WM80 OWNERS MANUAL Page 5 of 10

Drawing No. :- TPC313

Issue :- 1

Date :- 08/05/07

INSTALLATION

The WM80 Dehumidifier can be left free standing unit, alternatively can be wall

mounted for instructions on mounting the unit please read the following:

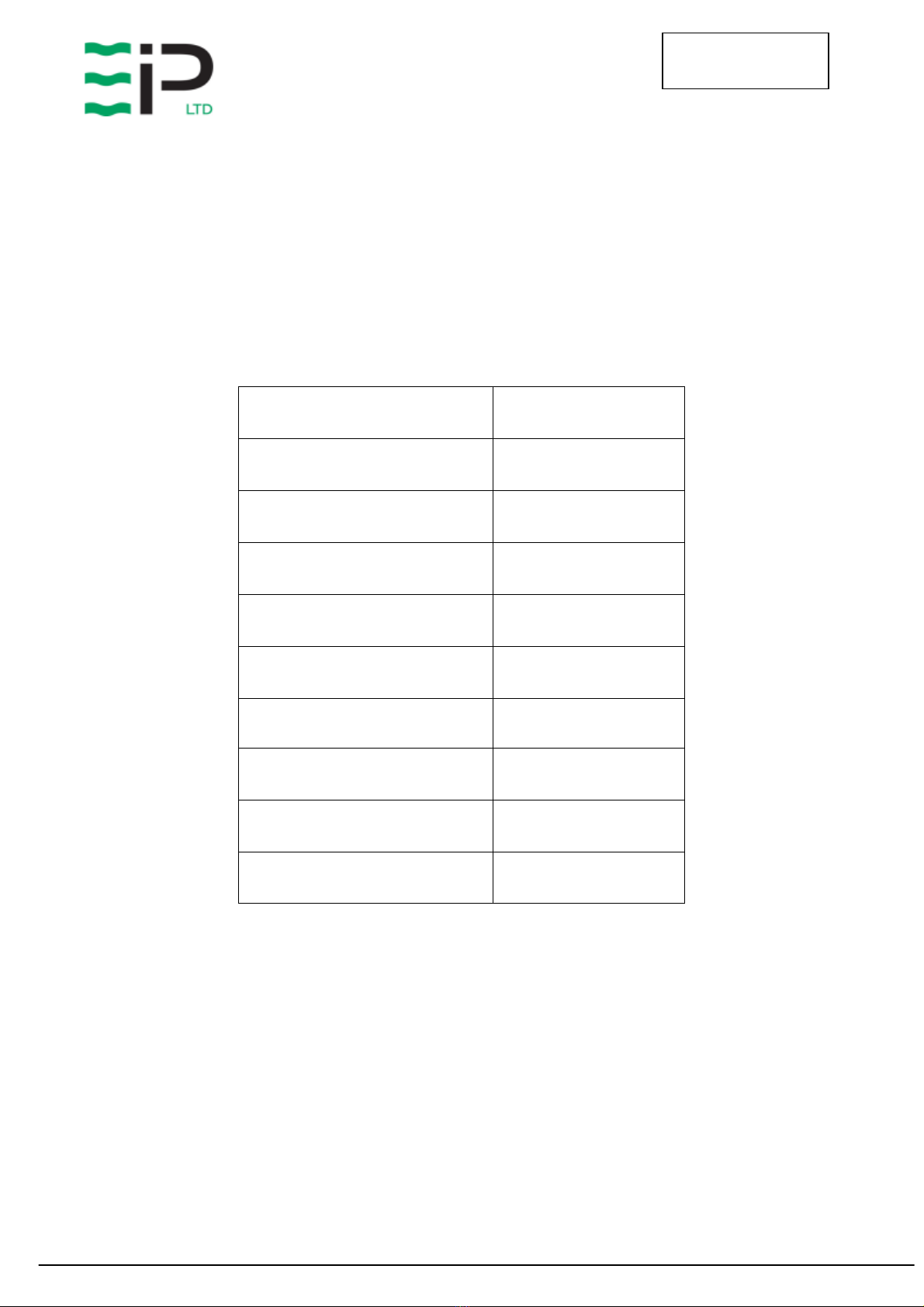

A full installation kit is included in the package to allow a problem free install. This kit

comprises of the following :-

1 X WM80 Dehumidifier

1 X Mounting Bracket

4 X Rawl plugs and screws

4 X M6 Hex Head Bolts, flat and spring washers

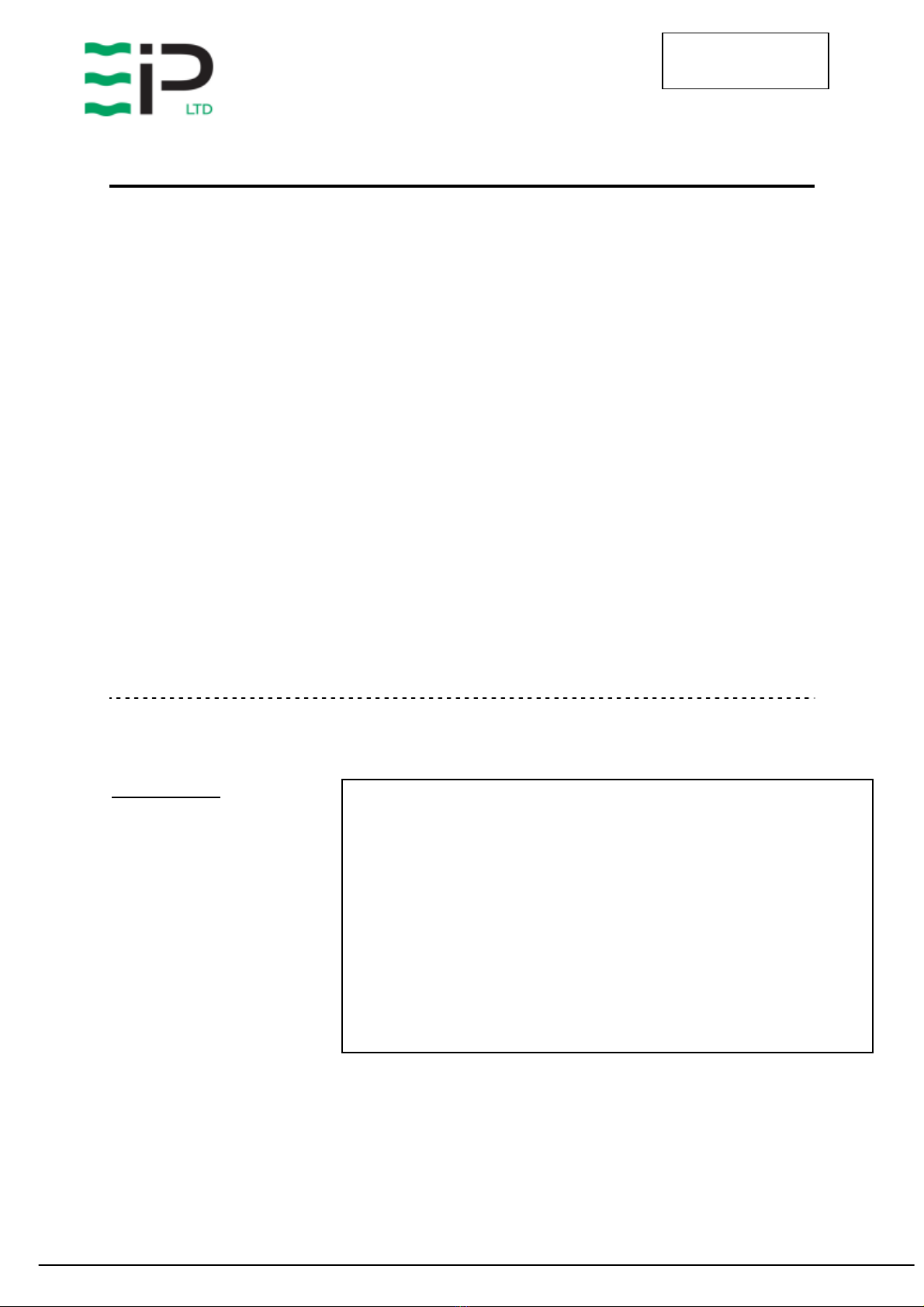

For mounting the WM80 Dehumidifier to a wall you will first need to remove the

cover from the unit and detach the wall mounting bracket from the rear of the unit by

removing the 4 bolts that secures it.

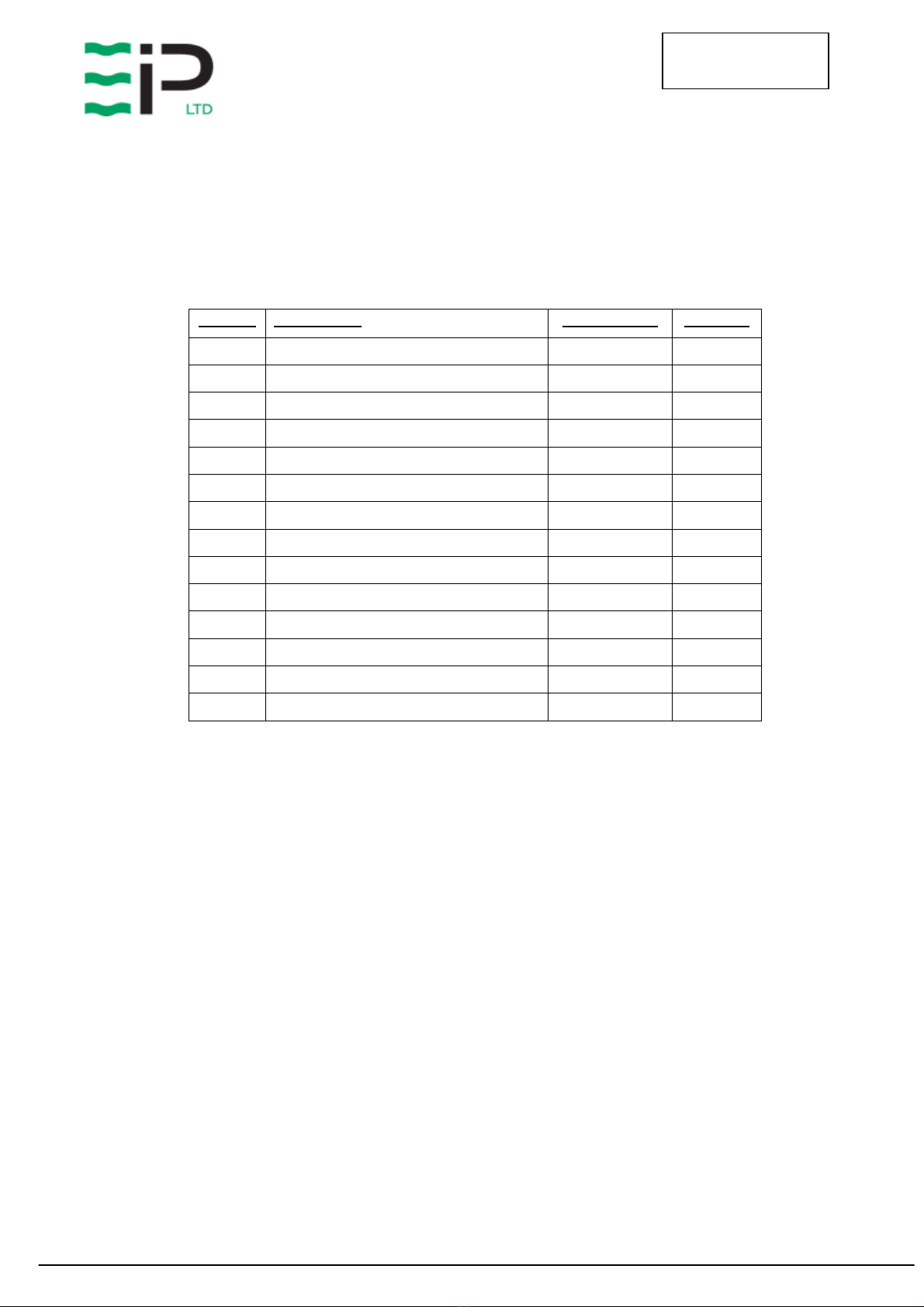

With reference to the installation drawing at the rear of this manual, maintain the

minimum clearances from adjacent objects (ie walls celings etc). Maintaining these

distances will ensure easy access for installation and maintaining the unit during the

products life

Place the wall mounting bracket onto the wall, ensuring the correct orientation, and

the bracket is level. Mark off 4 points on the wall where you will be securing the

bracket, the bracket has numerous holes and slots to allow the bracket to be

mounted at different points depending on the wall you are mounting it to. It is

advised to have the fixing points spaced out as far as possible to allow a more

ridged and secure installation.

Using a 7mm masonry bit, drill the 4 points you marked off earlier to a depth of

40mm, insert the 4 Rawl plugs into the wall that are supplied with this unit.

Secure the wall mounting bracket to the wall using the 4 brass screws supplied with

the unit.

Ensure all fixings are tight and bracket is secured to the wall.

Screw 2 X M6 Bolts into the top fixings on the bracket, only screwing them in a 2-3

turns. Lift the unit onto the bracket and hook the unit onto the bolts using the keyhole

slots in the rear of the unit do not tighten the bolts yet. Fit the 2 remaining bolts

through bottom holes in the rear of unit and into the wall mounting bracket and

tighten all 4 bolts.

Check to make sure the unit is secure to the wall mounting bracket.

Replace cover and refit all fixings that have been removed.