Issue 6 – December 2006 2

Contents

FOR YOUR SAFETY ................................................................................................. 3

INTENDED USE......................................................................................................... 4

CE marking and ATEX approval.............................................................................. 5

Other tests and approvals ....................................................................................... 5

Special conditions for safe use............................................................................... 5

DESCRIPTION ........................................................................................................... 6

Main board .............................................................................................................. 7

Display board ........................................................................................................ 10

Pellistor board ....................................................................................................... 11

Options board........................................................................................................ 11

INSTALLATION ....................................................................................................... 13

Installation environment ........................................................................................ 13

Mounting points..................................................................................................... 13

AC supply.............................................................................................................. 14

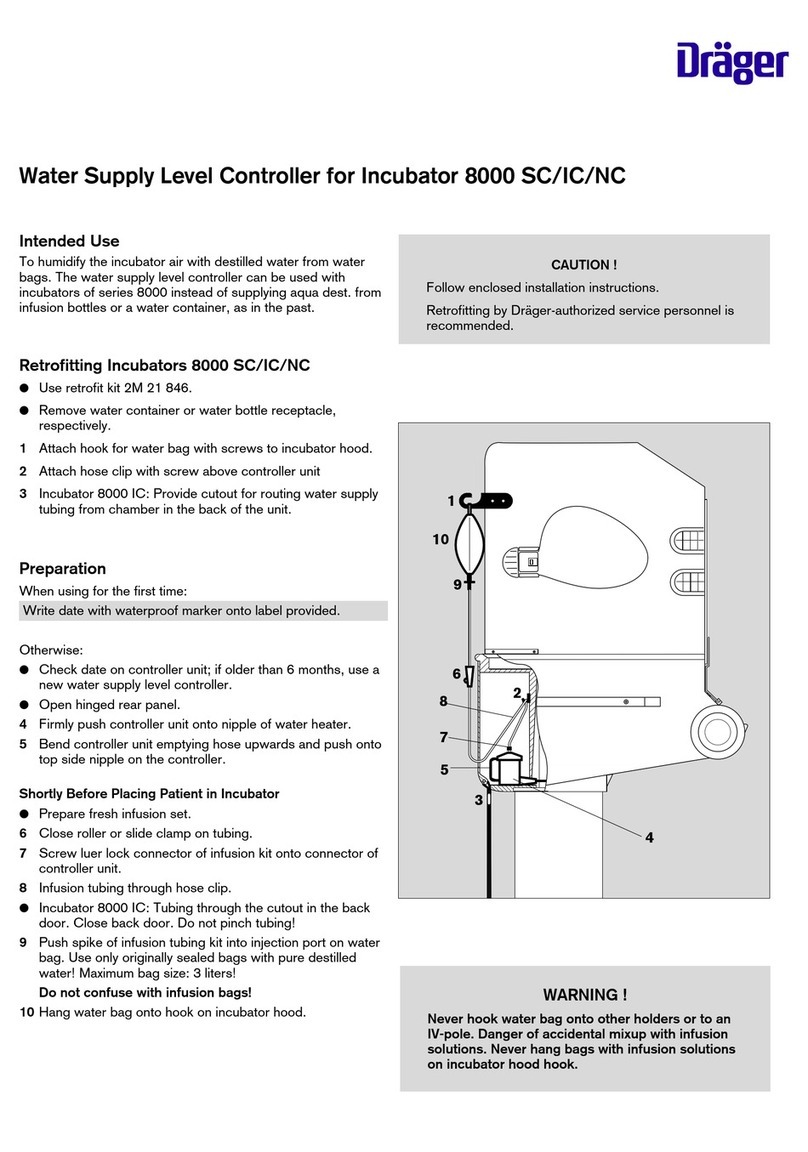

Connecting transmitters and measuring heads ..................................................... 15

Relay outputs ........................................................................................................ 18

A1 and A2 24V “digital” outputs............................................................................. 18

Remote reset input................................................................................................ 20

CONFIGURATION AND CALIBRATION................................................................. 21

Set measuring range ............................................................................................. 21

Calibrating a 4-20 unit ........................................................................................... 23

Calibrating an SE Ex unit ...................................................................................... 25

Configuring alarms ................................................................................................ 28

MAINTENANCE ....................................................................................................... 35

Fault finding........................................................................................................... 35

SPECIFICATIONS ................................................................................................... 36

Part numbers......................................................................................................... 37

EC type-examination certificate............................................................................. 38

EC Declaration of Conformity................................................................................ 43