Catalog #66012 & #66013

©2006 Edelbrock Corporation Page 2 of 3

Brochure #63-66012

Rev. 5/06 - DA/mc

DISASSEMBLY

1. Disconnect negative battery cable.

2. Raise vehicle and remove O2 sensor from catalytic

converter, being careful not to damage.

3. Unbolt and remove exhaust pipe/catalytic converter

assembly. Before removing exhaust pipe/catalytic

converter assembly, determine the position of

catalytic inlet for re-installation. Either note

measurements or mark bottom of floorboard with

chalk to show catalytic location. (Do not damage

converter).

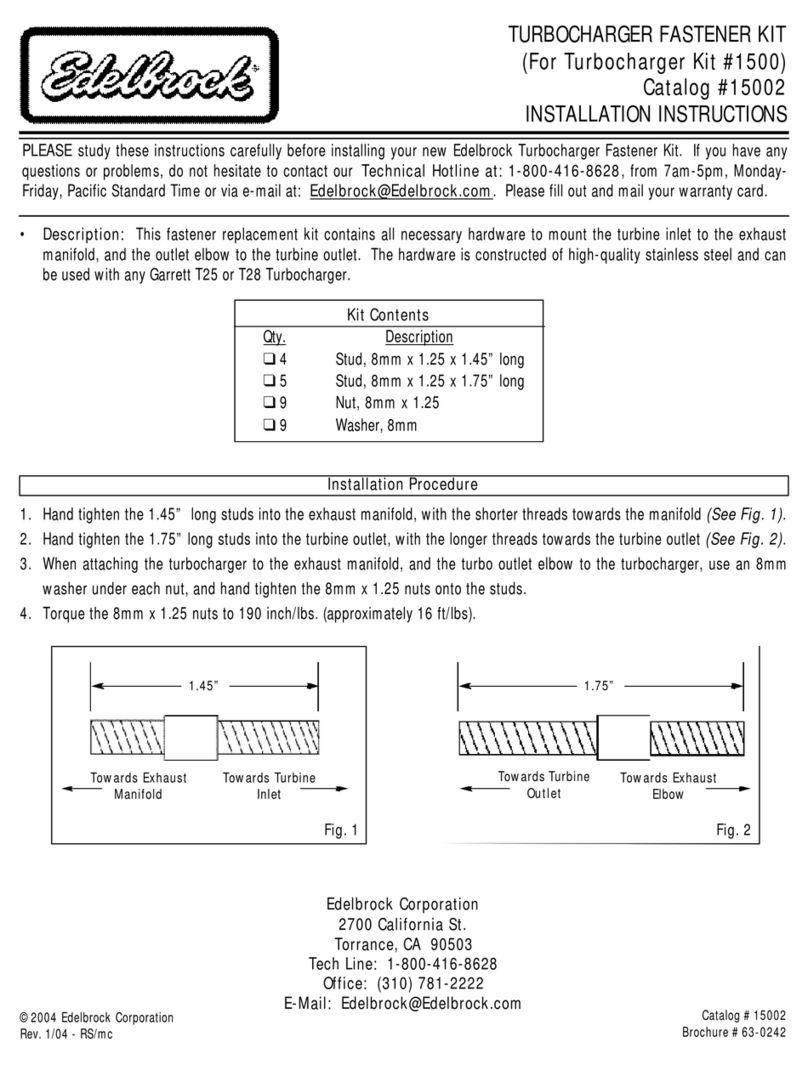

4. Cut head pipes off from catalytic converter

approximately 1/2” ahead of weld

(See Figure 1)

.

RIGHT SIDE

1. Remove air inlet from engine to intake manifold.

2. Remove spark plugs.

3. Unbolt E.G.R. flange from manifold.

4. Remove manifold and studs.

5. Install T.E.S. flange gasket and T.E.S. manifold from

top. Install header bolts supplied, and leave loose

enough to ensure proper alignment.

NOTE: Use flat washers at slotted ends and lock

washers on all bolts.

6. Re-attach E.G.R. tube (1996 only - install block-off

plate supplied on T.E.S.).

7. Install right extension to catalytic (slip over the top

catalytic nipple) and bolt onto right T.E.S. manifold

with donut gasket in place.

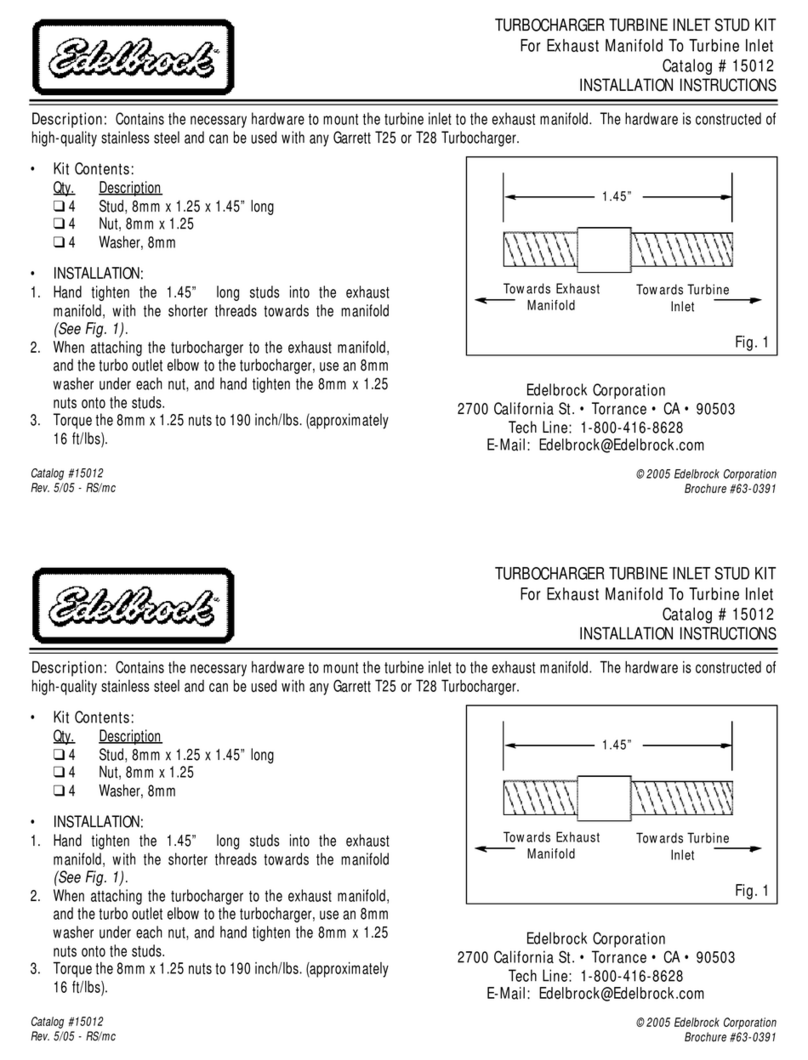

8. Tighten flange bolts. Be sure to locate donut gasket

with equal space all around for the best seal

(See

Figure 2)

.

9. With everything in place, tack weld extension pipe to

catalytic converter.

NOTE: Tack welding should not be done until the

entire system is securely bolted in place. MIG

welding is desirable but gas welding can be used.

LEFT SIDE

1. Remove spark plugs.

2. Remove exhaust manifold and studs.

3. Install T.E.S. flange gasket and T.E.S. manifold from

top.

4. Install left crossover pipe with donut gasket over

catalytic nipple and bolt onto T.E.S. Be sure to

locate donut gasket with equal space all around for

the best seal (See Figure 2).

5. With everything in place, tack weld left crossover

pipe to catalytic converter.

NOTE: MIG welding is desirable but gas welding

can be used.

6. After tack welding, remove assembly and complete

weld.

7. Re-install assembly and tighten all bolts.

8. Re-install spark plugs and wires.

9. Check all wires and lines for adequate clearance.

FINAL INSPECTION

1. Check all hydraulic, vacuum, and fuel lines to

ensure there is adequate clearance to T.E.S.

components.

2. Re-connect battery.

3. At this point, it is a good idea to look everything

over and make sure that nothing was missed in

assembly.

4. Start vehicle and bring up to normal operating

temperature. Check for possible leaks.

5. Turn engine off and let cool. Tighten all bolts again.

INSTALLATION INSTRUCTIONS