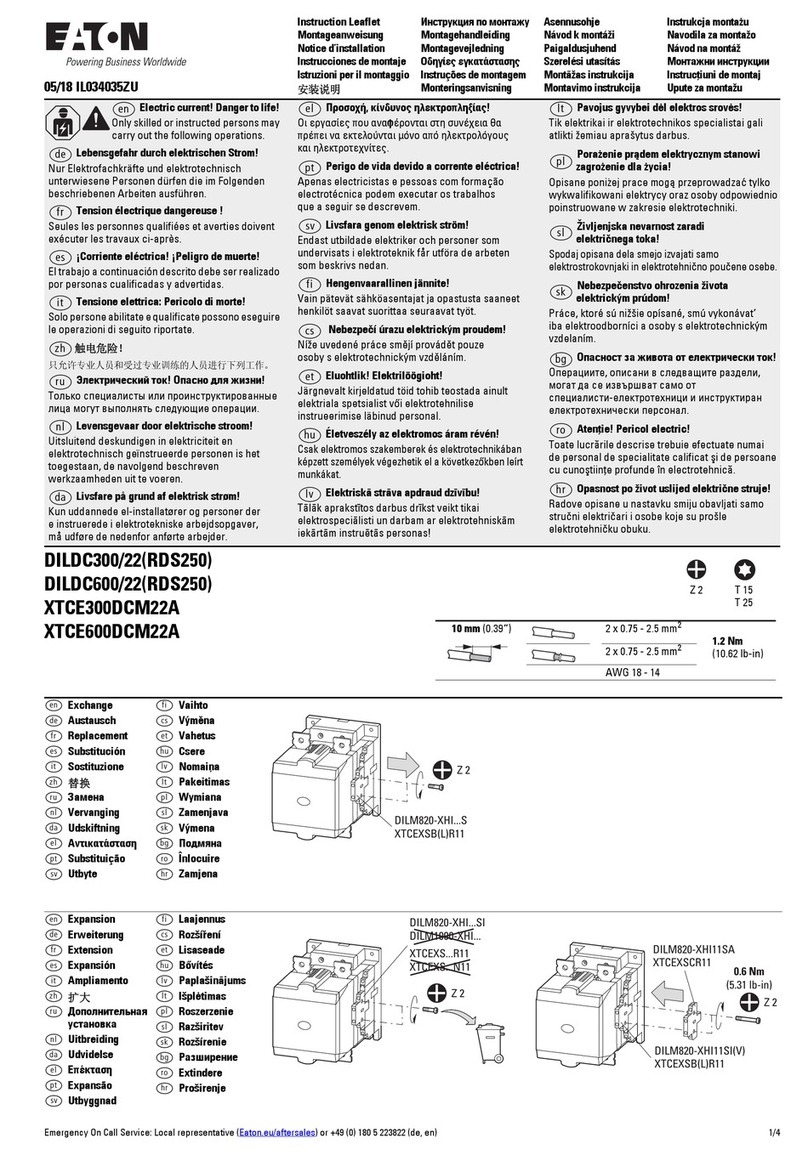

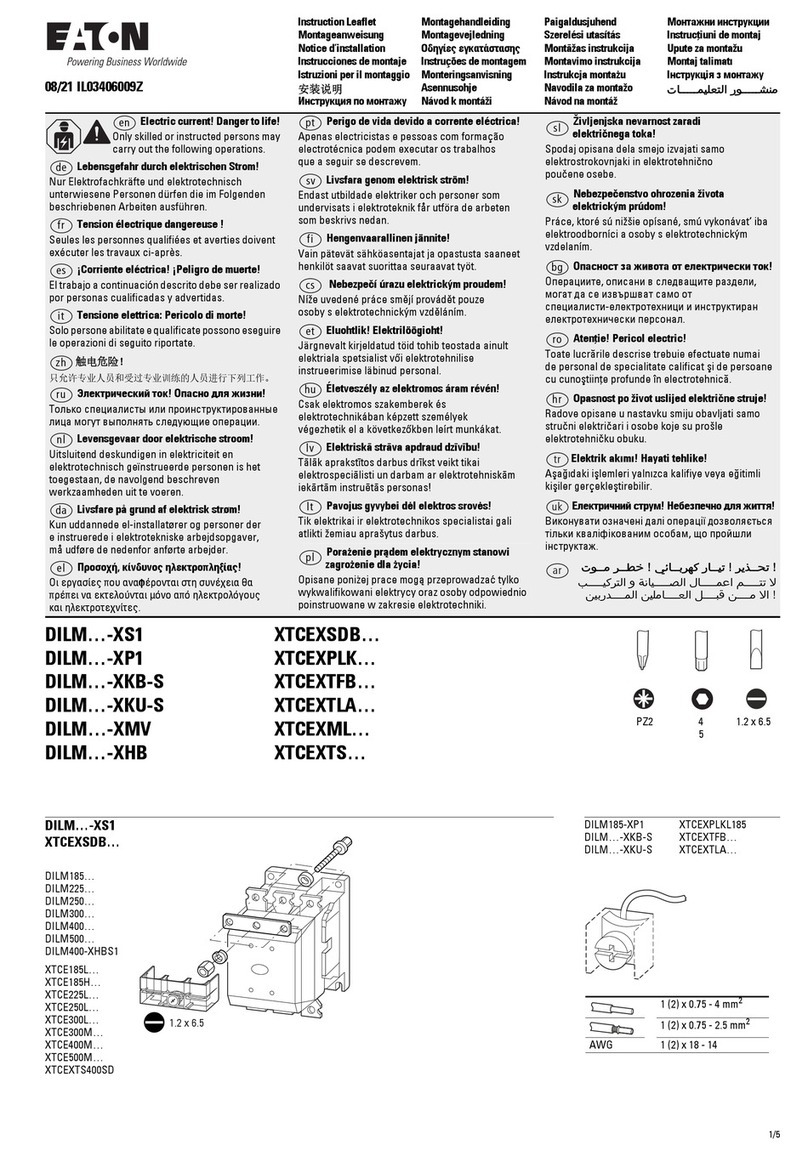

MOUNTING INSTRUCTIONS

This product may not be used alone and should be installed in equipment with the

appropriate type of protection, and using the procedures described below to ensure its

degree of ingress protection.

To install the product correctly, follow the steps below:

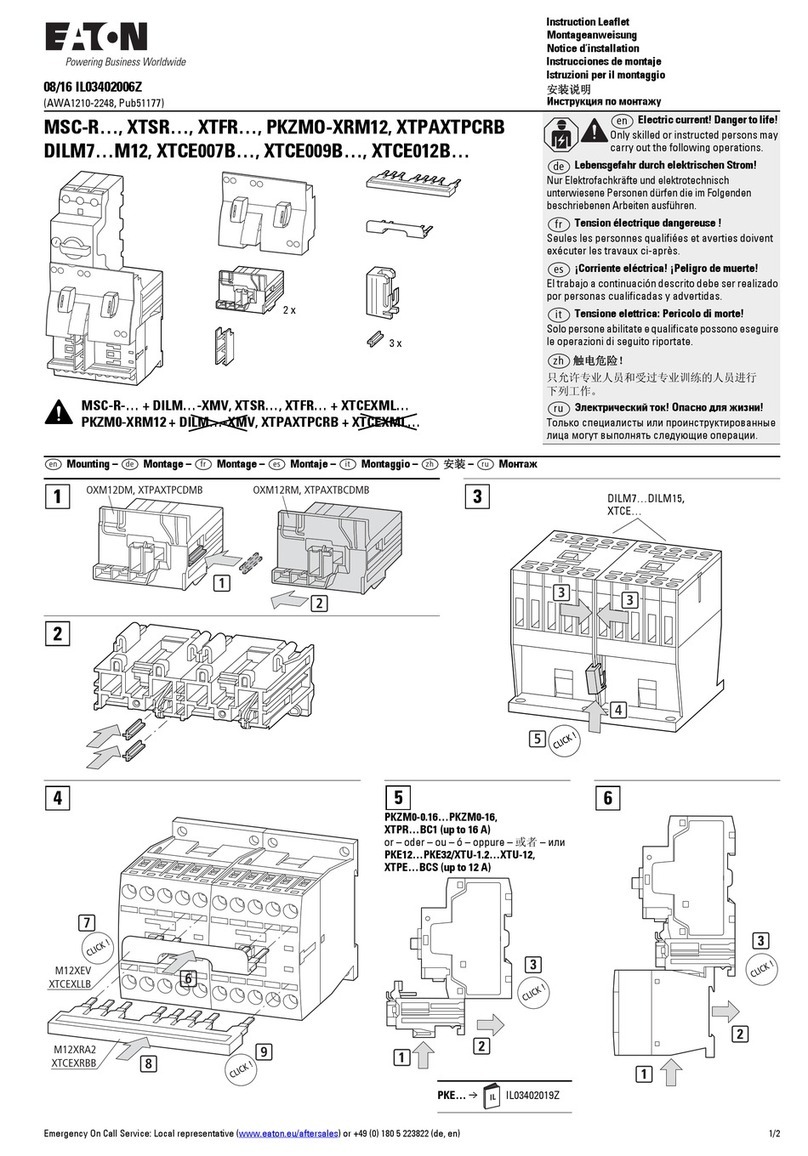

PUSHBUTTONS (for reset pushbuttons, omit Steps 1 and 6):

1. Disconnect the contact block from the assembly by sliding the cage locking tab

clockwise.

2. Remove the nut and protective sleeve from the threaded body.

3. Place the legend plate under the knob, or attach to the enclosure.

4. Make sure the operator threads and surface being attached to are clean and free

of debris. Apply STL thread lubricant and screw the pushbutton assembly into the

enclosures 3/4” NPSM threaded entry and torque 27 in.-lbs. to 53 in.-lbs. (3 N-m to 6

N-m). Ensure legend plate is held in place to prevent rotation.

5. Install the nut onto the assembly threaded body and torque to 18 in.-lbs. (2 N-m) with

an appropriate tool.

6. Installing the contact block to the assembly:

a. With the cage locking tab held in the clockwise position, align the assembly

channel with the locking cage ID tabs on the contact block and slide the block

onto the assembly.

b. Finally move the cage tab counterclockwise to lock switch in place.

c. Verify orientation of block is such that control wires won’t be directed into ame

path of cover/body.

After performing the connections described above, the product can be safely used, and the

ingress of protection is assured.

PILOT LIGHTS AND ILLUMINATED PUSHBUTTONS:

1. Disconnect the contact/terminal block from the assembly by sliding the cage locking

tab clockwise.

2. Install LED into terminal block.

3. Remove the nut and protective sleeve from the threaded body.

4. Place the legend plate under the knob, or attach to the enclosure.

5. Make sure the operator threads and surface being attached to are clean and free

of debris. Apply STL thread lubricant and screw the pushbutton assembly into the

enclosures 3/4” NPSM threaded entry and torque to 27 in.-lbs. to 53 in.-lbs. (3 N-m to

6 N-m).

6. Install the nut onto the assembly threaded body and torque to 18 in.-lbs. (2 N-m) with

an appropriate tool.

7. Installing the contact block to the assembly:

a. With the cage locking tab oriented in the bottom, ensure it is slid to the left

position.

b. Align the assembly channel with the locking cage ID tabs on the contact block

and slide the block onto the assembly.

c. Finally move the cage tab counterclockwise to lock switch in place.

d. Verify orientation of block is such that control wires won’t be directed into ame

path of cover/body.

After performing the connections described above, the product can be safely used, and

the ingress protection is assured.

ROTARY SWITCHES:

1. Disconnect the rotary switch from the switch assembly by sliding the cage locking

tab clockwise.

2. Remove the nut and protective sleeve from the threaded body.

3. Place the legend plate under the rotary knob, or attach to the enclosure.

4. Make sure the operator threads and surface being attached to are clean and free of

debris. Apply STL thread lubricant and screw the rotary knob into the enclosures

3/4” NPSM threaded entry and torque to 27 in.-lbs. to 53 in.-lbs. (3 N-m to 6 N-m).

5. Align the rotary knob pointer to the legend plate.

6. Install the nut onto the switch assembly threaded body, but do not tighten yet.

7. Installing the rotary switch to the switch assembly:

a. With the cage locking tab held in the clockwise position, align the assembly

channel with the locking cage ID tabs on the rotary switch and slide onto the

assembly.

b. Apply pressure to the rotary switch while rotating the knob handle until the

splined shaft aligns and drops into place.

c. Move the cage tab counterclockwise to lock switch in place.

d. If the knob pointer is misaligned from the legend plate markings, the switch

assembly may need to be rotated by threading the assembly in or out while

maintaining the 27 in.-lbs. to 53 in.-lbs. (3 N-m to 6 N-m) torque requirement.

e. Torque nut to 18 in.-lbs. (2 N-m) with an appropriate tool.

NOTE: During the cables/wires installation, make sure that no mechanical tension is

applied to the rotary switch to avoid any damage.

After performing the connections described above, the product can be safely used, and

ingress protection is assured.

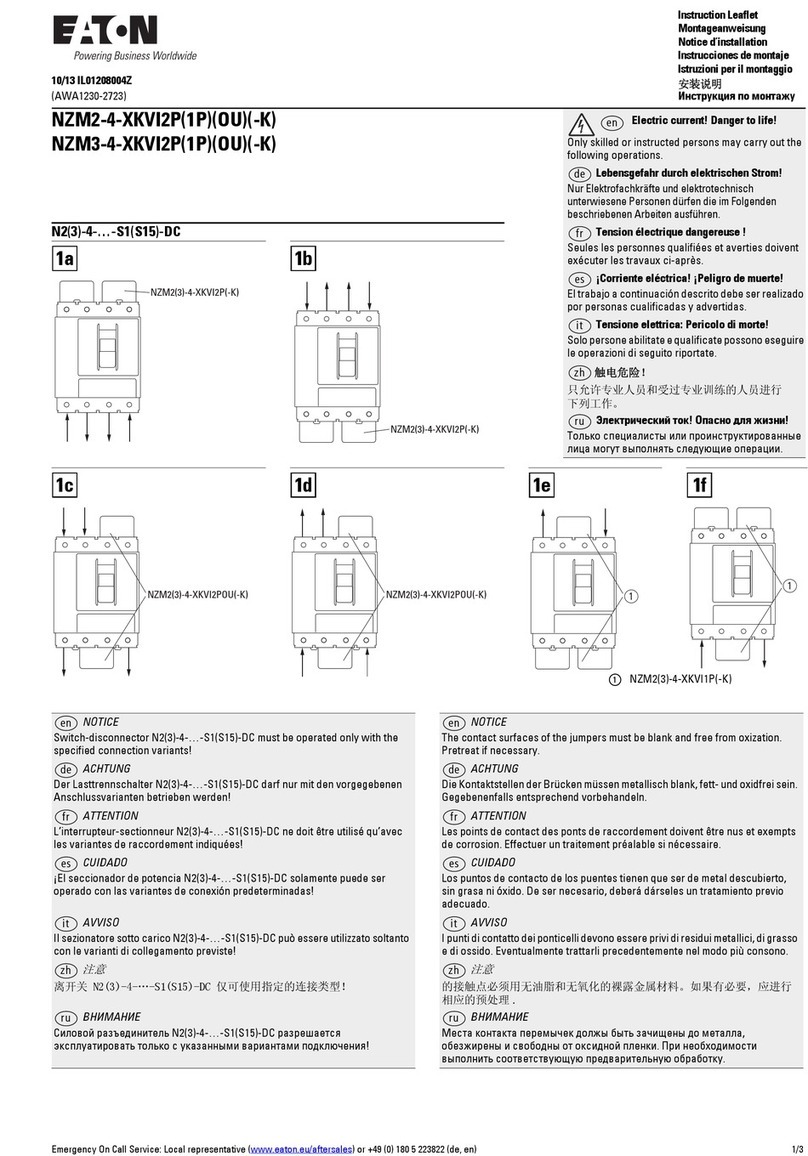

TYPICAL CONTACT POSITIONS

IF 1857 • 09/18 Copyright © 2018, Eaton’s Crouse-Hinds Division Page 2

WARNING

To avoid fire or explosion, operators must be used within their ratings, and installed by

a qualified technician.

CAUTION

To maintain environmental ratings, operators shall be installed in the horizontal position;

vertical position (facing up) is not permitted. Additionally, extra precaution shall be

taken if operators are stored outdoors in the vertical position.

ASSEMBLY

ASSEMBLY

NUT

KNOB

CONTACT

BLOCK CAGE

NUT KNOB

ASSEMBLY

PILOT LIGHT

HOUSING

CAGE

LED

NUT

PILOT

LIGHT

CONTACT

BLOCK

CAGE

LED

ASSEMBLY

NUT

KNOB

UNLOCKED LOCKED

ROTARY

SWITCH CAGE

NUT

KNOB

ASSEMBLY

!CAUTION

To avoid ingress, use of non-Crouse-Hinds legend plates must be verified by user.

Pushbutton and

two-position switches

1 NO & 1 NC

Three-position

switches

1 NO & 1 NC

Pushbutton and

two-position switches

2 NO & 2 NC

Three-position

switches

2 NO & 2 NC