SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IF 267

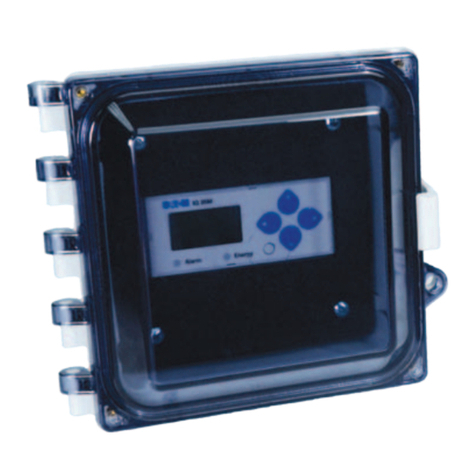

EPC series circuit breaker enclosure with

interlocked Arktite®receptacle

Installation & maintenance information

APPLICATION

EPC Series circuit breakers with interlocked Arktite receptacle are designed

for use as a service outlet to portable electric equipment with the circuit

breaker providing overcurrent and short circuit protection.

EPC Series circuit breakers are rated at 20, 30, 40, 50, 70, 90 and 100

amperes. The Arktite receptacles are rated at 30, 60 and 100 amperes,

and provided in 2-wire, 3-pole and 3-wire, 4-pole designs. The receptacles

provide attachment of the grounding wire to an extra grounding pole and

direct connection between plug and receptacle housings and grounding

pole. The polarized receptacle is compatible with APJ, NPJ and CPH Series

Style 2 plugs with the same style, current rating and number of poles. EPC

Series circuit breakers with interlocked Arktite receptacle are designed for

use in Class I, Groups C, D; Class II, Groups F, G; and Class Ill hazardous

(classified) areas as defined by the National Electrical Code® (NEC) as well

as in damp, wet, or corrosive locations.

CAUTION

To reduce the risk of ignition of hazardous atmospheres, do not use in

Class II, Group F locations that contain electrically conductive dusts.

!

The interlocked receptacle and mating plug cannot be made or broken

under load.

The circuit breaker cannot be closed until the plug is fully inserted into the

receptacle. When the plug is fully inserted and the circuit breaker closed,

the plug cannot be removed until the breaker is opened.

ENCLOSURE INSTALLATION

1. Install conduit sealing fittings into EPC enclosure hubs before fastening

unit to mounting location for installation of conduit and power supply

wires.

2. Select mounting location that will provide suitable strength and rigidity

for supporting the unit and all contained wiring. Be sure to provide

adequate space for insertion and removal of the plug.

3. Fasten unit to mounting location: Position top keyway slot onto 5/16

inch diameter bolt or lag screw; level unit; then secure bottom at

two open slots with 5/16 inch diameter bolts or lag screws. Refer to

DIMENSIONS section of these instructions.

4. Depress locking tab and remove top cover using a standard pinch bar

or similar tool as a pry between the notches on the rim of the cover

and the lug attached to the center section of the enclosure.

5. Install circuit breaker into units supplied without one.

• Select the proper circuit breaker from Table I.

• Secure circuit breaker to mounting plate in location indicated on

mounting plate label.

• Secure upper operating rod guide with two upper circuit breaker

mounting screws.

• Adjust operating rod bracket as necessary to captivate circuit

breaker toggles.

6. Install wiring. Refer to WIRING CONNECTION section of these

instructions.

7. Check wiring per ELECTRICAL TESTING section of these instructions.

8. Replace top cover.

WARNING

To prevent ignition of hazardous atmospheres, disconnect the device

from the supply circuit before opening. Keep tightly closed when in

operation. Conduit runs must have a sealing fitting connected within 18

inches of the enclosure.

Electrical power must be off before and during installation and

maintenance.

!

CAUTION

• Hazardous location information specifying class and group listing of

each device is marked on the nameplate of each enclosure.

• No conduit openings are to be added in the field.

• All unused conduit openings must be plugged. Plug must engage a

minimum of five full threads and be a minimum of 1/8 inch thick.

• All conduits entering and leaving the enclosure, must be sealed

with explosionproof seals within 18 inches of the enclosure.

• Conduit sealing fittings must be installed in each attached conduit

run to comply with the latest edition of the NEC Section 501-5 and/

or 502-5 plus any other applicable code.

30, 60 and

100 ampere

size EPC

®National Electrical Code is a Registered Trademark of the National Fire Protection Association.

IF 267 • 04/20 Copyright © 2020, Eaton’s Crouse-Hinds Division Page 1

CAUTION

• Check for dirt, grit or other foreign material on the threads. If any

such material settles on these threads, clear them with kerosene or

Stoddard solvent*, then lubricate with Crouse-Hinds Company Type

STL thread lubricant.

*To avoid the possibilities of an explosion, oxidation and corrosion, do

not use gasoline or similar solvents.