3356838 (A3-D-P) 1 / 3

BS8468-1 lung demand valve (LDV)

With CBRN special instructions for breathing apparatus Instructions for use

1 Safety-related information

– Before using this product, carefully read these instructions for use and

those of the associated products.

– Strictly follow the instructions for use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the intended use section (see section 3.2).

– Do not dispose of the instructions for use. Ensure that they are

retained and appropriately used by the product user.

– Only trained and competent users are permitted to use this product.

– Comply with all local and national rules and regulations associated

with this product.

– Only specialist, trained personnel are permitted to check, repair and

maintain the product as described in these instructions for use. Further

maintenance work that is not detailed in these instructions for use must

only be carried out by Dräger or qualified personnel. Dräger

recommend a Dräger service contract for all maintenance activities.

– Only use genuine Dräger spare parts and accessories when

performing maintenance work, or the proper functioning of the product

may be impaired.

– Do not use a faulty or incomplete product. Do not modify the product.

– Notify Dräger in the event of any component fault or failure.

2 Conventions in this document

2.1 Definitions of alert icons

The following alert icons are used in this document to provide and highlight

areas of the associated text that require a greater awareness by the user.

A definition of the meaning of each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could

result in physical injury. It may also be used to alert against unsafe

practices.

NOTICE

Indicates a situation which, if not avoided, could result in damage to the

product or the environment.

2.2 Typographical conventions

► A triangle is used in safety statements to indicate possible ways of

avoiding the hazard.

An information symbol is used for notes and additional useful

information.

1. Numbered paragraphs indicate that the information is sequential.

– Dashed paragraphs indicate that the information is non-sequential.

2.3 Trademarks

The following website lists the countries in which the Dräger trademarks

are registered: www.draeger.com/trademarks.

Molykote® is a registered trademark of DDP Specialty Electronic Materials

US 9, LLC.

The trademarks listed are only registered in certain countries and not

necessarily in the country in which this document is published.

3 Description

3.1 Feature description

The Dräger BS8468-1 positive pressure lung demand valve (LDV) controls

the breathing air supplied into the mask of a breathing apparatus wearer.

The lung demand valve connects the medium-pressure supply from the

breathing apparatus to the mask, and a sealed and balanced piston unit

inside the valve controls the quantity of air flow through the valve in

response to the breathing demand of the wearer.

The positive-pressure valve maintains a greater pressure than

atmospheric inside the mask. Although the pressure drops as the wearer

inhales, the pressure inside the mask remains above atmospheric.

3.2 Intended use

When the product is used with an approved breathing apparatus, face

mask and cylinder, it provides a wearer with respiratory protection for

working in contaminated or oxygen-deficient conditions, including CBRN

(Chemical, Biological, Radiological and Nuclear) scenarios.

To ensure approved protection in CBRN scenarios, the Dräger BS8468-1

lung demand valve must only be used in the approved breathing apparatus

configurations specified in the BS8468-1 configuration matrix that

corresponds to the breathing apparatus. Contact Dräger for details.

WARNING

Using unapproved equipment combinations is unsafe.

► Only use the lung demand valve with approved Dräger face masks in

CBRN environments.

► Contact Dräger for a list of the equipment combinations that are

approved for CBRN use in the breathing apparatus.

3.3 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

the declaration of conformity or www.draeger.com/product-certificates).

The BS8468-1 lung demand valve is approved for use with Dräger Self-

Contained Breathing Apparatus (SCBA) protection equipment meeting the

requirements of BS8468-1, EN137:2006 Type 2 and EN136:1998 Class 3.

Only a Dräger face mask complying with EN136:1998 Class 3 and marked

with BS8468-1 must be used in conjunction with the approved

configurations for respiratory protection in CBRN scenarios.

To ensure complete protection in CBRN scenarios, Dräger advise that

users should consider a personal protective ensemble conforming to

BS8467.

Specific kits are available of BS8468-1 conforming lung demand valves

and face masks to be used with Dräger breathing apparatus. Contact

Dräger for details.

3.4 Explanation of type-identifying marking and

symbols

NOTICE

The device may be damaged, or approvals invalidated, by engraving it, or

by applying chemical marking or paint.

► Do not use marker pens or apply paint, and do not scratch or engrave

the device.

► Dräger recommend using adhesive labels to add personal marking to

the device.

Refer to the relevant authority for explanation of approval body symbols

and marking on the equipment. Examples of other marking on component

parts of the breathing apparatus are:

4 Use

WARNING

Only trained and competent users (those who have attended a relevant

training course) are permitted to prepare and use this product.

► Ensure that any accessories, ancillary equipment, and other

protective clothing items do not interfere with the breathing apparatus

and do not create a safety hazard.

4.1 Prerequisites

WARNING

If there is not a good seal between the mask and the face of the wearer,

the mask may leak inward or outward during use.

► Select and test the face mask from the available sizes.

Ensure that you have selected and are using the correct size face mask.

– The face mask is available in 3 sizes. The size is marked on the left

side of the mask.

– S – small

– M – medium

– L – large

– The nose cup is available in 3 sizes. The size is marked on the front of

the nose cup, and is visible through the visor.

– 1 – small

– 2 – medium

– 3 – large

4.2 Preparation for use

4.2.1 Fitting the fabric head harness (optional)

The face mask is supplied as standard with a five point adjustable rubber

head harness fitted. If it is required to use the five point adjustable fabric

head harness, fit the harness as follows:

1. Remove the 5-point adjustable rubber head harness by pushing

forward each of the five plastic buckle attachments (Fig 1, Item 1) until

the buckle clicks out of place from the stud. Lift and remove each

buckle from the stud.

2. Attach the 5-point adjustable fabric head harness to the mask.

3. Position the non-adjustable buckle to the top forehead attachment

(centre) of the face mask. Ensure that the head harness is positioned

so that the finished side of the harness will be seen when the mask has

been donned (Fig 2, Item 1).

4. Place the larger keyhole circle on the buckle over the studs and pull

the buckle back until the smaller keyhole circle of the buckle clicks and

locks onto the stud. Repeat this procedure with each of the remaining

buckles.

When correctly assembled, the pull tabs on the adjustable straps will be

located away from the head when worn (Fig 2).

BRXX-1234 – Dräger serial number

P – Positive-pressure

09/09 – Month and year of manufacture

3356812 or R21034 – Dräger part number

– Barcode of serial number

1

2116

1

2

4710

1

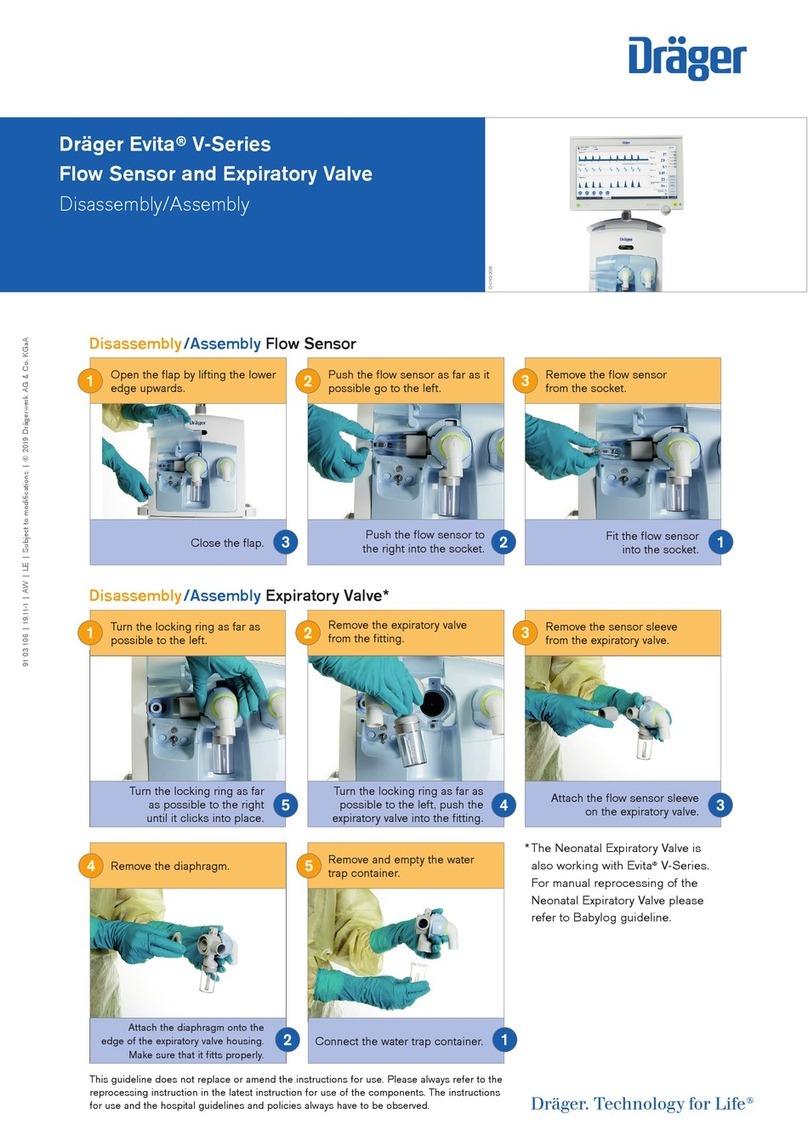

4.2.2 Pre-use inspection

Carry out a full visual inspection of the equipment as detailed in the

breathing apparatus instructions for use and section 5.3.

Ensure the retaining groove of the connector (Fig 3, Item 3) and the mask

port are clean and free from foreign material. Inspect the connector O-ring

for damage and dirt, and ensure that lubricant is present on the surface of

the O-ring.

For an ESA type lung demand valve, check the release buttons on the side

of the lung demand valve. Briefly press both buttons and ensure that they

depress and then return without restriction.

Clean parts as necessary (see section 5.2), and ensure that any damaged

or faulty parts are replaced before use. Check the O-ring on the lung

demand valve. As a guide, lubricant should be felt on the fingers but not

seen. If relubrication is required, lightly apply Molykote®111 (other

lubricants are not tested and may damage the equipment).

4.2.3 Connecting the LDV

1. Disconnect and then reconnect the male coupling of the lung demand

valve hose. To connect, press the male coupling into the female

coupling until an audible click is heard. If there is any difficulty

disconnecting or connecting, see the troubleshooting information in

the breathing apparatus instructions for use.

2. Press the reset button (Fig 3, Item 1) to switch off the positive

pressure.

3. Open the cylinder valve (counterclockwise) slowly, but fully, to

pressurise the system.

– After storage at temperatures below 0 °C leakage may be observed

when the cylinder valve is initially opened due to ice formation.

– If leakage is observed from the lung demand valve, press the front

button (Fig 3, Item 2) to allow a rush of air to pass through the lung

demand valve and then quickly press the reset button (Fig 3,

Item 1) to switch off the positive pressure. Resume normal

operation.

– If leakage still occurs, remove the breathing apparatus from

service and report the fault to trained service personnel or contact

Dräger.

4. Carry out all functional testing as described in the breathing apparatus

instructions for use.

5. Align and push the lung demand valve into the face mask port until it

clicks into position (Fig 4). Check the attachment by gently attempting

to pull the coupling apart.

4.2.4 Putting on the face mask

WARNING

Correct fit of the face mask can only be achieved if the complete mask seal

contacts the skin.

► Do not allow head hair styles (buns, pony-tails, hairpieces, etc.) to

affect the fit of the face mask.

► Do not allow head hair, facial hair (including beard stubble and

sideburns), earrings, other facial piercings, and normal spectacles to

interfere with the face mask seal.

See also the face mask selection information (section 4.1).

1. Inspect the face mask: ensure that head harness is securely attached,

the nose cup is correctly located and secure, and that all parts are in

good condition.

2. If fitted, move the spectacle frame to the preferred position.

3. Fully extend the straps of the head harness (Fig 5).

4. Place the carrying strap over the head and locate the face mask on the

chest. (Dräger recommend using the carrying strap to position the

mask in this way to prevent damage and dirt ingress until the mask is

put on.)

5. If fitted, clip the communication system push-to-talk (PTT) button to a

suitable chest location.

6. Spread the head harness and place the chin into the face mask.

7. Pull the head harness over the head and centre the fabric panel (Fig 2,

Item 1), ensuring the straps are flat and not twisted.

8. Ensure that nothing is interfering with the face seal (hair, head

harness, carrying strap, etc.). Also ensure that the full face seal is

touching and following the contours of the face.

3

2739

D

r

ä

g

e

r

1

2

3

4

2867/2863

5

4709