Trigenflex R96 Ceiling, Wall, Standmodel Dr. Mach

Lamps and Engineering

59230001 Edition 01 18.02.2002 / Bak Page 2/23

List of contents

1. Safety instructions ......................................................................................Page 3

2. Operating the lamp Trigenflex R96.............................................................Page 4

2.1 Checking the lamp Trigenflex R96 with light intensity control...............Page 4

2.2 ON/OFF switch, light intensity adjustment............................................Page 6

2.3 Positioning............................................................................................Page 7

2.4 Light field adjustment (merging of lightfields) .......................................Page 7

3. Cleaning .....................................................................................................Page 8

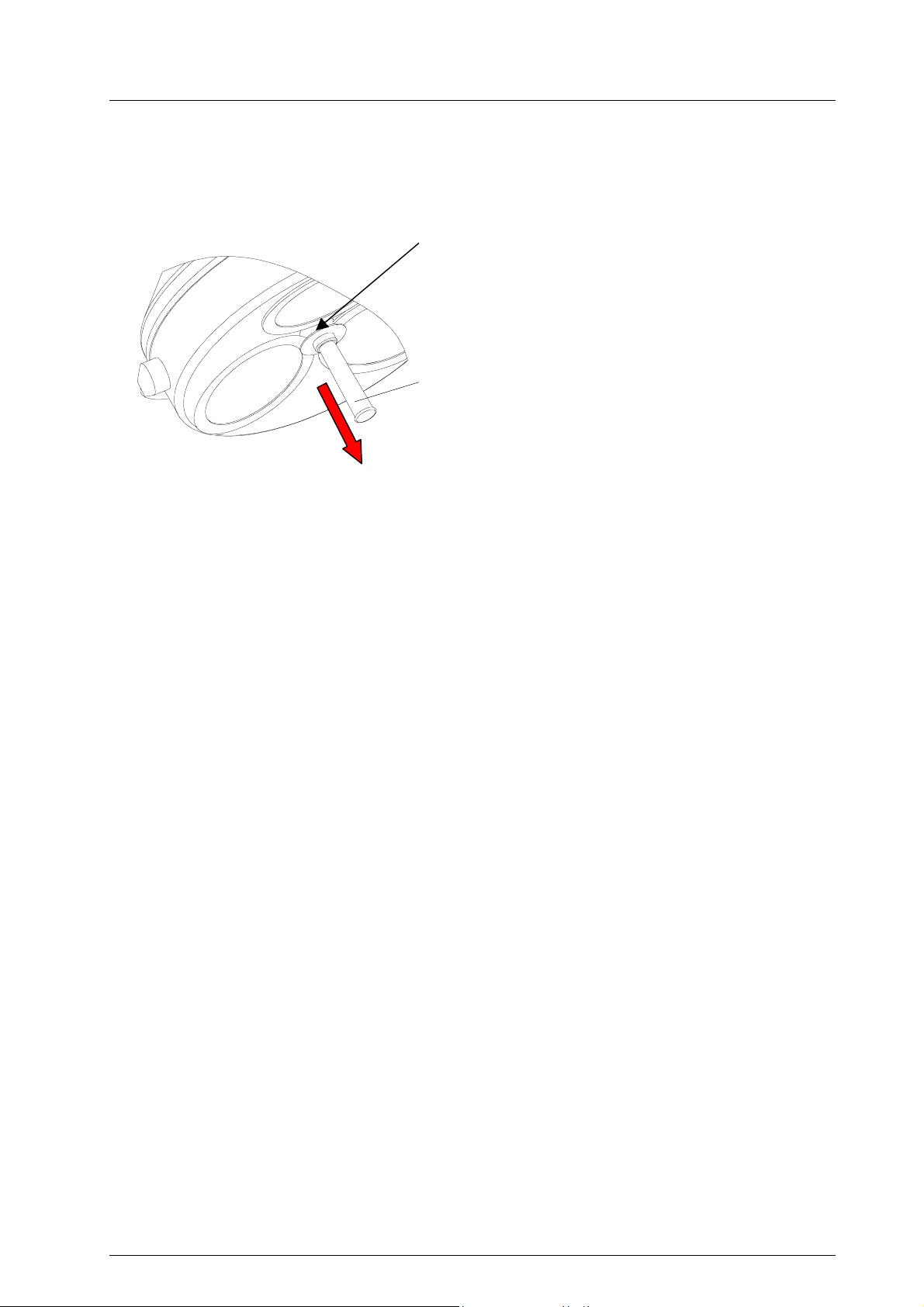

3.1 Sterilizable handle ................................................................................Page 8

3.2 Lamp head, splinter protection disk......................................................Page 8

4. Maintenance ...............................................................................................Page 9

4.1 Adjustments at the ceiling/ wall attachment..........................................Page 9

4.2 Adjustments at the stand model ...........................................................Page 10

4.3 Adjustments at the lamp head ..............................................................Page 10

4.4 Changing of spare parts .......................................................................Page 11

4.4.1 Changing the halogen bulbs .......................................................Page 11

4.4.2 Changing the fuses .....................................................................Page 12

4.4.3 Changing the filter disk................................................................Page 13

4.4.4 Changing the splinter protection disk ..........................................Page 13

5. Data............................................................................................................Page 14

5.1 Technical data ......................................................................................Page 14

5.2 Wiring ...................................................................................................Page 15

5.3 Environmental conditions .....................................................................Page 16

6. Marking.......................................................................................................Page 16

6.1 Specification of bulb .............................................................................Page 16

6.2 Specification of fuse .............................................................................Page 17

6.3 CE-mark ...............................................................................................Page 17

7. Disposal......................................................................................................Page 17

8. Spare parts .................................................................................................Page 18

8.1 Design with power supply 230V/120V ..................................................Page 18

8.2 Design with power supply 24V .............................................................Page 19

8.3 Swivel arm - stand model .....................................................................Page 19

8.4 Spare parts list .....................................................................................Page 20