99.823.67 2.6/03/16

CDC 200/350(-SBD)-BSY+

6/20 English

Intended use

- Chain drive for electric opening and closing of

windows and flaps in the facade and roof area

- Operating voltage 24 V DC

- Usable for smoke extraction, D+H Euro-SHEV in

accordance with DIN EN 12101-2 as well as daily

ventilation

- Suitable for indoor mounting only

Safety notes

Safety extra low voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection must be carried out by a certified

electrical technician

- Danger of crushing hands and fingers!

- Keep people away from the operating area of the

drive

- Keep children away from the control

- Observe pressure load diagram of the chain

- Use only in dry rooms

- Suitable for indoor mounting only. Use rain

detector in locations if there is a risk of rain

- Use unmodified original D+H parts only

Observe enclosed red safety note!

Features

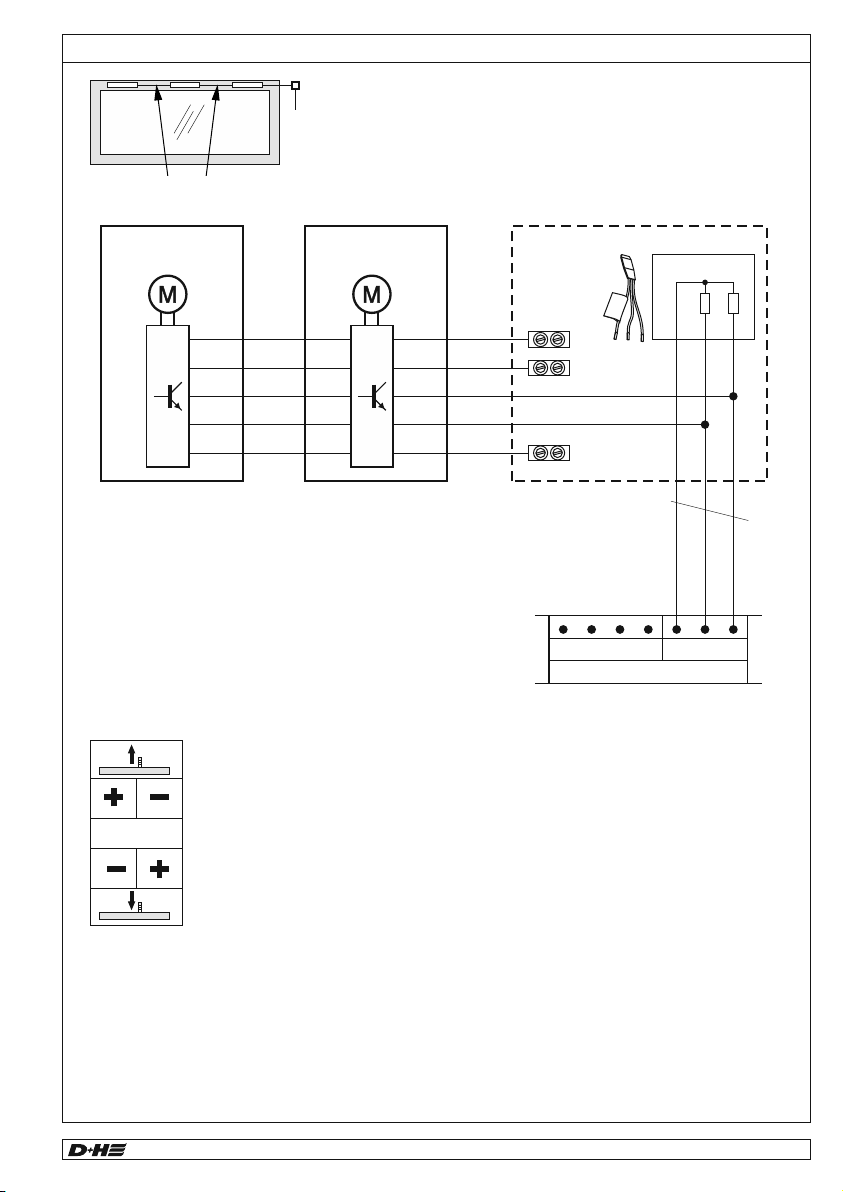

- Microprocessor-controlled synchronous

electronics BSY+ for safe and precise

synchronous running of up to 8 drives

- Individually programmable via software SCS

- Especially quiet motor running in ventilation mode

- Protection system for the main closing edge

- Rated voltage and Bus-signals loopable for max.

3 drives

- Power supply from left or right

- Relief of pressure on window gasket after closing

- Direct connection of an additional closing edge

pinch protection ledge to drive is possible

(Option -SKS)

CDC 200/350 (-SBD)-BSY+ 7/20

99.823.67 2.6/03/16 English

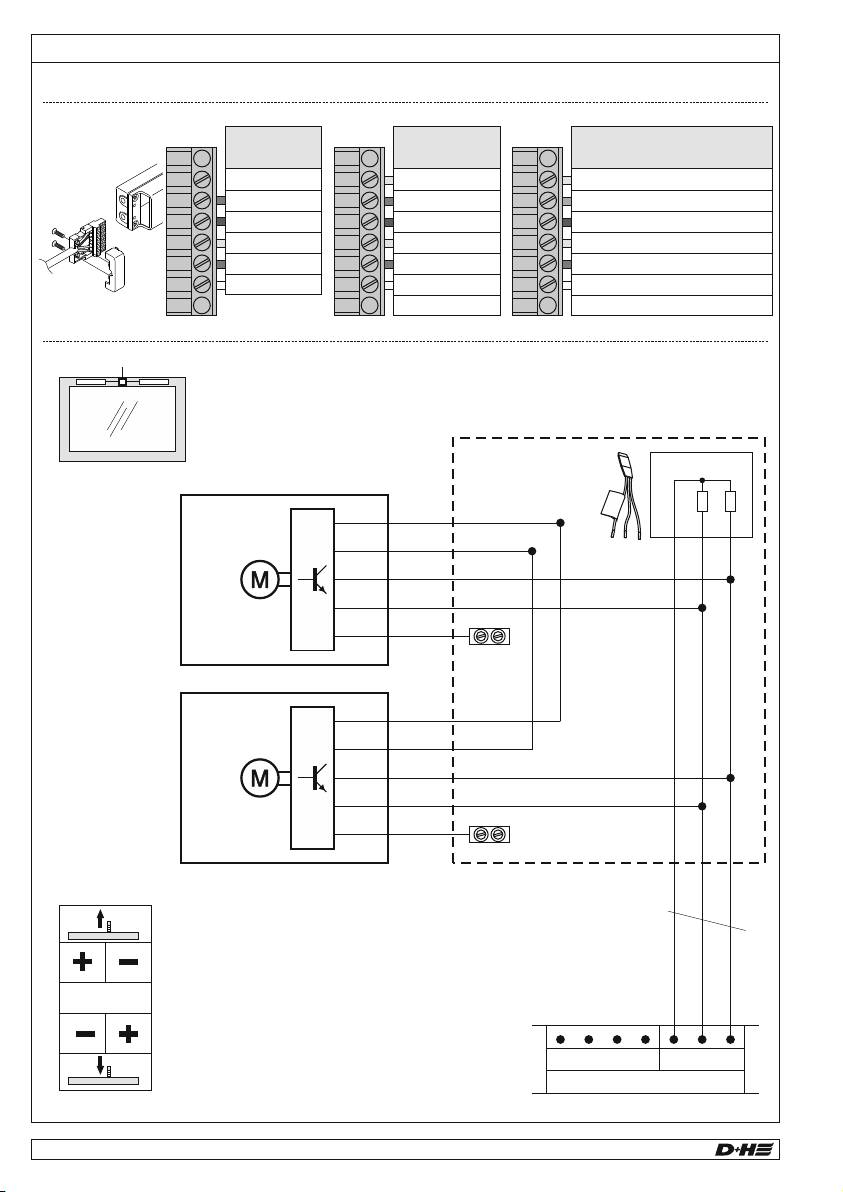

Type CDC 200/350 -BSY+ CDC 200/350 -SBD -BSY+

Rated voltage 24 V DC, ±15 %, 0,6 A 24 V DC, ±15 %, 0,5 A

Chain type Standard chain Side bow chain

Nominal pressure 200 N 150 N

Nominal locking force approx. 1500 N

Service life >20.000 double strokes

Housing Aluminium die casting

Protective system IP 50

Temp.range -5 ... +75 °C

Fire stability 30 min / 300 °C

Emission sound pressure level LpA ≤ 70 dB(A)

Stroke lenght * max. 350 mm

Additional functions * Closing edge protection = activated (3 repetitions of stroke)

Locking relief = activated (retraction lift max. 0,2 mm)

* Programmable with software SCS

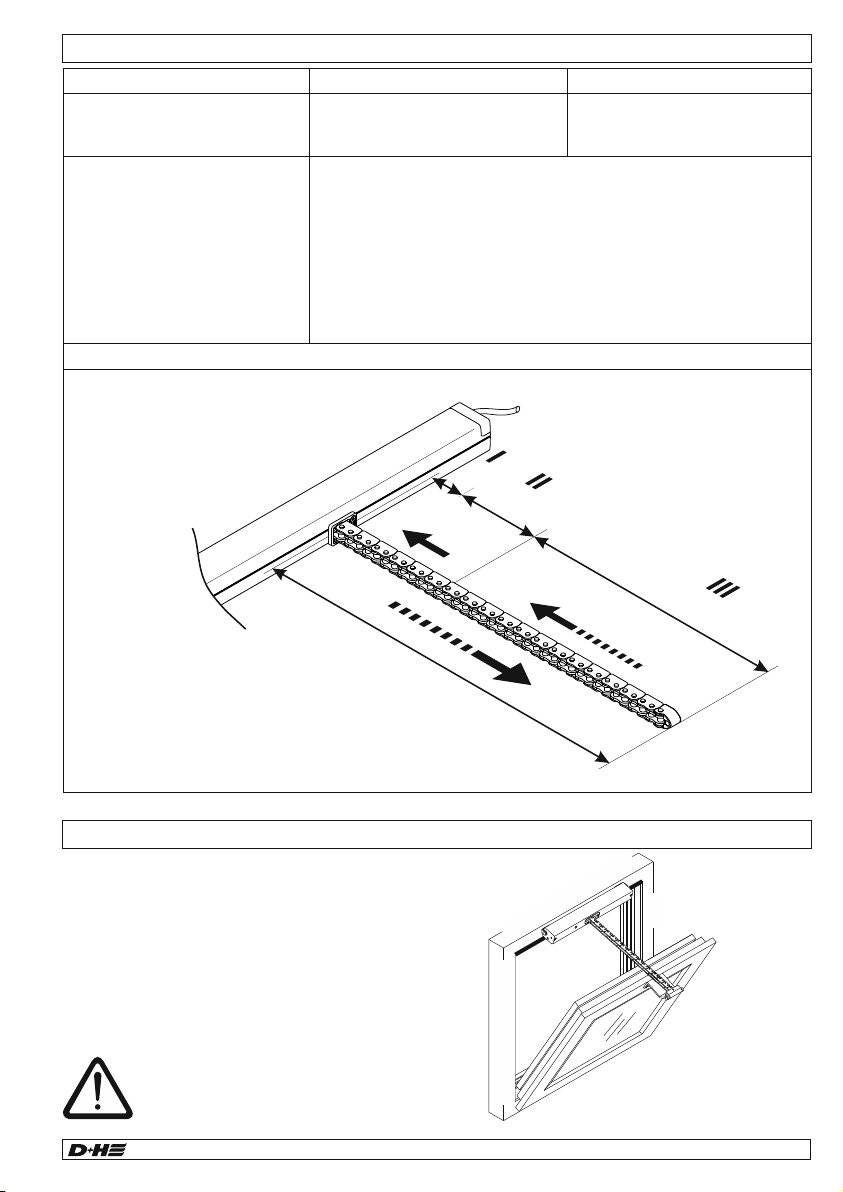

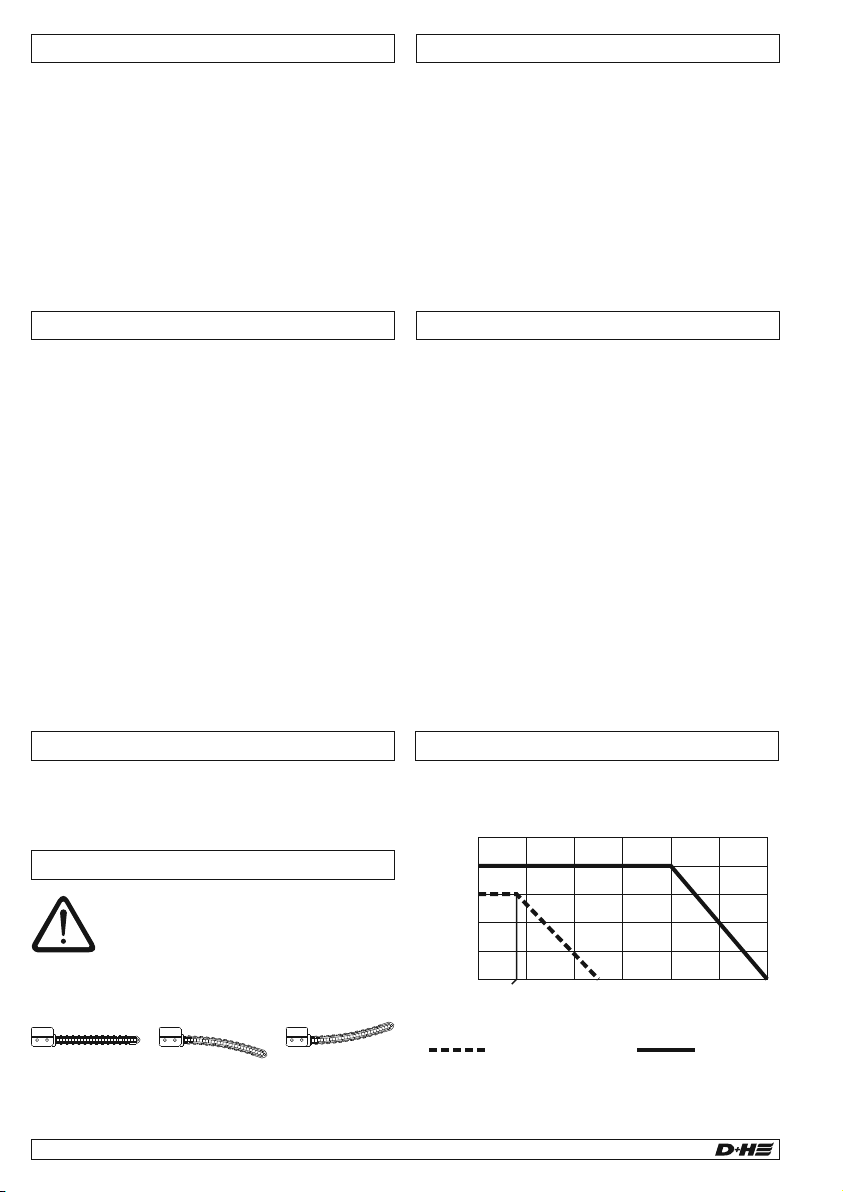

Running speed and forces

Closing Range

77 mm

5 mm/s

150 N

5 mm/s

150 N

23

CDC 200/350-BSY+:200 N, 6,7 mm/s

CDC 200/350-SBD-BSY+: 150 N, 6,7 mm/s

All forces + approx. 20 % switch-off reserve (temporary)

Main closing edge

Beside closing edge

Beside

closing edge

Closing edge protection

In the "CLOSE" direction the drive has an active

protection for the main closing edge. If there is an

overload in the closing ranges 3 and 2, the drive runs

"OPEN" for 10 seconds, then "CLOSE" again. If

closing is not possible after three attempts, the drive

remains in this position.

In addition, the drive is equipped with passive

protection. The closing speed in closing range 2 and

1 is reduced to 5 mm/s.

Significantly greater forces can be

exerted at the secondary closing

edges. Danger of crushing hands and

fingers!

Scope of supply

Drive unit with 2.5 m silicone cable. Depending on

the type of window, different bracket sets are

available separately.

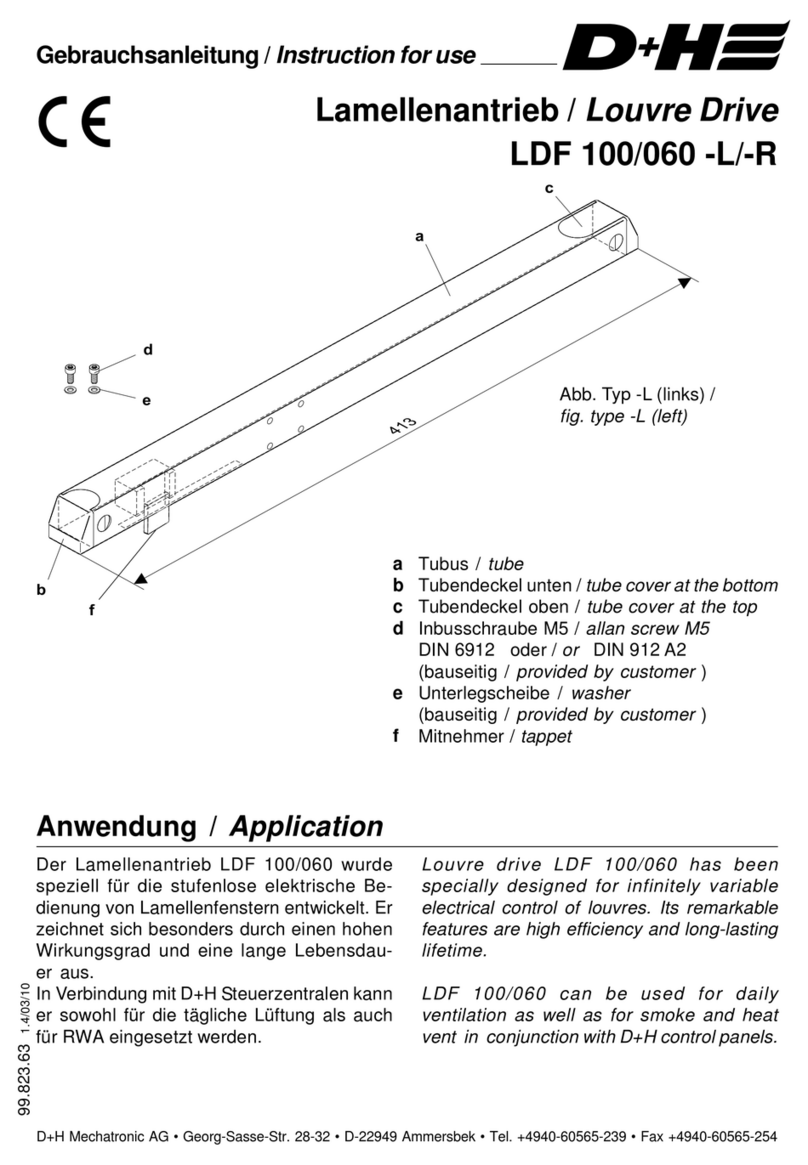

-SBD

Standard chain

-SBU

Side bow chain Side bow chain

Chain type

The mounting instructions for the bracket

set must be observed before mounting.

Always observe and comply with the

information in the mounting instructions.

Attention with side bow chains SBD and SBU

Observe maximum pressure load of the chain!

Maximum pressure load of chain is not automatically

identical with maximum pressure force of the drive!

Pressure load diagram

Pressure load (N)

-SBD / -SBU Standard

100

200

300

400

500

600

50

100

150

200

250

250

80

Stroke (mm)

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Technical Data