3

Safety Instructions

• Please ensure that the voltages of power supply you are using match with rated working

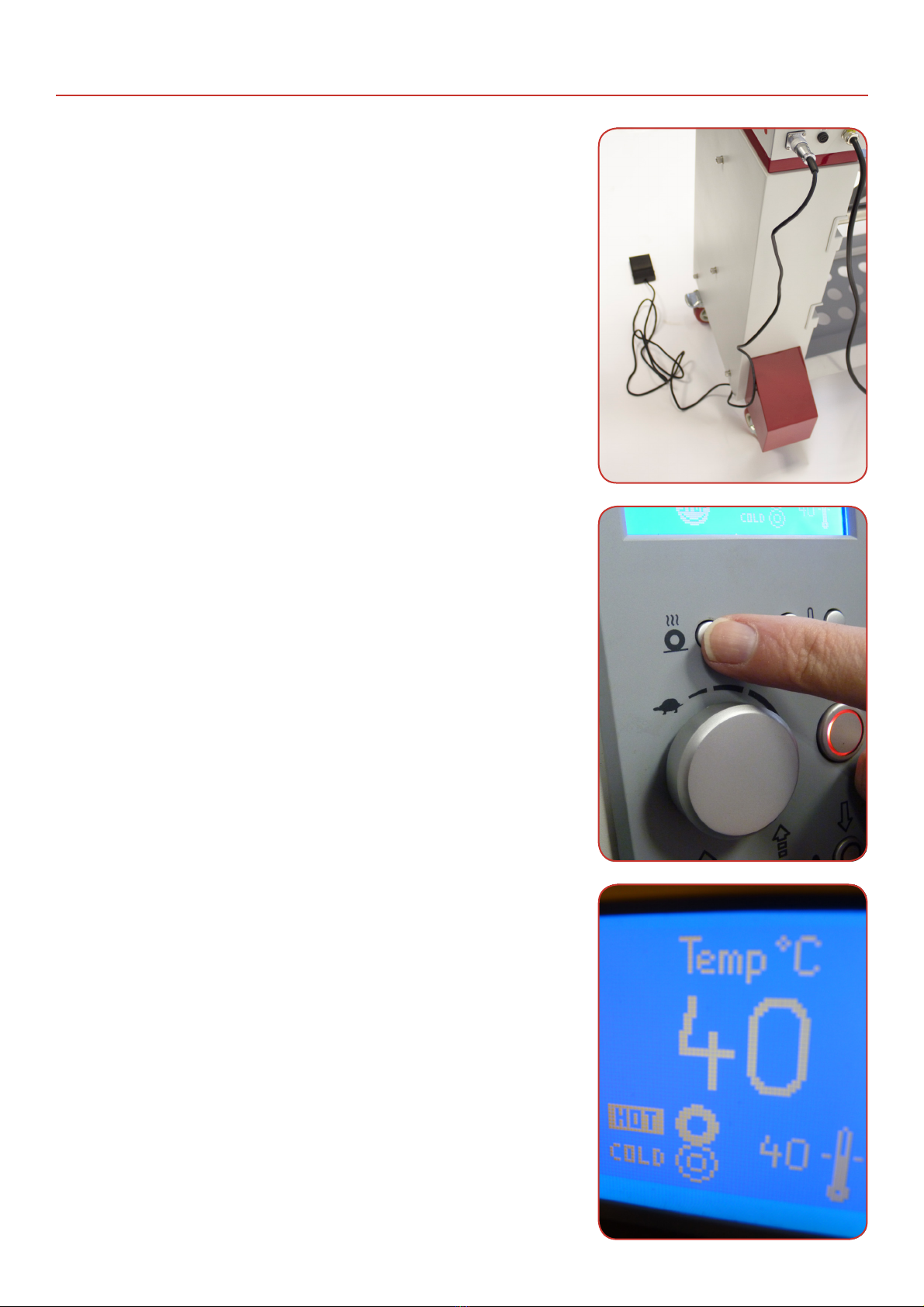

voltages before operating the machine

• The power supply should be close to the machine for convenient use

• The power supply should provide reliable protective earthing connection

• This machine must be earthed reliably as to ensure the safety of the machine during

operation

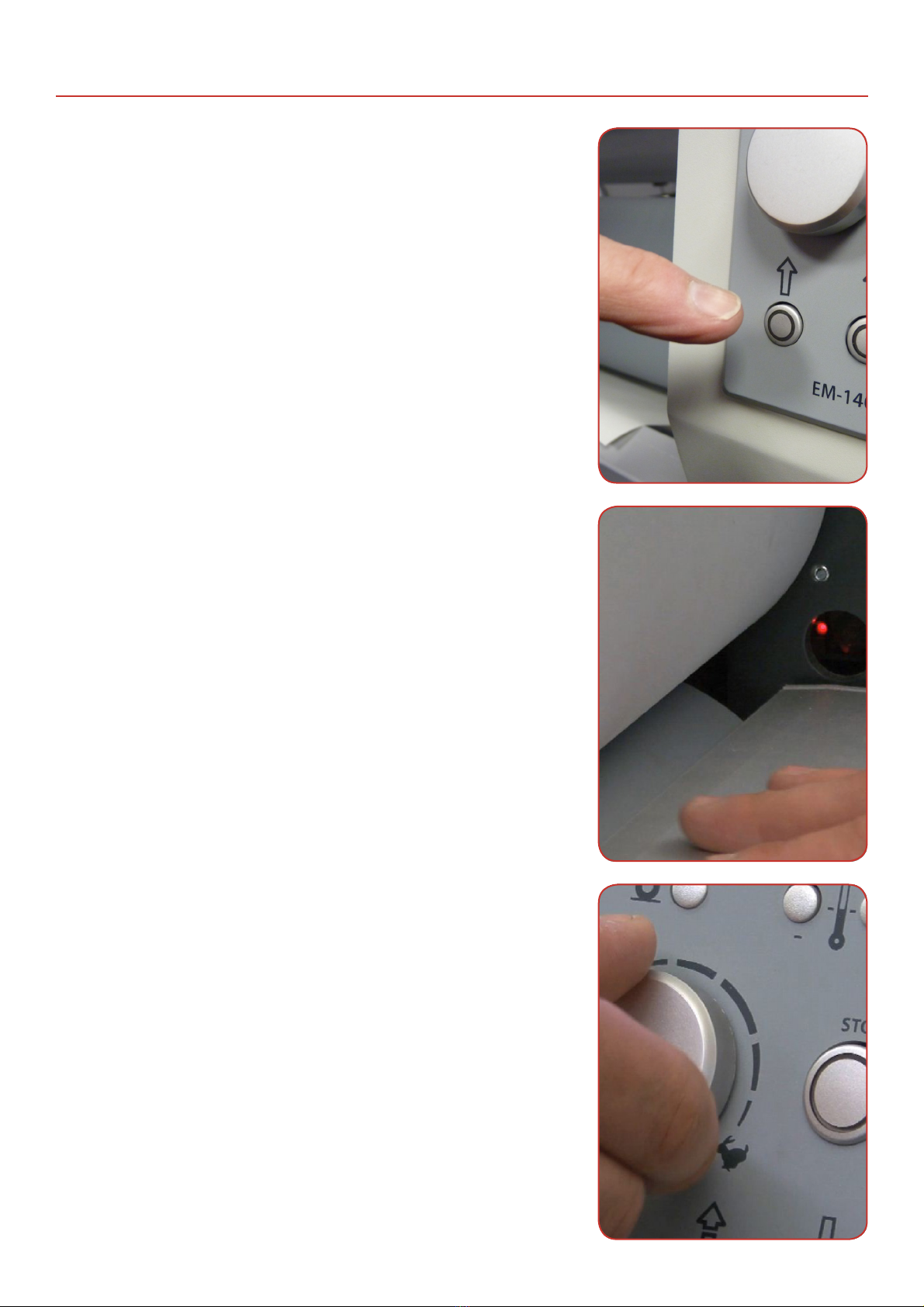

• Only the operators of this machine should operate the electric or motion

components/controls

• Please don’t use damaged wires or sockets

• Please keep children away from touching and operating this machine

• Please do not spray water or other liquid on the machine otherwise electric shock or

machine faults could occur

• Please do not replace power cord or plugs yourself, do not put heavy objects on the

power lines as this may cause electric shocks

• During use please take care that no clothes, neckties, hair, necklaces etc are near the

machine otherwise injuries could occur

• Please don’t put burrs, sharp blades or over thick rigid materials into the two rubber

covered rollers (for example, tools, rulers and knives etc.)

• Don’t cut adhesive films directly on the surfaces of the rubber covered rollers to avoid

damage

• Please shut down this machine after laminating to avoid misuse of the machine

• At the end of the working day always gape the rollers to ensure no flat spots or

distortions occur

• When you need to move this machine, please shut down the power switch and pull out

the plugs

• Please be aware of the location of the wheels during moving or operating this machine to

avoid foot injuries

• Always ensure the machine is positioned on a flat and level floor

• Please shut off the power supply (pull out the power plug) when the machine isn’t going

to be used for long periods of time.

Environmental Requirements

• Ambient temperature 10°C - 40°C, humidity 30% - 80%, Ideal humidity 55%

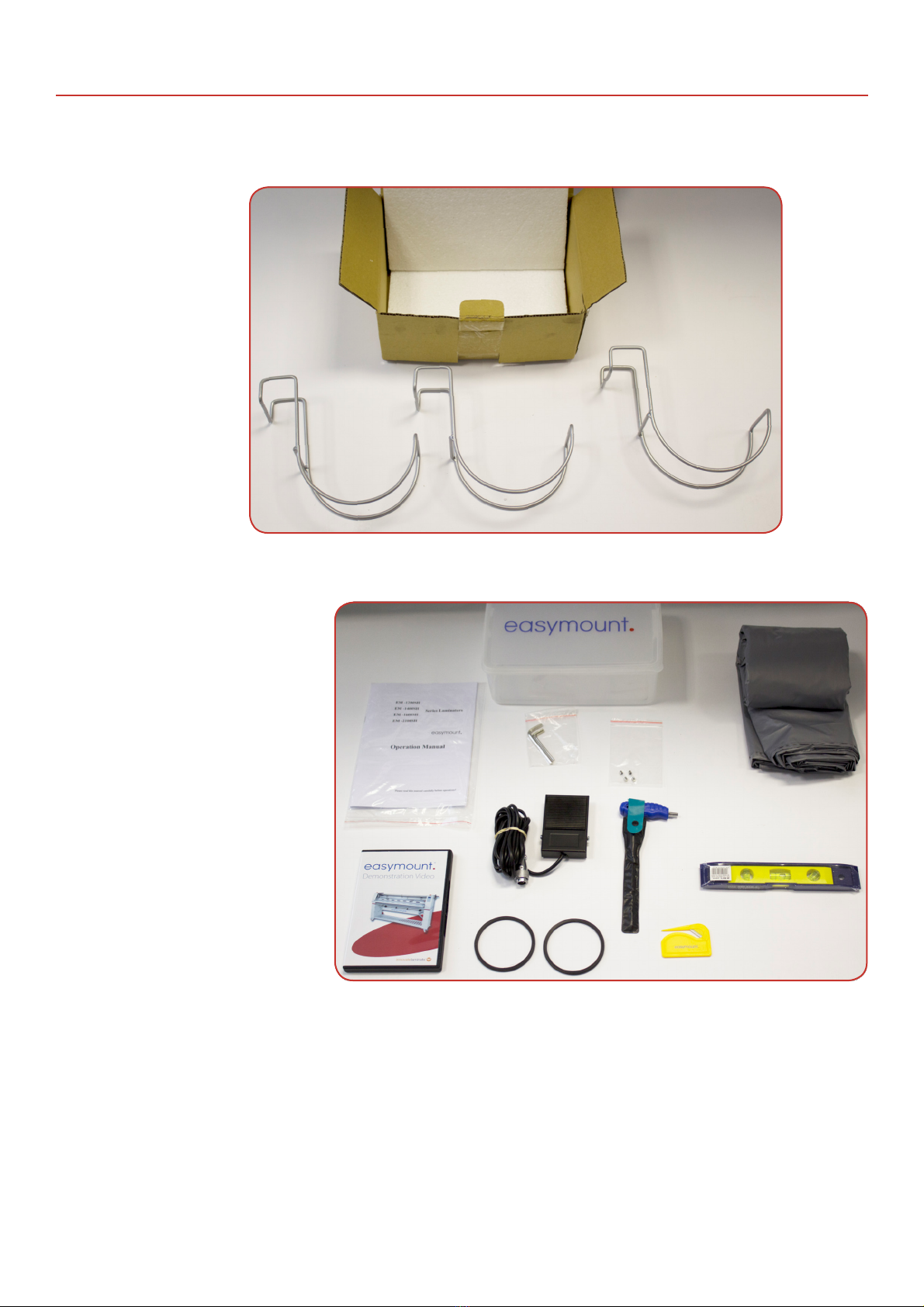

• Dust - Due to the static adherence of the film, you should keep the environment clean, a

dust cover is provided with the machine

• Please do not keep the machines in direct sunlight

• Please do not keep the machine in or around dusty areas

• Enough space should be kept around the machine to ensure the secure and effective

application. The minimum holding areas are 2.5m x 3m