Order Entry: 800-247-4081 Answer Line: 877-257-1781

4

Duracable®Machine Manual

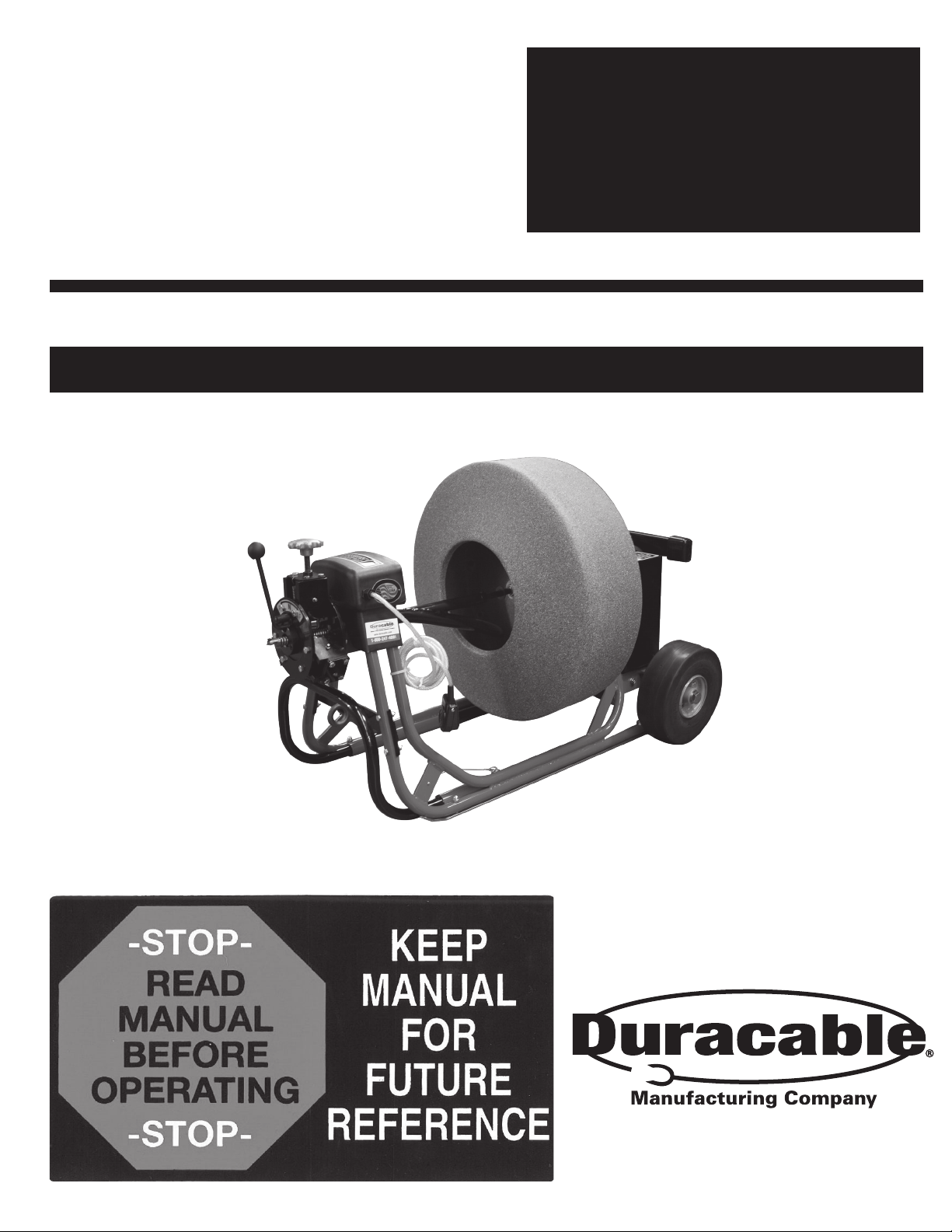

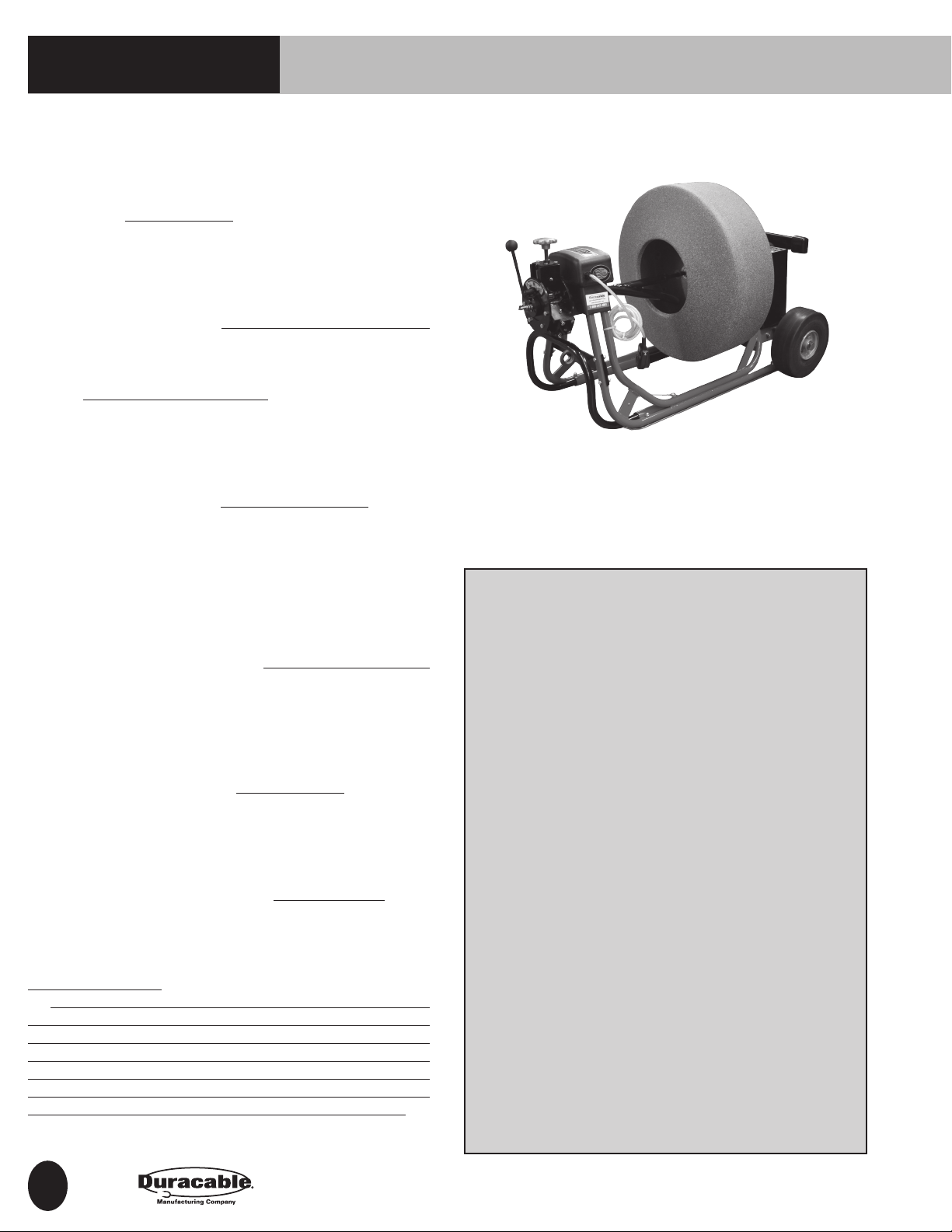

Model DM55

Safe Machine Operation

Read this machine manual thoroughly before assembling or

operating the machine. Become familiar with its controls and

proper use before operating. Keep this manual in a handy

place for reference and parts replacement referral. This

machine is designed specically for the purpose of opening

and cleaning drains. Use it for this purpose - do not use it for

other purposes.

Use gloves to protect your hands. Wear them to feed and

retrieve cable. Use a material that cannot be easily grabbed

by the cable. Most leather gloves and certain rubber gloves

work well. Duracable Manufacturing Company has each type

available through the Duracable Product Catalog. Also, avoid

the use of loose-tting clothes or jewelry when operating this

machine. Keep guards in place to protect the operator from

the electric motor and electrical wiring. These guards are for

safety protection and must be in place when running the

machine.

Each machine is equipped with an air foot switch. Use of

the air foot switch to operate the machine is required for

safe operation. This allows the machine operator to turn the

machine on or off with the foot while keeping both hands

on the cable. Select a work area free from obstruction with

room to work. Keep the machine within three feet of the pipe

opening, allowing only enough room to work.This is required

to shorten the length of exposed cable, thus providing

maximum control in high-torque situations. Take a position

that is comfortable to the left or right side of the machine

for feeding or retrieving cable. For high work openings, the

machine can be placed on its back as conditions require.

When performing a job, use the smallest blade rst. Rinse the

pipe after each blade is run through the line in order to clean

out loosened debris. Then follow with the increasing sizes of

blades until the size used is one that actually scrapes the side

of the pipe or sewer. The cutting blades are exible and can

be compressed to enter most cleanout openings. Centrifugal

force created by the spinning cable forces the blades to

expand to their natural diameter or to the walls of the pipe.

It is advisable to maintain a very keen cutting edge on the

blades at all times. Place two hands on the cable between the

outlet of your machine and the cleanout, and keep them there

at all times during operation.Your hands placed in the proper

position, will provide a guide for the cable.

As the blade makes contact with an obstruction in the line, it

stops the blade from turning and builds torque in the cable.

Do not permit the blade to get hung up in an obstruction for

more than three seconds.Torque buildup can be both helpful

and dangerous. It is helpful when pulled from the obstruction

in a timely manner. When the cable is pulled away, the tension

is released and the blade turns at a high speed. When the

blade is free, feed it back into the obstruction to make use of

the built-up power to clean the line. It is dangerous because

excess torque can cause looping over of the cable. Serious

injury to ngers and hands is possible unless precautions are

observed.

When retrieving cable from the line, feed the cable into the

machine until the blade is close to the cleanout opening.

Shut off the machine and hand-feed the remaining cable into

the machine. Use of a Power Cable Feed and Return (PCFR)

will reduce stress and strain on both the drain cleaning

machine and the service technician. Duracable Manufacturing

Company recommends a PCFR unit be used on every Model

DM55 machine. This unit mounts in front of the head casting

assembly and with movement of a handle will feed or retrieve

cable from a sewer line. Mounting time for the unit is minimal.

UnpackingYour Machine

The Model DM55 is shipped to you with the following parts:

the base machine, a reel, a revolving arm, a oating ring, and

a oating ring attachment. When it arrives, remove the parts

immediately and inspect for damage. If any of the contents

are damaged, contact your motor freight carrier immediately.

AssemblingYour Machine

• Set the base machine in a down position on its rails.

• Pick up the reel with the cone shape to the front of the

machine (toward the switches), and slide it onto the reel

shaft. Be sure the orange drive lugs slide into the openings

in the back of the reel and engage fully.

• Place the oating ring inside the reel and mount it to the

tail piece or cable using the oating ring attachment. Attach

a tail piece (10’ of cable) to the oating ring attachment.

• Feed the tail piece through the revolving arm until about

1” of the cable shows.

• Position the revolving arm inside the reel.

• Place the revolving arm with cable extended into the rear

side of the head bearing.

• Position the extension shaft on the revolving arm into the

center of the reel bearing.

• Slide the tail piece through the head bearing. Attach the

full length of cable to the tail piece and feed cable back into

the machine.

DisassemblingYour Machine

To disassemble the Model DM55 machine, reverse the

assembly process

MovingYour Machine

Break the machine down into lighter-weight components to

move it to and from the job site. To do this, wrap the GFCI

cord and the air foot switch pedal in a convenient spot on

the machine, remove the revolving arm from its assembled

position (leave the cable inside it and keep it with the reel),

and remove the reel assembly. Various accessories are

available from Duracable Manufacturing Company to assist

and protect the operator during the moving process.

Information and Specifications