_______________________________________________________________________________________________________________________________

European

Safety

Systems

Ltd.

Impress House, Mansell Road, Acton, London W3 7QH sa[email protected]m Tel: +44 (0)208 743 8880 www.e2s.com Fax: +44 (0)208 740 4200

Document No. D191-00-201-IS Issue 1 03-06-2019 Sheet 2 of 8

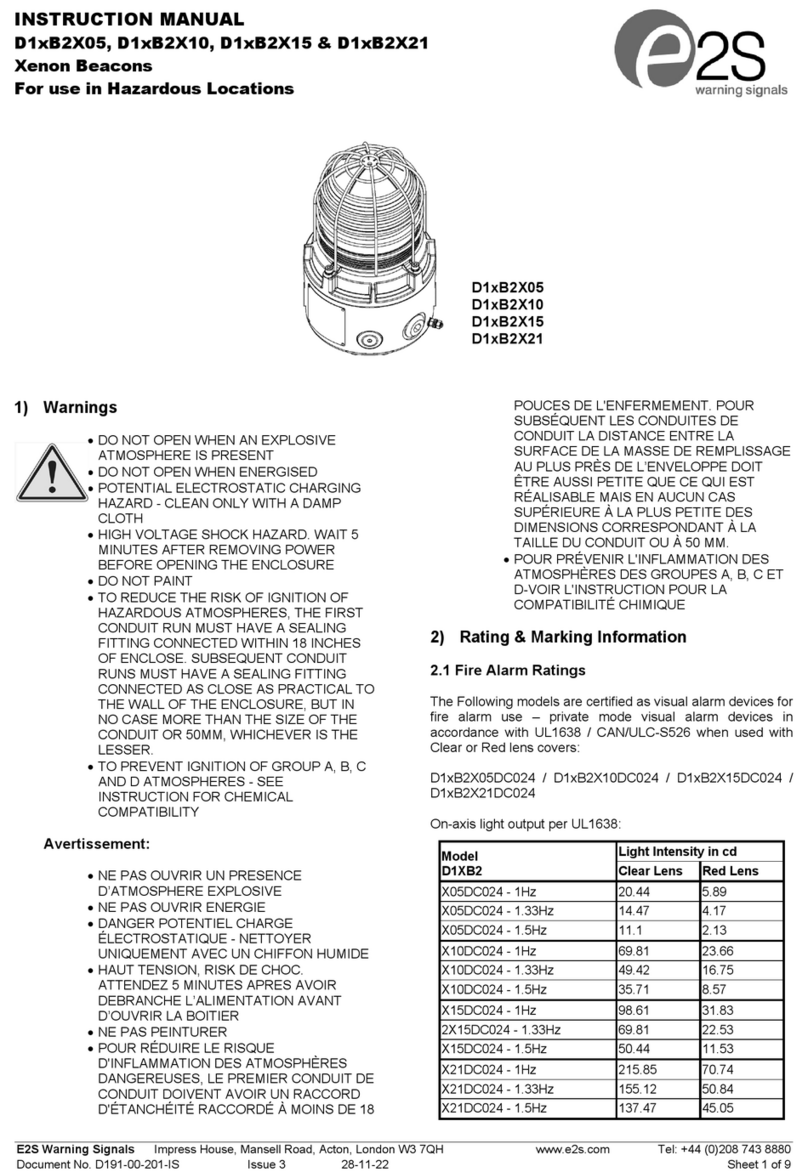

2.3 NEC & CEC Class / Division Ratings for US / Canada

The D1xB2X Xenon beacons comply with the following

standards:

UL 1203 (Ed. 5) 2018

UL1638A (Ed. 1) 2016

UL1638 (Ed. 5) 2017

CSA C22.2 No. 30-M1986 (Ed. 3) 2016

CSA C22.2 No. 25 (Ed. 4) 2017

CSA C22.2 No. 205 (Ed. 3) 2017

The D1xB2X05DC012, D1xB2X05DC024 &

D1xB2X05DC048 Xenon Beacons are rated as follows:

Class I Div 1 Group ABCD T5 Ta -55°C to +80°C

Class I Div 1 Group ABCD T6 Ta -55°C to +65°C

Class II Div 1 Group EFG T5 Ta -55°C to +80°C

Class III Div 1 Ta -55°C to +80°C

The D1xB2X05AC115 & D1xB2X05AC230 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T4A Ta -55°C to +70°C

Class I Div 1 Group ABCD T5 Ta -55°C to +55°C

Class I Div 1 Group ABCD T6 Ta -55°C to +40°C

Class II Div 1 Group EFG T4 Ta -55°C to +40°C

Class III Div 1 Ta -55°C to +40°C

The D1xB2X10DC024 & D1xB2X10DC048 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T4 Ta -55°C to +80°C

Class I Div 1 Group ABCD T4A Ta -55°C to +70°C

Class I Div 1 Group ABCD T5 Ta -55°C to +50°C

Class II Div 1 Group EFG T4 Ta -55°C to +80°C

Class III Div 1 Ta -55°C to +80°C

The D1xB2X10AC115 & D1xB2X10AC230 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T4 Ta -55°C to +70°C

Class I Div 1 Group ABCD T4A Ta -55°C to +55°C

Class II Div 1 Group EFG T4 Ta -55°C to +40°C

Class III Div 1 Ta -55°C to +40°C

The D1xB2X15DC024 & D1xB2X15DC048 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T3C Ta -55°C to +80°C

Class I Div 1 Group ABCD T4 Ta -55°C to +55°C

Class II Div 1 Group EFG T4 Ta -55°C to +80°C

Class III Div 1 Ta -55°C to +80°C

The D1xB2X15AC115 & D1xB2X15AC230 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T4 Ta -55°C to +70°C

Class I Div 1 Group ABCD T4A Ta -55°C to +55°C

Class II Div 1 Group EFG T4 Ta -55°C to +40°C

Class III Div 1 Ta -55°C to +40°C

The D1xB2X21DC024 & D1xB2X21DC048 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T3B Ta -55°C to +80°C

Class I Div 1 Group ABCD T3C Ta -55°C to +75°C

Class I Div 1 Group ABCD T4 Ta -55°C to +50°C

Class II Div 1 Group EFG T3C Ta -55°C to +40°C

Class III Div 1 Ta -55°C to +40°C

The D1xB2X21AC115 & D1xB2X21AC230 Xenon Beacons

are rated as follows:

Class I Div 1 Group ABCD T3C Ta -55°C to +60°C

Class I Div 1 Group ABCD T4 Ta -55°C to +55°C

Class I Div 1 Group ABCD T4A Ta -55°C to +40°C

Class II Div 1 Group EFG T4 Ta -55°C to +40°C

Class III Div 1 Ta -55°C to +40°C

Installation must be carried out in compliance with the

National Electric Code / Canadian Electric Code

2.4 NEC Class / Zone ratings US

The D1xB2X Xenon beacons comply with the following

standards:

UL 60079-0 (Ed. 6) 2017

UL 60079-1 (Ed. 7) 2015

UL 60079-31 (Ed. 2) 2015

The D1xB2X05DC012, D1xB2X05DC024 &

D1xB2X05DC048 Xenon Beacons are rated as follows:

Class I Zone 1 AEx db IIC T4 Ta -55°C to +80°C

Class I Zone 1 AEx db IIC T5 Ta -55°C to +75°C

Class I Zone 1 AEx db IIC T6 Ta -55°C to +60°C

Zone 21 AEx tb IIIC T99°C Ta -55°C to +80°C

The D1xB2X05AC115 & D1xB2X05AC230 Xenon Beacons

are rated as follows:

Class I Zone 1 AEx db IIC T4 Ta -55°C to +70°C

Class I Zone 1 AEx db IIC T5 Ta -55°C to +50°C

Zone 21 AEx tb IIIC T153°C Ta -55°C to +70°C

The D1xB2X10DC024 & D1xB2X10DC048 Xenon Beacons

are rated as follows:

Class I Zone 1 AEx db IIC T4 Ta -55°C to +80°C

Class I Zone 1 AEx db IIC T5 Ta -55°C to +45°C

Zone 21 AEx tb IIIC T132°C Ta -55°C to +80°C

The D1xB2X10AC115 & D1xB2X10AC230 Xenon Beacons

are rated as follows:

Class I Zone 1 AEx db IIC T3 Ta -55°C to +70°C

Class I Zone 1 AEx db IIC T4 Ta -55°C to +65°C

Zone 21 AEx tb IIIC T153°C Ta -55°C to +70°C

The D1xB2X15DC024 & D1xB2X15DC048 Xenon Beacons

are rated as follows:

Class I Zone 1 AEx db IIC T3 Ta -55°C to +80°C

Class I Zone 1 AEx db IIC T4 Ta -55°C to +65°C

Zone 21 AEx tb IIIC T132°C Ta -55°C to +80°C

The D1xB2X15AC115 & D1xB2X15AC230 Xenon Beacons

are rated as follows:

Class I Zone 1 AEx db IIC T3 Ta -55°C to +70°C

Class I Zone 1 AEx db IIC T4 Ta -55°C to +65°C

Zone 21 AEx tb IIIC T153°C Ta -55°C to +70°C