Electrical Requirements

IMPORTANT

Basic Requirements

In addition, all electrical services, including earth ground, must comply

with local and national electrical codes.

• 30 A, single-phase, 208/220, 3-wire, earth ground

required.

• Main Power Disconnect (wall-mounted, not furnished)

The main power disconnect switch must consist of a minimum 2-pole thermo-magnetic

circuit breaker with solid neutral and common trip, or a fused disconnect switch. This

switch must be:

• located on a wall adjacent to the processor in the lighted area

• easily accessible from the processor site

• visible from the processor site.

IMPORTANT

Standard Service

Options In addition, all electrical services, including earth ground, must comply

with local and national electrical codes.

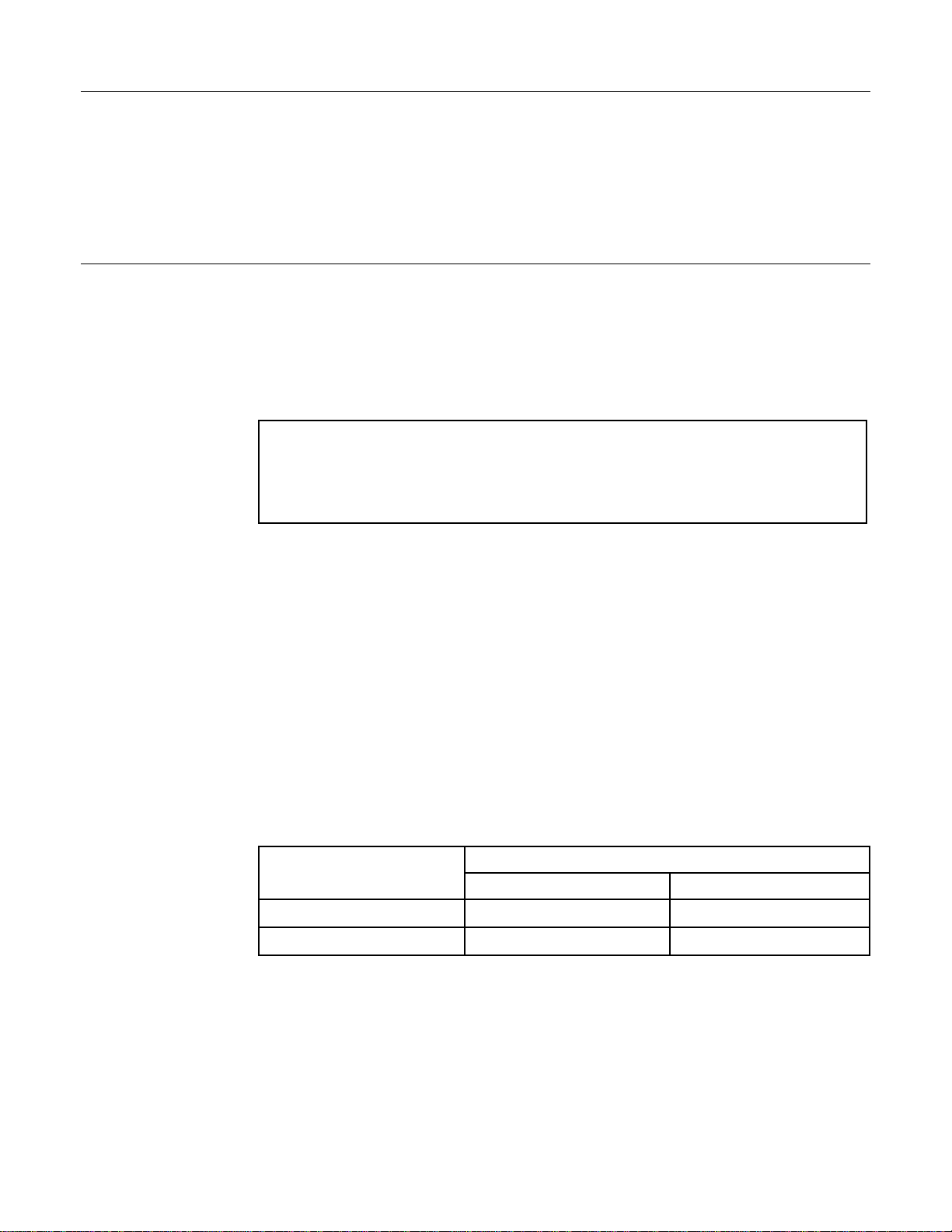

Table 3 Service Options

Voltage Frequency Service

Volts Hz

100/200 50/60 Single-phase, 3-wire

120/208 60 Three-phase*, 3-wire, Wye

120/240 60 Single-phase, 3-wire

127/220 50 Three-phase*, 3-wire, Wye

220/380 50 Three-phase*, 3-wire, Wye

240/415 50 Three-phase*, 3-wire, Wye

220 50/60 Single-phase, 2-wire

240 50/60 Single-phase, 2-wire

*L1, L2, and Neutral used in this configuration are sometimes referred to

as Single-Phase connections.

1C7070 7