07-00274D 2009-01 6Copyright 1999, Dri-Eaz Products, Inc.

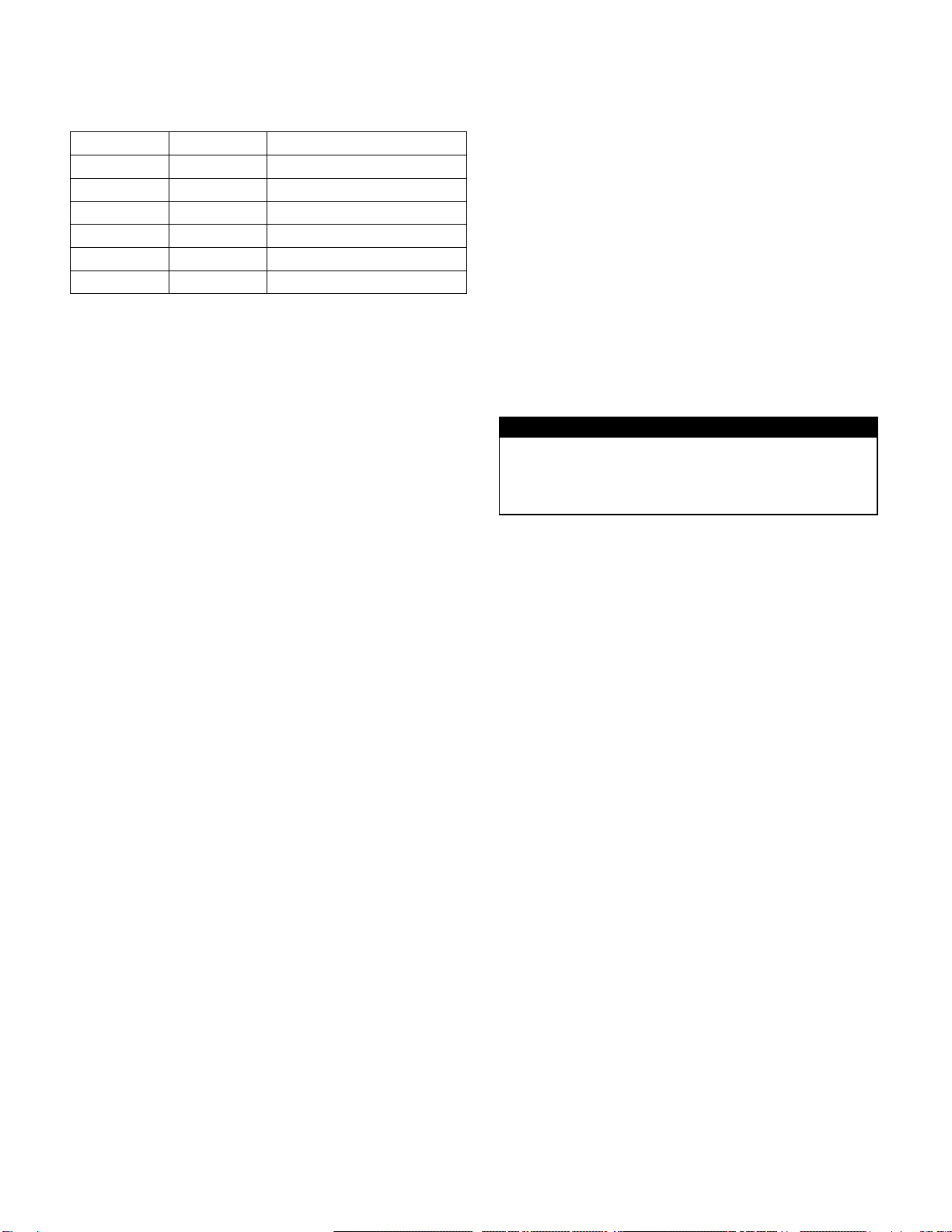

2. Set up the remaining FIVE manifolds with the fol-

lowing lengths of tubing:

Quantity Length Locations on Manifolds

2 7.5 feet Outlets 1 and 12

2 6.5 feet Outlets 2 and 11

2 5.5 feet Outlets 3 and 10

2 4.5 feet Outlets 4 and 9

2 2.5 feet Outlets 5 and 8

2 1 foot Outlets 6 and 7

To each outlet on a manifold, attach a length of

supply tubing, and insert an air nozzle in the other

end of the tubing.

Seal off the last manifold on each run of ADS

with a supplied endcap plug. Now place the air noz-

zles into the holes you have drilled or punched.

Although not necessary in most cases, it is some-

times helpful to awl-punch or drill a small vent hole

placed just above the highest moisture point on the

wall. This vent hole can speed up the drying process

by supplying more dry air to affected materials. The

small size of the hole often allows you to patch it

with little difficulty.

Standard Drying Procedure

Now you are ready to dry. Make sure you have

undamaged electrical cords, plugs, extension cords if

used, and circuits with 3 amps of available power.

Turn on the power switch, and ensure that all the

ADS, T-fittings, hose cuffs, manifolds, supply lines,

and air nozzles are properly installed with minimum

air leakage.

Attach the ADS to the vacuum side of the Dri-

Force blower unit. For the first portion of the job, it is

recommended to use the system in the vacuum or

extraction mode to remove the bulk of the humidity

laden air from structural cavities (see “Extraction

Drying,” below.) Run in the vacuum mode until the

specific humidity in the affected area of the job reads

the same or lower as the specific humidity in an unaf-

fected area of the job.

After the humidity in the affected area of the job

is the same or lower as that in an unaffected area,

move the ADS from the vacuum to the pressure out-

let of the DriForce and install the muffler-filter. You

will now be forcing air at high pressure into the struc-

tural cavity, to finish the drying process.

Extraction Drying

As explained above, drying by vacuuming air

from structural cavities, setting up the DriForce in the

extraction mode can speed drying times. Also, using

the extraction mode ensures that moist and possibly

contaminated air does not get forced into previous

dry and unaffected areas.

When using the DriForce in the vacuum or extrac-

tion mode, do not exhaust the air into an occupied

structure. Use vacuum hose to exhaust the air to the

outdoors, completely outside the structure. This will

ensure that contaminants (including moisture, mold

spores, mold mycotoxins and byproducts) are not

transferred from within structural cavities into an oc-

cupied area. Contaminants may create health con-

cerns such as allergic reactions and illness.

Do not use the muffler-filter that is supplied with

the DriForce in the vacuum or extraction mode. This

filter is not a HEPA-grade filter, and will not meet

the requirement to ensure that possible contaminants

are not exhausted into an occupied area. Use the muf-

fler-filter only in the injection or blowing mode.

CAUTION

When using the DriForce in the vacuum or extraction

mode, exhaust the air to the outdoors or use a HEPA

filter attachment, to ensure that possible contami-

nants are not exhausted into an occupied area.

Drying Ceilings and Cabinets

Drying ceilings is accomplished in much the same

manner as walls, and can be done at the same time as

wall drying. Remember that ceiling joists are usually

a minimum of 2 × 6. Larger lumber and larger struc-

tural cavities will require more air nozzles.

Drying under and behind cabinets is often a chal-

lenge, as it is difficult to measure trapped moisture,

and also difficult to access the areas with tubing and

air nozzles. If your moisture measurements are un-

sure, it is better to assume that materials are wet.

Wherever water flowed, make sure you provide flow-

ing dry air. When necessary, remove, dry, and reset

cabinets.

Supplying Extra-Dry Air

To increase drying speed when forcing air into

cavities, ensure that that air going into the DriForce

blower is as dry as possible. One way is to position

the output airflow from a dehumidifier near the Dri-

Force air inlet.

Even better is to attach ducting to the air output

from the dehumidifier and lay it near the DriForce.

Attach a short piece of ADS to the air inlet of the

DriForce, and slip the other end a foot or two up into

the ducting from the dehumidifier. Do NOT tape up

or completely seal such ducting. This could unbal-

ance the airflow through the dehumidifier and possi-

bly damage the dehumidifier.

Super-dry air from a desiccant dehumidifier can

be especially helpful to speed up a drying job, or to

dry difficult materials like lath and plaster, double-