3

Instructional Leaet IL03902001E

Effective February 2011

S811 quick installation guide

EATON CORPORATION www.eaton.com

FLA setting calculation

The FLA setting is a function of the product of the motor nameplate

full load amperes (FLA) and a multiplier from the service factor

multiplier (SF) in Table 2 below.

FLA setting = Motor FLA x SF multiplier

For example, an S811R13N3S with a 100A, 1.15 service factor motor

should have an FLA setting of 115 (100 x 1.15).

Please refer to sizing charts in product user manual, MN03902002E,

or call 877-ETN-CARE (386-2273) for assistance in sizing a soft

starter for specific applications.

Table 2. FLA Ranges

Frame

Size FLA Current

Range Catalog

Number

N (65 mm) 11–37 S811N37N3S

20–66 S811N66N3S

R (110 mm) 32–105 S811R10N3S

42–135 S811R13N3S

T (200 mm) 56–180 S811T18N3S, S811T18V3S

75–240 S811T24N3S, S811T24V3S

95–304 S811T30N3S, S811T30V3S

U (200 mm) 112–360 S811U36N3S

131–420 S811U42N3S

156–500 aS811U50N3S

V (290 mm) 112–360 S811V36N3S, S811V36V3S

131–420 S811N42N3S, S811V42V3S

156–500 S811N50N3S, S811V50V3S

203–650 S811N65N3S, S811V65V3S

225–720 S811N72N3S, S811V72V3S

265–850 S811N85N3S, S811V85V3S

310–1000 S811V10N3S

a 500A rating does not have IEC certification.

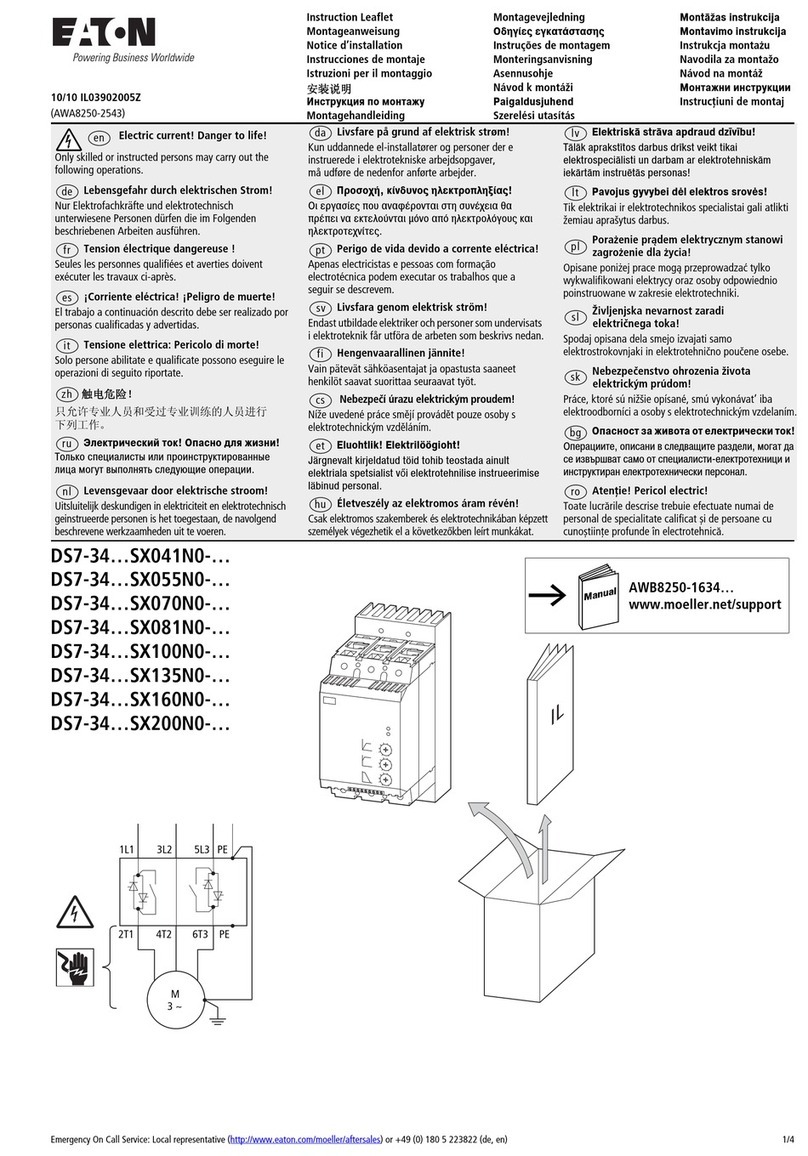

Wiring and control check list for operating

through the control terminal block

A jumper is installed between terminals P and 1 for two-wire

control (e.g., RUN/STOP toggle switch or PLC control)

24V power supply meets minimum requirements (55 watt

steady-state, 240 watt inrush for 180 ms, 30 Vdc maximum.)

Control power wire for the positive and negative terminals

is 14 AWG or larger

Control wire length less than 100 feet

24V is supplied to pin 3 on the control terminal block if controlling

through these terminals is desired

Power wiring check list

24 Vdc control voltage will be applied to terminal P

Phase sequence is correct (ABC); otherwise, soft starter will

trip on phase reversal

If output isolation contactor is used, it cannot open until the

soft starter stops to prevent a low current trip

After completing the above, apply line power, apply 24 Vdc control

voltage, and then initiate start signal to energize motor.

Check list—settings—special applications

You may improve performance if operating on generator power

by setting the kick start time to 2 seconds and kick start torque

to half the value of the initial torque setting. This creates a step

loading effect of the generator, allowing the governor to regulate

the power demand of starting larger motors.

Troubleshooting

For additional setting details, refer to the S811 User Manual

MN03902002E available at www.eaton.com/electrical.

For technical questions, please contact EatonCare at

877-ETN-CARE (386-2273).