__________________________________________________________________________________________________________________________________

European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH [email protected] Tel: +44 (0)208 743 8880 www.e2s.com Fax: +44 (0)208 740 4200

Document No. D157-00-201 Issue 3 25-06-20 Sheet 1 of 4 (1)

INSTRUCTION MANUAL (ATEX

GNExL2 and GNExL1 Flameproof Loudspeakers

1) Introduction

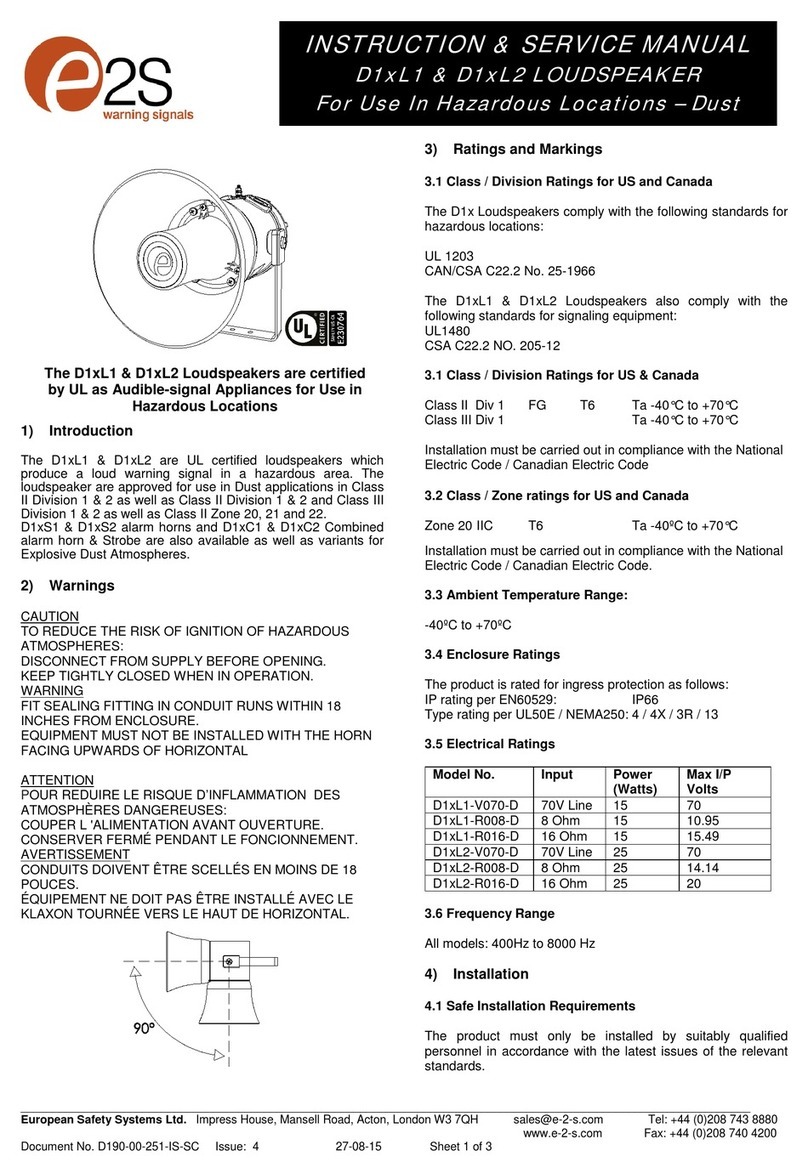

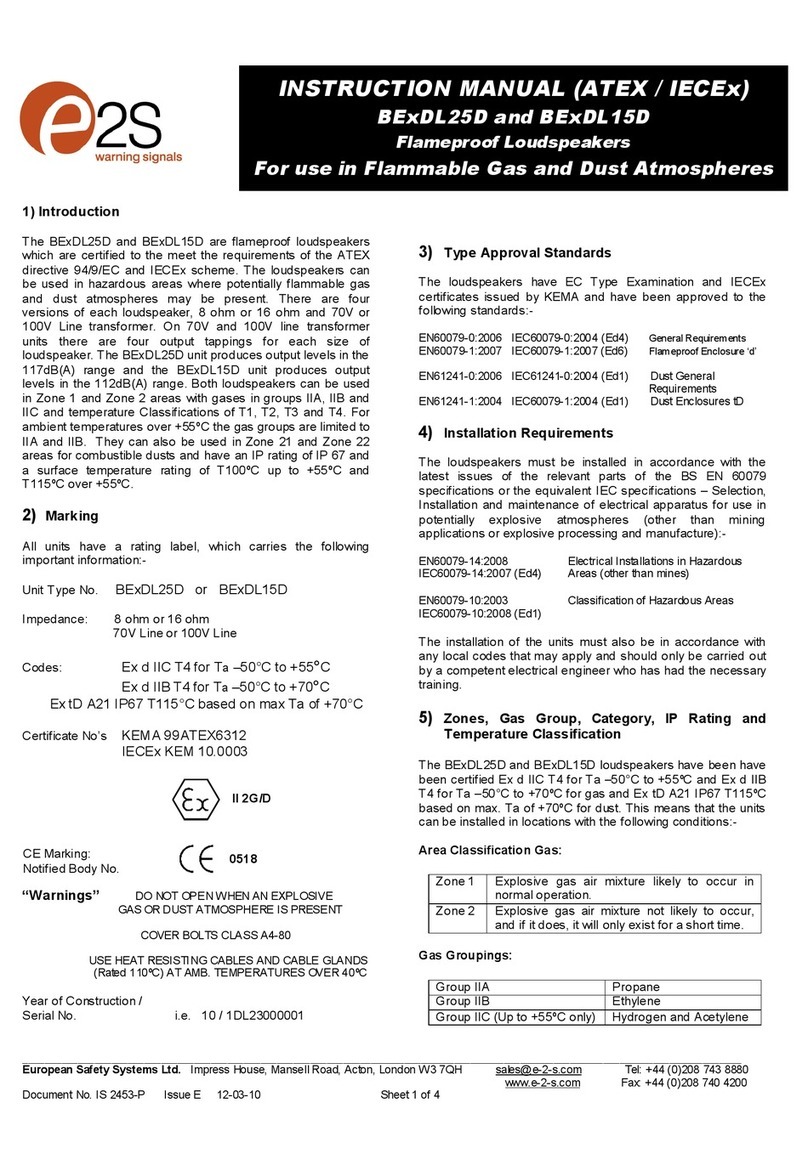

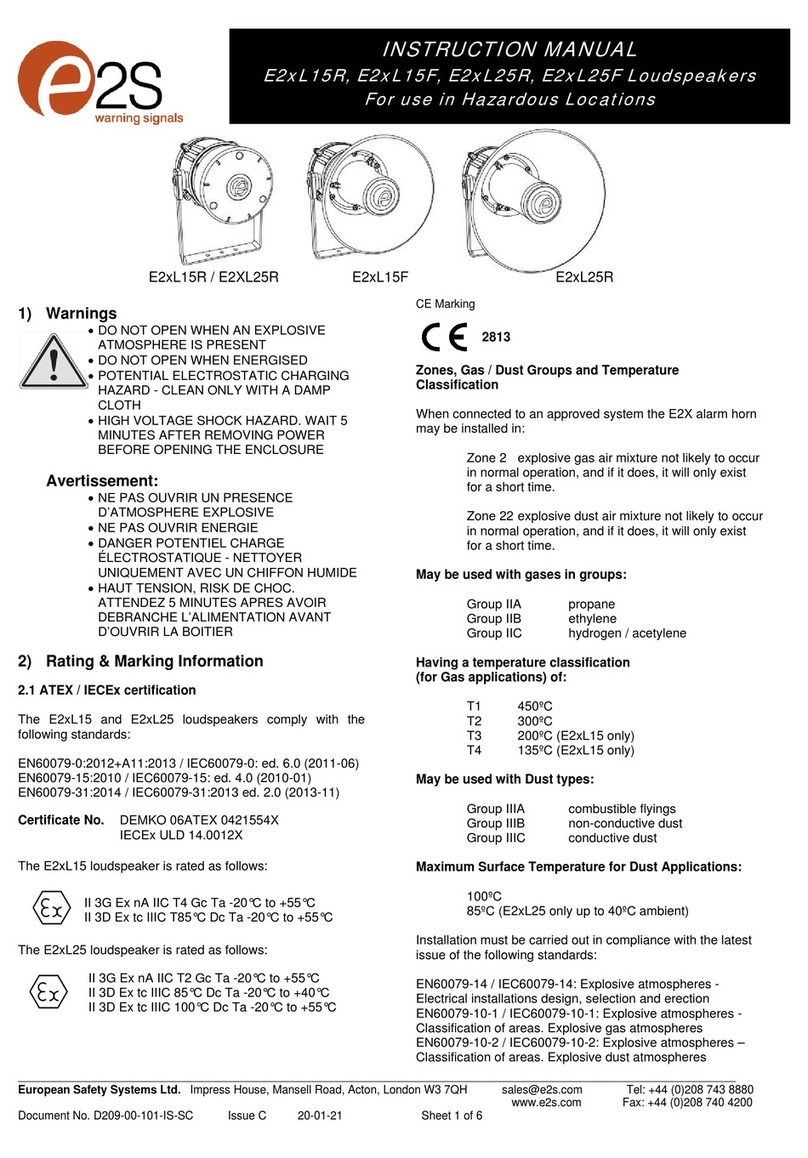

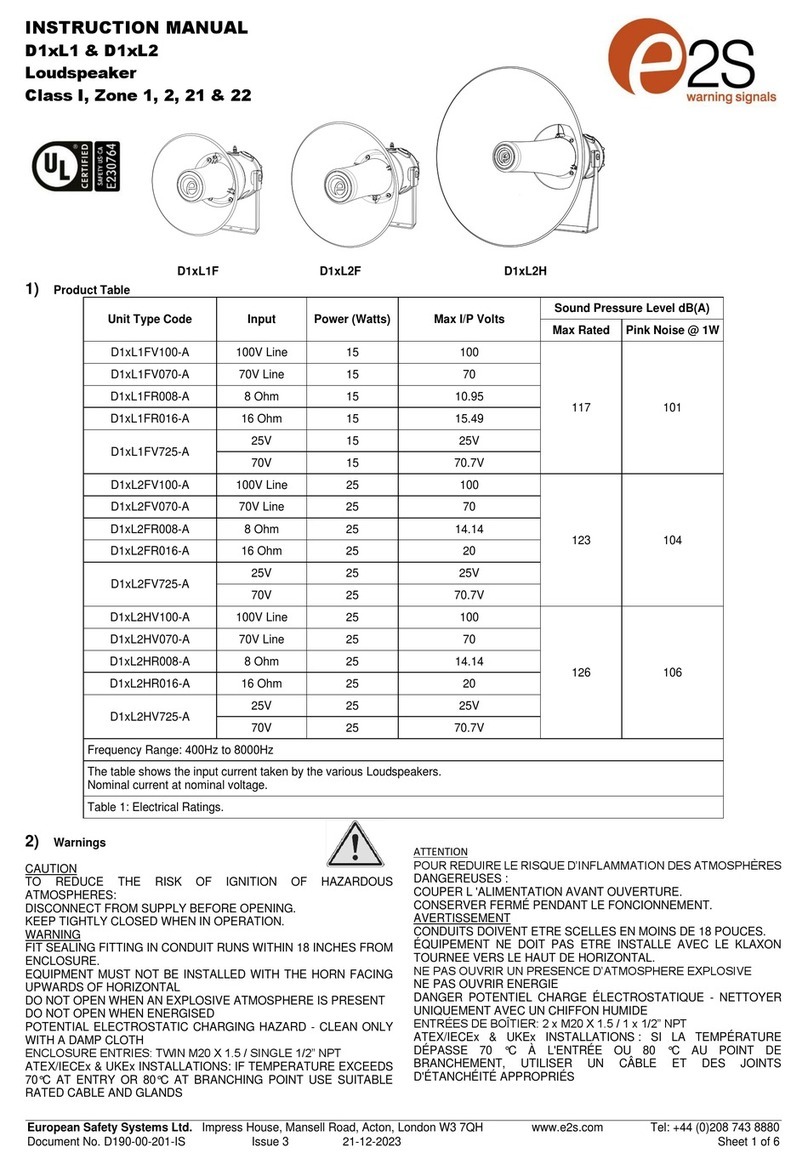

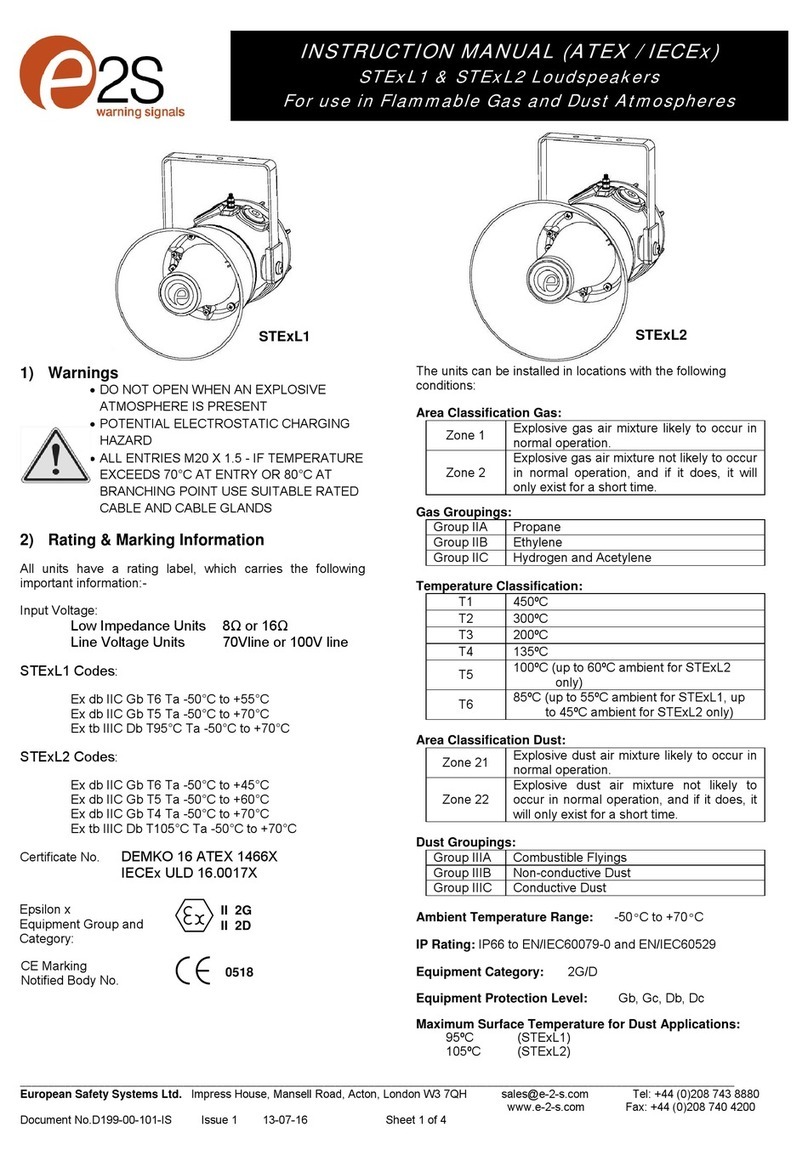

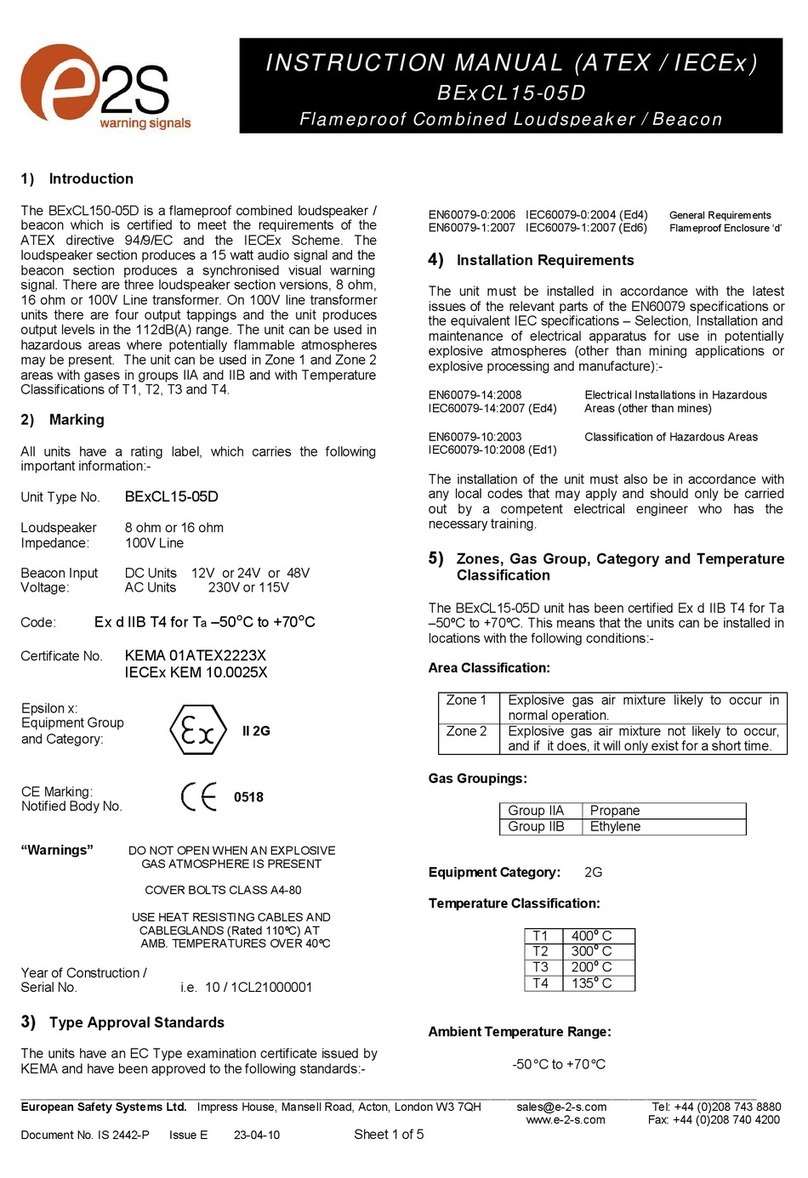

The GNExL2 and GNExL1 are second generation flameproof

loudspeakers which are certified to meet the requirements of

the ATEX directive 94/9/EC and the IECEx scheme. The

loudspeakers can be used in hazardous areas where

potentially flammable atmospheres may be present. There are

four versions of each loudspeaker, 8 ohm or 16 ohm and

70V/100V Line transformer. On 70V/100V line transformer

units there are four output tappings for each size of

loudspeaker. The GNExL2 unit produces output levels in the

117dB(A) range and the GNExL1 unit produces output levels

in the 112dB(A) range.

The loudspeakers are Group II, EPL (equipment protection

level) Gb. Dependant on unit type and ambient temperature

the equipment is certified ‘Ex db IIC Gb’ and as such may be

used in Zones 1 and 2 with flammable gases and vapours with

apparatus groups IIA, IIB & IIC and temperature Classifications

of T1, T2, T3 and T4 dependant on ambient temperature, see

marking codes in section 2.

The equipment is also certified ‘Ex db IIB Gb’ and as such may

be used in Zones 1 and 2 with flammable gases and vapours

with apparatus groups IIA & IIB and temperature

Classifications of T1, T2, T3, T4, T5 and T6 dependant on

ambient temperature, see marking codes in section 2.

2) Marking

All units have a rating label, which carries the following

important information:-

Unit Type No. GNExL2 or GNExL1

Impedance: 8 ohm or 16 ohm

70V Line or 100V Line

Codes: GNExL1

Ex db IIC T4 Gb for Ta –60°C to +50°C

Ex db IIC T3 Gb for Ta –60°C to +70°C

Ex db IIB T6 Gb for Ta –60°C to +50°C

Ex db IIB T5 Gb for Ta –60°C to +65°C

Ex db IIB T4 Gb for Ta –60°C to +70°C

Codes: GNExL2

Ex db IIC T4 Gb for Ta –60°C to +50°C

Ex db IIC T3 Gb for Ta –60°C to +65°C

Ex db IIB T6 Gb for Ta –60°C to +50°C

Ex db IIB T5 Gb for Ta –60°C to +65°C

Certificate No. SIRA 13ATEX1139X

IECEx SIR 13.0029X

“Warnings”

DO NOT OPEN WHEN ENERGISED

DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE MAY BE

PRESENT

ELECTROSTATIC HAZARD - CLEAN ONLY WITH A DAMP CLOTH

IF TEMPERATURE EXCEEDS 70ºC AT ENTRY OR 80ºC AT

BRANCHING POINT USE SUITABLY RATED CABLE AND CABLE

GLANDS

Year of Construction /

Serial No. i.e. 20 / 1GL25000001

3) Type Approval Standards

The loudspeakers have an EC Type examination certificate

issued by SIRA and have been approved to the following

standards:-

EN60079-0:2018 EN IEC60079-0:2018 General Requirements

EN60079-1:2014 A/C:2018 EN 60079-1:2014 ed. 7

Flameproof Enclosure ‘d’

4) Special Conditions for Safe Use

4.1) Installation

The sounders must be installed in accordance with the latest

issues of the relevant parts of the EN 60079 and IEC60079

standards – Selection, Installation and maintenance of

electrical apparatus for use in potentially explosive

atmospheres (other than mining applications or explosive

processing and manufacture):-

EN60079-14:2008 Electrical Installations in Hazardous

IEC60079-14:2007 (Ed4) Areas (other than mines)

EN60079-10-1:2009 Classification of Areas, Gas

Atmosphere

IEC60079-10:2008 (Ed1)

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried out

by a competent electrical engineer who has the necessary

training.

4.2) Specific Conditions

Flameproof joints shall not be repaired or modified in any way

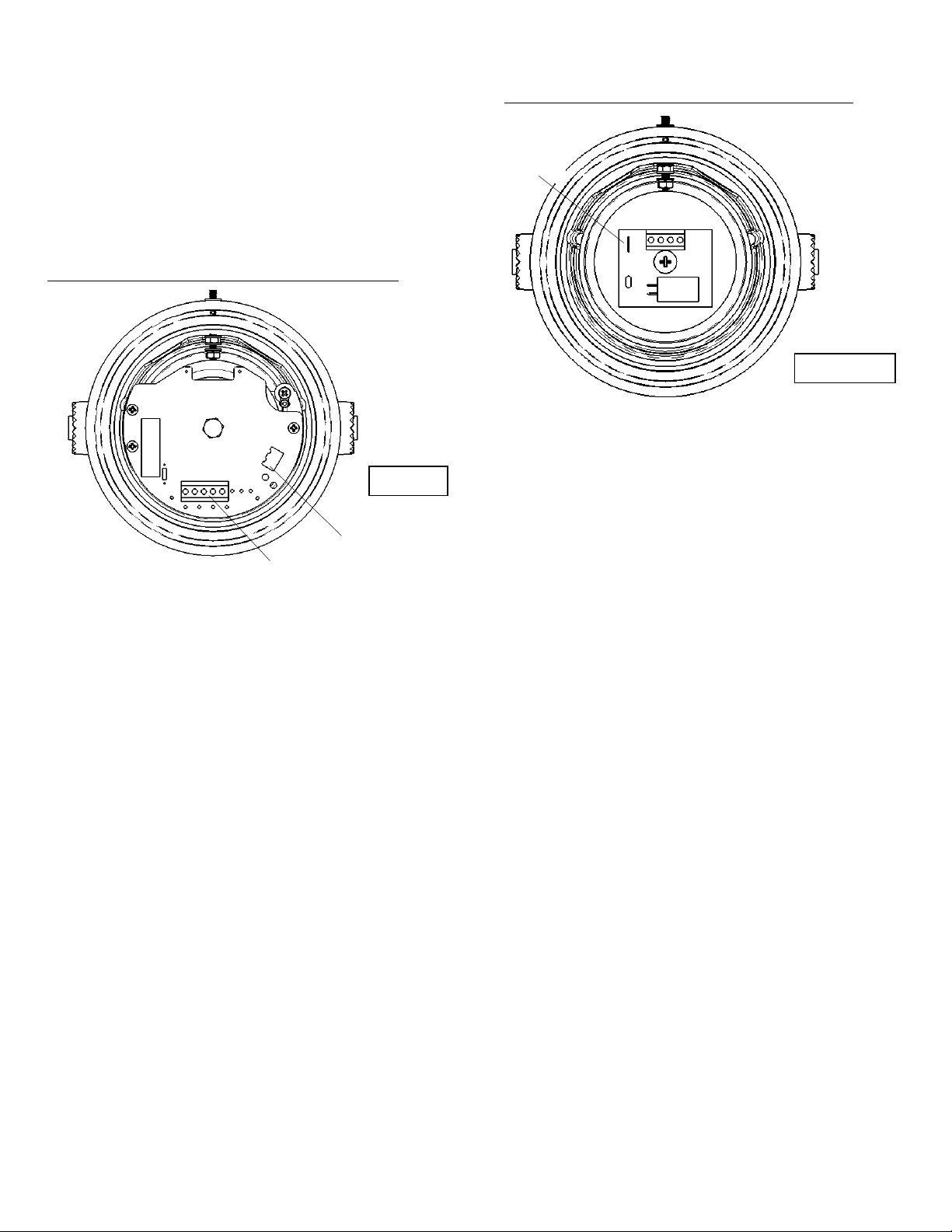

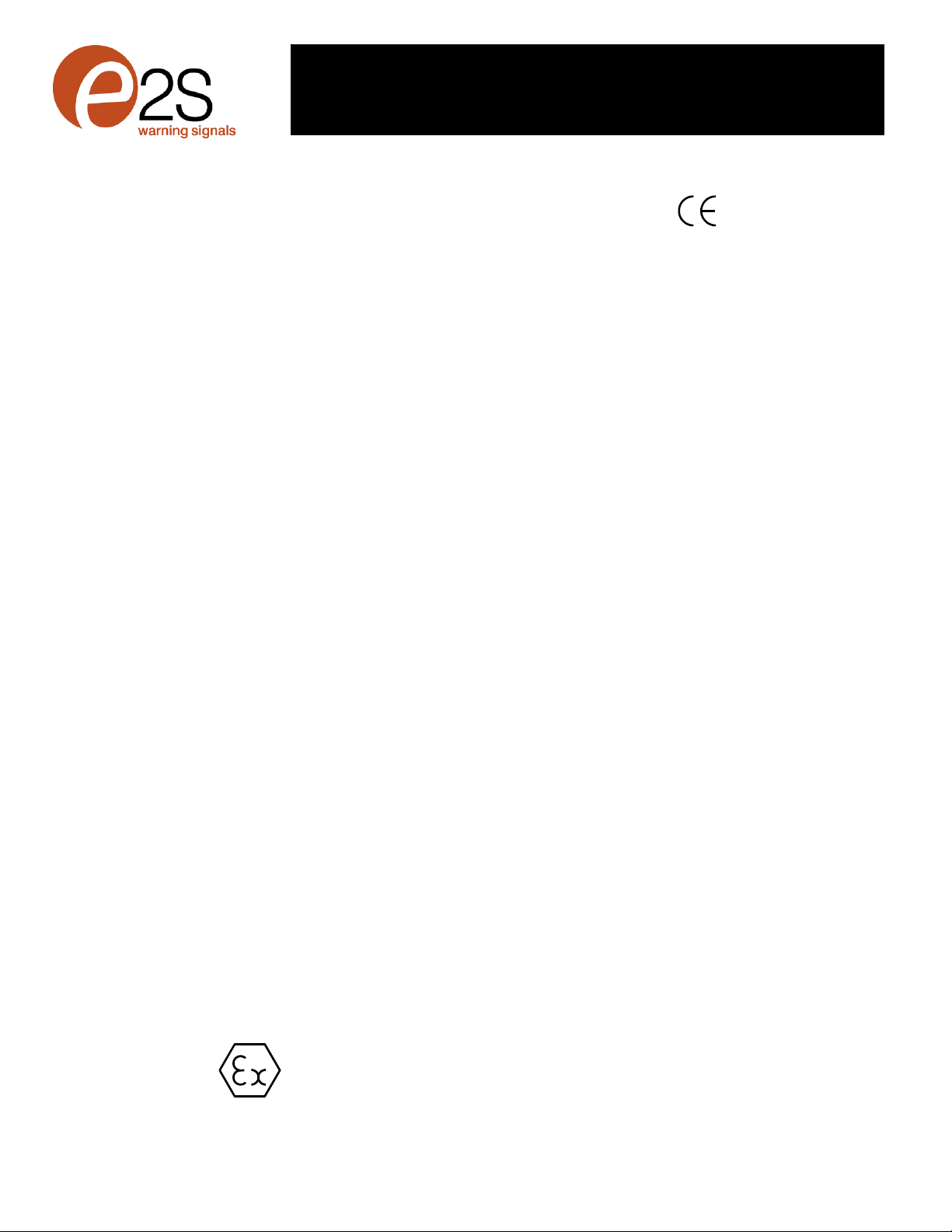

(See figures 1 & 2 for location of flameproof joints).

The enclosure is non-conducting and under certain extreme

conditions may generate an ignition capable level of

2813

II 2G

Epsilon x:

Equipment Group

and Category:

CE Marking:

Notified Body No.