INSTR: 17622 REV: ECO-10003 2014-11-06 / TB GODK: SID: Sida 7 / 37

SAFETY INFORMATION

Hazards may arise from improper use of the DRESTER Compact DC11. Hazards may also arise from improper choice/handling of

drums or solvent. In order to maintain the high safety standard of the unit, it is important that these instructions are followed.

-Do not operate the unit until you have read and fully understood this entire User’s Manual.

-The unit should be isntalled as described in the instructions.

-The unit should be used as described in the instructions.

-The unit should be maintained as described in the instructions.

-Only original spare parts may be used.

-This User’s Manual must be available and in legible condition in close proximity to the unit. Every user shall know where

to find the User’s Manual.

-Operating instructions should be formulated on the basis of this Users Manual, and translated into the language spoken by

the employees.

-Do not modify or in any way alter the unit.

-Do not operate the unit unless it is properly vented. Do not operate the unit if the extraction of vapors is insufficient.

-Avoid contact with liquid and vapor. Refer to the solvents’ MSDS (Material Safety Data Sheet).

-Wear chemical goggles or similar, to protect your eyes. Wear chemical-resistant gloves to prevent skin-contact. Wear

chemical-resistant clothing to protect against spills or splash.

-Personnel suffering from respiratory problems or allergies to solvents used, must not operate the machine.

-Clean up spills immediately. Solvent vapours are heavier than air and can spread a long way. They may also collect in pits

or other low areas.

-Do not smoke, eat or drink while close to the unit.

-The unit is equipped with a safety valve that will interrupt the automatic wash cycle if the lid is opened before the wash

cycle is completed.

-A fire extinguisher must always be kept nearby when working with flammable solvents. Do not use water.

-Spray guns or any other paint equipment items cleaned in the unit must be suitable for cleaning in a Zone 1 area (ref.

Category 2 according to EN 13463-1/2001). If unsure, please contact the spray gun manufacturer.

-The unit must be properly grounded using the attached grounding cable. If plastic drums are used, the openings should be

wiped off with a damp cloth, to avoid static electricity, before inserting or removing any hoses or other equipment.

TECHNICAL DATA

Manufacturer HEDSON TECHNOLOGIES AB

Hammarvägen 4

SE-232 37 Arlöv

Sweden

Tel.: +46-40- 53 42 00

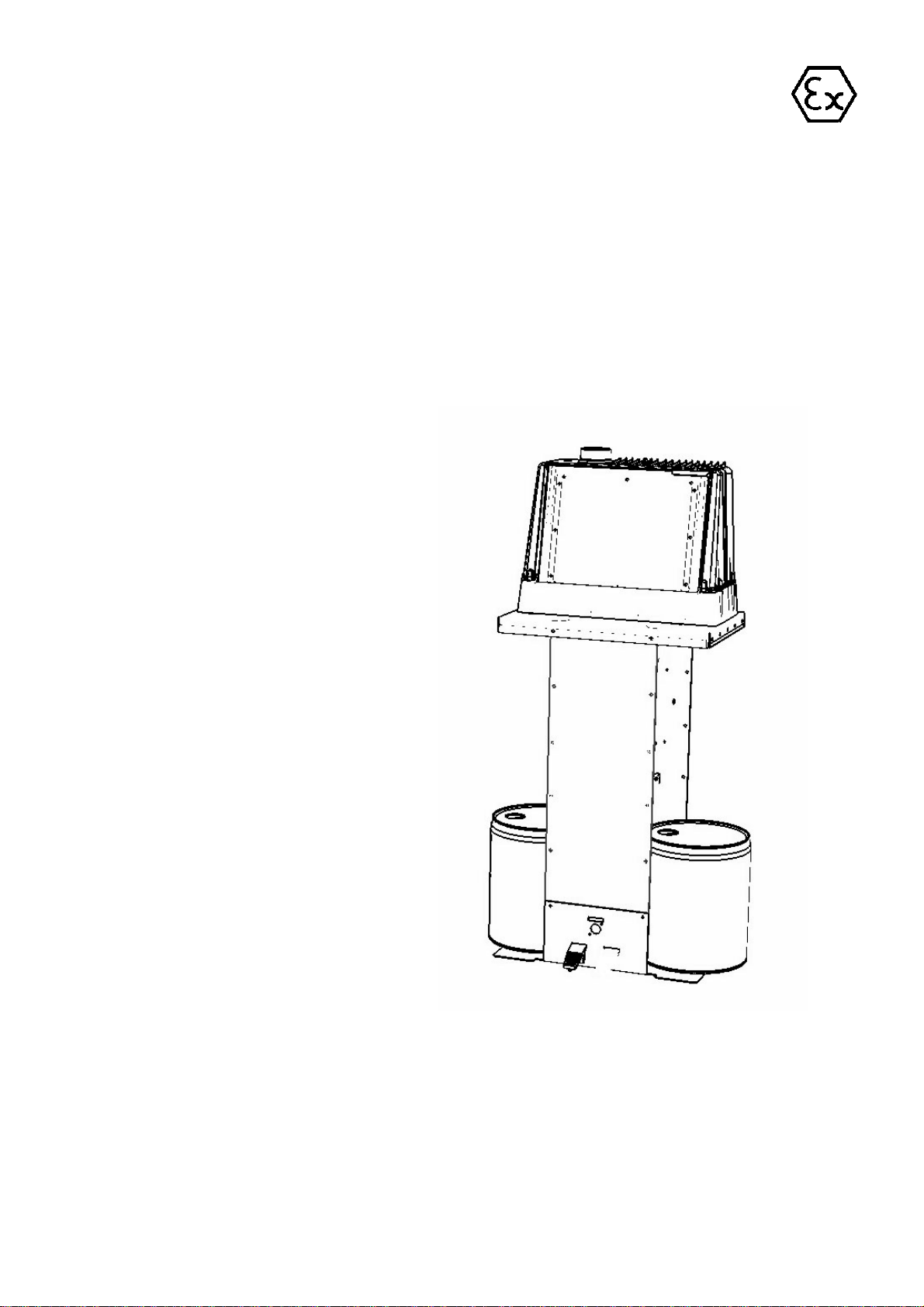

Type of machine: DRESTER Compact DC11

Permitted solvents: See section “Permitted Solvents”

Max solvent volume of machine: 15 + 15 litres

(Check for local regulations concerning max allowed volume for keeping solvent in the unit)

Maximum drum size: 30 litres

Compressed air needed: 7-12 bar (110-180 psi), 300 litres/min (11 cfm)

Extraction capacity: 360 m3/hour (225 cfm) (with a 5 m extension)

330 m3/hour (206 cfm) (with a 15 m extension)

Pump capacity: 10 l/min

Solvent pressure 2 bar (30 psi)

Weight 30 kg (66 lb)

Overall dimensions: Height: 1340 mm (53”) width (without drums): 570 mm (22,5”)

Depth (lid closed): 440 mm (17,5”)

Depth (lid opened): 590 mm (23”)

Extractor diameter: 80 mm (3 3/16”)

Sound pressure level: <70 dB(A)