Ecolab EcoPro-ES-00510X-PFC-00S-1S-S0 User manual

Ecolab Dynamic Pump

EcoPro

Operating instructions

EcoPro

417102264 Rev. 5-01.2019

08.01.2019

ENGLISH

Table of contents

1General information................................................................................................. 5

1.1 Information on User Manual............................................................................... 5

1.2 Availability and updating of the operating instructions........................................ 5

1.3 Call up operating instructions with smartphone.................................................. 6

1.4 Article numbers / EBS-Article numbers.............................................................. 6

1.5 Copyright............................................................................................................ 6

1.6 Symbols, highlighting and enumerations............................................................ 6

1.7 Transport............................................................................................................ 8

1.8 Packaging........................................................................................................... 9

1.9 Storage............................................................................................................. 10

1.10 Identification of the installation - Nameplates................................................. 10

1.11 Warranty.......................................................................................................... 11

1.12 Manufacturer's service and contact address.................................................. 11

2 Safety....................................................................................................................... 12

2.1 General Safety.................................................................................................. 12

2.2 Proper use........................................................................................................ 12

2.2.1 Reasonable foreseeable incorrect use.......................................................... 13

2.2.2 Unauthorised modification and spare parts manufacture.............................. 13

2.3 Lifetime............................................................................................................. 14

2.4 Safety measures taken by the operator............................................................ 14

2.5 Workforce requirements................................................................................... 14

2.6 Personal protective equipment (PPE)............................................................... 15

2.7 Explanation of the safety symbols used........................................................... 15

2.7.1 Personal protective equipment - PPE............................................................ 15

2.7.2 Indications of risks......................................................................................... 16

2.7.3 Environmental protection measures.............................................................. 19

2.8 Obligations of the operator............................................................................... 20

2.9 Installation, Maintenance and Repairs.............................................................. 20

3 Package content..................................................................................................... 22

4Functional description........................................................................................... 24

4.1 Features - ‘EcoPro’.......................................................................................... 25

5 Description of the pump........................................................................................ 26

5.1 Identification of the pump - Type plates............................................................ 26

5.2 Control elements ‘EcoPro’............................................................................... 26

5.3 Connection sockets / cable bushings............................................................... 27

5.4 Pump head variants.......................................................................................... 28

6 Assembly, installation, modification and upgrades ........................................... 29

6.1 General information and safety......................................................................... 29

6.2 Assembly variants............................................................................................. 31

6.2.1 Stand mounting or floor mounting.................................................................. 32

6.2.2 Wall mounting................................................................................................ 33

6.3 Installation......................................................................................................... 34

6.3.1 Hydraulic installation...................................................................................... 34

6.3.2 Installation examples..................................................................................... 35

6.3.3 Connection of the suction and pressure lines (dosing lines)......................... 37

Table of contents

2417102264 Rev. 5-01.2019

6.3.3.1 Pipe and hose connection with integrated support sleeve......................... 38

6.3.3.2 Pipe and hose connection with tapered part.............................................. 39

6.3.3.3 Pipe and hose connection with attachment nipple and hose clamp........... 40

6.3.3.4 Pipe and hose connection with female coupling......................................... 41

6.3.4 Electrical Installation...................................................................................... 42

6.3.4.1 Terminal assignment - External enable signal............................................ 43

7 Start-up ................................................................................................................... 44

7.1 Initial start-up of the ‘EcoPro’........................................................................... 45

7.2 Auto start function............................................................................................. 46

7.3 Terminal assignment ‘external enable"’ ‘EcoPro’............................................ 47

7.4 Calibration on initial start-up............................................................................. 48

8 Operation................................................................................................................. 49

8.1 Switching the pump on and off......................................................................... 49

8.2 Setting of the capacity / flow rate...................................................................... 50

8.3 Setting / changeover of the viscosity................................................................ 50

8.4 Changing a container - Empty signal................................................................ 51

9 Maintenance............................................................................................................ 52

9.1 Service position................................................................................................ 53

9.2 Maintenance table............................................................................................ 54

9.3 Replace the suction / pressure valve and metering cartridge........................... 55

9.4 Installing the dosing valve in the correct position............................................. 56

9.5 Changing the valve cartridges (V3 type)........................................................... 56

9.6 Replacing the pump head and diaphragm........................................................ 57

9.7 Pump head size 5 l/h and 11 l/h........................................................................ 58

9.8 Pump head size 30 l/h and 50 l/h..................................................................... 59

9.9 Pump head size 120 l/h.................................................................................... 60

10 Consumables and spare parts.............................................................................. 61

10.1 Wearing parts................................................................................................. 61

10.1.1 Set of wearing parts 5 l/h and 11 l/h............................................................ 61

10.1.2 Set of wearing parts 30 l/h, 50 l/h and 120 l/h............................................. 62

10.2 Spare parts..................................................................................................... 62

10.2.1 EcoPro control unit ‘’................................................................................... 62

10.2.2 Pump heads................................................................................................. 64

10.2.2.1 Replacement part module: Pump head 5 l/h............................................ 64

10.2.2.2 Replacement part module: Pump head 11 l/h........................................... 65

10.2.2.3 Replacement part module: Pump head 30 l/h and 50 l/h......................... 66

10.2.2.4 Replacement part module: Pump head 120 l/h........................................ 67

11 Repair, conversion, upgrade................................................................................. 68

11.1 Repair............................................................................................................. 68

11.1.1 Replacing the control unit............................................................................ 68

11.2 Modification/upgrade....................................................................................... 69

11.2.1 Modification - turning the pump head........................................................... 69

11.2.2 Modification - change from stand mounting to wall mounting...................... 70

11.2.3 Upgrading - From ‘EcoPro’ to ‘EcoAdd’..................................................... 71

12 Operational malfunctions / troubleshooting........................................................ 72

12.1 General troubleshooting and fault rectification............................................... 73

Table of contents

3 417102264 Rev. 5-01.2019

12.2 LED - fault messages .................................................................................... 73

13 Technical specifications........................................................................................ 74

13.1 Packaging....................................................................................................... 74

13.2 Equipment marking / Type plate..................................................................... 74

13.3 ‘EcoPro’ pump key......................................................................................... 75

13.3.1 Pump key group I......................................................................................... 75

13.3.2 Pump key group II........................................................................................ 76

13.3.3 Pump key group III....................................................................................... 76

13.3.4 Pump key group IV...................................................................................... 76

13.4 General data................................................................................................... 77

13.5 Electrical data................................................................................................. 78

13.6 Tightening torques.......................................................................................... 78

13.7 Materials......................................................................................................... 79

13.8 Dimensions..................................................................................................... 79

13.8.1 Mounting plate............................................................................................. 79

13.8.2 EcoPro metering pump................................................................................ 80

13.9 Metering capacity diagrams/flow rates........................................................... 80

13.9.1 Flow rate: 5 l/h, metering back-pressure: 1 MPa (10 bar)........................... 80

13.9.2 Flow rate: 11 l/h, metering back-pressure: 1 MPa (10 bar).......................... 81

13.9.3 Flow rate: 30 l/h, metering back-pressure: 0.3 MPa (3 bar)........................ 81

13.9.4 Flow rate: 50 l/h, metering back-pressure: 1 MPa (10 bar)......................... 82

13.9.5 Flow rate 120 l/h, metering back-pressure: 0.3 MPa (3 bar)....................... 82

14 Decommissioning / dismantling / environmental protection............................. 83

14.1 Shutting down................................................................................................. 83

14.2 Dismantling..................................................................................................... 84

14.3 Disposal and environmental protection........................................................... 85

15 EC Declaration/Declaration of Conformity........................................................... 86

16 Index........................................................................................................................ 87

Table of contents

4417102264 Rev. 5-01.2019

1 General information

1.1 Information on User Manual

Read the instructions!

Before beginning all work and/or operating devices or machines, it is essential to

read and understand these instructions.

In addition, always heed all the instructions relating to the product that are included

with the product!

This operating manual contains all the instructions for installing, commissioning,

maintenance and repairs.

–Personnel must have carefully read and understood this manual before

starting any work. The basic premise for safe operation is observing all

safety instructions and work instructions in this manual.

The local accident-prevention regulations and general safety instructions

also apply to the area of application.

–Illustrations in this manual are provided to aid basic understanding and may

deviate from the actual design.

–The original language of this guide is German and, as such, the German

version of the original operating manual shall prevail.

All other languages are translations.

WARNING!

– All instructions must be placed at the disposal of the operating and

maintenance personnel at all times. Please store all manuals and guides as

a reference for operation and service.

– If the system is resold, the operating manual must be supplied with it.

– The relevant sections of this operating manual must be read, understood

and noted before installing the system, using it for the first time, and before

carrying out any maintenance or repair work.

1.2 Availability and updating of the operating instructions

All operating instructions are kept up to date at all times and freely available

online for download.

To download the instructions with a PC, tablet or Smartphone, use the links

below or scan the QR code.

Download of the operating instructions ‘EcoPro’

(Article No. 417102264):

https://www.ecolab-engineering.de/fileadmin/download/

bedienungsanleitungen/dosiertechnik/Dosierpumpen/

417102264-EcoPro.pdf

General information

5 417102264 Rev. 5-01.2019

1.3 Call up operating instructions with smartphone

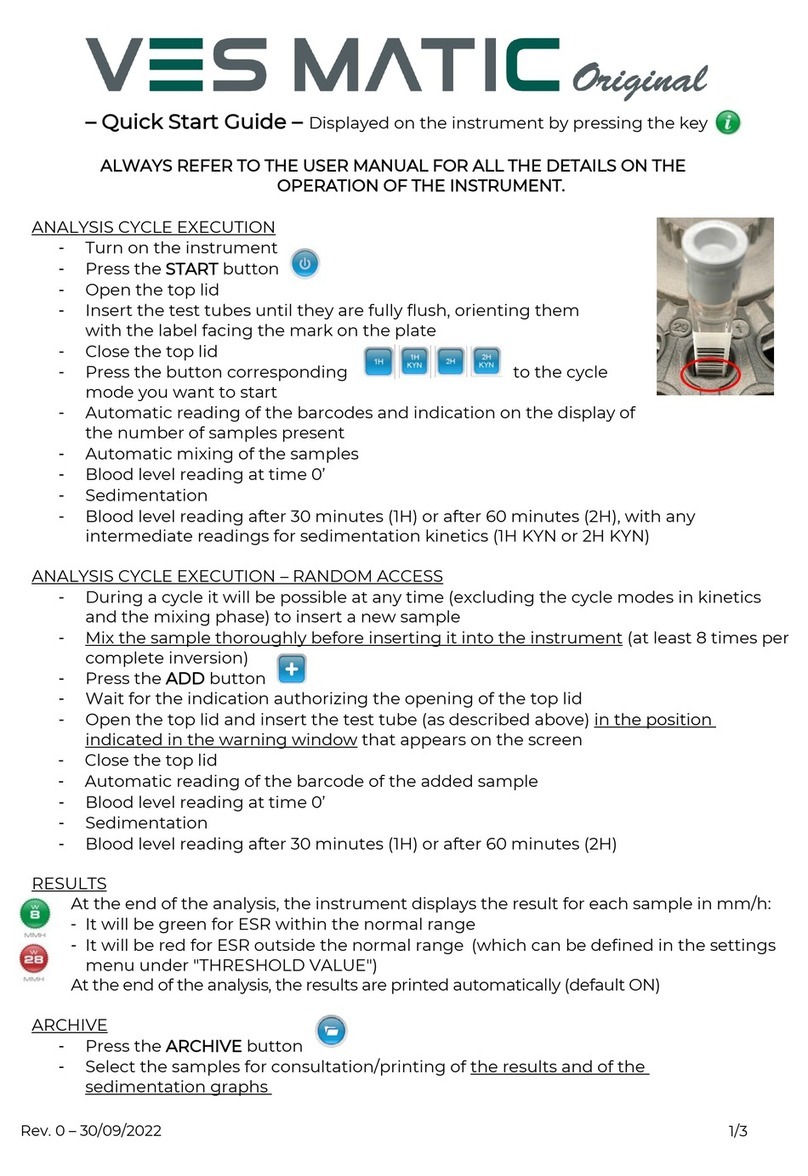

Fig. 1: Ecolab DocuAPP

The Ecolab ‘DocuApp’ can be used to call up all published operating instructions,

catalogues, certificates & CE Declaration of Conformity from Ecolab Engineering using

smartphones (Android & IOS ).

The documents shown in the ‘DocuApp’ are always up-to-date and new versions are

displayed immediately.

Android smartphones have the "Google Play" app .

This app can be used to access the app store for the Android system.

This can be searched for and installed by entering the app name "Ecolab DocuAPP" .

IOS smartphones have the "APP Store" app .

This app can be used to access the app store for the Apple IOS system.

This can be searched for and installed by entering the app name "Ecolab DocuAPP" .

1.4 Article numbers / EBS-Article numbers

Both item numbers and EBS numbers could be shown in these operating

instructions. EBS numbers are Ecolab-internal item numbers and are used

exclusively “internal within the group”.

1.5 Copyright

This manual is copyright protected.

Transferring this manual to third parties, reproduction in any form – even partially – and

the exploitation and/or disclosure of the contents without written permission from Ecolab

Engineering (hereinafter “the manufacturer”) is prohibited except for internal purposes.

Any contravention of this will result in claims for damages.

The manufacturer reserves the right to assert additional claims.

The copyright lies with the manufacturer. © Ecolab Engineering GmbH

1.6 Symbols, highlighting and enumerations

Symbols, safety information

Safety instructions are marked in this manual with symbols.

The safety instructions are introduced with signal words which express the extent of the

danger.

DANGER!

This combination of symbol and signal word indicates an imminently

dangerous situation that will lead to serious or fatal injury if not avoided.

General information

6417102264 Rev. 5-01.2019

WARNING!

This combination of symbol and signal word indicates a potentially dangerous

situation which could result in serious or fatal injury if not avoided.

CAUTION!

This combination of symbol and signal word indicates a potentially dangerous

situation that could lead to minor or slight injuries if not avoided.

NOTICE!

This combination of symbol and signal word indicates a potentially dangerous

situation that could lead to material damage if not avoided.

ENVIRONMENT!

This combination of symbol and signal word indicates possible dangers to the

environment.

Safety instructions in the operating instructions

Safety instructions can refer to specific, individual operating instructions.

These safety instructions are embedded in the operating instructions, so they do not

interrupt the reading flow when executing the action.

The signal words described above are used.

Example:

1. Loosen screw.

2.

CAUTION!

Risk of trapping on the cover!

Close the cover carefully.

3. Tighten screw.

Tips and recommendations

This symbol highlights useful tips, recommendations and information for an

efficient and trouble-free operation.

General information

7 417102264 Rev. 5-01.2019

Further markings

The following markings are used in this manual to highlight operating instructions, results,

collections, references and other elements:

Marking Explanation

1., 2., 3. ... Step by step operating instructions

ðResults of the operating steps

References to sections of this manual and related documents

Collections in no set order

[Button] Controls (e.g. button, switch), indicators (e.g. signal lights)

‘Display’ Screen elements (e.g. buttons, assignment of function keys)

1.7 Transport

Please refer to the “Technical data” section for the packaging dimensions and packaging

weight

Improper transport

NOTICE!

Material damage due to improper transportation!

Transport units can fall or tip over if improperly transported.

This can cause a high degree of damage.

– Be careful when unloading the transport units on delivery and during

in-house transport in-house transport; observe the symbols and instructions

on the packaging.

– Only use the attachment points provided.

– Remove packaging just before assembly.

DANGER!

Risks when commissioning equipment which has been damaged during

transportation.

Installation or commissioning must not take place if any transport damage is

detected when unpacking the system.

By installing/commissioning damaged components, unmanageable errors may

occur, which may lead to irreparable damage to personnel and/or the system

with the use of aggressive dosing agents.

General information

8417102264 Rev. 5-01.2019

Transport inspection

NOTICE!

Check the delivery for completeness and any transport damage.

In case of visible damage, proceed as follows:

nDo not accept the delivery or accept provisionally.

nNote down the extent of damage in the transport documents or on the delivery slip.

nLodging a complaint.

Claim for any damages as soon as you notice them.

Damage claims can only be filed within the applicable period for complaints.

1.8 Packaging

The individual packages are packaged according to the expected transport conditions.

Only environmentally-friendly materials were used for the packaging. The packaging is

designed to protect the individual components up to assembly against shipping damage,

corrosion and other damage.

Do not destroy the packaging and only remove it just before assembly.

ENVIRONMENT!

Risk of environmental damage due to incorrect disposal!

Packaging materials are valuable raw materials and can, in many cases,

be used again or be usefully processed and recycled.

Incorrect disposal of packaging materials can be a threat to the

environment.

–Observe the locally applicable disposal regulations!

– Environmentally-friendly disposal of packaging materials.

– If necessary, hire a specialist to carry out disposal.

General information

9 417102264 Rev. 5-01.2019

Symbols on the packaging

Symbol Name Description

Top

The individual package must always be transported, handled and stored in

such a way that the arrows point upwards at all times.

Rollers, flaps, heavy tipping or edges and other forms of handling must be

avoided. ISO 7000, No 0623

Fragile The symbol shall be affixed to goods that are very fragile.

Goods marked as such must be handled with care and in no way dropped

or laced. ISO 7000, No 0621

Keep this product

dry

Goods marked as such must be protected against excessive humidity and

must therefore be stored in a covered location.

If particularly heavy or bulky individual packages cannot be stored in

warehouses or sheds, they must be covered with a canvas.

ISO 7000, No 0626

Protect against

cold Goods marked as such must be protected against excessive cold. These

individual packages should not be stored outdoors.

Stack limiting Maximum number of identical individual packages that can be stacked,

where n stands for the number of permissible individual packages.

ISO 7000, No 2403

Electrostatic

sensitive device

Avoid touching individual packages marked as such at low relative humidity,

especially when wearing insulating footwear or when the substrate is not

conductive.

Low relative humidity is to be expected especially on warm, dry summer

days and very cold winter days.

1.9 Storage

Under certain circumstances, instructions for storage, which go beyond the

requirements listed here, can be found on the package.

These must be complied with accordingly.

Please note the following storage conditions:

nDo not store outdoors.

nStore in a dry and dust-free place.

nDo not expose to aggressive media.

nProtect from sunlight.

nAvoid mechanical vibrations.

nStorage temperature: +5 to 40° C.

nRelative humidity: max. 80 %.

nFor storage periods of more than 3 months, check the general condition of all parts

and packaging regularly. If necessary, refresh or renew the preservative.

1.10 Identification of the installation - Nameplates

All information for the identification of the installation or the information on the

nameplate of the installation and all components are located in the chapter

"Technical Data ".

Important for inquiries is the correct specification of the designation and the

type. This is the only way of ensuring that we can answer your query correctly

and quickly.

General information

10417102264 Rev. 5-01.2019

1.11 Warranty

The manufacturer provides a warranty for operational safety, reliability and

performance under the following conditions only:

nAssembly, connection, adjustment, maintenance and repairs must be carried out by

qualified and authorised specialists with the aid of the User Manual and all the

provided documents.

nOur products are used in accordance with the instructions in the User Manual.

nOnly original equipment spare parts are to be used for repairs.

Our products are built, tested and CE certified in accordance with current

standards/guidelines. They left the factory in a safe, faultless condition.

To keep the equipment in this condition and to ensure risk-free operation, the

user must observe the instructions / warnings, maintenance regulations, etc.

contained in these operating instructions and, if applicable, affixed to the

product.

The general warranty and service conditions of the manufacturer also

apply.

1.12 Manufacturer's service and contact address

Ecolab Engineering GmbH

Raiffeisenstraße 7

D-83313 Siegsdorf, Germany

Telephone (+49) 86 62 / 61 0

Fax (+49) 86 62 / 61 166

Email: [email protected]

http://www.ecolab-engineering.com

General information

11 417102264 Rev. 5-01.2019

2 Safety

2.1 General Safety

DANGER!

If you assume that safe operation is no longer possible the pump must be put

out of service immediately and be secured against unauthorized use.

This is the case if:

–is visibly damaged

– appears no longer functional

– prolonged storage under unfavorable circumstances has occurred

(carry out function check).

The following notes should be observed:

–Before any work on the electrical section, disconnect power and secure

against being switched on again .

– The safety provisions for handling chemicals must always be observed and,

if applicable, suitable protective clothing must be worn

– Notes in the product data sheet of the used dosing medium has allways to

be observed.

– The installation may only used with the specified supply and control voltage

in the technical data.

2.2 Proper use

WARNING!

Proper use particularly includes the following points:

–Only validated chemical liquids may be metered.

– Depending on the material used, the metering system is designed for clean,

alkaline products.

– The temperature application range, the permissible ambient temperature

and the maximum media temperature are only permissible as indicated in

the "Technical Data".

– The metering capacity is between 5 and 120 l/h depending on viscosity and

back-pressure.

– The back-pressure must not exceed 1 MPa (10 bar), to DIN EN 809.

– The operating voltage may only be established as indicated in the

"Technical Data".

– The ambient temperature must be between +5 and +45 °C.

– The pump has been developed, designed and built for industrial and

commercial use. The unit is not intended for private use!

Any use which extends beyond or differs from the appropriate use is

considered improper use.

Intended use also includes compliance with all control and operating instructions

stipulated by the manufacturer, as well as with all maintenance and servicing conditions.

Safety

12417102264 Rev. 5-01.2019

WARNING!

Danger of improper use!

Improper use may result in dangerous situations:

–Never use metering media other than the specified product.

– Never change the product metering guidelines beyond the tolerable range.

– Do not use in potentially explosive areas.

– Installation, maintenance and repair work may only be carried out by

trained personnel.

– Wear the appropriate personal protective equipment (PPE) when carrying

out all installation, maintenance and repair work.

2.2.1 Reasonable foreseeable incorrect use

To maintain the function, we use this section in particular to draw your attention to ways in

which you may use the pump which, according to the risk analysis conducted by the

manufacturer, could result in reasonable foreseeable incorrect use.

nIncorrect use of design versions

(for example incorrect sealing materials, incorrect pump head materials).

nOperational incorrect voltage supplies.

nExcessive back-pressures.

nExcessive ambient temperatures.

nExcessive media temperature.

nIncompatible accessory parts.

nIncorrect dosing lines.

nLine cross-sections too small.

nIncorrect ambient temperatures or media temperatures.

nExcessive viscosities.

nOperation in potentially explosive atmospheres.

nUse of unsuitable dosing media.

2.2.2 Unauthorised modification and spare parts manufacture

CAUTION!

Unauthorised modifications or changes are only permissible following

discussion with and the approval of the manufacturer.

Original spare parts and accessories authorised by the manufacturer ensure

safety.

The use of other parts excludes liability for the consequences arising

from this.

Safety

13 417102264 Rev. 5-01.2019

2.3 Lifetime

In relation to the dependence of the adequate maintenance protocols the life time

is 2 years (visual and functional testing, replacement of wearing parts, etc.)

Afterwards a revision is necessary, in some cases also a subsequent general overhaul

by the manufacturer.

2.4 Safety measures taken by the operator

It is expressly up to the owner to train, monitor and instruct his operating and maintenance

personnel so that they comply with all of the necessary safety measures.

The frequency of inspections and controls must be complied with and documented.

2.5 Workforce requirements

Qualifications

DANGER!

Risk of injury if personnel are inadequately qualified!

If inadequately qualified personnel work on the system or are in the hazardous

area, hazards may arise that can cause serious injuries and significant material

damage.

– All work must be carried out by qualified personnel only!

–Keep unqualified personnel away from hazard areas.

NOTICE!

Only those individuals who can be expected to perform their work reliably are

authorised as personnel. Individuals whose reactions are impaired, e.g. by

drugs, alcohol, medicines, are not authorised. When selecting personnel, the

valid age and occupation-specific regulations must be observed.

Manufacturer

Certain work may only be carried out by specialist staff of the manufacturer or by staff

authorised or specially trained by the manufacturer. Other people or personnel are not

authorised to carry out this work.

To carry out this work, contact our customer service team.

Mechanic

The mechanic is trained for the particular range of tasks in which s/he operates and

knows the relevant standards and regulations.

The mechanic can perform work on pneumatic and hydraulic systems because of his/her

specialized training and experience and can independently recognise and avoid potential

dangers.

Operator

The operator has been instructed by the owner on the tasks entrusted to them and is

aware of the potential dangers associated with incorrect behaviour. The operator is only

permitted to carry out tasks that go beyond the scope of normal operation if these tasks

are specified in this manual and the owner has authorised the operator to do so.

Safety

14417102264 Rev. 5-01.2019

Production supervisor

The production supervisor is capable of performing the work assigned to them because of

their technical training, knowledge and experience, as well as awareness of the relevant

standards and regulations; they are able to autonomously identify and prevent potential

risks. The production supervisor is authorised to give orders to other listed personnel.

The production supervisor or authorised personnel are responsible for parameterisation of

the system.

Qualified electrician

Qualified electricians are able to carry out the work on electrical system because of their

technical training, knowledge and experience, as well as awareness of the relevant

standards and regulations; qualified electricians are capable of autonomously identifying

and preventing potential risks.

Qualified electricians are specially trained for the type of work they do and are familiar

with the relevant standards and regulations.

Service personnel

Certain work may only be carried out by the service staff of the manufacturer or by staff

authorised or specially trained by the manufacturer. Other people or personnel are not

authorised to carry out this work. To carry out this work, contact our customer service

team.

Specialist

A person with appropriate training, schooling and experience enabling him or her to

identify risks and avert danger.

2.6 Personal protective equipment (PPE)

DANGER!

Personal protective equipment, hereinafter referred to as PPE, is used to

protect personnel. It is imperative to pay attention to the PPE described in the

product data sheet (safety data sheet) for the metered medium.

2.7 Explanation of the safety symbols used

2.7.1 Personal protective equipment - PPE

WARNING!

Face guard

A face mask must be worn when working in areas which are marked with the

symbol opposite. The face protection is used to protect the eyes and face from

flames, sparks or glow as well as hot particles, exhaust gases or liquids.

WARNING!

Protective eyewear

Goggles must be worn when working in areas marked with the symbol

opposite. Protective eyewear protects the eyes against flying parts and liquid

splashes.

Safety

15 417102264 Rev. 5-01.2019

WARNING!

Protective work clothing

In the event of works in areas, which are identified with an adjacent symbol,

appropriate protective clothing is to be worn. Protective work clothing is close-

fitting clothing with low resistance to tearing, close-fitting sleeves and no

protruding parts.

WARNING!

Chemical resistant protective gloves

Suitable protective gloves must be worn when working in areas marked with

the symbol opposite. Chemical resistant safety gloves protect the hands from

aggressive chemicals.

WARNING!

Protective gloves, mechanical hazards

In the event of works in areas, which are identified with an adjacent symbol,

appropriate protective gloves are to be worn. Safety gloves provide protection

of the hands against friction, grazes, punctures or deeper wounds and against

coming into contact with hot surfaces.

WARNING!

Safety shoes

Suitable protective shoes must be worn when working in areas marked with the

symbol opposite. Safety shoes protect the feet from bruising, falling parts,

slipping on surfaces and protecting against aggressive chemicals.

2.7.2 Indications of risks

Electrical dangers

DANGER!

Electrical hazards are marked by the symbol opposite.

Work in these areas may only be carried out by trained personnel with the

appropriate authorisation.

Safety

16417102264 Rev. 5-01.2019

Risk due to electrical energy

DANGER!

Risk of fatal injury from electric current!

Contact with live parts represents immediate danger to life due to electrocution.

Damage to the insulation or individual components can be life-threatening.

– Before starting work, create a de-energised state and ensure this state for

the duration of the work.

–Work on electrical components may only be carried out by professional

electricians.

– Turn off immediately and organise repairs if there is any damage to the

insulation voltage supply.

– Never bridge or decommission fuses.

– When replacing fuses, observe the correct rating.

– Keep voltage-carrying parts away from moisture, as this can cause a short

circuit.

Risk of fire

DANGER!

Risk of fire

If there is a risk of fire, it is imperative to use the designated extinguishing

agent and to implement suitable safety measures to tackle the fire.

It is also imperative here to comply with the safety data sheet for the chemicals

you use to tackle the fire!

Risk of slipping

DANGER!

Slipping hazards are marked by the symbol opposite.

Spilled chemicals create a risk of slipping when wet.

WARNING!

Risk of slipping due to fluid in the operation and provisioning area!

–Wear non-slip, chemically resistant shoes when working.

– Place product containers in a tank to prevent a slipping hazard caused by

leaking fluids.

ENVIRONMENT!

Immediately soak up any leaking liquids with a suitable binding agent and

dispose of properly.

Safety

17 417102264 Rev. 5-01.2019

Unauthorised access

DANGER!

Unauthorised access

The owner must ensure that unauthorised personnel are prevented from

accessing the operating area.

Chemical hazards (dosing medium/active substance)

DANGER!

Risk of injury to the skin and eyes caused by the chemical used

(dosing medium).

– Read the enclosed safety data sheet carefully before using the dosing

medium.

– The safety regulations and the prescribed protective clothing must be

complied with when working with chemicals.

– Attention must be paid to the information included on the product data

sheet of the dosing medium used.

DANGER!

It is essential that that hands are washed prior to work breaks and at the end of

the working day. Information about the usual precautions when handling

chemicals and about the use of PPE can be found on the relevant safety data

sheet for the chemical being used and must be complied with.

ENVIRONMENT!

Leaked, spilled dosing media can harm the environment.

Leaked, spilled dosing media must be cleaned and disposed of correctly,

according to the instructions on the product data sheet. It is essential to ensure

that the required personal protective equipment is used.

Preventive action:

–Place product containers in a tank to collect leaking fluids without harming

the environment.

Safety data sheets

DANGER!

Safety data sheets are always provided with the supplied chemicals. These

sheets must be read, understood and all instructions implemented on site

before using the chemicals.

The operator must provide the required personal protective equipment (PPE)

and the described emergency equipment based on the safety data sheets

(e.g. eye bottle, etc.). In addition, the operator must instruct and train the

persons entrusted with machine operation as appropriate.

The safety data sheet is primarily intended for the user so that he or she can take any

steps necessary for safeguarding his health and safety at work.

Safety

18417102264 Rev. 5-01.2019

If you are not sure you have a current version of the safety data sheet, please contact

your Ecolab consultant. He/she will be glad to assist you in ensuring that the measures for

safeguarding health in the workplace are guaranteed.

DANGER!

The safety data sheets must be displayed close to the instrument or close to

the supply containers so that the relevant countermeasures can be initiated in

the event of an accident.

Hazard arising from automatic start-up

DANGER!

Automatic start-up poses a hazard in areas marked with the symbol opposite.

An automatic start-up can be initiated as soon as the power supply is

connected with no need to press a switch/button beforehand.

DANGER!

Danger of automatic start of the pump

The the pump is automatically started by connecting the power supply already,

without having to press a switch / button before.

For security reasons the [auto start] function is not activated when the

pump is delivered.

Hazards caused by pressurised components

DANGER!

Danger of injury from pressurised components!

With improper handling, pressurised components can move uncontrollably and

cause severe injuries. Liquid under high pressure can escape from pressurised

components if handled improperly or in the case of a defect. This can lead to

severe or fatal injuries.

– Establish a pressure-free state.

–Discharge any residual energy.

– Make sure that liquids cannot discharge accidentally.

– Immediately call in qualified staff to replace defective components which

are pressurised during operation.

2.7.3 Environmental protection measures

ENVIRONMENT!

The environmental symbol denotes environmental protection measures.

Safety

19 417102264 Rev. 5-01.2019

2.8 Obligations of the operator

In the EEA (European Economic Area), national implementation of the

Directive (89/391/EEC) and corresponding individual directives, in particular

the Directive (2009/104/EC) concerning the minimum safety and health

requirements for the use of work equipment by workers at work, as amended,

are to be observed and adhered to.

The operator must adhere to the local legal provisions for:

npersonnel safety (employers' insurance association and accident prevention

regulations, workplace directives), e.g. operating instructions, including those in

accordance with Section 20 Hazardous Substances Ordinance (GefStoffV), personal

protective equipment (PPE), health screening;

nsafety of work materials and tools (protective equipment, work instructions, procedural

risks and maintenance);

nproduct procurement (safety data sheets, list of hazardous substances);

ndisposal of products (Waste Act);

ndisposal of materials (decommissioning, Waste Act);

ncleaning (detergents and disposal);

nas well as complying with current environment protection regulations.

The owner is also required:

nto provide personal protective equipment (PPE).

nto incorporate the measures into operating instructions and to instruct personnel

accordingly;

nfor operating sites (from 1m above ground): to provide safe access;

nto provide suitable workplace lighting in accordance with ASR 7/3.

nto ensure that local regulations are complied with during installation and

commissioning, if these procedures are conducted by the owner.

2.9 Installation, Maintenance and Repairs

NOTICE!

Material damage by using incorrect tools!

Material damage may arise by using incorrect tools during assembly,

maintenance or troubleshooting. Only use the correct tools.

Safety

20417102264 Rev. 5-01.2019

This manual suits for next models

39

Table of contents

Other Ecolab Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

illumina

illumina MiSeqDx Instrument Safety and compliance guide

Heathrow Scientific

Heathrow Scientific Mini Stirrer 1L instruction manual

Leica

Leica CM3600 XP Instructions for use

Flexicon

Flexicon PF7 user manual

Hach Ultra

Hach Ultra ORBISPHERE 3658 Operator's quick guide

Hexagon

Hexagon IRP60.00 operating instructions

amsbio

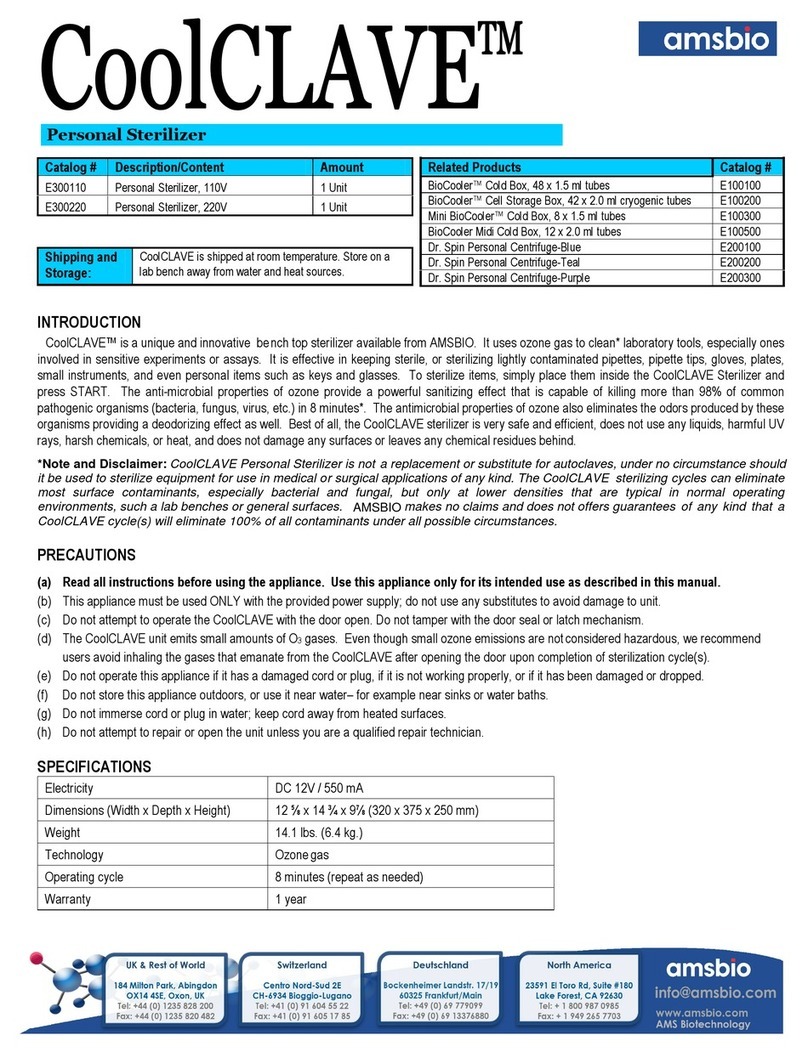

amsbio CoolCLAVE E300110 manual

HumanLab

HumanLab SHWB-30 Operation manual

Thermo Scientific

Thermo Scientific Finnpipette F2 Instructions for use

Bibby Sterilin

Bibby Sterilin Stuart SBS40 Instructions for use

Thermo Scientific

Thermo Scientific Cryofuge 8 instruction manual

Vestfrost

Vestfrost VLS 024 SDD Instructions for use