2/8 3/8

VCD 204 VCD 204

99.831.09 1.4/02/22 99.831.09 1.4/02/22

English English

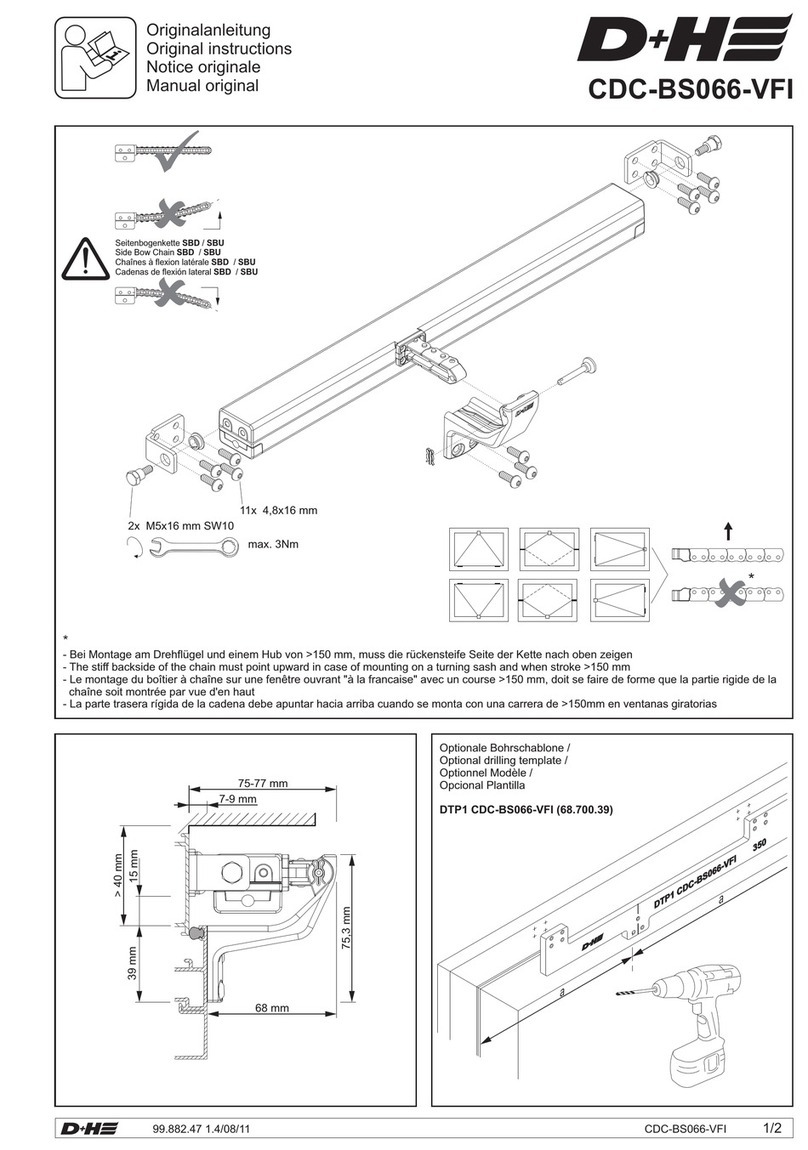

Entrapment protection (see N.12 of Safety Notes; p 2/8)

In "CLOSE" direction the drive has an active

clamping protection for the main closing edge. With

an overload in the closing range 3 and 2 the drive

runs "OPEN" for 20 seconds, then drive "CLOSE"

again. If after three attempts a closing is not possible,

the drive remains in this position.

In addition, the drive has a passive clamping

protection. The closing speed in closure Range 2

and 1 is reduced to 5 mm/s (0.2"/s). The drives were

not evaluated for entrapment protection.

Higher forces can occur on

besides closing edges.

Danger of violent pressure

in handaccessible area.

The dri ves were not evalua ted f or

entrapment protection.

All forces + approx. 20 % switch-off reserve (temporary)

Running speed and forces

6 mm/s (0.24"/s)

150 N (33.7 lbf)

(Safety cut-off force)

77 mm

(3")

6 mm/s (0.24"/s)*

200 N (45 lbf) **

23 mm

(0.9")

Closure Ranges

5 mm/s (0.2"/s)

150 N (33.7 lbf)

Main closing edge

Beside closing edge

Beside -

closing edge

! IMPORTANT ! Safety Notes

1. Mounting of the drive should be carried out by a D+H distributor, whose qualification and experience is

ensured by regular in-house training.

2. All wiring must be installed by a qualified electrican according to National Electrical Codes, NFPA 70.

3. For indoor use only. Use always rain detector with danger of rain (e.g. at domelights or roof windows).

4. Observe enclosed red safety slip!

5. Danger of violent pressure in handaccessible area.

6. The window operators have been evaluated for Residential or Light Duty Commercial Use only.

7. A suitable field wiring means should be provided in the end use application.

8. The mounting and routing of external wiring should be determined in the end product.

9. The mounting of each unit shall be evaluated in the end use.

10. The suitability of the leads for field wiring should be determined in the end-use application.

11. The drive must be mounted a min of 8 feet above the floor or any access level.

12. The drives were not evaluated for entrapment protection since they are to be installed at least 8 feet above

the floor. Where entrapment is a consideration, the need for additional tests and evaluation should be

determined during the end product investigation.

13. The drive shall be connected to a Class 2 power supply.

For North America:

14. The Uniform Building Code Standard Vols. 1, 2 & 3 have to be observed.

Intended use

- Chain drive for electric opening and closing of

windows and flaps in the facade and roof area

- Useable for daily natural ventilation

- Operating voltage 24 V DC

- Only for inside mounting

Performance features

- Micro processor controlled electronics

- Individually programmable via Powerline (PLP1

with BI-BT 2 and SCS)

- Stroke programming with magnets

- Low running noises

- Connection via plug connector

- Tandem-safety function for operation of two

VCD 204 drives on one sash

Operating voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection has to be carried out only by an

authorized electrical specialist

- Danger of violent pressure in handaccessible area

- Keep away People from the operating area of the

drive

- Keep away children from the control

- Use only in dry rooms

- Only for inside mounting.

Use rain detector with danger of rain

(e.g. at domelights or roof windows)

- Just use unchanged original D+H parts

- Observe mounting instructions of bracket set!

Observe enclosed r ed safety slip!

Safety notes

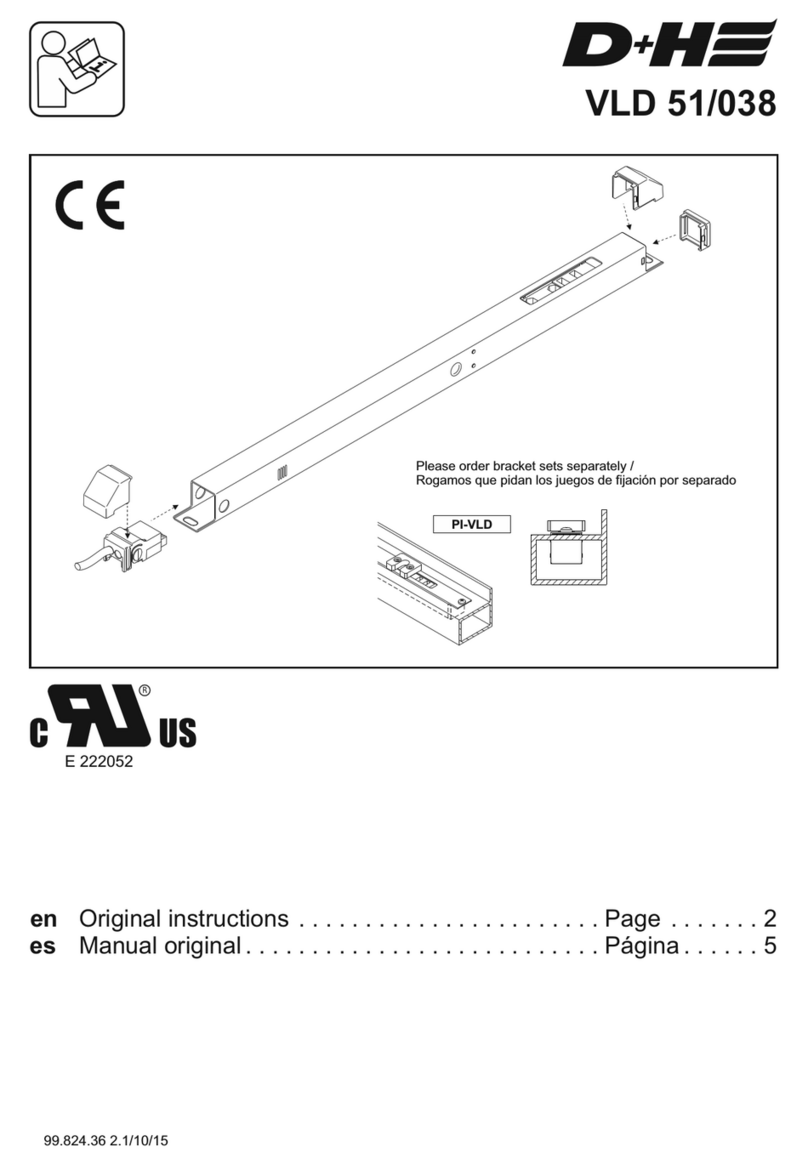

Drive unit with 2,5 m (97.5") PVC cable. Dependent

on the type of window, different bracket sets are

available separately.

Extent of supply

Up to two VCD 204 drives and one locking drive can

be used in tandem. Combined TMS and BRV signal.

The BRV signal is only output when in the end

position - this prevents locking drives and modules

from malfunctioning.

During the learning phase, the activated stroke is

transferred to the tandem drive via the TMS+

function.

TMS+ / -BRV function

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

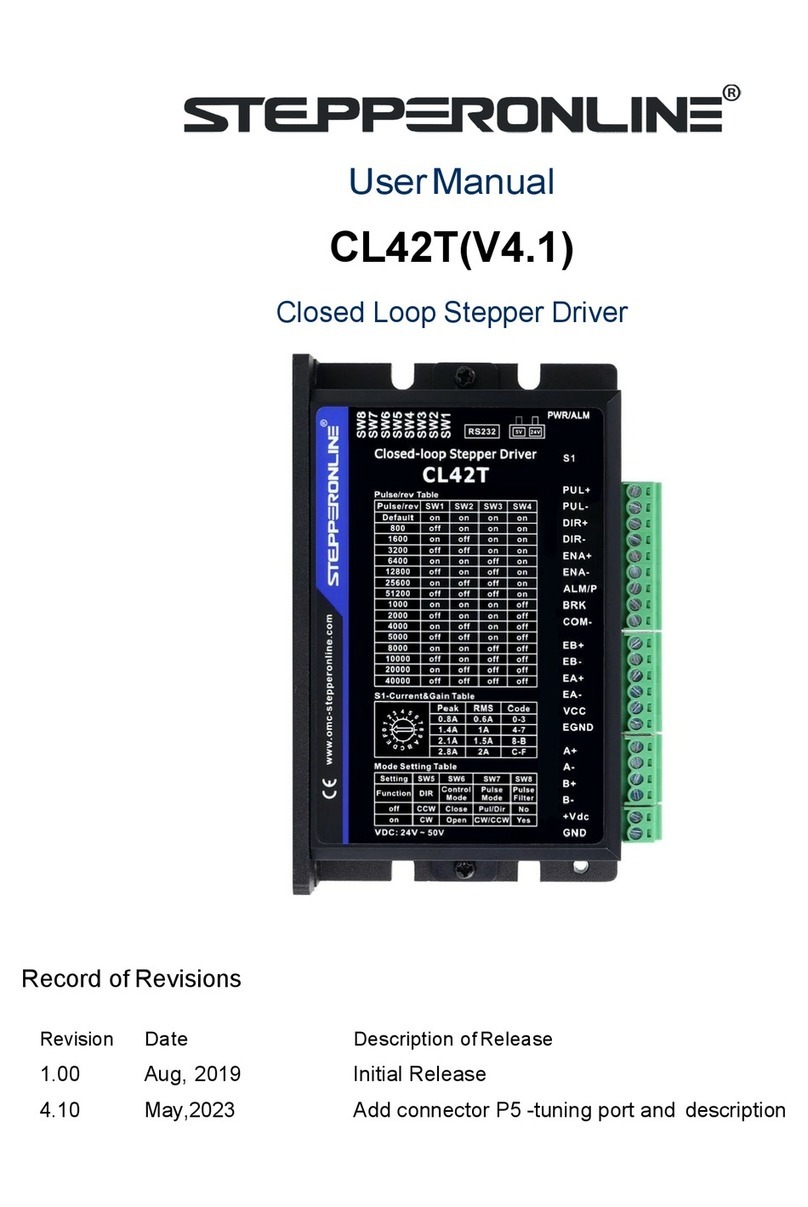

Type VCD 204/yyy

Power supply 24 V DC / ± 20 %

Nominal current 0.35 A

Nominal force 200 N (45 lbf)

Nominal locking force approx. 2000 N (449.6 lbf) (excluding bracket)

Service life >20 000 double strokes

Duty cycle 30 % (With cycle time 10 minutes)

Housing Zinc-diecasting, powdercoated

Ingress protection IP 30

Temp. range 0 ... +60 °C (+32 °F ... + 140 °F)

Emission sound pressure level LpA ≤ 46 dB(A)

/

Nominal stroke length * ** 250 or 350 mm (see type plate)

Additional functions ** Closing edge protection activated (3 stroke repeatings);

Locking relief activated

*Adjustable with PLP 1 ** Programmable with PLP 1 and SCS

Technical data