5B6331 – 01JUN99 3

Removing the BEARING from the DRIVE SHAFT on the Feed End . . . . . . . . . . . . . 30

Removing the BEARING from the DRIVE SHAFT on the DRYER . . . . . . . . . . . . . . 31

DRYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removing the BLOWER B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removing the DRYER OVER-TEMPERATURE THERMOSTAT . . . . . . . . . . . . . . . 34

Removing the DRYER THERMISTOR RT3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Removing the DRYER HEATER HR3 or THERMAL CUTOFF . . . . . . . . . . . . . . . . . 36

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Developer Recirculation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removing the RECIRCULATION PUMP B5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removing the IMPELLER HOUSING or the IMPELLER . . . . . . . . . . . . . . . . . . 39

Removing the DEVELOPER HEATER HR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Removing the DEVELOPER FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Removing the DEVELOPER THERMISTOR RT1 . . . . . . . . . . . . . . . . . . . . . . . 43

Removing the DEVELOPER COOLING SOLENOID L2 . . . . . . . . . . . . . . . . . . 44

Removing the HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fixer Recirculation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removing the FIXER HEATER HR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removing the FIXER THERMISTOR RT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

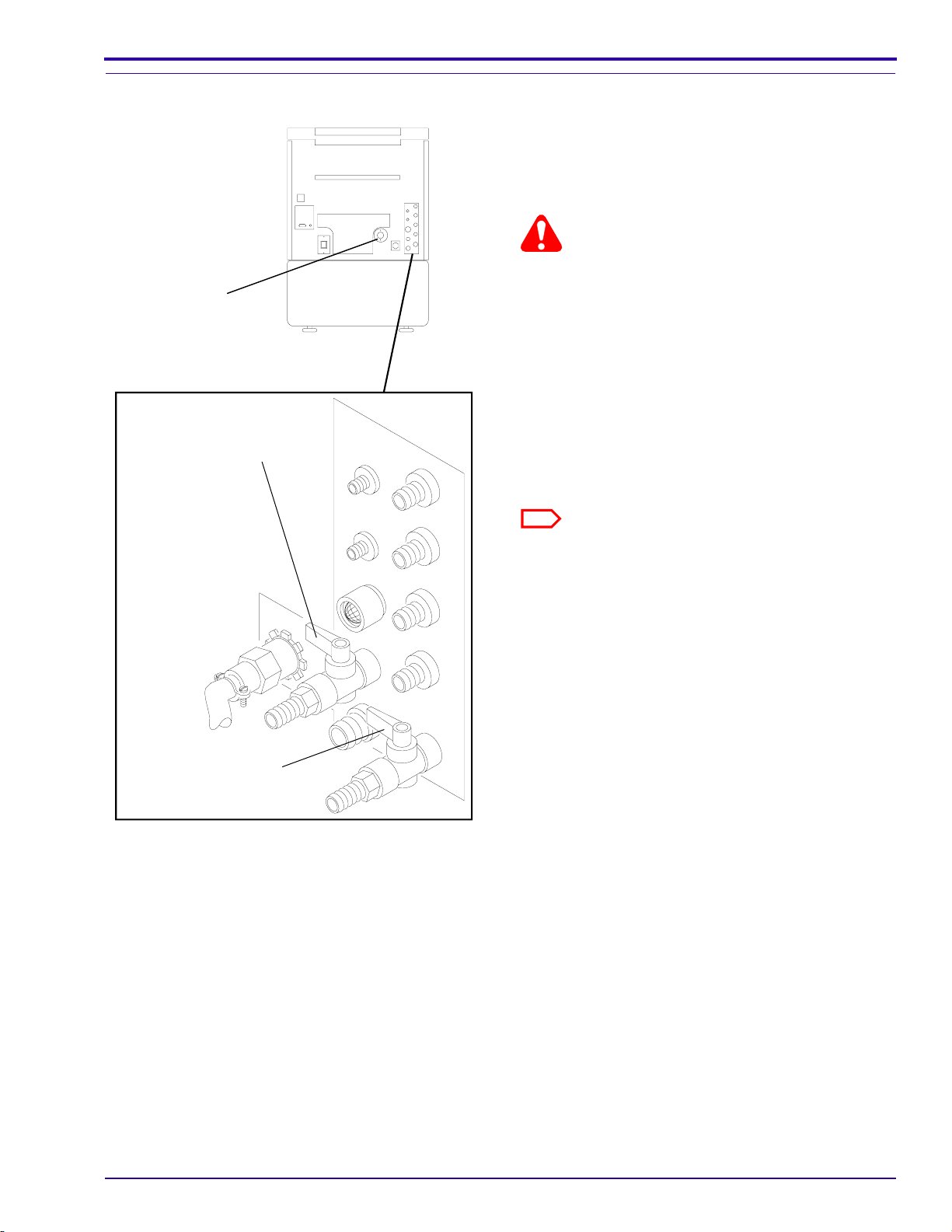

Wash System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing the WASH WATER SOLENOID L1 . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replenishment System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Removing the REPLENISHMENT STRAINERS and SCREENS . . . . . . . . . . . 51

Removing the DEVELOPER or FIXER REPLENISHMENT PUMP, B3 or B4 . . 52

Removing the POPPET VALVES for the REPLENISHMENT PUMPS . . . . . . . 53

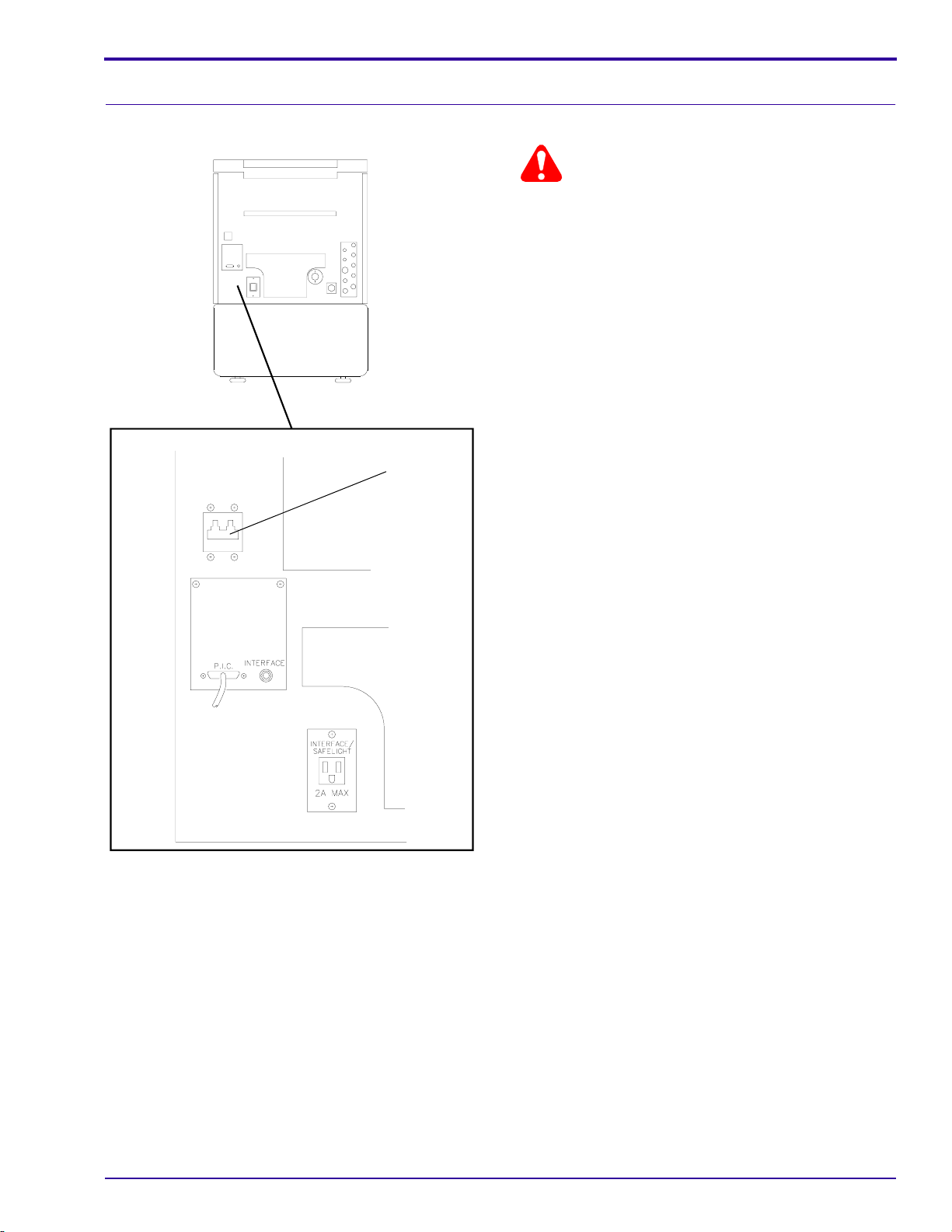

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removing the AUTOTRANSFORMER T1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removing the EMI LINE FILTER FL1 or FL2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removing the SAFELIGHT RECEPTACLE J35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Removing the AC CIRCUIT BREAKER CB1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Removing the QUAD POWER SUPPLY A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing the 5 V DC POWER SUPPLY - for Serial No. 100500 and above . . . . . . 60

Removing the 5 V DC POWER SUPPLY - for Serial Nos. below 100500 . . . . . . . . . 61

Adjusting the 5 V DC POWER SUPPLY Voltage - Serial No. below 100500. . . . . . . 62

Removing a SOLID STATE RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing the LEVEL SENSOR HOUSING and LEVEL SENSOR PROBES . . . . . . 64

Removing the 600 BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Adjusting the LAMP Intensity on the 2000 BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Removing the 2000 BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Removing the 3000 BOARD, LCD DISPLAY, and DISPLAY PANEL . . . . . . . . . . . . 68

Enabling and Disabling the Automatic Dimming Feature on the

DISPLAY PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Adjusting the Sensitivity of the DISPLAY PANEL LIGHT SENSOR. . . . . . . . . . . . . . 70

Removing the 5000 BOARD-Microprocessor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Bypassing or Resetting the Access Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Access Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Service Bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

User Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Downloading the Operating Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Removing the 6000 BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Maximizing the Accuracy of the Film Logging Feature. . . . . . . . . . . . . . . . . . . . . . . . 77

Removing the 7000 BOARD and MOTOR CONTROLLER BOARD . . . . . . . . . . . . . 78

Removing the 8000 BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

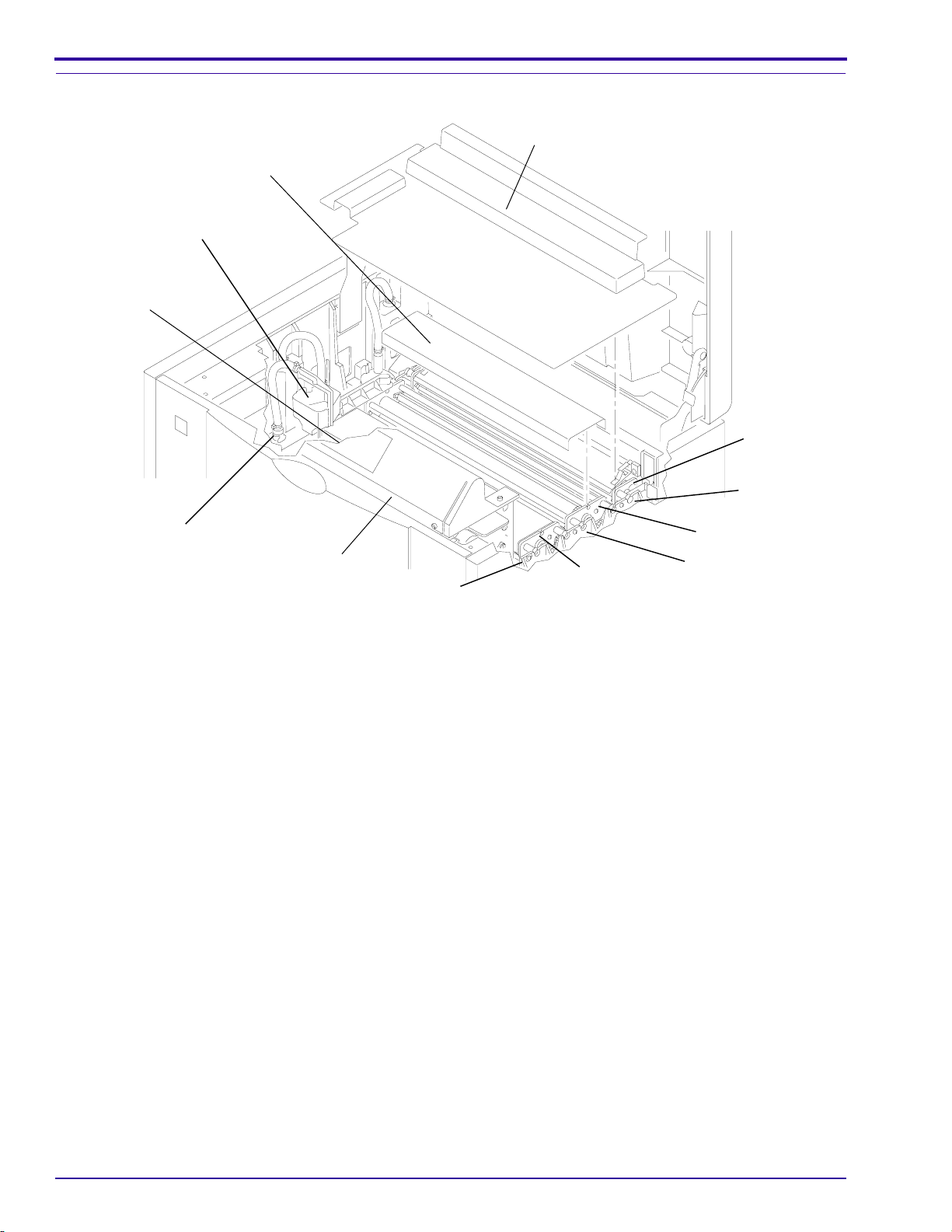

Adjusting the ACTUATORS and FILM DETECTOR SWITCHES . . . . . . . . . . . . . . . 81

Adjusting the ACTUATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adjusting the DETECTOR SWITCHES from Side to Side . . . . . . . . . . . . . . . . . 82

Adjusting the DETECTOR SWITCH Up and Down . . . . . . . . . . . . . . . . . . . . . . 83

Checking the DETECTOR SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84