Collectors must be anchored in a manner

consistent with local code requirements.

Anchors must be sufficient to support dead,

live, seismic, and other anticipated loads.

Consult a qualified engineer for final selection

of anchorage.

Do not set compressed-air

pressure above 100-psig as

component damage can occur.

All compressed air components must be sized

to meet the system requirements of 90-100-psig

supply pressure.

The compressed-air supply must be oil

and moisture free. Contamination in the

compressed air used to clean filters will result

in poor cleaning, cleaning valve failure, or poor

collector performance.

Purge compressed air lines to remove

debris before connecting to the collector’s

compressed air manifold.