QUICK START GUIDE

8|P a g e

clockwise then platform goes down, screw anti-clockwise then platform goes up),

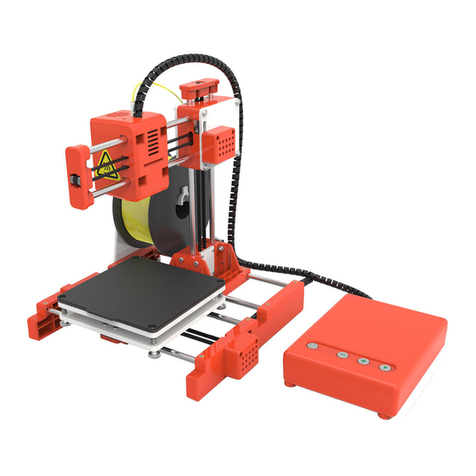

(4)Choose the following 4 points to check and adjustment.

(4.1) Adjust Point A, pull the extruder gently in X axis to point A(above), then observe the distance between platform and

nozzle, its the thickness of a piece of A4 paper, if the distance is too big, then needs to rotate (anti-clockwise) its below

screws to make platform up, if the distance is too small, then needs to rotate(clockwise) its below screws to make platform

down.

(4.2) Adjust Point B, After well adjust point A, then to pull the extruder gently in X axis to Pint B(above), then observe the

distance between platform and nozzle, its the thickness of a piece of A4 paper, if the distance is too big, then needs to

rotate (anti-clockwise) its below screws to make platform up, if the distance is too small, then needs to rotate(clockwise)

its below screws to make platform down.

(4.3) Adjust Point C, After well adjust point A, then to pull the extruder gently in Y axis to point C(Above). then observe the

distance between platform and nozzle, its the thickness of a piece of A4 paper, if the distance is too big, then needs to

rotate (anti-clockwise) its below screws to make platform up, if the distance is too small, then needs to rotate(clockwise)

its below screws to make platform down.

(4.4) Adjust Point D, After well adjust point D, then to pull the extruder gently in Y axis to point C(Above). then observe

the distance between platform and nozzle, its the thickness of a piece of A4 paper, if the distance is too big, then needs to

rotate (anti-clockwise) its below screws to make platform up, if the distance is too small, then needs to rotate(clockwise)

its below screws to make platform down.

(4.5) After 4 points all well adjust, then to pull the exturder in X and Y axis to observe if the distance between platform and

the nozzle is the same.

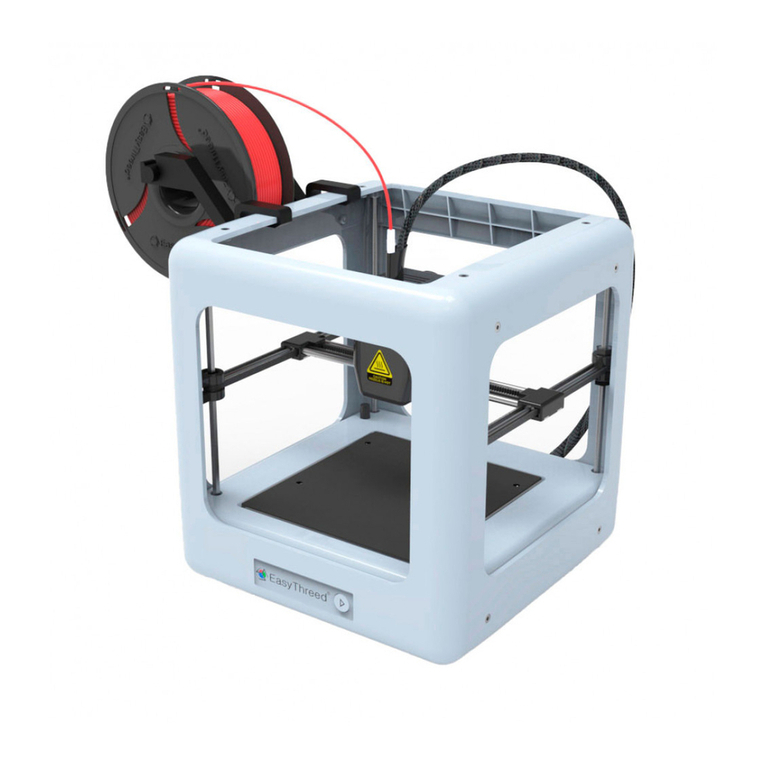

D13. How to assemble the filament holder?

(1) Takes the filament accessories out from the box to assemble the filament holder (as below,there are 2 side panels, 1

base, 2 M3 screws, 2 nuts, 1 bridge