5

2. INTRODUCTION

Congratulations for acquiring a genuine, professional ECLER device!

The NUO4.0 is a professional DJ mixer designed and manufactured by ECLER; an enterprise with headquarters in

Barcelona, which works on professional audio equipment since 1965.

The NUO4.0 is a professional audio mixer thought for any kind of DJ, due to its wide range of functions, which

make it a console able to mix any kind of music style: techno, house, minimal, electro, hip hop, …

The NUO4.0 is a mixer thought for scratching techniques, due to the versatility of the adjustments of faders and

crossfaders. The NUO4.0 is furthermore able to wear the ETERNAL crossfader, ECLER’s magnetic crossfader with

5 years guarantee, which has been specially designed for scratching specialists.

This genuine mixer uses the best components available on the market, obtaining the highest possible sound

quality. The over 40 years of experience in the design of professional audio equipment make that the circuits are

extremely efficient and a warm and crystal clear analogue sound is obtained. All circuits are mounted and tested in

our factory site in Barcelona.

Furthermore, the NUO4.0 is a mixer which has been specially designed for all kinds of professional installations,

thanks to its two balanced outputs and its two microphone inputs. Its design and resistance turn it into the ideal

console for professional installations, as well as for mobile applications executed by trendiest DJ’s.

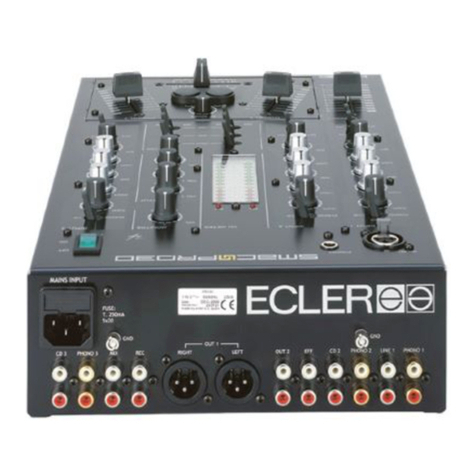

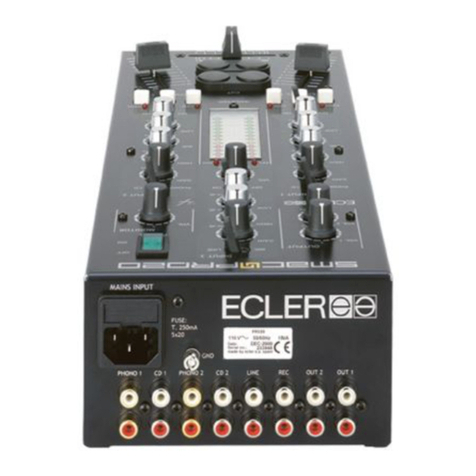

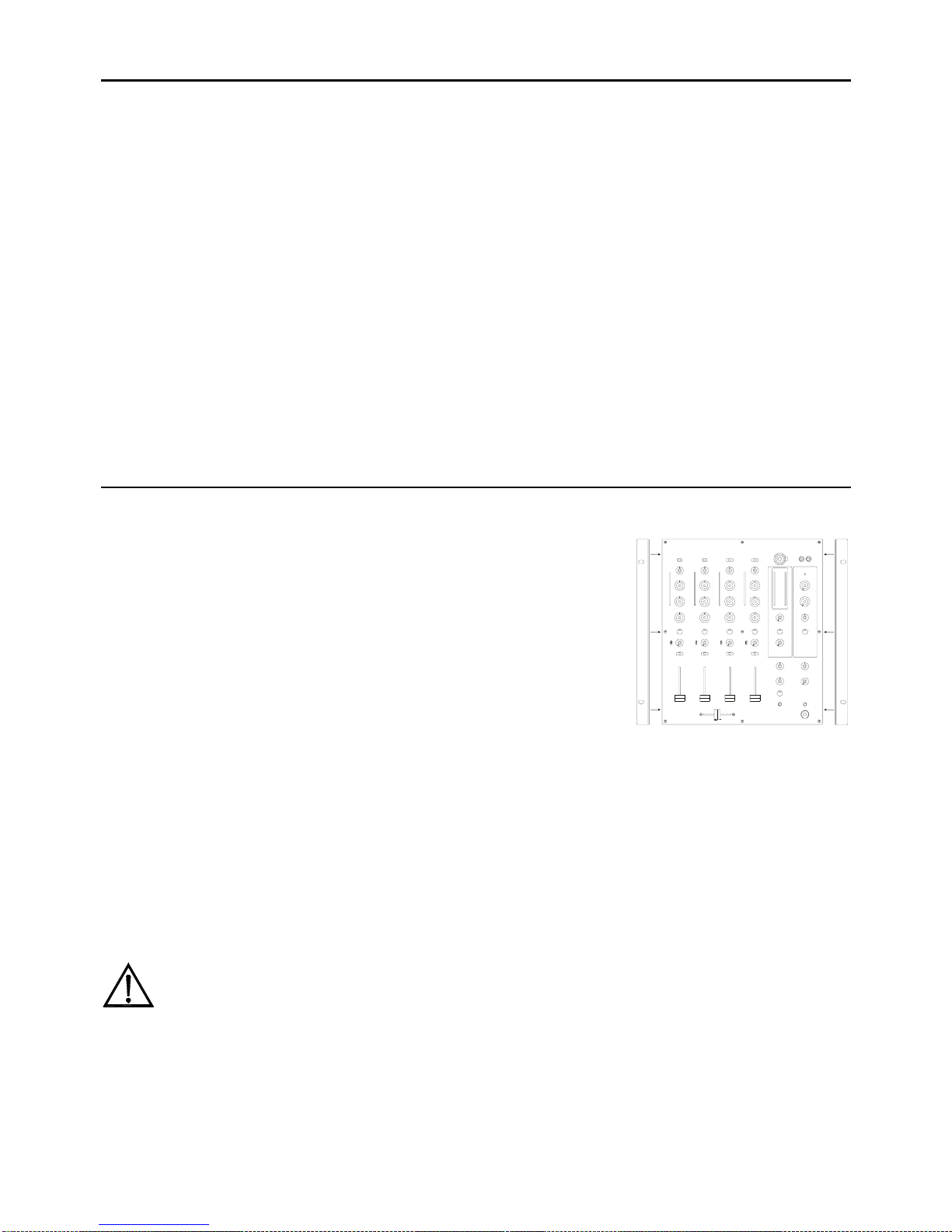

3. INSTALLATION

The main consideration to be taken when looking for the best setup location for the NUO4.0 has to be the

maximum commodity for the user and the easiness for realizing the necessary

connections.

The NUO4.0 has been basically designed as an on desk mixer and its usual

location will be between two turntables or CD players. The mixer is 37 cm

(14.57") deep and 32 cm (12.6") wide.

Using the metallic side panel kit (optionally available) you may fix your NUO4.0

directly on a support surface or on those side panels which also allow you to

skew it. The "NUORAKI" metallic holders allow you to install the mixer in a

standard 19" rack.

Because of the high gain of the PHONO and MICRO inputs, always try to place the mixer as far away as possible

from noise sources (dimmers, engines, etc.) and mains wires. For the very same reason, and under any

circumstance, you should never remove the unit's metallic cover.

The power consumption of the NUO4.0 is very low, so they do not need any cooling, but you should avoid extreme

temperatures and the atmosphere should be as dry and dust free as possible.

The NUO4.0 operates now with a new universal input power supply “Switching Power Supply” and can perfectly

works without any internal modification from 90V to 264V – 47 to 63Hz. Make sure that the mains-wire is far away

from the signal-cables in order to avoid any possible audio hum.

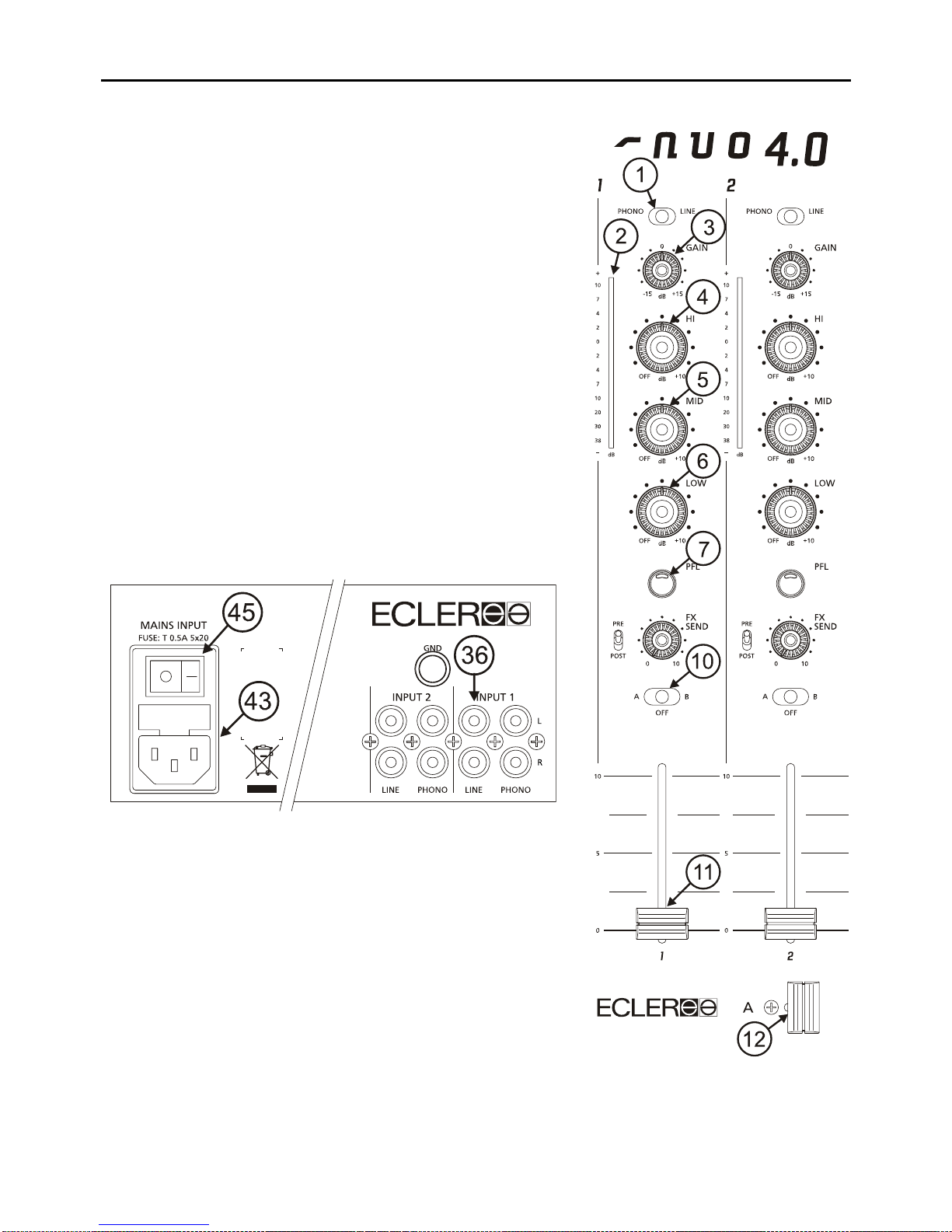

In order to protect the unit from an eventual electrical overload it carries a T 0.5A fuse. Should it ever blow up,

unplug the unit from mains and replace it with an identical one. If the new fuse blows again contact immediately

with our authorized technical service.

ATTENTION: NEVER SHORT-CIRCUIT THE SECURITY PATH NOR USE A HIGHER VALUE FUSE.

CAUTION: Fuse substitutions have to be performed by a qualified technician.