MADE IN U.S.A PAGE 4

PUBLICATION NO. 17228

PROCEDURE FOR REMOVAL OF A SHOE LEVER

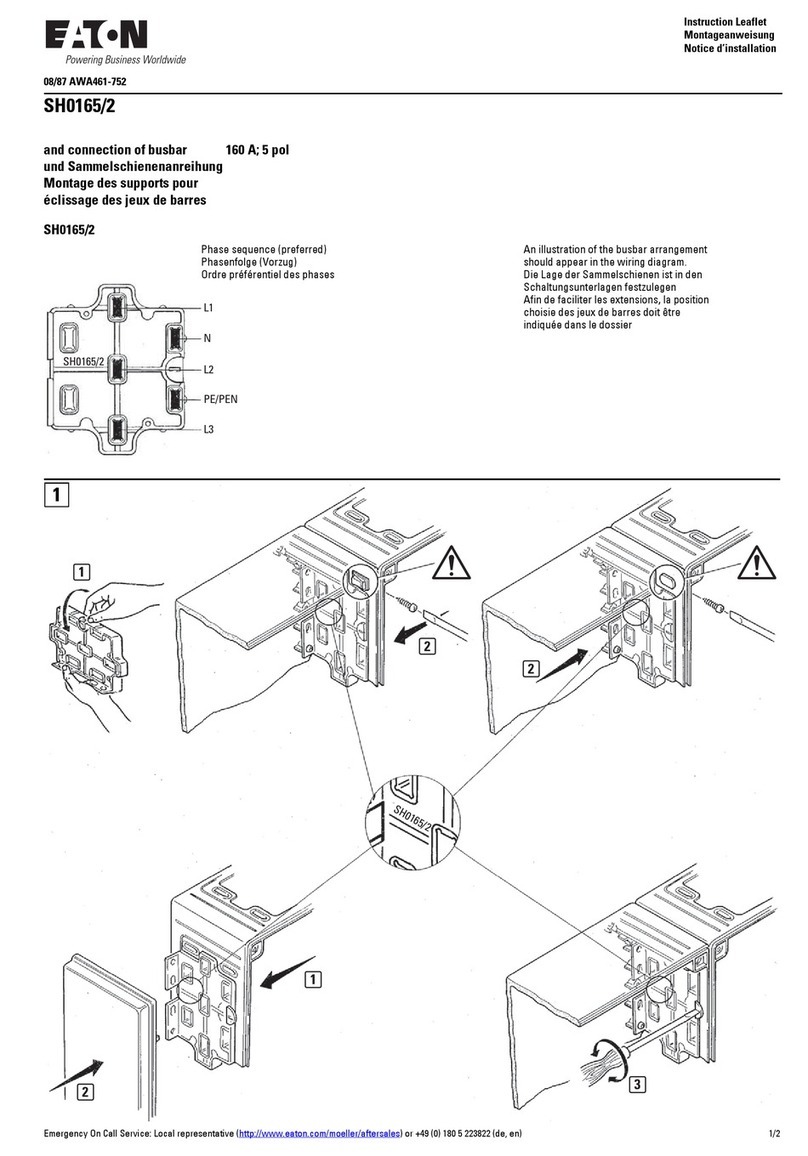

(Refer to Fig. 1, Page 1)

1. If removal of the outer shoe lever “N” is

required, loosen locknut “U” and back off nut

“P” until the pull rod “A” may be lifted up

around the pivot in the outer armature “F”.

2. Refer to shoe retainer “M”. Both sides of the

shoe lever are equipped with a lock bracket,

screw, and retainer plate. Bend back tab of

the lock bracket. Remove screw and retainer

plate. When re-installing and after tightening

the screw, bend the tab of the lock bracket

against the flat of the screw.

3. With the retaining plate removed, slide the

outer shoe lever “N” to either side of the

brake.

4. To remove the inner shoe lever “L”, loosen

locknut “T” and turn screw “C” clockwise until

the pressure of the shoe against the wheel is

relieved. Refer to shoe retainer “M”. Both

sides of the shoe lever are equipped with a

lock bracket, screw, and retainer plate. Bend

back tab of the lock bracket. Remove screw

and retainer plate. When re-installing and

after tightening the screw, bend the tab of the

lock bracket against the flat of the screw.

5. With the retaining plate removed, slide the

outer shoe lever “L” to either side of the

brake.

REPLACEMENT OF A COIL

(Refer to Fig. 1, Page 1)

1. Turn torque adjuster “G” counter clockwise

until the torque spring is loose.

2. Disconnect thee pull rod end from the outer

armature “F”.

3. Remove screws “H” from base.

4. Lift the outer armature “F” out of the pocket

in the base and pull outward.

5. Remove the screws “J” used to attached the

coil to the base pedestal and slide coil from

basepedestal.

6. Set the new coil on the pedestal and install

mounting screws “J”. Do not tighten at this

time.

7. Set the armature “F” back into position. The

spring gland of the torque adjuster must be

centered in the hole of the inner armature

”D”. Assemble angle bracket and screws “H”

and “R” with screws hand tight only.

8. Attach pull rod “A” to armature “F”.

9. Pull armatures “F” and “D” together

magnetically or by using a clamp. Tighten

screws “H” and the base such that a

clearance of 0.25 ±0.015 will be maintained

between the armature “F” and bracket “S”.

The clearance should be uniform. Remove

clamp (if used).

10. Adjust the torque spring and shoe positions

as described in the installation instructions.

PROCEDURE FOR RE-ADJUSTMENT FOR LINING WEAR

(Refer to Fig. 1, Page 1)

Periodic checks should be made on the

installation and when the sounding pins depress

more than 1/64” below surface, adjustments

should be made to compensate for normal lining

wear. This check and the adjustments should be

made when the wheel is at normal operating

temperature to allow for thermal expansion of the

wheel. Re-inspect after several operations.

1. Loosen the locknut “U” and tighten nut

“P” on the outer end of pull rod “A” until

the sounding pin in the outer armature

is flush with the surface when it is

pressed.

2. Loosen locknut “T”. Turn screw “C”

counter-clockwise to move the wedge

downward until the inner armature

sounding pin is flush when it is pressed

inward.

3. Tighten locknuts “U” and “T”.

It is recommended the brake shoe linings be

replaced when the lining thickness at the

center of the shoe has decreased to .125”

for riveted construction and .062 for bonded

construction. Use genuine OEM lining

material only to insure brake maintains

rated torque.

(See paragraph 14, Page2)