Edwards ATC-E User manual

D351-08-880

Issue K

Original Instructions

Instruction Manual

Active Thermocouple Gauge

Description Item Number

ATC-E D351-08-000

This product has been manufactured under a quality management system certified to ISO 9001:2008

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

Active Thermocouple Gauge D351-08-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61326-2-3: 2013 Electrical equipment for measurement, control and laboratory

(Class B Emissions, Use. EMC requirements. Particular requirements. Test

Basic Immunity) configuration, operational conditions and performance criteria

for transducers with integrated or remote signal conditioning

EN50581: 2012 Technical Documentation for the Assessment of Electrical and

Electronic Products with respect to the Restriction of Hazardous

Substances

and fulfils all the relevant provisions of

2014/30/EU Electromagnetic Compatibility (EMC) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

2012/19/EU Waste Electrical and Electronic Equipment (WEEE) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

19.08.2015, Eastbourne

Larry Marini, Senior Technical Manager Date and Place

P200-02-560 Issue H

© Edwards Limited 2015. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D351-08-880 Issue K

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope of this manual .................................................................................................... 1

1.2 General .................................................................................................................... 1

2 Technical data ....................................................................................3

2.1 Operating conditions .................................................................................................... 3

2.2 Performance .............................................................................................................. 3

2.2.1 Output signal .............................................................................................................3

2.2.2 setpoint ................................................................................................................... 3

2.2.3 Gauge identification signal ............................................................................................. 3

2.3 Mechanical data .......................................................................................................... 4

2.4 Electrical data ............................................................................................................ 4

2.4.1 Electrical supply data ................................................................................................... 4

2.4.2 Electronic interface ..................................................................................................... 4

2.5 Thermocouple gauge tubes ............................................................................................. 4

2.5.1 Materials exposed to vacuum .......................................................................................... 4

2.5.2 Colour coding .............................................................................................................5

2.5.3 Pressure range ........................................................................................................... 5

2.5.4 Thermocouple temperature ............................................................................................ 5

2.5.5 Maximum internal overpressure ....................................................................................... 5

3 Installation .........................................................................................7

3.1 Unpacking and inspection .............................................................................................. 7

3.2 Connection to the vacuum system .................................................................................... 7

3.3 Positioning the gauges .................................................................................................. 7

3.4 Electrical connection .................................................................................................... 7

3.5 Gauge setpoint trip ...................................................................................................... 7

3.5.1 Adjusment ................................................................................................................ 7

3.5.2 Trip output ................................................................................................................ 8

4 Operation ........................................................................................ 13

4.1 Reading the pressure ...................................................................................................13

4.2 Gas dependency .........................................................................................................13

5 Maintenance ..................................................................................... 15

5.1 General ...................................................................................................................15

5.2 Fault finding .............................................................................................................15

6 Storage and disposal ........................................................................... 17

6.1 Storage ...................................................................................................................17

6.2 Disposal ...................................................................................................................17

7 Accessories ...................................................................................... 19

7.1 Introduction .............................................................................................................19

7.2 Accessories ...............................................................................................................19

7.2.1 Cables ....................................................................................................................19

7.3 ATC spares ...............................................................................................................19

For return of equipment, complete the HS Forms at the end of this manual.

dcs/7692/07/15

D351-08-880 Issue K

Page ii © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

Illustrations

Figure Page

1 General view of gauge .................................................................................................. 9

2 Connection to external power supply ...............................................................................10

3 Connection of external relay .........................................................................................10

Tables

Table Page

1 Pressure/voltage characteristic for DV4D ...........................................................................11

2 Pressure/voltage characteristic for DV6M ..........................................................................12

© Edwards Limited 2015. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

D351-08-880 Issue K

1Introduction

1.1 Scope of this manual

This manual provides installation, operation and routine maintenance instructions for the Edwards Active

Thermocouple Gauge. Read this manual before installing and operating the gauge.

This manual contains essential safety information which supplements the safety features of the gauge. Safety

procedures are highlighted as WARNING and CAUTION instructions. You must obey these instructions. The use of

WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The following labels appear on the gauge:

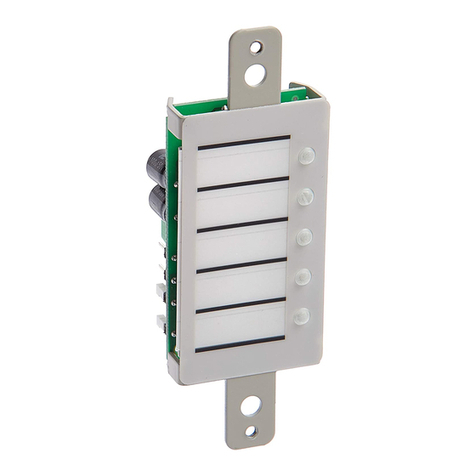

1.2 General

The family of Active vacuum instruments is a new generation of stand-alone units which combine gauge-head and

controller in one active unit. The Active Thermocouple Gauge (ATC) consists of an electronics module which is

compatible with two types of Thermocouple gauge tubes, the DV4D and DV6M. The module connects to the tube via

a standard octal socket. The ATC requires a 13.5 to 36 V d.c. power supply, the pressure reading can be monitored

with a simple voltmeter or the analogue to digital converter of a data acquisition system. The type of Gauge tube to

be used is selected by a colour-coded two-position switch located in the top of the electronics module. The

electronics module also has a potentiometer used to adjust the operating pressure of a setpoint and a LED which

indicates the status of the setpoint. The gauge tubes terminate in a 1/8 inch NPT fitting. An adapter to allow

connection to NW16 flanges is available from Edwards (refer to spares list). Figure 1 illustrates the main features of

the ATC gauge.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

D351-08-880 Issue K

Page 2 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2015. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D351-08-880 Issue K

2Technicaldata

2.1 Operating conditions

2.2 Performance

2.2.1 Output signal

2.2.2 setpoint

The setpoint consists of an open drain transistor (FET) output which operates when the gauge pressure is below a

preset value. The setpoint has a fixed hysteresis of 1.2 V, that is, if the trip level is set to 4 V, then the trip is set

(ON) when the gauge output is below 4 V and reset (OFF) above 5.2 V. When the trip is 'ON' pin 6 is internally

connected to pin 2 (power supply common) and the red LED is illuminated.

Note: The external load must not exceed these ratings.

2.2.3 Gauge identification signal

The gauge identification signal is measured between pins 4 and 5, the readings are dependent upon the position of

the gauge select switch.

Operating temperature 5 °C to 50 °C

Relative humidity (non-condensing) 10 - 90%

Maximum operating altitude 2000 m

Voltage range 2 V to 10 V d.c.

Error status < 2 V or > 10 V d.c.

Minimum load 10 k

Maximum current source 1 mA

Settable range 2.2 to 8.5 V

Fixed hysteresis 1.2 V

setpoint output transistor ratings

Voltage rating 40 V

Current rating 100 mA

DV4D 56 k

DV6M 68 k

D351-08-880 Issue K

Page 4 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

2.3 Mechanical data

2.4 Electrical data

2.4.1 Electrical supply data

2.4.2 Electronic interface

2.5 Thermocouple gauge tubes

Data refers to DV4D and DV6M unless otherwise stated.

2.5.1 Materials exposed to vacuum

Nickel plated steel, alloy 52 (iron nickel) pins, stainless steel, gold, platinum, rhodium and palladium. The DV4D also

has a small amount of 60 Tin/40 lead solder.

Electronics module 56 mm (height) x 57 mm diameter.

Gauge tube 78 mm (length) x 32 mm diameter.

Assembled length of tube and electronics module 115 mm

Gauge tube volume DV4D 0.82 cm3

DV6M 8.2 cm3

Total weight:

Electronics module and gauge tube 120 grams

Vacuum connection 1/8 inch NPT

Input voltage range 13.5 V to 36 V d.c.

Maximum voltage ripple 1 V peak to peak

Maximum power consumption 540 mW

(when driven at 36 V d.c. at vacuum)

Socket connection FCC68, 8 way Western Electric

Pin allocation (See Figure 1 inset)

1 Power supply positive voltage

2Powersupplycommon

3 Gauge output signal

4 Gauge identification signal

5 Signal common

6setpointoutput

7Notconnected

8Notconnected

© Edwards Limited 2015. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D351-08-880 Issue K

2.5.2 Colour coding

The gauge tubes are colour-coded on the label and plastic socket moulding as follows:

2.5.3 Pressure range

When used with ATC electronics module.

2.5.4 Thermocouple temperature

All values relative to ambient temperature.

2.5.5 Maximum internal overpressure

DV4D Purple

DV6M Yellow

DV4D 50 to 5 E-2 torr (65 to 6.5 E-2 mbar)

DV6M 1 to 1E-3 torr (13 - 1.3E-3 mbar)

At vacuum DV4D 250 °C

DV6M 300 °C

At atmosphere DV4D 30 °C

DV6M 6 °C

DV4D 10.3 bar absolute. (150 psia)

DV6M 3.4 bar absolute. (50 psia)

D351-08-880 Issue K

Page 6 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2015. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D351-08-880 Issue K

3 Installation

3.1 Unpacking and inspection

Remove all packing materials and protective covers and check the gauge for damage. If the gauge is damaged, notify

the supplier and the carrier in writing within three days; state the Item Number of the gauge together with the order

number and the supplier's invoice number. Retain all packing materials for inspection. Do not use the gauge.

3.2 Connection to the vacuum system

The Thermocouple Gauge tubes terminate in an 1/8 inch NPT fitting. To connect to a tube terminating in a NW16

flange, an 'O' ring, a centring ring (or coseal) and clamp will be required. A tube terminating in a 1/8 inch NPT fitting

must be connected to the corresponding female 1/8 inch NPT part. To ensure a leak tight connection wrap a few

turns of PTFE tape round the 1/8 inch NPT thread before joining the mating parts. The gauge can be mounted in any

orientation, however in order to avoid the build-up of condensable material / liquids in the body tube (causing

probable reading errors) a vertical attitude is preferred, that is, the body tube should be vertical with the

1/8 inch NPT fitting below it.

3.3 Positioning the gauges

The gauges should be mounted as close a possible to the point at which the pressure is to be measured. Use a short

connecting tube with an internal diameter not less than that of the gauge tube. Long, narrow and angled connections

can cause a significant reading error.

3.4 Electrical connection

Figure 2 shows how the gauge should be connected to an external power supply and voltmeter. Refer to Section 2.2

for full specification of the power supply. A voltage between 13.5 - 36 V should be applied between pins 1 and 2 of

the connector. Connect the gauge before switching ON. The signal output can be measured between pins 3 and 5. It

is important to keep the signal common (Figure 3, item 5) separate from the power supply common (2) for accurate

readings. Note that the electronics earth is isolated from the metal thermocouple body tube.

When using a cable longer than 30 m, full compliance with European Standards requires an in-line surge suppressor

(please refer to Section 7.2.1).

3.5 Gauge setpoint trip

3.5.1 Adjusment

The setpoint trip is adjusted by a single turn potentiometer accessed through a labelled hole in the top of the

electronics module (see Figure 1). The pressure at which the trip operates can be visually set by comparing the

position of the arrow on the single turn potentiometer with the adjacent moulded scale. This scale is calibrated in

volts, each tick mark representing 1 volt intervals (see Figure 1). The voltage to pressure conversion for the trip level

is identical to that of the gauge signal output and is shown in Table 1 and 2.

D351-08-880 Issue K

Page 8 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

3.5.2 Trip output

Figure 3 illustrates how the open drain transistor output of the setpoint could be connected to operate an external

relay (D) (refer to Key).

Note: The external load must not exceed the ratings specified in Section 2.2.2.

Due to the inductive nature of a relay, a transient voltage can be generated when the relay is switched OFF. The

surge rating of the back emf clamping diode must be at least ten times the rated operating current of the relay, that

is, a minimum of 1 amp surge rating and have a minimum reverse voltage rating of 100 volts.

© Edwards Limited 2015. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D351-08-880 Issue K

Figure 1 - General view of gauge

View of socket

End view showing switch, LED and

setpoint adjustment

D351-08-880 Issue K

Page 10 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 2 - Connection to external power supply

Figure 3 - Connection of external relay

A. Active thermocouple gauge

B. Power supply

C. Voltmeter or chart recorder

1. Positive supply

2. Supply common

A. Active thermocouple gauge

B. Power supply

D. External d.c. relay

E. Back EMF suppressor diode

1. Positive supply

2. Supply common

3. Signal output

5. Signal common

6. Set-point output

© Edwards Limited 2015. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D351-08-880 Issue K

Table 1 - Pressure/voltage characteristic for DV4D

Pressure torr Output voltage DV4D Pressure mbar

1.0E-02 2.00 1.3E-02

2.0E-02 2.07 2.6E-02

4.0E-02 2.23 5.3E-02

5.0E-02 2.31 6.6E-02

6.0E-02 2.39 8.0E-02

8.0E-02 2.53 1.1E-01

1.0E-01 2.68 1.3E-01

2.0E-01 3.32 2.6E-01

4.0E-01 4.41 5.3E-01

5.0E-01 4.79 6.6E-01

6.0E-01 5.18 8.0E-01

8.0E-01 5.74 1.1E+00

1.0E+00 6.18 1.3E+00

2.0E+00 7.60 2.6E+00

4.0E+00 8.73 5.3E+00

5.0E+00 8.92 6.6E+00

6.0E+00 9.11 8.0E+00

8.0E+00 9.32 1.1E+01

1.0E+01 9.42 1.3E+01

2.0E+01 9.72 2.6E+01

4.0E+01 9.88 5.3E+01

5.0E+01 9.89 6.6E+01

6.0E+01 9.91 8.0E+01

8.0E+01 9.93 1.1E+02

1.0E+02 9.94 1.3E+02

2.0E+02 9.97 2.6E+02

5.0E+02 9.98 6.6E+02

7.6E+02 10.00 1.0E+03

D351-08-880 Issue K

Page 12 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Table 2 - Pressure/voltage characteristic for DV6M

Pressure torr Output voltage DV6M Pressure mbar

1.0E-04 2.00 1.3E-04

5.0E-04 2.19 6.6E-04

1.0E-03 2.25 1.3E-03

2.0E-03 2.38 2.6E-03

4.0E-03 2.62 5.3E-03

6.0E-03 2.84 8.0E-03

8.0E-03 3.06 1.1E-02

1.0E-02 3.27 1.3E-02

2.0E-02 4.16 2.6E-02

4.0E-02 5.56 5.3E-02

5.0E-02 6.01 6.6E-02

6.0E-02 6.46 8.0E-02

8.0E-02 7.04 1.1E-01

1.0E-01 7.42 1.3E-01

2.0E-01 8.59 2.6E-01

4.0E-01 9.40 5.3E-01

5.0E-01 9.50 6.6E-01

6.0E-01 9.60 8.0E-01

8.0E-01 9.71 1.1E+00

1.0E+00 9.76 1.3E+00

2.0E+00 9.89 2.6E+00

4.0E+00 9.96 5.3E+00

5.0E+00 9.97 6.6E+00

1.0E+01 10.00 1.3E+01

© Edwards Limited 2015. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Operation

D351-08-880 Issue K

4 Operation

CAUTION

Do not operate Active Thermocouple gauges above an ambient temperature of +50 °C.

4.1 Reading the pressure

The Active Thermocouple gauges have a 2 - 10 V d.c. analog output signal which is a function of pressure. To find the

pressure, the output voltage is measured (between pins 3 and 5 on the connector) using a standard voltmeter and

compared to the appropriate calibration table. (Table 1 or 2).

4.2 Gas dependency

The rate of heat transfer through a gas is dependent upon both the pressure and the relative molecular mass (RMM)

of the gas. Hence the output of signal of the ATC gauge will also be gas dependent. The calibration Table 1 and 2

apply to Nitrogen and dry air, but can also be used when measuring the pressure of gases having a similar RMM such

as Oxygen and Carbon Monoxide. Generally, with gases having a lower RMM than Nitrogen, the gauge output will read

too high, and with high RMM gases the output will read too low. Calibration graphs for use with argon, krypton,

helium, carbon dioxide and carbon monoxide are available on request. (Application Note P400-71-000).

WARNING

Do NOT exceed the maximum internal pressure stated in Section 2.

WARNING

Do NOT use the Active Thermocouple gauge to measure the pressure of explosive or flammable gas

mixtures.

WARNING

Do NOT operate the Active Thermocouple Gauge in external explosive atmospheres. (No special

precautions are made to limit the energy in the gauge electronics to the low levels necessary to

make an explosion impossible).

WARNING

An Instrument failure could cause a malfunction of signal outputs. If malfunction of a gauge could

cause danger to life or limb, additional safeguards MUST be taken.

WARNING

When measuring gases of high molecular weight the pressure indicated can be well below the true

pressure. Ensure that the gauge is not over-pressurised when using heavy gases.

D351-08-880 Issue K

Page 14 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2015. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

D351-08-880 Issue K

5Maintenance

5.1 General

There are no user serviceable parts in either the electronics module or the gauge tubes.

5.2 Fault finding

There are three major causes of a fault indication.

The gauge type is incorrectly selected on the 'SELECT' switch

The power supply or electronics has failed

The gauge tube is faulty.

If the gauge output is < 1.5 V or >10.5 V it is possible that the electronics module is not correctly connected to the

gauge tube, or that the gauge tube is faulty. The user should check for correct connections (Section 3) and ensure

that the power supply voltage is in the range 13.5 - 36 V d.c. positive and that the polarity of the voltmeter is correct

with respect to pins 3 and 5, that is, Pin 3 is signal output positive (see Figure 2). The user should also check the

position of the gauge tube selector switch, Yellow for DV6M and Purple for DV4D.

If the gauge output is >1.5 V and < 2 V (or >10 and < 10.5 V) it could be caused by a difference in gauge tubes, or an

indication that the gauge tube is nearing the end of its useful life, due to contamination.

D351-08-880 Issue K

Page 16 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

Table of contents

Other Edwards Measuring Instrument manuals

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards TruWave User manual

Edwards

Edwards IG40 BA User manual

Edwards

Edwards APGX-H User manual

Edwards

Edwards GXS 0-60 SLM User manual

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards AIM User manual

Edwards

Edwards PRG20K User manual

Edwards

Edwards AIM-S-NW25 User manual