Eaton A201 Manual

Other Eaton Controllers manuals

Eaton

Eaton Cutler-Hammer Jockey User manual

Eaton

Eaton ELCM Series User manual

Eaton

Eaton EMS-SWD Series User manual

Eaton

Eaton ELC2 Series User manual

Eaton

Eaton CGLine+ Operating and maintenance instructions

Eaton

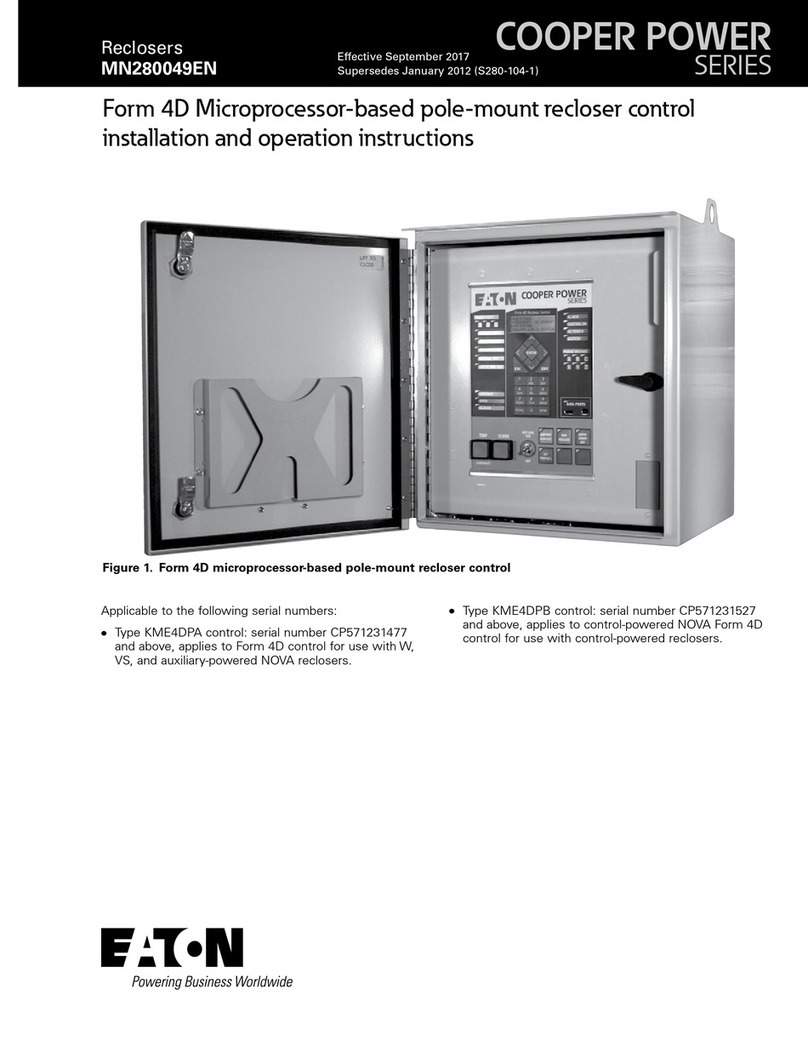

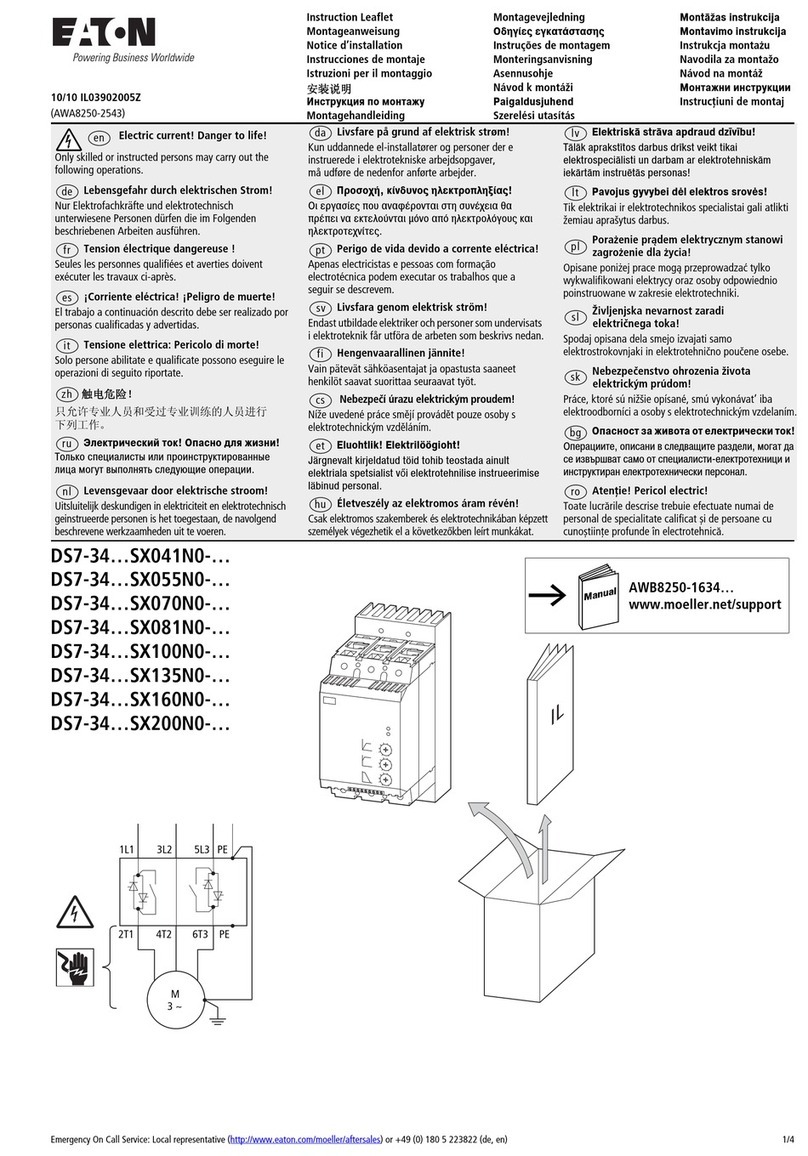

Eaton DS7-34 SX041N0 Series Manual

Eaton

Eaton A200 Manual

Eaton

Eaton AMPGARD Manual

Eaton

Eaton ELC-PB Owner's manual

Eaton

Eaton A210 Manual

Eaton

Eaton Greengate RC3 User manual

Eaton

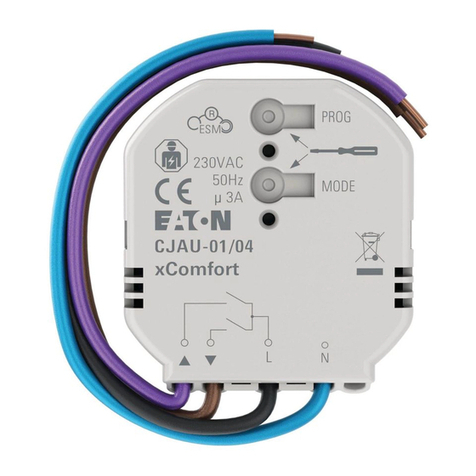

Eaton CDAE-01/04 User manual

Eaton

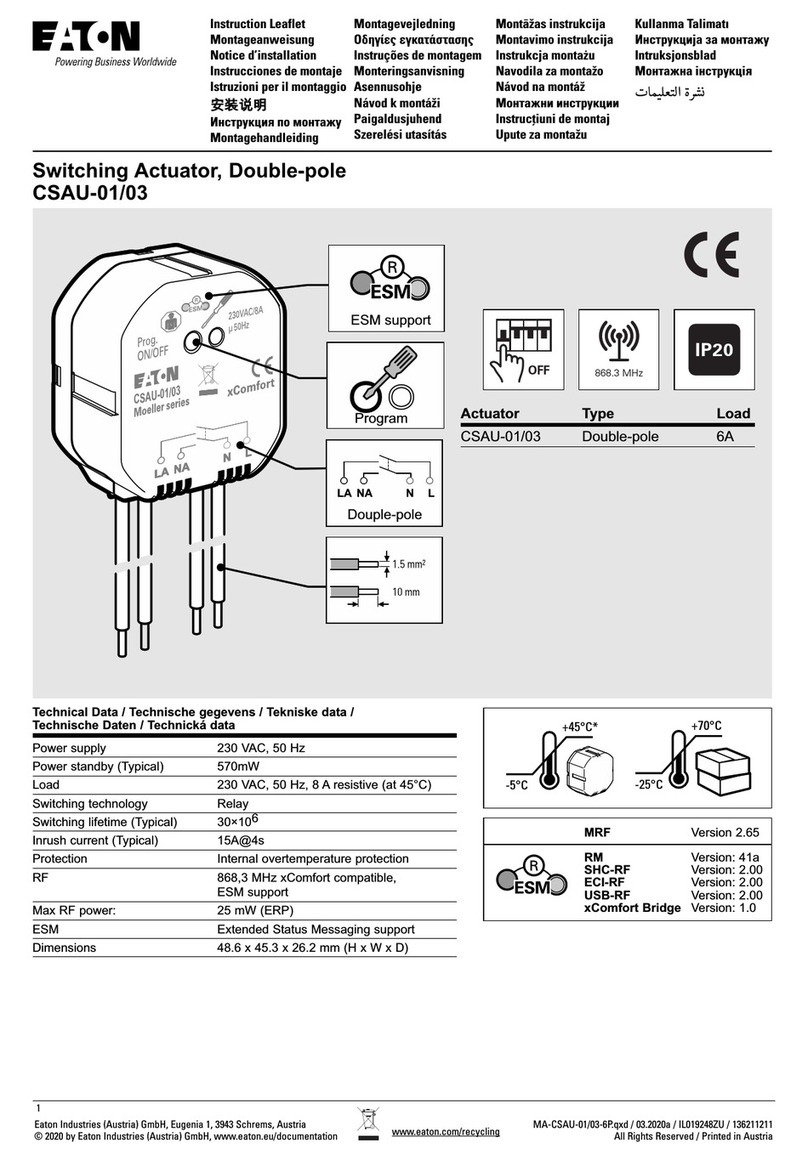

Eaton CSAU-01 Manual

Eaton

Eaton ELCM Series User manual

Eaton

Eaton Ampgard 400 User manual

Eaton

Eaton HFX Series User manual

Eaton

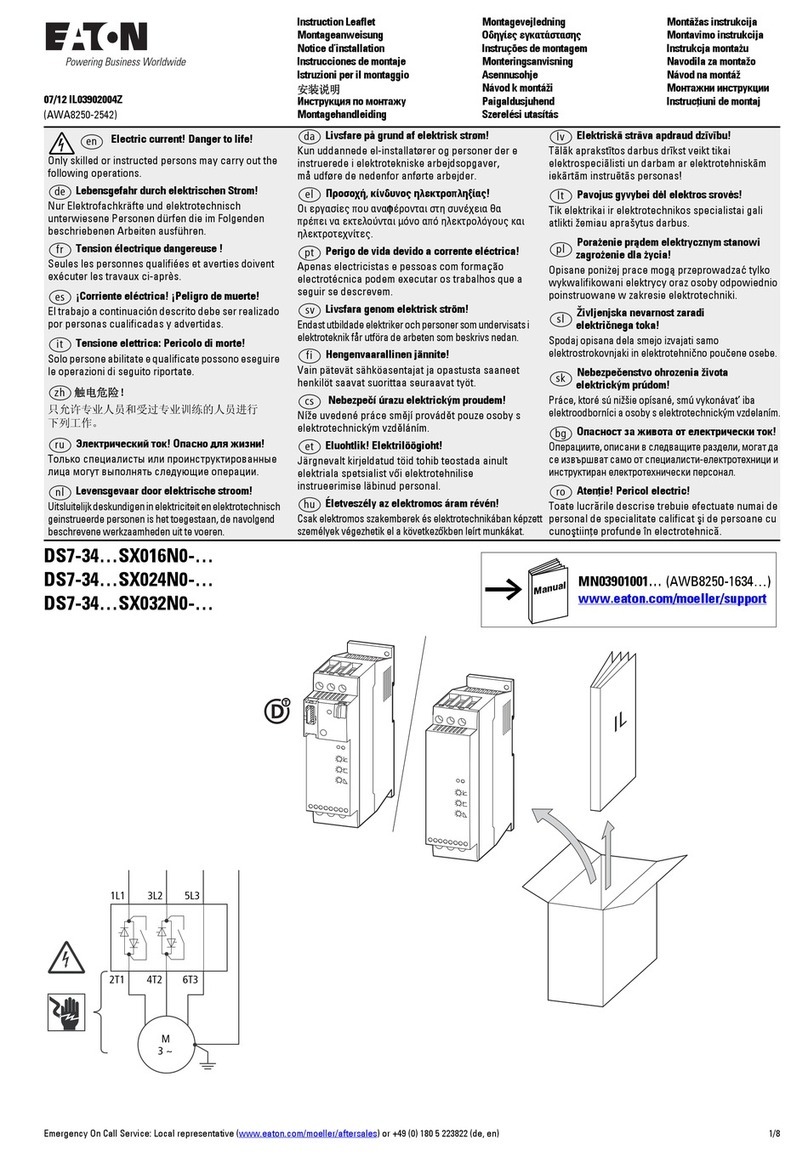

Eaton DS7-34 SX016N0 Series Manual

Eaton

Eaton ATC-900 User manual

Eaton

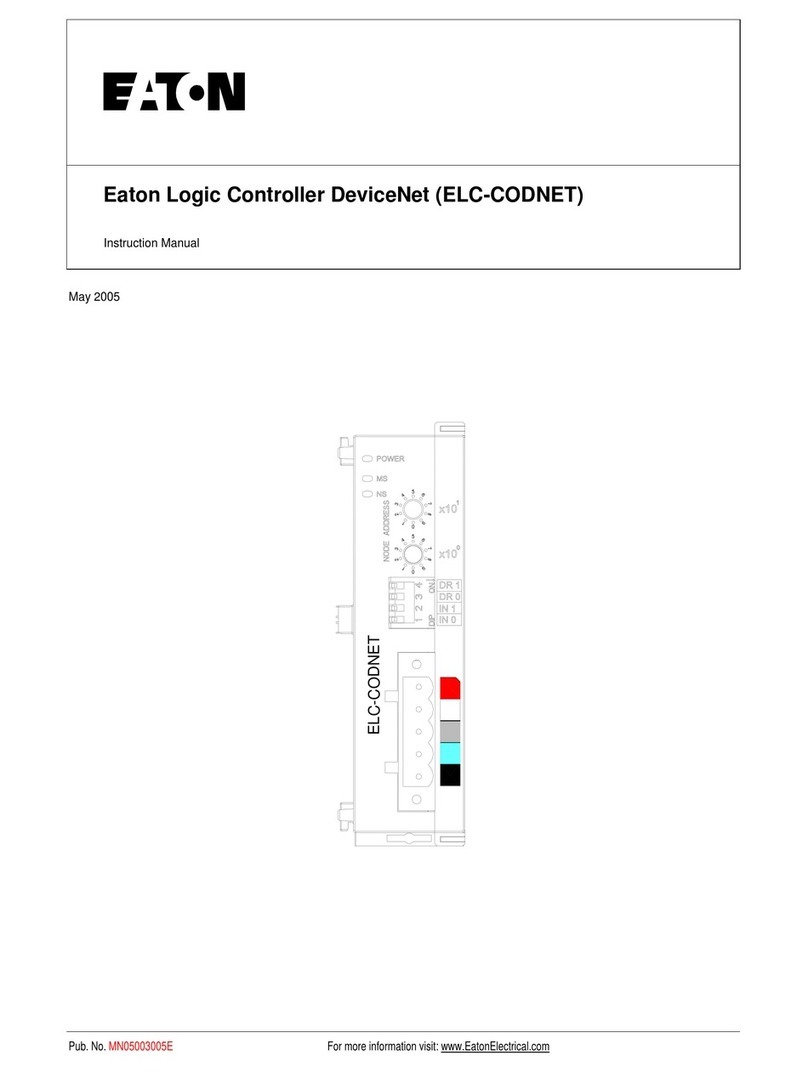

Eaton ELC-CODNET User manual

Eaton

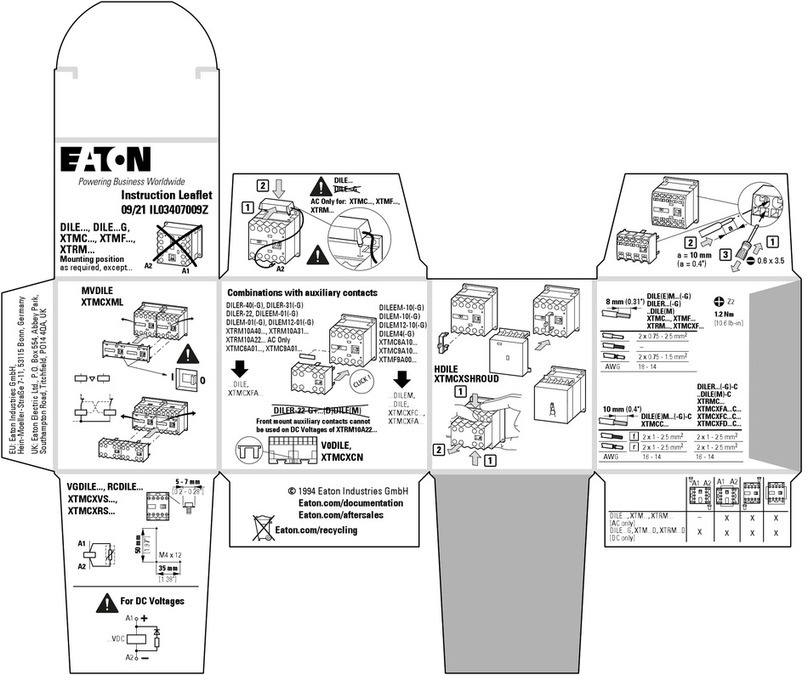

Eaton DILE Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions