_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document No. D204-00-001-IS Issue 9 12-01-2024 Sheet 5 of 8

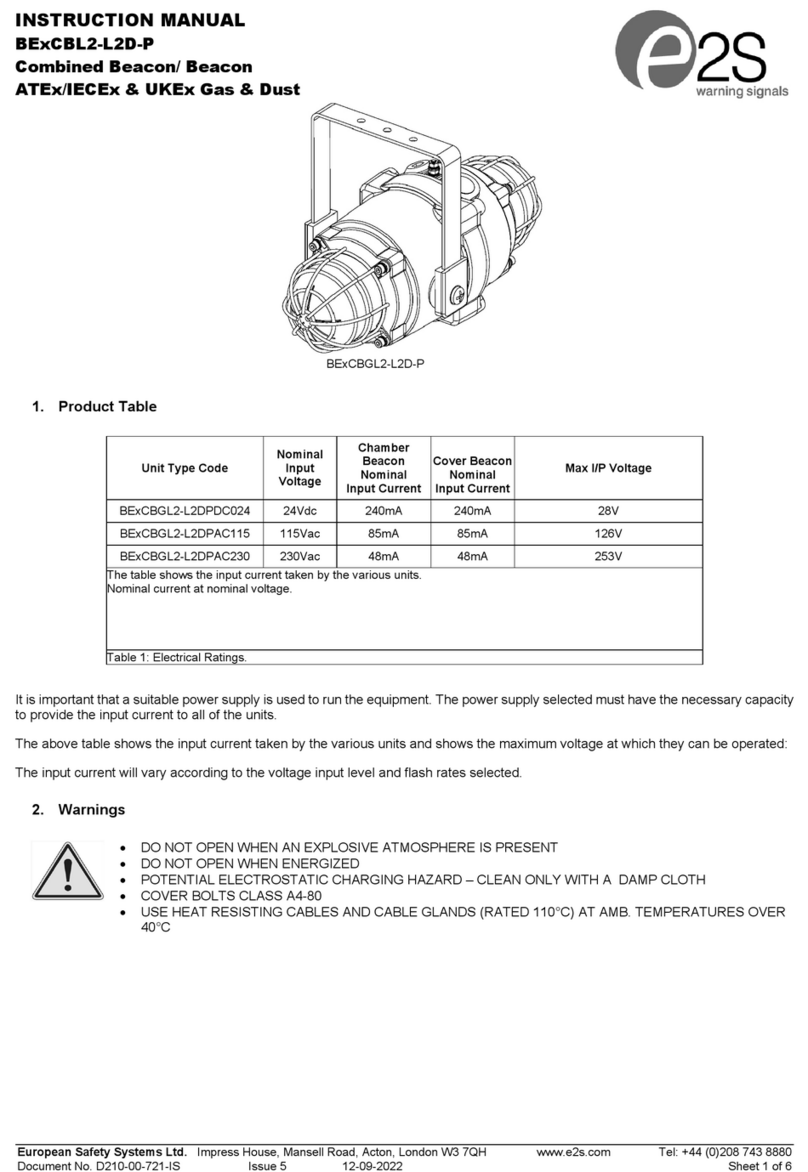

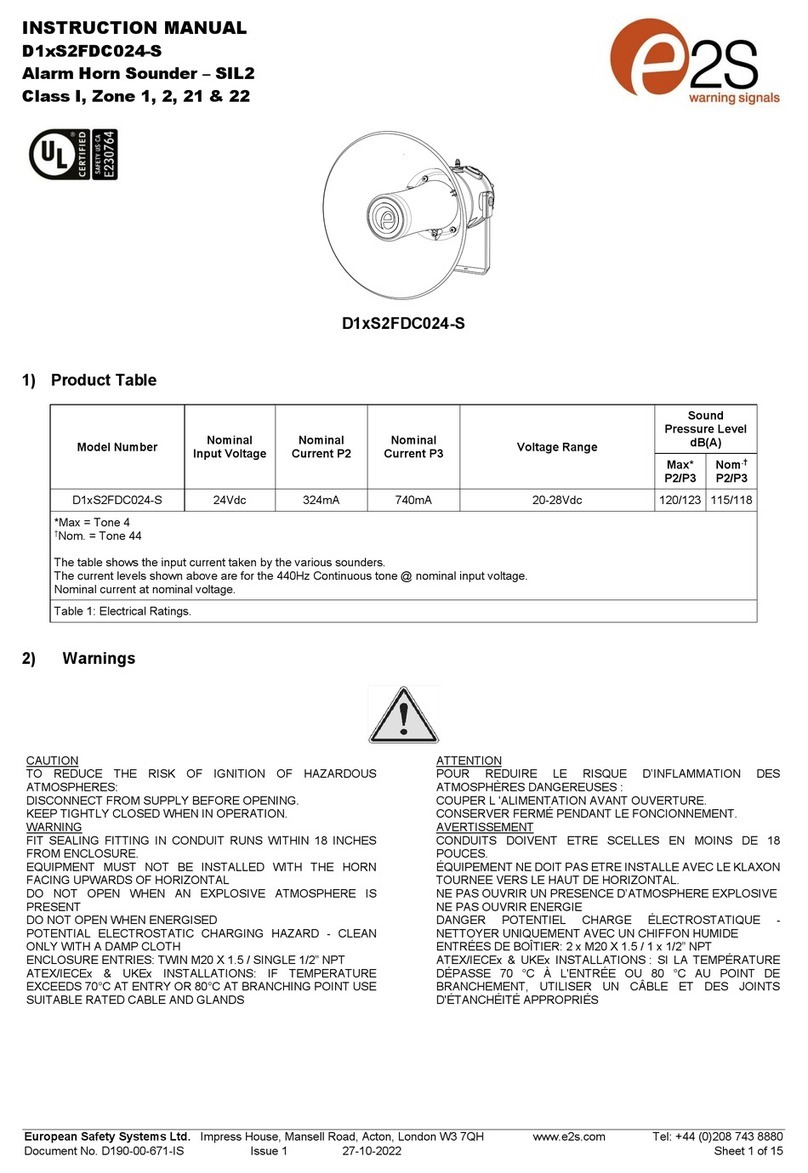

10) Power Supply Selection

Electrical Ratings

See table 1

250Vac max. / 5.0A max (3.33A max NEC/CEC)

48Vdc max. / 1.0A max

24Vdc max / 3.0A max

48Vdc max / 20mA (LED -C option with no ballast resistor)

11) Selection of Cable. Cable Glands, Blanking

Elements & Adapters

ATEx/IECEx & UKEx Installations:

The equipment must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards:

EN60079-14 / IEC60079-14: Explosive atmospheres -

Electrical installations design, selection and erection

EN60079-10-1 / IEC60079-10-1: Explosive atmospheres -

Classification of areas. Explosive gas atmospheres

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried

out by a competent electrical engineer who has the

necessary training.

The equipment must not be installed with any obstruction to

the flanged flameproof joint any closer than permitted as per

EN/IEC60079-14, table 13.

For high ambient temperatures the cable entry temperature

may exceed +70ºC or the cable branching point temperature

may exceed 80ºC and therefore suitable heat resisting cables

and cable glands must be used, with a rated service

temperature of at least the values stated below:

For Single Switch models STExCP8-BGS:

Max. ambient

temperature ºC

50 55 60 65 70

req. Cable / Cable

Gland rating: ºC

76 81 86 91 96

For Dual Switch models STExCP8-BGD:

Max. ambient

temperature ºC

40 45 50 55 60 65 70

req. Cable /

Cable Gland

rating: ºC

85 90 95 100 105 110 115

The cable gland entries have an M20 x 1.5 entry thread. Only

suitably rated ATEX / IECEx or UKEx certified cable glands

which must be suitable for the type of cable being used and

also meet the requirements of the current Ex ‘d’ flameproof

installation standards EN 60079-14 / IEC60079-14.

When only one cable entry is used the other entries must be

closed with suitably rated ATEX / IECEx or UKEx certified

blanking plugs that meet the requirements of the current Ex

‘db’ flameproof installation standards EN 60079-14 /

IEC60079-14 (tightening torque 10Nm).

NEC / CEC Installations:

The equipment must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards:

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried

out by a competent electrical engineer who has the

necessary training.

The equipment must not be installed with any obstruction to

the flanged flameproof joint any closer than permitted as per

the NEC/CEC.

For high ambient temperatures the cable entry temperature

may exceed +60ºC or the cable branching point temperature

may exceed 60ºC and therefore suitable heat resisting cables

and cable glands must be used, with a rated service

temperature of at least the values stated below:

For Single Switch model STExCP8-BG-S:

Max.

ambient

temperature

ºC

35 40 45 50 55 60

req. Cable /

Cable

Gland

rating: ºC

61 66 71 76 81 86

For Dual Switch model STExCP8-BG-D:

Max.

ambient

temperature

ºC

20 25 30 35 40 45 50 55 60

req. Cable /

Cable

Gland

rating: ºC

65 70 75 80 85 90 95 100 105

For use in Class I Division II locations, in order to maintain

the db type protection, flameproof conduit seals and/or cable

glands must be used.

The cable gland entries have an M20 x 1.5 entry thread. Only

suitably rated and certified cable glands which must be

suitable for the type of cable being used and also meet the

requirements of the current Ex ‘db’ flameproof and NEC/CEC

installation standards (tightening torque 10Nm).

When only one cable entry is used the other entries must be

closed with suitably rated and certified blanking plugs that

meet the requirements of the current Ex ‘db’ and Ex ‘tb’

flameproof and NEC/CEC installation standards (tightening

torque 10Nm).

All Installations:

To access the Ex d chamber, remove the four off M6 x 60

stainless steel A4-70 Cap Head cover bolts.

If the installation is made using conduit, openings must have

a sealing fitting connected as close as practical to the wall of

the enclosure, but in no case more than the size of the

conduit or 2” of enclosure, whichever is the lesser.

If a high IP (Ingress Protection) rating is required then a

suitable sealing washer must be fitted under the cable glands

or blanking plugs.