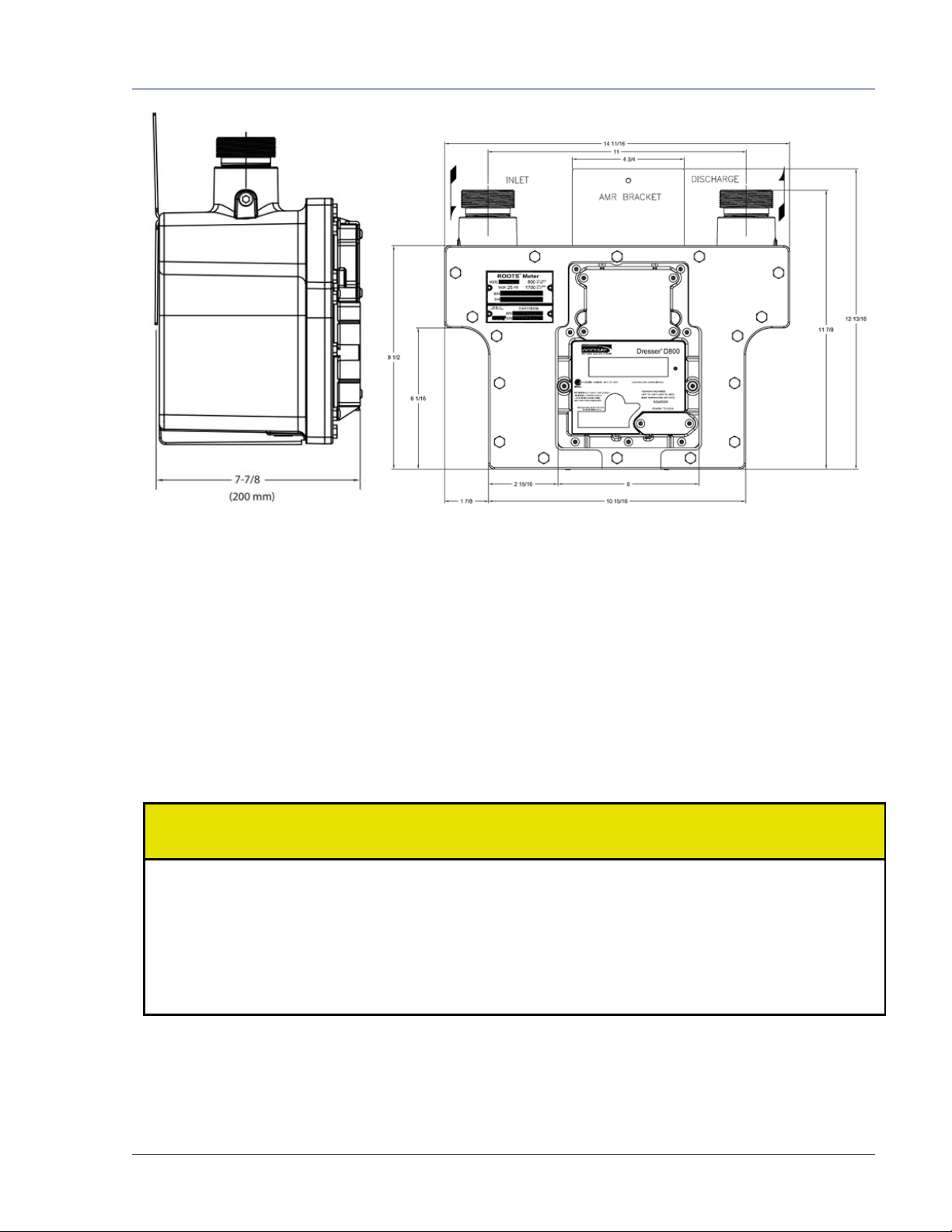

Dresser Series D Installation Supplement

© 2019 Natural Gas Solutions North America, LLC Page 3 of 24

1Introduction

This manual provides information to install and start using the Dresser D800/D1000 Series D meters.

Please read the entire manual and refer to the Dresser Series D Installation, Operation, and Maintenance

Manual for information about how to properly and safely install, use, and maintain these meters and

some of their accessories. The Dresser MeterWare software provides the user interface to the meter’s

digital indexes with an IrDA (infrared) communication interface.

This manual provides recommendations when no established company procedure or practice is available.

The following additional resources are available:

•The Dresser™ Series D Meter Installation, Operation, and Maintenance Manual, which contains

detailed information about installing, operating, and maintaining the D800 and D1000 Series D meters

•The Dresser MeterWare Software Manual, which contains detailed information about the meter’s

digital index software

Manuals are available by request or online at www.dresserngs.com.

2Receiving, Handling, and Storage

Follow the steps and recommendations in this section to ensure your meter and its accessories are ready

for installation and use.

2.1 At Time of Delivery

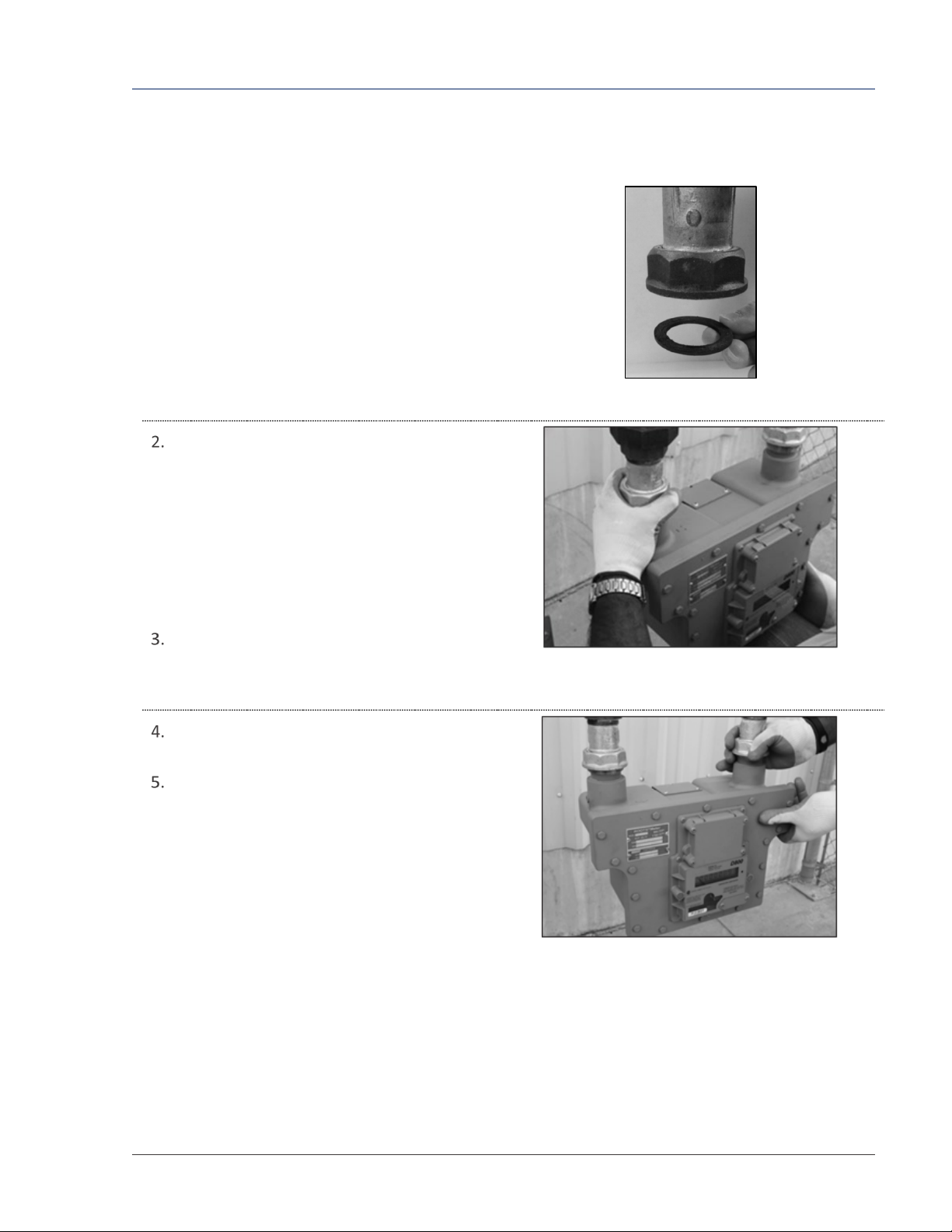

Perform the following steps when you receive your shipment:

Check the packing list to verify all items have been received.

Inspect each item for damage and, if necessary:

a. Record any visible damage or shortages on the delivery record.

b. File a claim with the carrier.

c. Immediately notify your Dresser meter supplier.

Note:

•Do not accept any shipment that appears damaged without immediately inspecting the

contents for damage.

•Check the meter for free rotation soon after arrival. Internal working parts might be

damaged without obvious external evidence. To check the meter, blow dry air lightly into

the meter inlet to verify the free rotation of the impellers.

2.2 Storage

If the product is not tested or installed soon after it is received, store it in a dry location in the original

shipping container for protection within the meter’s operating temperature range of -40°F to 140°F

(-40°C to 60°C).