Correct treatment of the microphone

cable

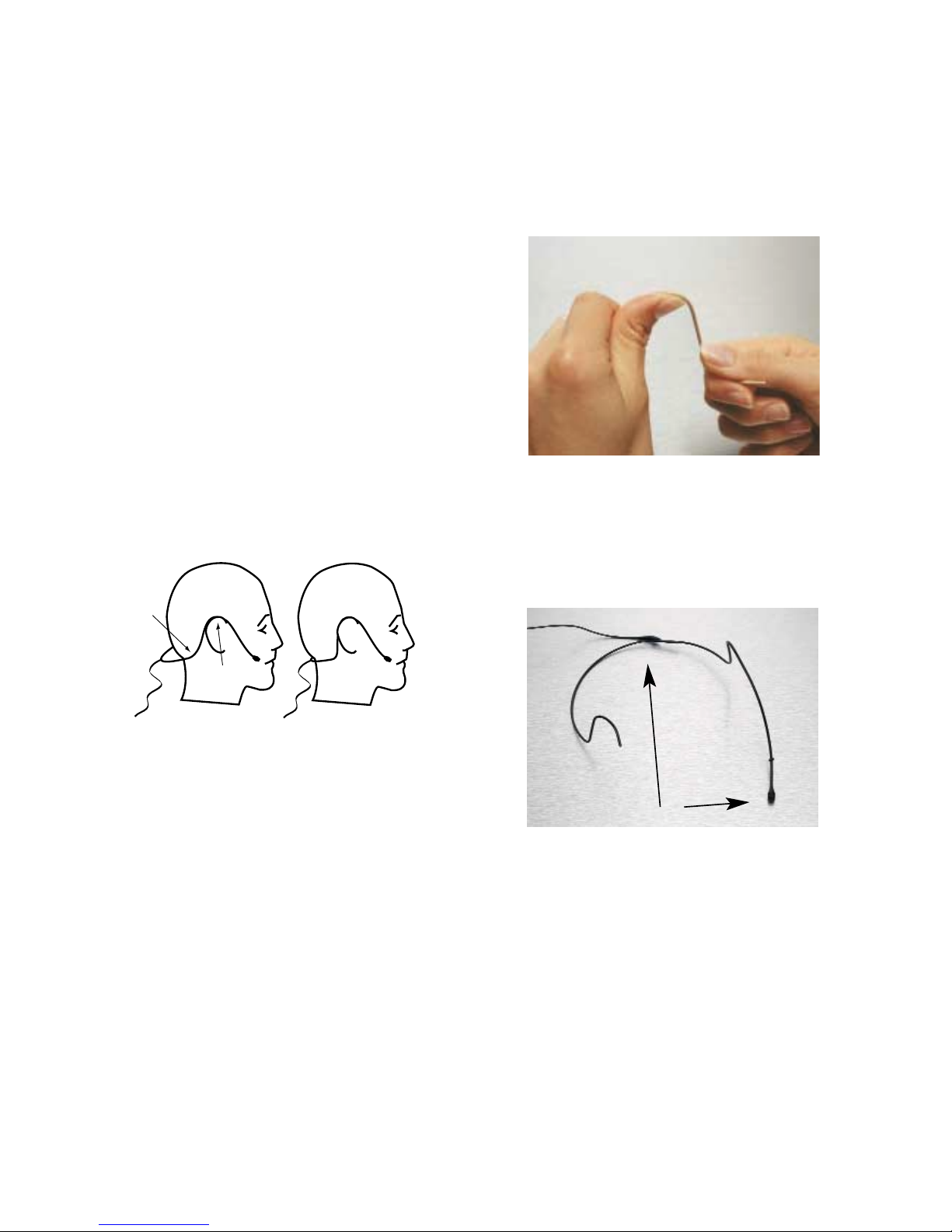

The cable is usually longer than required for

its actual purpose. Ensure that superfluous

cable is wound up in soft loops (preferably

6-8 cm in diameter). Avoid ’kinks’ in the cable.

Exposing the cable to stretching beyond its

specifications or stressing it by winding it

tightly over sharp edges will reduce the

microphone’s operational life.

Tip: Handling noise from the cable can

be decreased by up to 30dB by making

a loose loop in the cable, as close to the

microphone element as possible. The

DMM0008 Miniature Clip, double lock,

is designed for this mounting tech-

nique. See picture on page 5.

Tip: The place where the cable enters

the MicroDot connector will sometimes

be exposed to excessive stress and

after long term heavy-duty use, the

cable might show signs of wear at this

point. As a preventive maintenance pro-

cedure, it may be advisable to replace

the connector in this instance. Contact

the nearest DPA Microphones repre-

sentative for maintenance advice or

assistance.

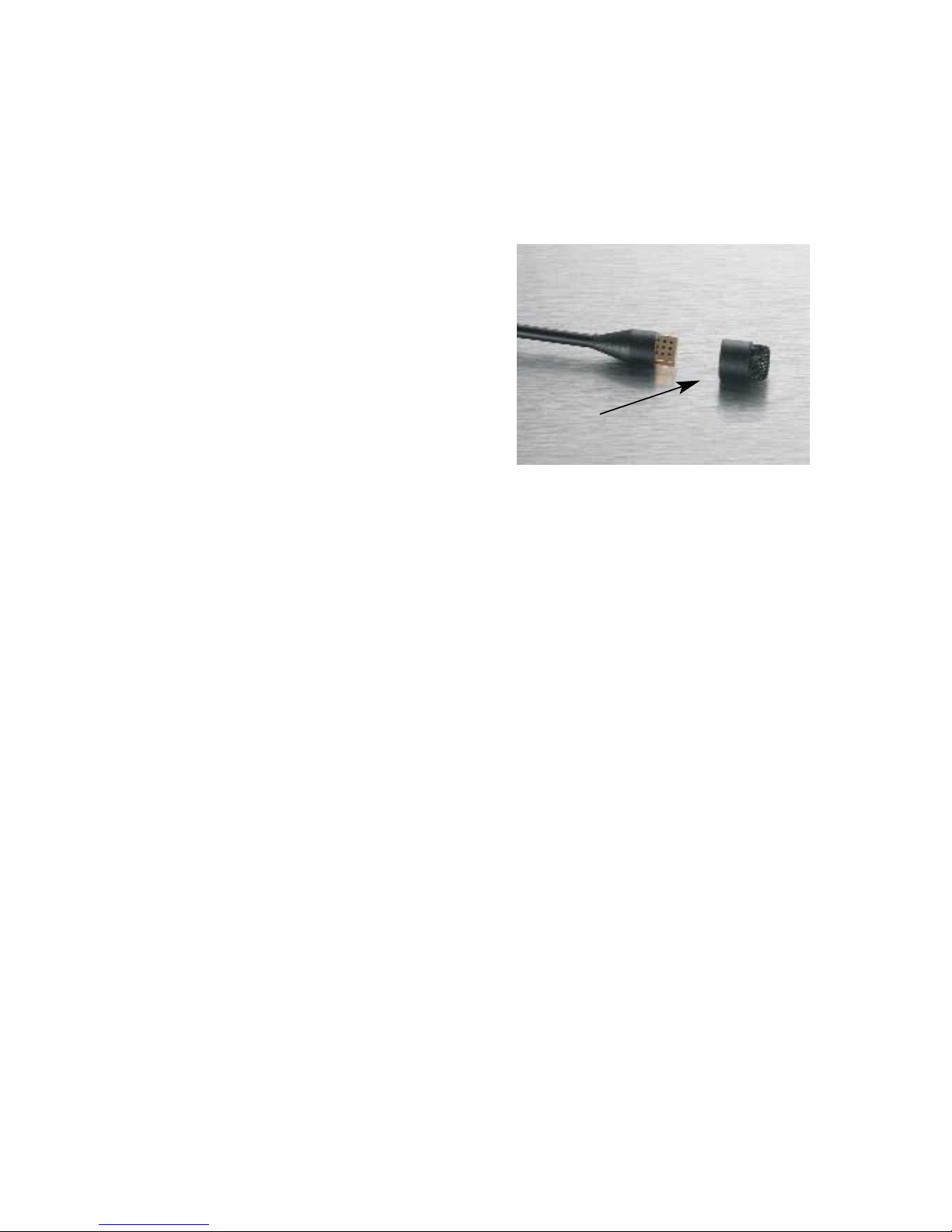

Correct use of adapters and MicroDot

connectors

To provide users with safe and compact

mounting of connectors, all Miniature

Microphones from DPA are fitted with the

MicroDot connector as standard. A broad

range of connection adapters is offered

as optional accessories for most VHF and

UHF systems for professional use. The

adapters are ultra-compact and will in most

cases take up no more space than the orig-

inal connectors.

A connector-tightening tool is supplied with

each adapter and should be employed

whenever the MicroDot connector needs to

be tightened safely onto the adapter for

long periods of time. Never attempt to

6

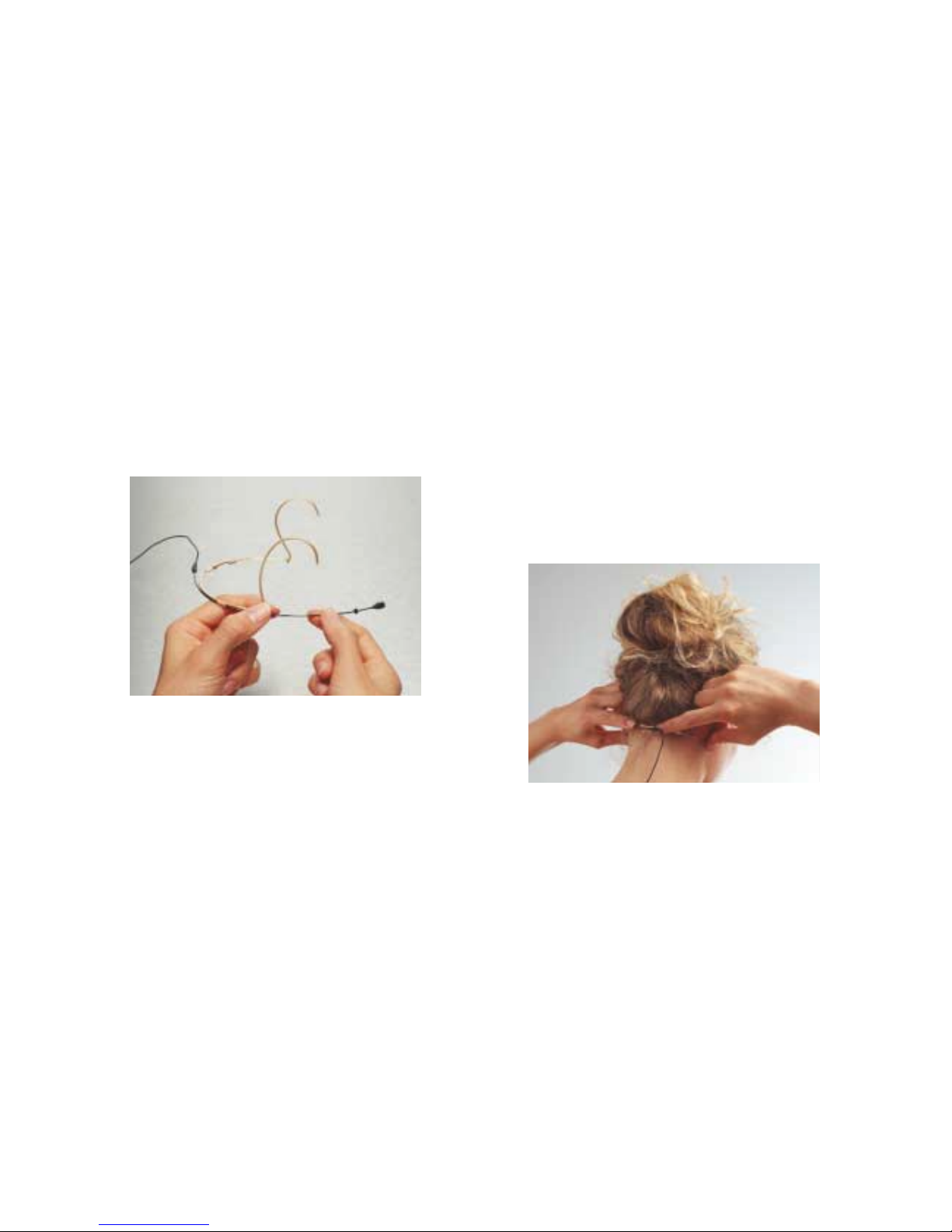

Correct way to wind up the cable of the

Miniature Microphone. Please note the

slack after the connector.