Dresser Model 10C25 Series K Installation, Operation, and Maintenance Manual

© 2018 Natural Gas Solutions North America, LLC Page 2 of 74

Contents

1Introduction .....................................................................................................................4

2Overview..........................................................................................................................4

2.1 Operating Principle..................................................................................................................... 5

2.2 Performance Characteristics ...................................................................................................... 5

2.3 Features...................................................................................................................................... 5

3Receiving, Handling, and Storage......................................................................................6

3.1 At Time of Delivery ..................................................................................................................... 6

3.2 Storage........................................................................................................................................ 6

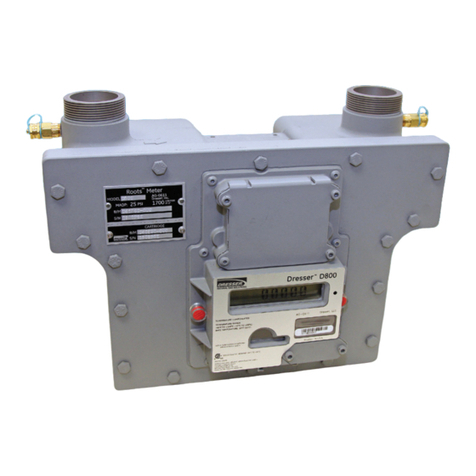

4Parts Identification...........................................................................................................7

4.1 Meter Display ............................................................................................................................. 7

4.2 Flow Indicator........................................................................................................................... 10

5Problems with Installation or Operation .........................................................................10

6Meter Installation...........................................................................................................11

6.1 Preinstallation Considerations ................................................................................................. 11

6.2 Placing Meter in Line ................................................................................................................ 14

7Meter Startup ................................................................................................................15

8Downstream Leak Tests..................................................................................................16

8.1 Flow Indicator Method............................................................................................................. 17

8.2 Electronic Method –Magnetic Interface ................................................................................. 17

8.3 Electronic Method –MeterWare Interface.............................................................................. 18

9AMR Installation.............................................................................................................19

10 Pulse Output Connections ..............................................................................................24

10.1 Pulse Output Allocation Settings and Testing .......................................................................... 24

10.2 Wiring Instructions for Hazardous Locations ........................................................................... 25

11 Meter Operation ............................................................................................................28

11.1 MeterWare Software Information ........................................................................................... 28

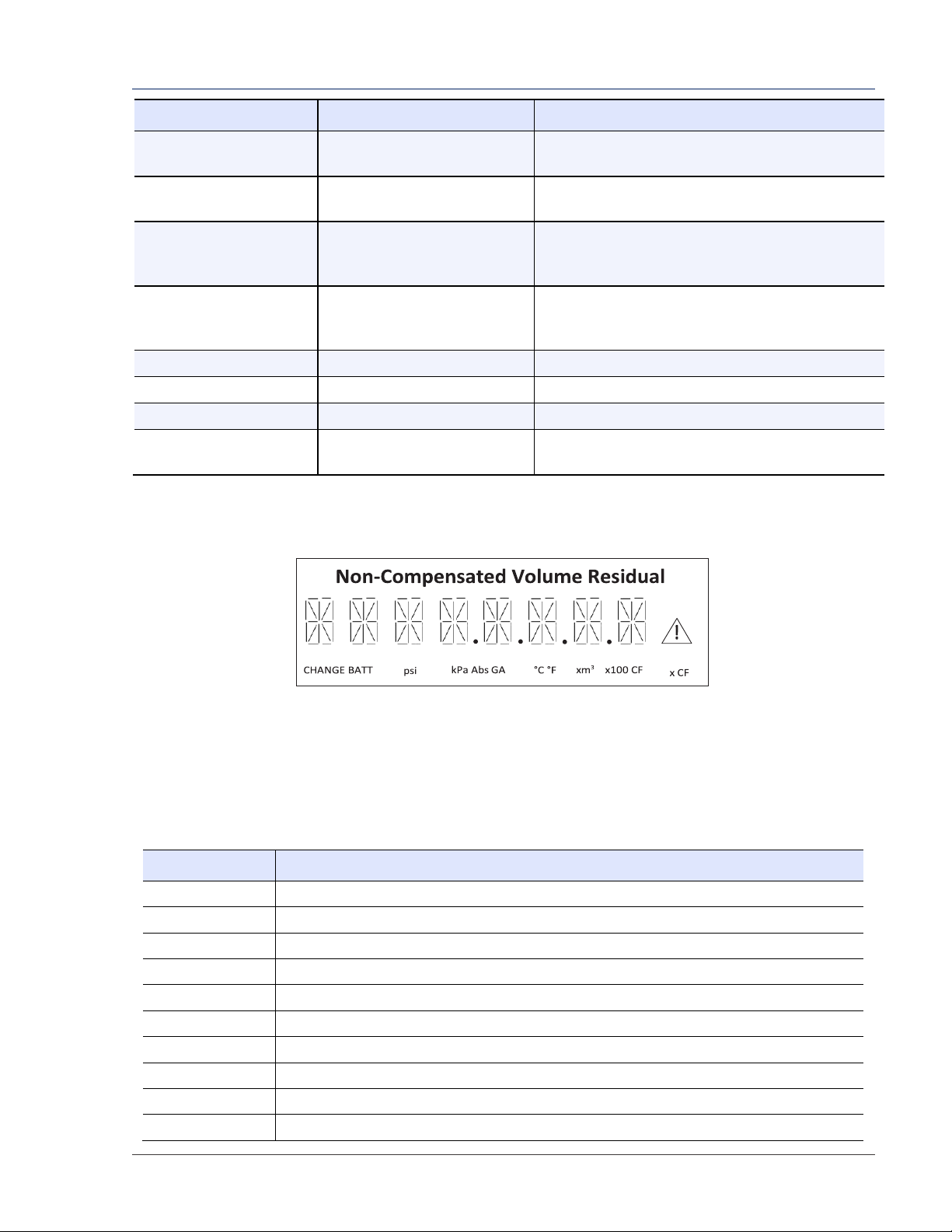

11.2 Volume Measurement.............................................................................................................. 28

11.3 Temperature Measurement..................................................................................................... 29

11.4 Flow Rate Measurement .......................................................................................................... 30

11.5 Faults and Alarms ..................................................................................................................... 30