__________________________________________________________________________________________________________________________________

EuropeanSafetySystemsLtd. Impress House, MansellRoad, Acton, LondonW3sales@e2s.com Tel:+44 (0)2087438880

www.e2s.com Fax:+44 (0)2087404200

DocumentNo. IS2424-PIssueB17-04-02 Sheet3of4

Thefollowingtableshows the rangeof loudspeakers:-

UnitTypeInputWattageMax.

I/PVolts

BExL25E100VLine25W100V

BExL25E8ohm25W14.14V

BExL25E16 ohm25W20V

BExL15E100VLine15W100V

BExL15E8ohm15W10.95V

BExL15E16 ohm15W15.49V

Theabove tablealso shows the maximum ACsignalvoltages

at which the loudspeakerscanbe operated.

Thecurrentlevelstakenbytheeachloudspeakerwill depend

onwhich outputtapping has beenselected (see section14of

this instructionmanual). BExL25E 100V Line units haveoutput

levels of 25W,12.5W,6Wand2W,BExL15E100V Line units

haveoutputlevelsof 15W, 7.5W, 3Wand1W.

11) CableSelection

Whenselecting thecable sizeconsideration mustbegivento

the current that eachunit draws,thenumberofloudspeakers

onthelineandthelengthof thecableruns.

SAFETY WARNING: Iftheloudspeakers are usedathigh

ambienttemperatures,i.e.over+40ºC,thenthecable entry

temperature mayexceed +70ºCand thereforesuitable heat

resistingcablesmustbeused,witharatedservice

temperature of at least 95ºC.

12) Earthing

Allloudspeakers mustbeconnectedtoagoodquality earth.

Theunitsareprovidedwithinternaland externalearthing

terminalswhichare bothlocatedonthe terminalchamber

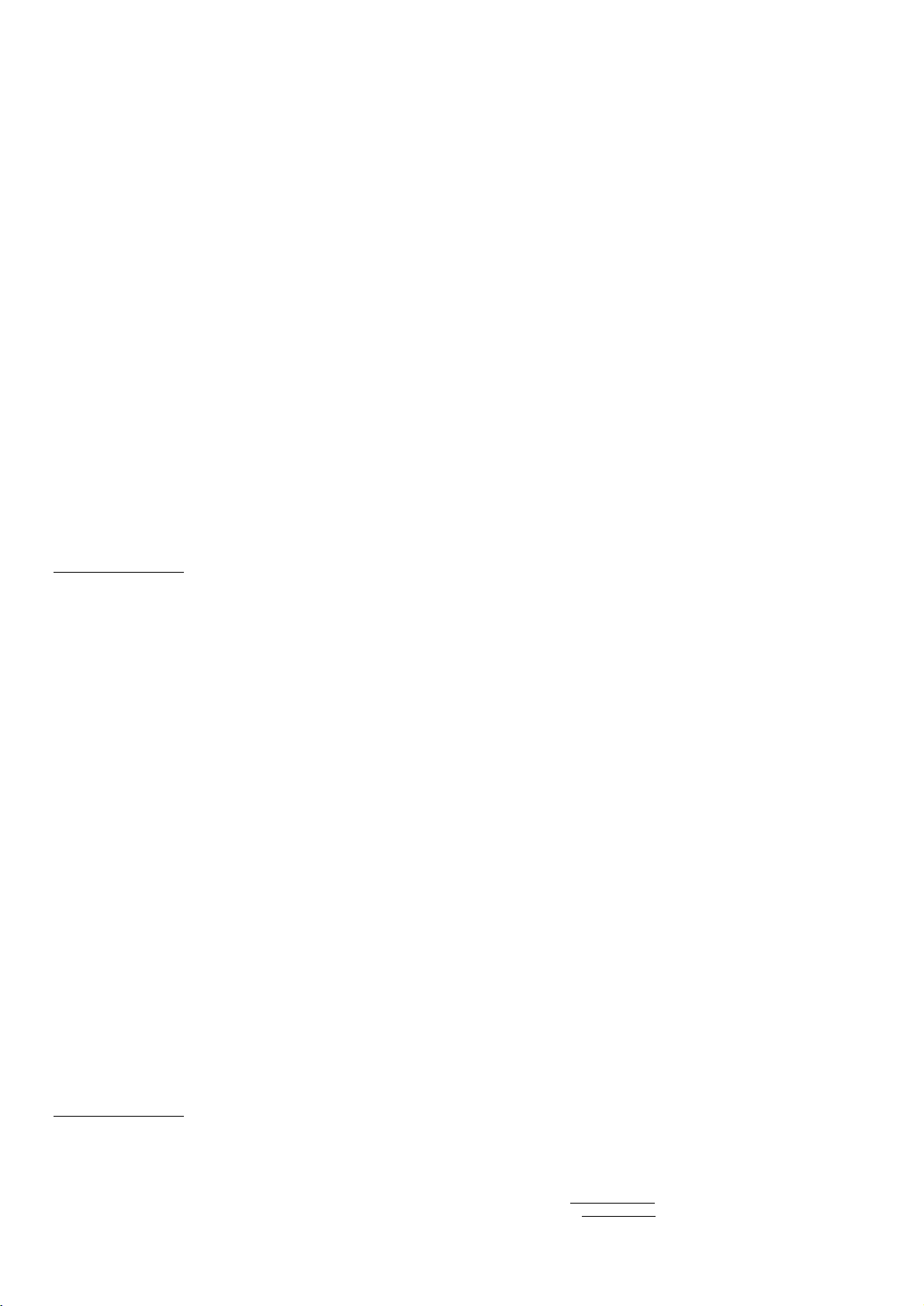

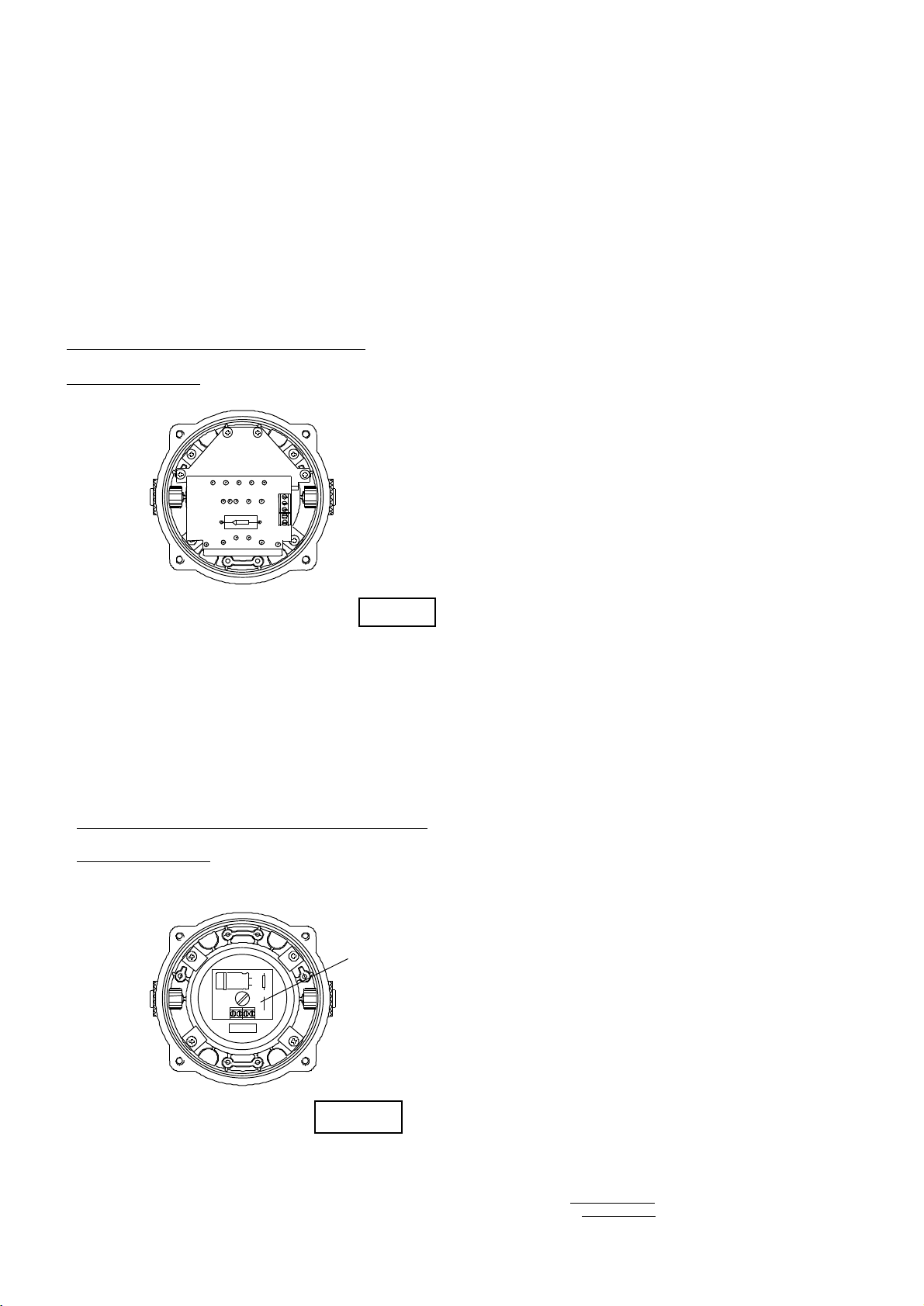

sectionoftheunit (seefigures 2and3).

Whenusing the external earthterminal acablecrimp lug must

be used. Thecablelugshouldbe located between thetwoM5

stainlesssteelflat washers.The M5 stainlesssteelspring

washermust befixedbetween theouterflat washerandthe

M5 stainlesssteelnut to ensurethat thecable lug is secured

againstlooseningandtwisting.

Theinternalearthbondingwiresensurethat agoodquality

earth is maintained betweentheflameproofchambercasting,

the terminalsection castingandtheterminal cover casting.

13) CableGlands

TheBExL25E andBExL15Eloudspeakershavedual cable

glandentrieswhich haveanM20 x1.5entrythreadasstandard

oraPG13.5thread asaspecial. Onlycableglandsapproved

forEx‘e’applications or better (i.e. Ex‘d’applications)can be

used.Theymust be suitable forthetype ofcabletobeused

andalso meet therequirementsof theExequipment

installation standardBS EN 60079-14:1997.

SAFETY WARNING: Iftheloudspeakers are usedathigh

ambienttemperatures,i.e.over+40ºC, thenthecable entry

temperature mayexceed +70ºCand thereforesuitable heat

resistingcableglandsmustbeused, with aratedservice

temperature of at least 95ºC.

IfahighIP(IngressProtection)ratingisrequiredthena

suitable sealingwasher must befitted under the cablegland.

Whenonly one cable entry isusedtheotherone mustbe

closedwith anEx‘e’ blankingplug,which mustbesuitably

approvedfor the installation requirements.

14) CableConnections

The cableconnectionsaremade into an EExeIIapproved

twelveway terminal block (six wayonlowimpedanceunits)

whichislocatedintheIncreasedSafety Areaterminal

chamber (see figure 3).See section9ofthismanualfor

accessto theterminal chamber. When wiringintoIncreased

Safety Areaterminalenclosures,youare onlypermitted to

connect onewireintoeach way on theterminal block.

Thereforeinorderthat loudspeakerscan beconnected in a

parallelline, theterminal block is fittedwith approved

connectingcombs so thateachelectrical connection hastwo

terminalsin parallel. TerminalNo’s. 1 and 12(1 and 6 on low

impedance units) must not be used onany units. Cables with a

cross-sectional areaof upto4mm² canbeconnected tothe

terminalblock. Cablesthat haveasmall cross-sectionalarea

shouldbefittedwith crimp ferules.

The lowimpedance loudspeakers are fittedwith twopairsof

terminals2-3and 4-5.

The 100VLine loudspeakersarefittedwithfive pairsof

terminals.Terminals 10-11whicharethecommonand one of

the other four pairs ofterminals 8-9, 6-7, 4-5or2-3 shouldbe

selecteddepending onwhat output levelis required (seethe

followingtable).

BExL25E(25W)BExL15E(15W)

Terminals 100VLine100VLine

10-11to8-925W15W

10-11to6-712.5W7.5W

10-11to4-56W3W

10-11to2-32W1W

15) EndofLineDC Monitoring

OnBExL25EandBExL15Eloudspeakers,dclinemonitoring

canbe used if required.Both the 100V Line units and the Low

Impedance units haveablocking capacitorfitted.Itshould be

noted that eachloudspeakerhas a1M ohmbleedresistor

connected acrosstheblockingcapacitorandthisshouldbe

takenintoaccount whenselecting the valueof the end ofline

monitoringresistance.

The endofline monitoringresistorcanbe connectedtothe

end ofline unit. Notethe monitoringresistorMUSTbe

connected totheterminals in theflameproof enclosure,it

MUSTNOTbe connected to the terminals in theIncreased

Safetyterminationenclosure (seesection 8of this manual

foraccessto theflameproofenclosure). Figures4and5

show theterminalsinthe flameproofenclosures forthe 100V

Lineandlowimpedanceunitsrespectively. Onthe low

impedanceunits caremustbetakenwiththepolarity of the

monitoringvoltage.