European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH

Document No. D190-00-201-IS

8) Installation Requirements

8.1 Safe Installation Requirements

Warning High voltage may be present,

risk of electric shock.

DO NOT open when energised,

disconnect power before opening.

The sounder must only be installed by suitably qualified personnel in

accordance with the latest issues of the relevant standards.

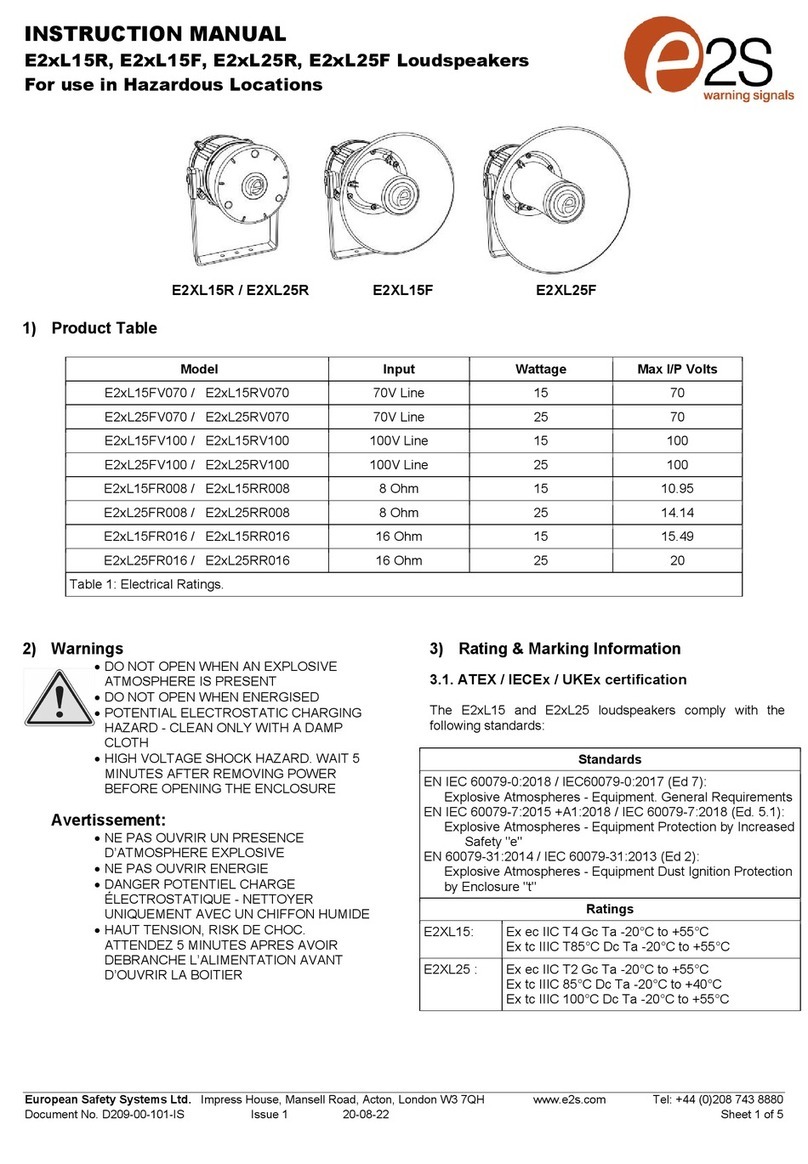

8.2 Cable Selection and Connections

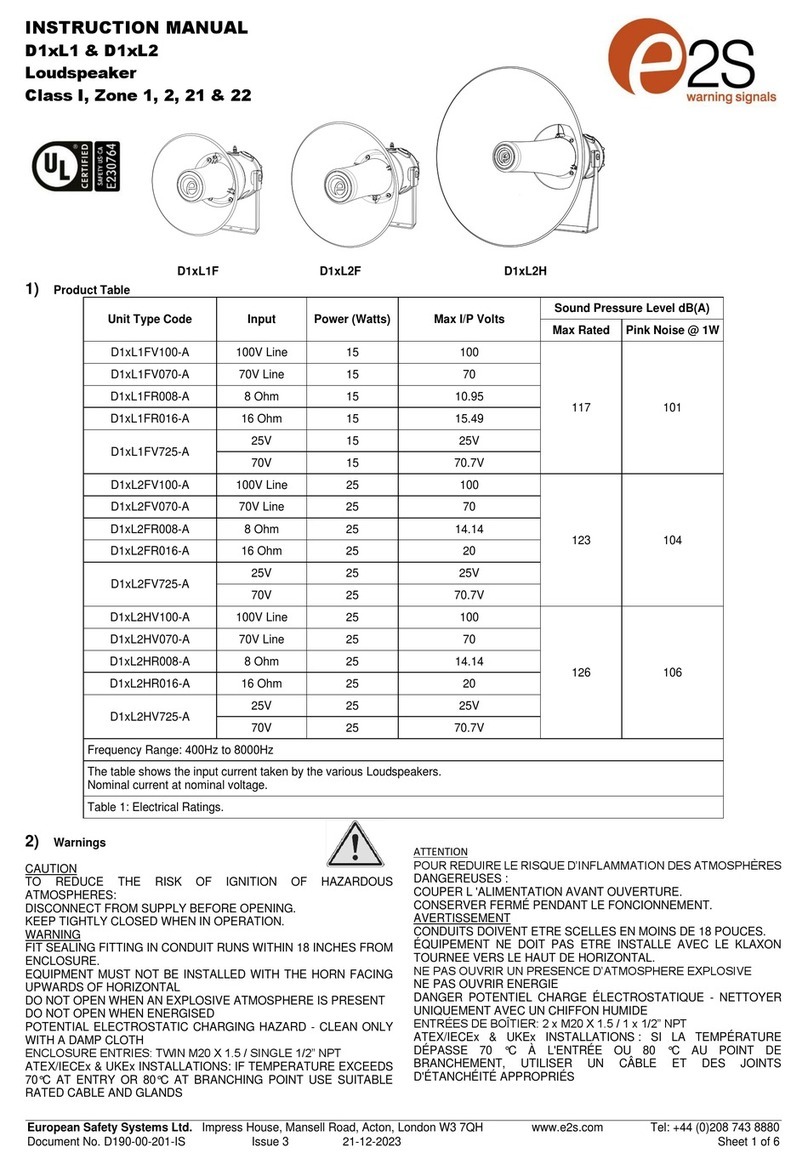

When selectingthe cable size,consideration must be given to the input

current that each unit draws (see table 1), the number of sounders on

the line and the length of the cable runs. The cable size selected must

have the necessary capacity to provide the input current to all the

sounders connected to the line.

A single wire with a cross sectional area of up to 2.5mm²/ AWG14 can

be connected to each terminal way or if an input and output wire is

required two wires can be connected to each terminal way when

crimped with a ferrule. If more than one wire is fitted into a terminal a

ferrule should be used to secure the wires. When connecting wires to

the terminals greatcare should be taken to dress the wire so that when

the cover is inserted into the chamber the wires do not exert excess

pressure on the terminal blocks.

D1xL2 and D1xL1 8 ohm and 16 ohm low impedance loudspeakers

have dual input terminals on the PCB assembly for input and output

wiring. A cable of up to 4.0mm² can be connected to each terminal.

Wire insulation needs to be stripped 8mm. Wires may be fitted

securely with crimped ferrules. Terminal screws need to be tightened

down with a tightening torque of 0.45 Nm / 3.5 Lb-in.

Line In: 0.2 - 2.5mm2/ AWG24 - AWG14

Low Impedance: 0.2 - 4mm2/ AWG24 - AWG12

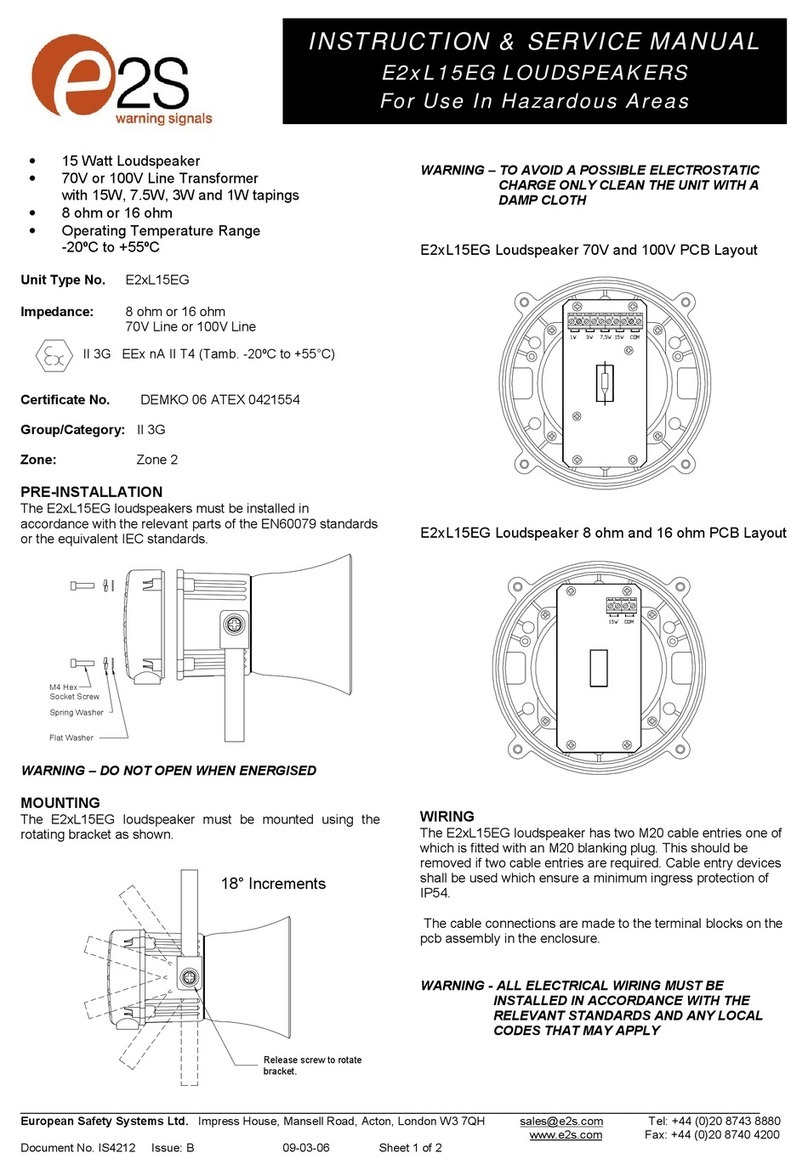

Figure 3: Wire Preparation.

When connecting wires to the terminals great care should be taken to

dress the wires so that when the cover is inserted into the chamber

the wires do not exert excess pressure on the terminal blocks. This is

particularly important when using cables with large cross-sectional

areas such as 2.5mm².

8.3 Earthing

Figure 4: Earth Locations.

8.4 Cable Glands, Blanking Elements & Adapters

Ingress Protection

Adapters

The D1x Loudspeaker range can be supplied with the following types

of adapters:

M20 to M25

It is important to note that stopping plugs cannot be fitted onto

adapters, only directly onto the M20 entries.

Any other adapters used must be suitably rated and certified.

9) Wiring

The cable connections are made into the terminal blocks on the PCB

assembly located in the explosionproof enclosure. See section 7.4 of

this manual for access to the explosionproof enclosure.

Refer to Wiring Schematic D190-06-201 Configs. 1a -2c for Line in

Loudspeakers and Config. 3 for Low impedance wiring details.

Internal Earth

Marked with G