European Safety Systems L

Mansell Road, Acton, London

Document No. D209-00-101-IS

Issue 1

20-08-22

Sheet 4 of 5

6.2. Access to the Enclosure

Warning – High voltage may be

present, risk of electric shock.

DO NOT open when energised,

disconnect power before opening.

Warning – Hot surfaces. External

surfaces and internal components

may be hot after operation, take

care when handling the equipment.

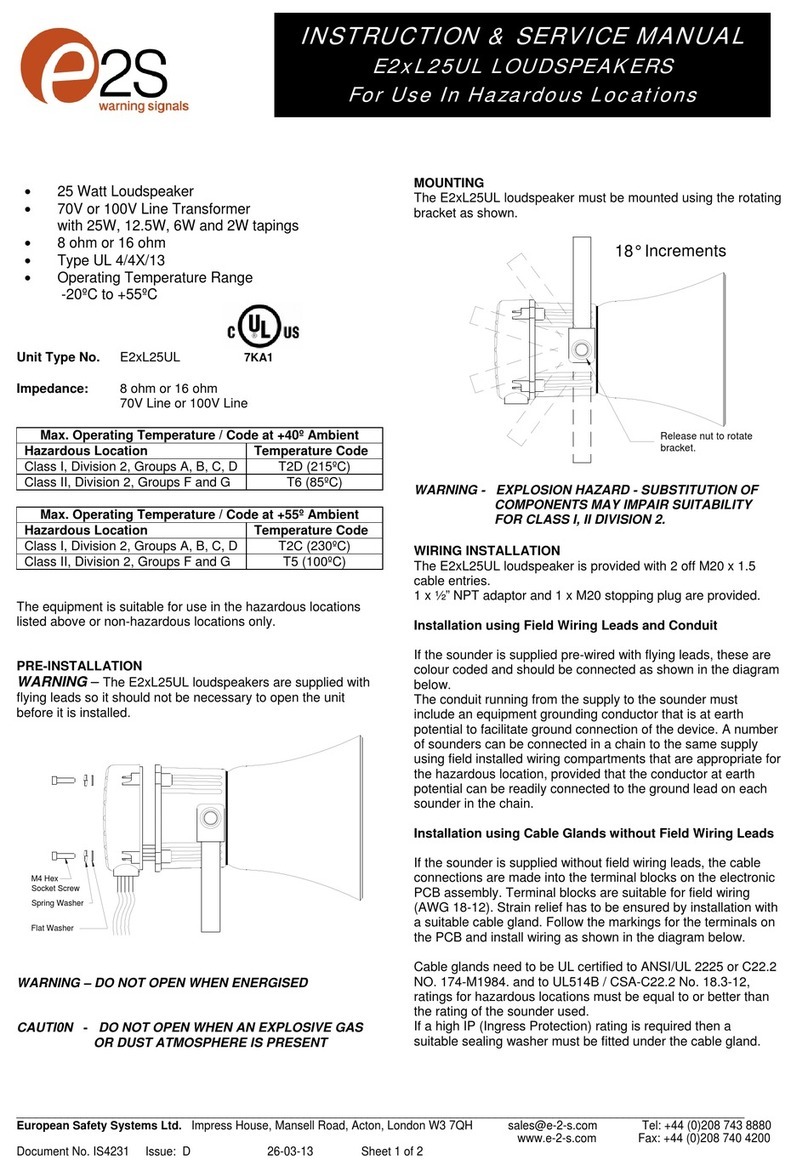

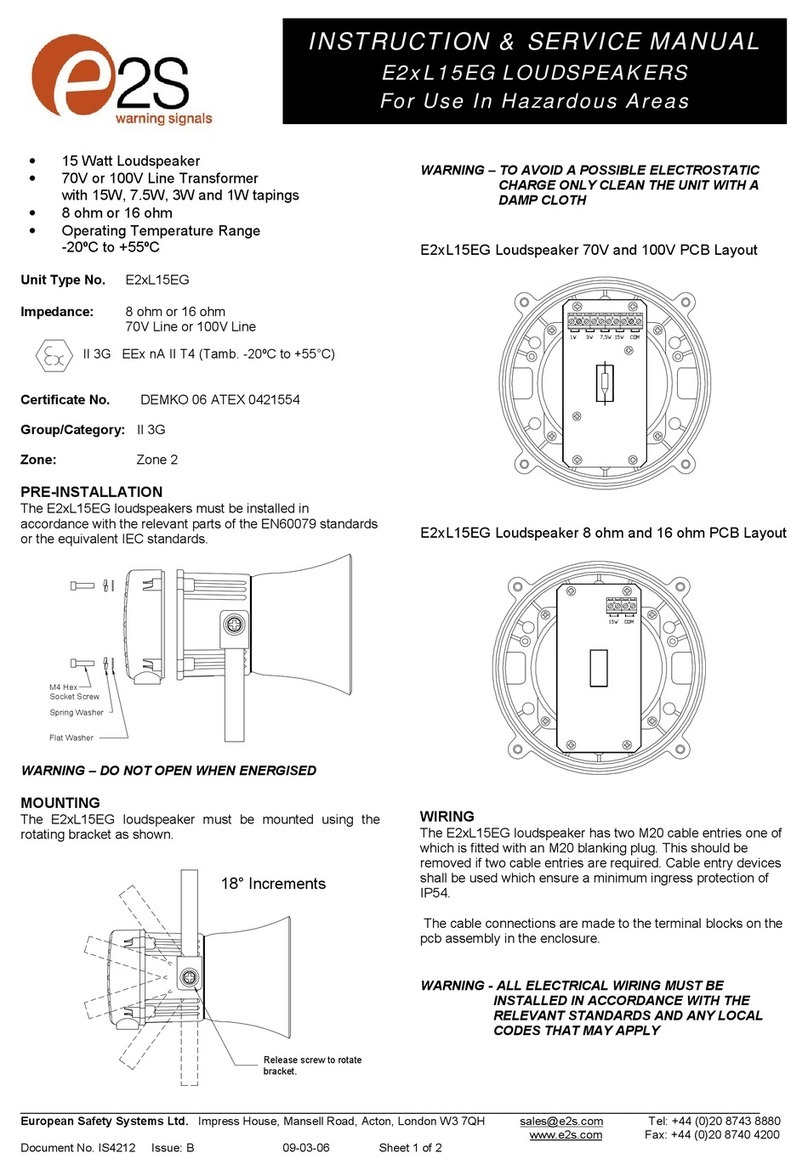

To access the enclosure, remove the four M4 posi pan head

screws, M4 spring and plain washers and withdraw the cover.

Fig. 2 Accessing the Enclosure.

To replace cover, check that the ‘O’ ring seal is in place.

Carefully push the cover in place. Insert and tighten down M4

screws, spring and plain washers in the order shown above

and tighten down.

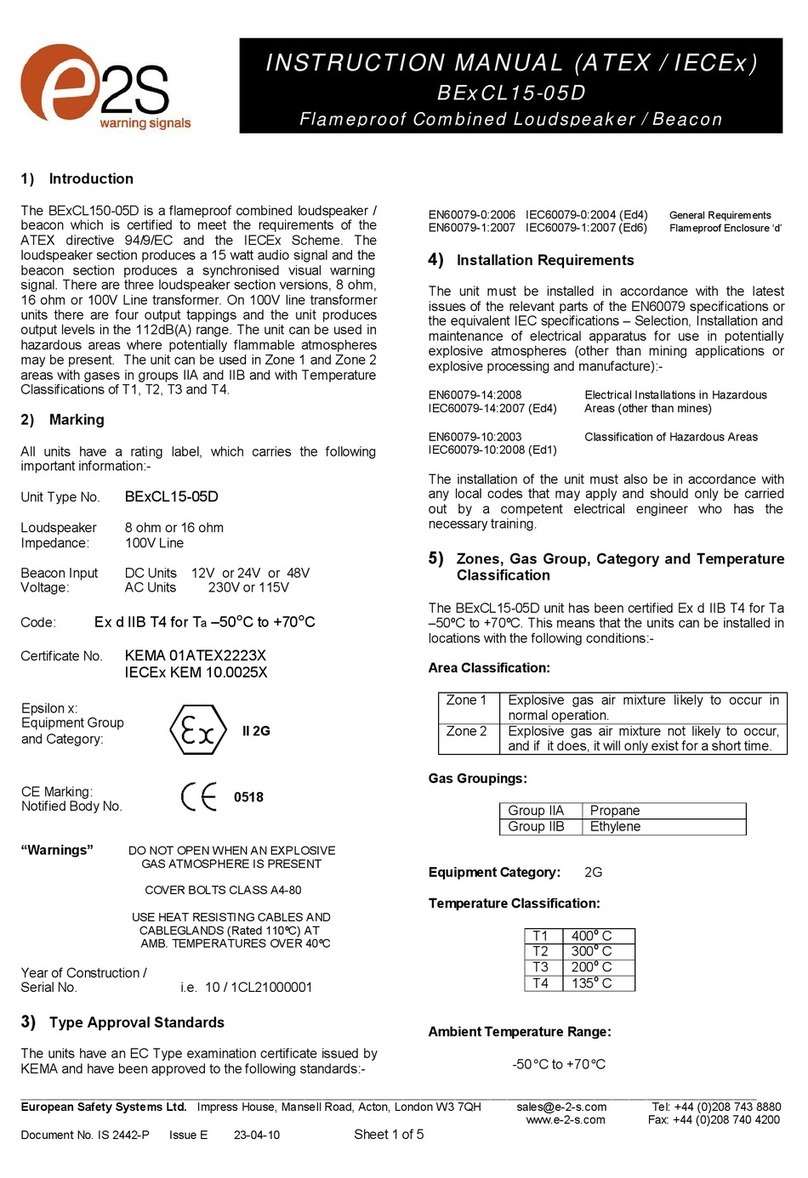

7. Selection of Cable. Cable Glands, Blanking

Elements & Adapters

When selecting the cable size, consideration must be given

to the input current that each unit draws (see Table 1), the

number of sounders on the line and the length of the cable

runs. The cable size selected must have the necessary

capacity to provide the input current to all of the sounders

connected to the line.

The dual entries can be ordered with one of the following

options:

2-off M20 x 1.5 thread

2-off ½” NPT thread

1-off M20 x 1.5 & 1-off ½” NPT thread

To maintain the ingress protection rating and mode of

protection, the cable entries must be fitted with suitably rated,

certified cable entry and/or blanking devices during

installation.

For ambient temperatures over +40ºC the cable entry

temperature may exceed +70ºC or the cable branching

temperature may exceed +80ºC. Therefore suitable heat

resisting cables and cable glands must be used as per table

below

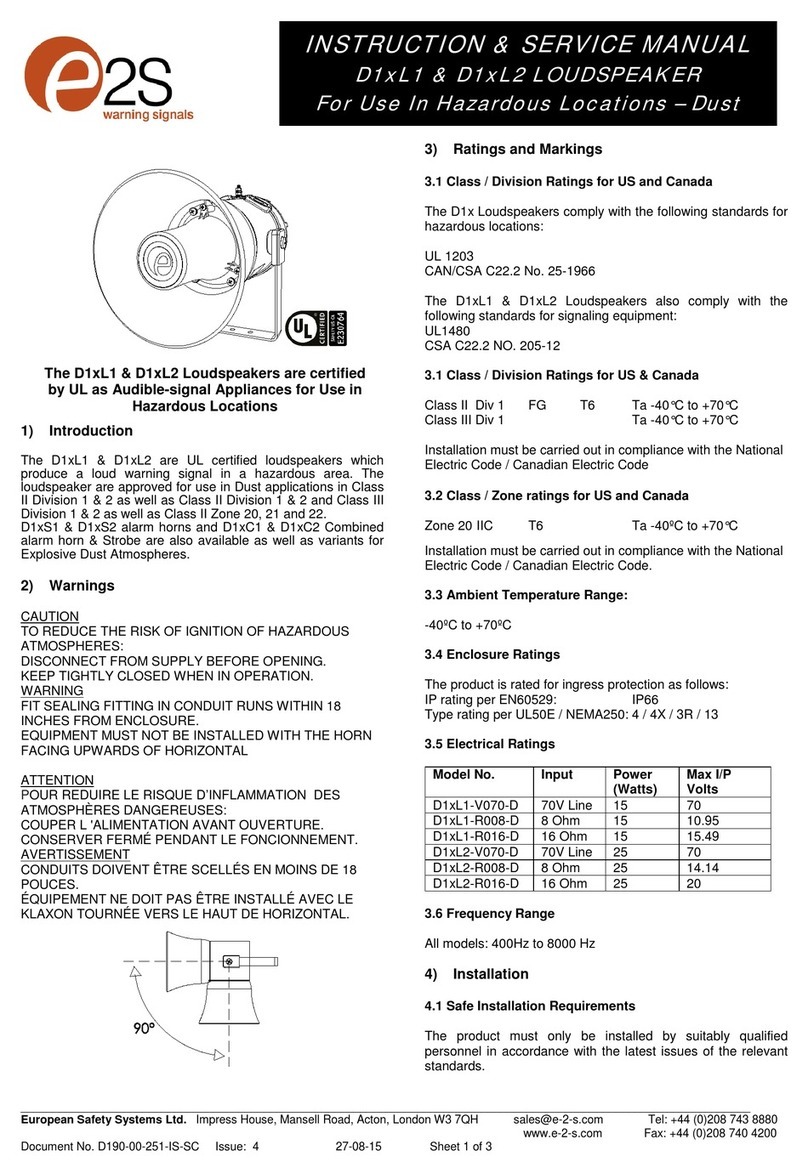

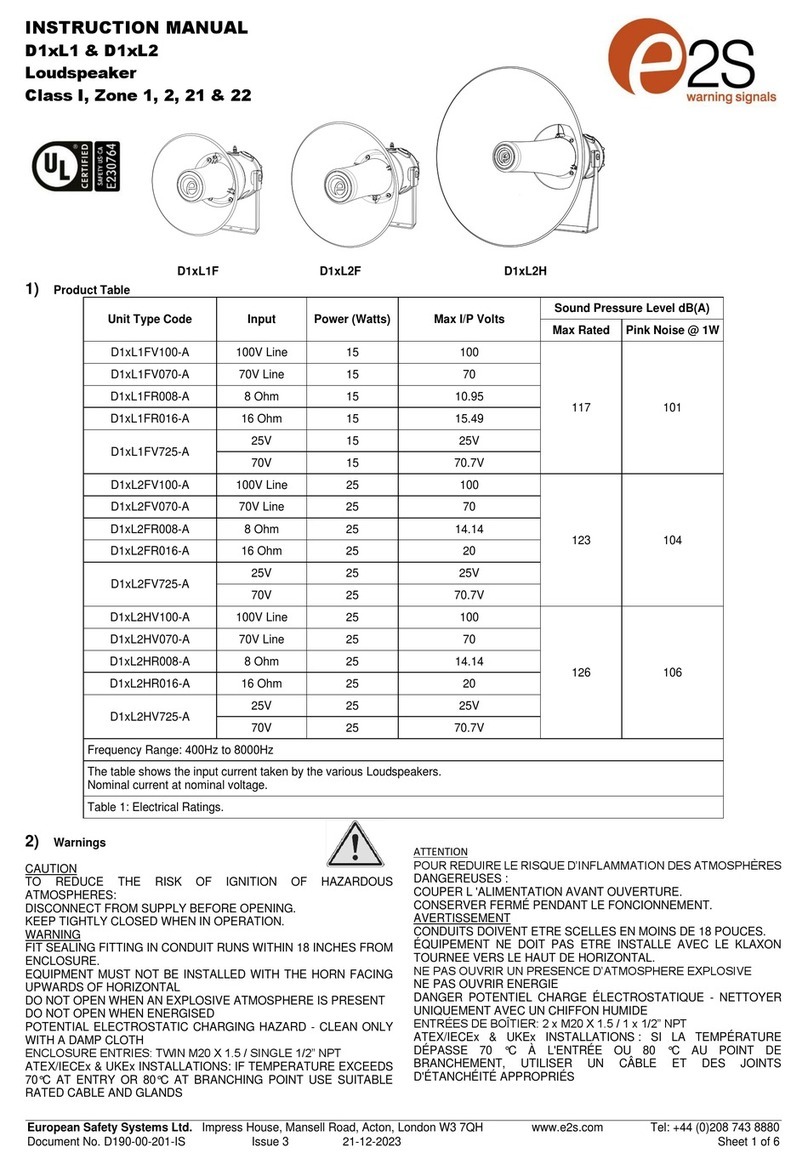

Ambient Temp. 40ºC 45ºC 50ºC 55ºC

Min. Rating of cables

and cable glands 90ºC 95ºC 100ºC 105ºC

If a high IP (Ingress Protection) rating is required then a

suitable sealing washer must be fitted under the cable glands

or blanking plugs.

For use in explosive dust atmospheres, a minimum ingress

protection rating of IP6X must be maintained.

For use in explosive gas atmospheres, a minimum ingress

protection rating of IP54 must be maintained.

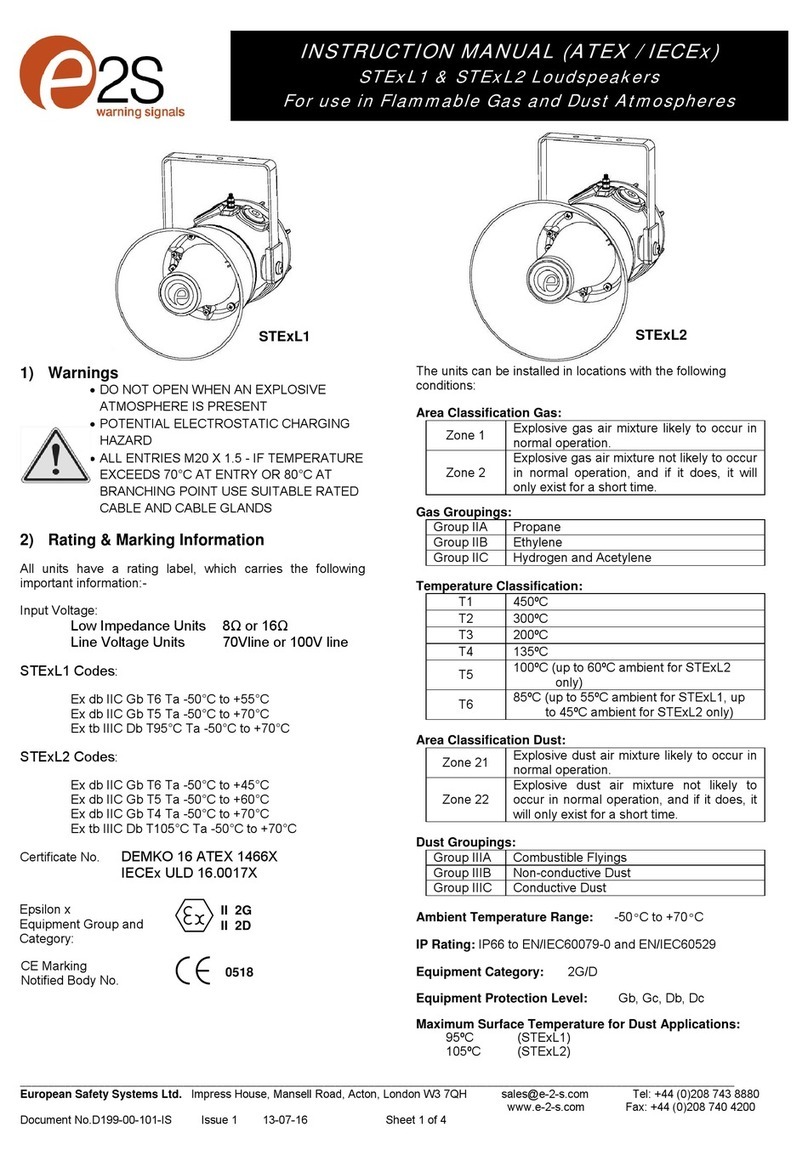

8. Cable Connections

Electrical connections are to be made into the terminal blocks

on the PCBA located in the enclosure. See section 5 of this

manual for access to the enclosure.

Wires having a cross sectional area between 0.5 mm² to

2.5mm² can be connected to each terminal way. If an input

and output wire is required the 2-off Live/Neutral or +/-

terminals can be used. If fitting 2-off wires to one terminal

way the sum of the 2-off wires must be a maximum cross

sectional area of 2.5mm². Strip wires to 8mm. Wires may also

be fitted using ferrules. Terminal screws need to be tightened

down with a tightening torque of 0.45 Nm / 4 Lb-in. When

connecting wires to the terminals great care should be taken

to dress the wires so that when the cover is inserted into the

chamber the wires do not exert excess pressure on the

terminal blocks. This is particularly important when using

cables with large cross sectional areas such as 2.5mm².

9. Line In Wiring

Refer to schematic document D209-06-101 for further detail

on terminal connections.

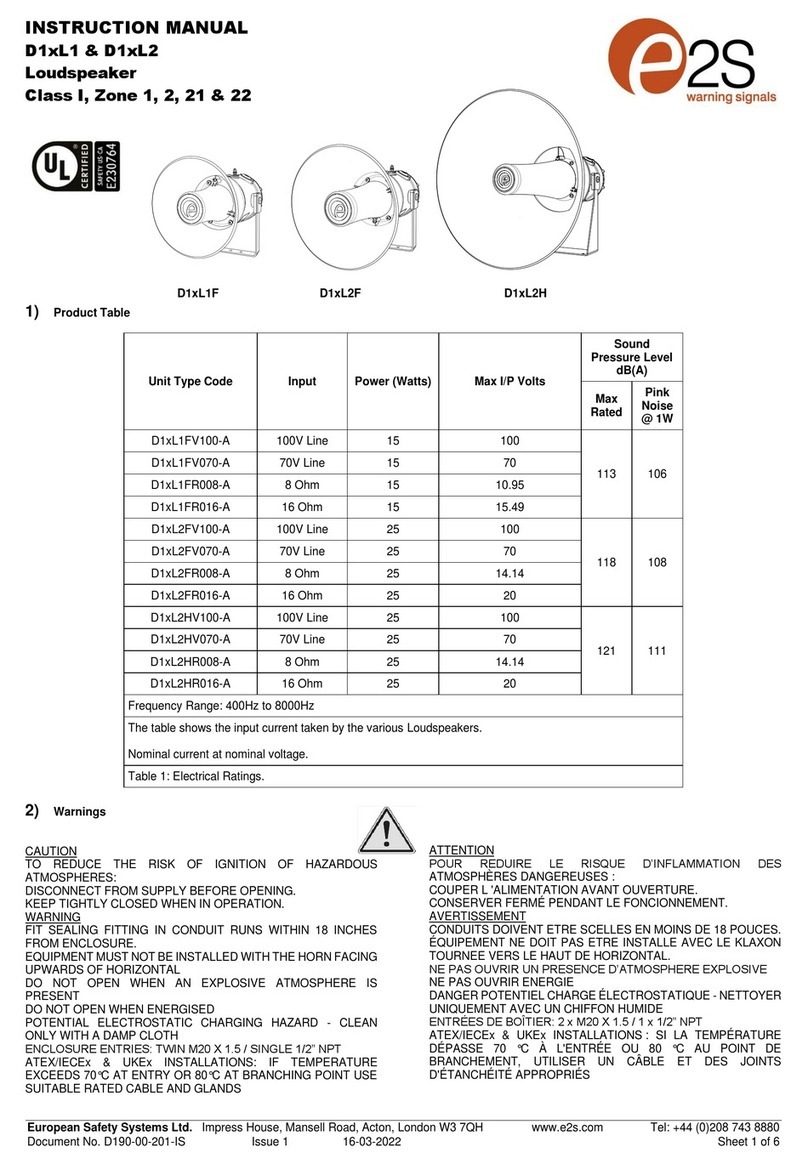

A 10-way terminal block is provided on the Line in

loudspeakers. There are 2-off Common, 2-off 15W/25W, 2-off

7.5W/12.5W, 2-off 3W/6W and 2-off 1W/2W terminals.

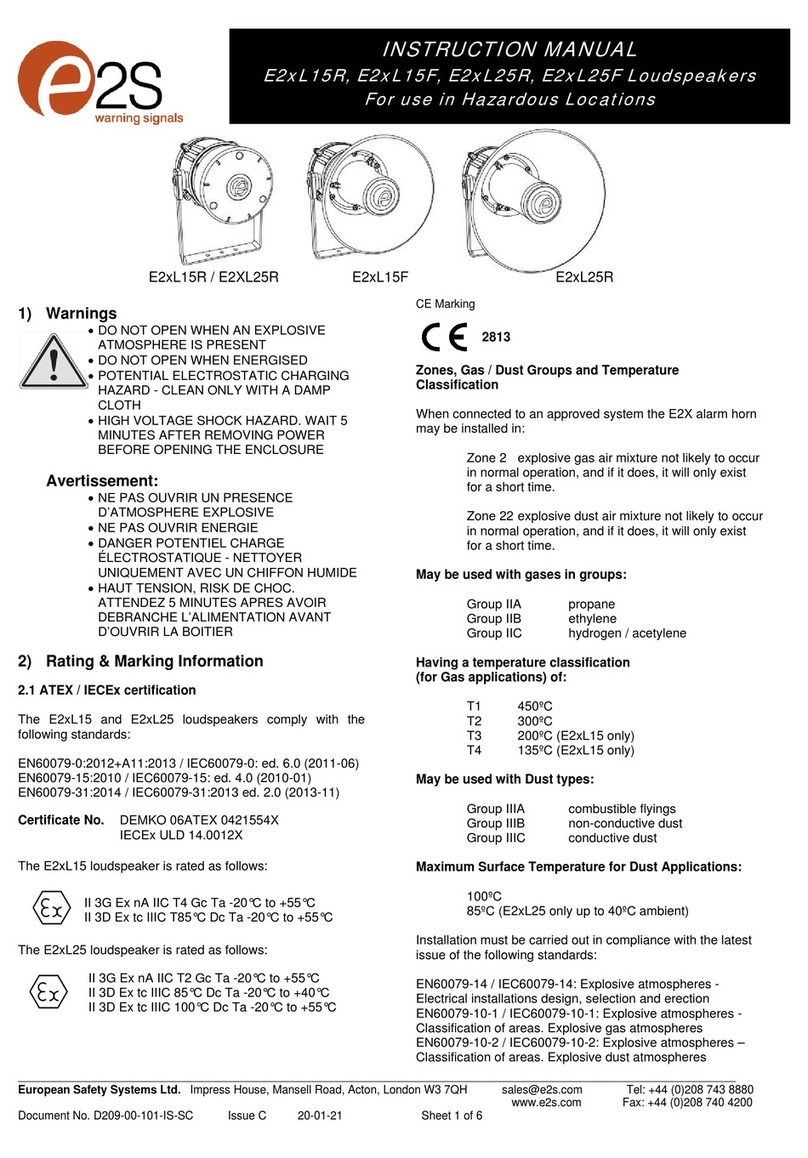

9.1 L15 PCBA Terminals

Fig. 4 L15 Line in Terminals

1W 3W 7.5W 15W C

(Appropriate cable entry devices

Cover

M4 Cover

Screw

M4 Spring

Washer

M4 Plain

Washer