© Edwards Limited 2015. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D146-71-880 Issue E

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 General description ..................................................................................................... 1

1.3 Gas dependency .......................................................................................................... 2

2 Technical data ....................................................................................3

2.1 Mechanical data .......................................................................................................... 3

2.2 Performance, operating and storage conditions .................................................................... 3

2.3 Electrical data ............................................................................................................ 3

2.4 Error monitoring ......................................................................................................... 4

2.5 Materials exposed to vacuum .......................................................................................... 4

3 Installation .........................................................................................5

3.1 Unpack and inspect ...................................................................................................... 5

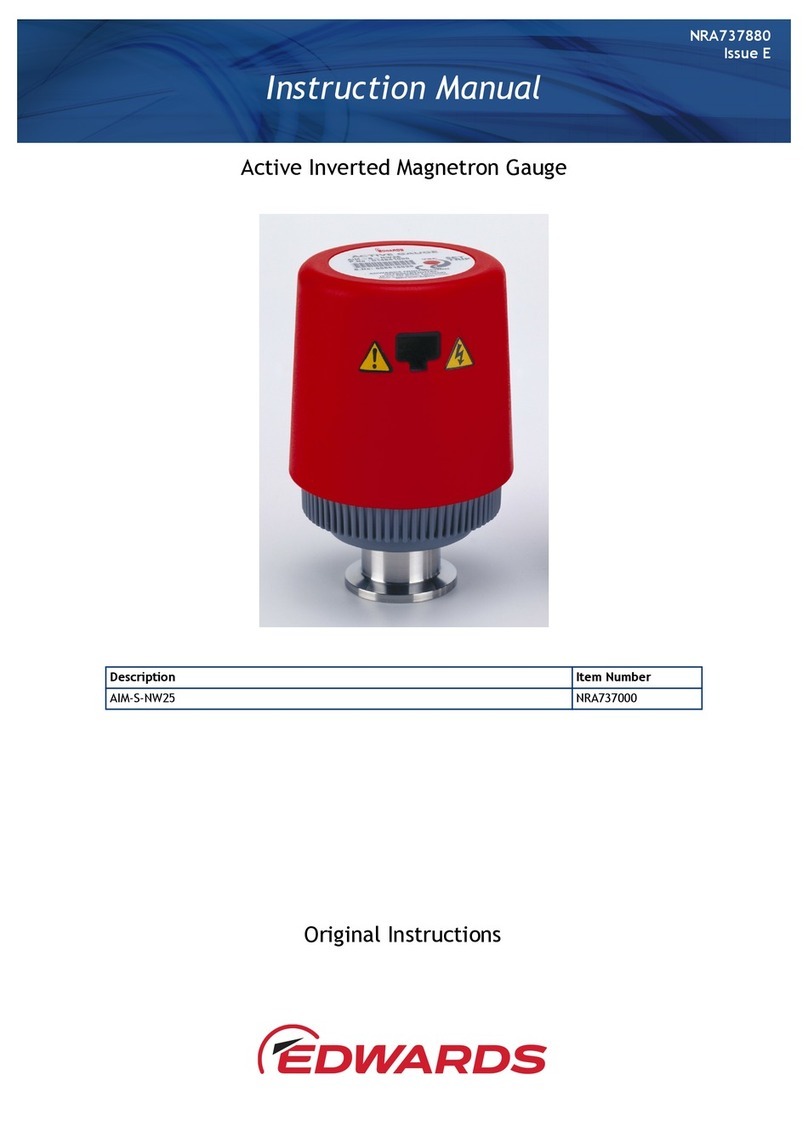

3.2 Fit the AIM gauge to the vacuum system ............................................................................. 5

3.3 Electrical connection .................................................................................................... 5

3.3.1 Connect to Edwards controllers or AGD display ..................................................................... 5

3.3.2 Connect to your own supply and control equipment ............................................................... 6

4 Operation ..........................................................................................9

4.1 Safety ......................................................................................................................9

4.2 Enable and disable the AIM gauge ..................................................................................... 9

4.3 Pressure measurement .................................................................................................. 9

4.4 Set-point .................................................................................................................10

5 Maintenance ..................................................................................... 13

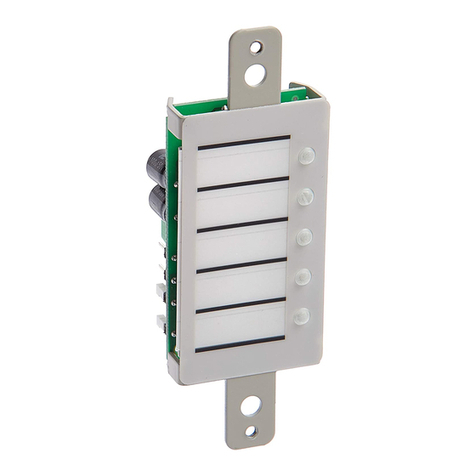

5.1 Introduction .............................................................................................................13

5.2 Replace the body tube .................................................................................................13

5.2.1 Remove the AIM gauge from the vacuum system ..................................................................13

5.2.2 Fit the new body tube .................................................................................................13

5.2.3 Refit the AIM gauge to the vacuum system .........................................................................13

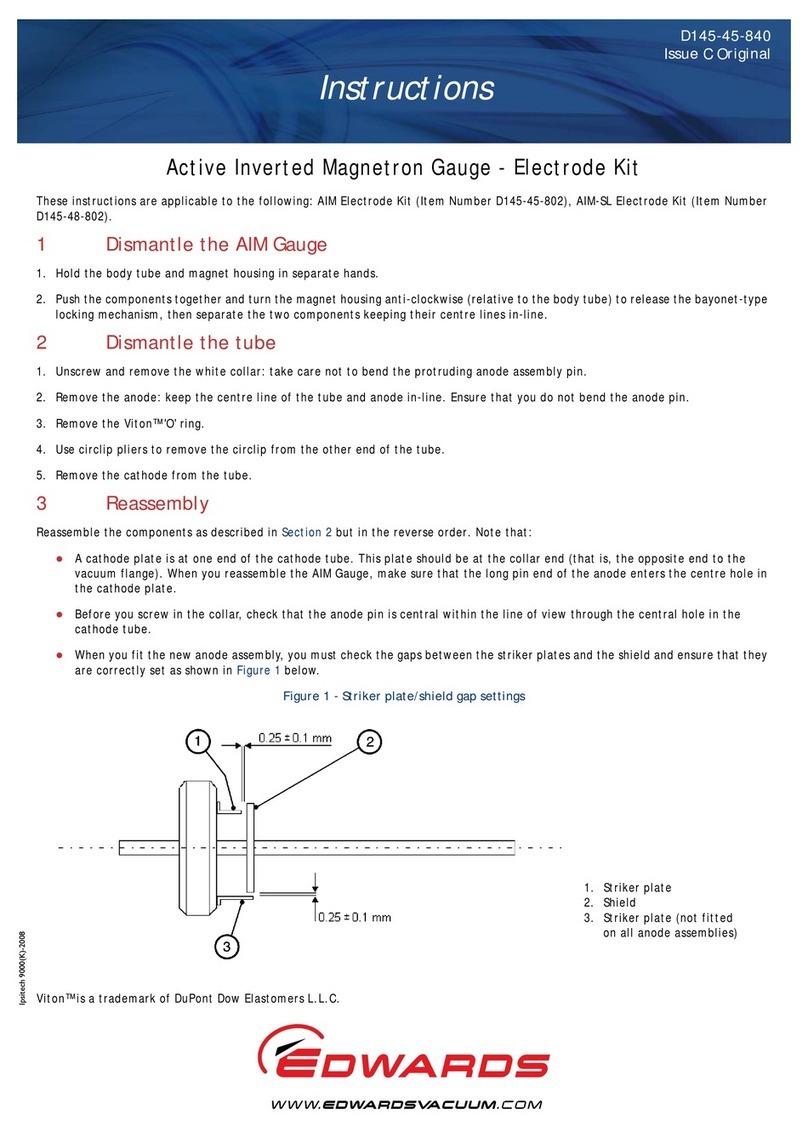

5.3 Replace the electrode assembly ......................................................................................14

5.4 Replace the electronics and magnet housing ......................................................................14

5.5 Clean the internal components .......................................................................................15

5.6 Fault finding .............................................................................................................15

6 Storage and disposal ........................................................................... 17

6.1 Storage ...................................................................................................................17

6.2 Disposal ...................................................................................................................17

7 Spares and accessories ......................................................................... 19

7.1 Introduction .............................................................................................................19

7.2 Spares .....................................................................................................................19

7.3 Accessories ...............................................................................................................19

Index .............................................................................................. 21

For return of equipment, complete the HS Forms at the end of this manual.

dcs/7692/07/15