Edwards GXS 0-60 SLM User manual

This manual suits for next models

3

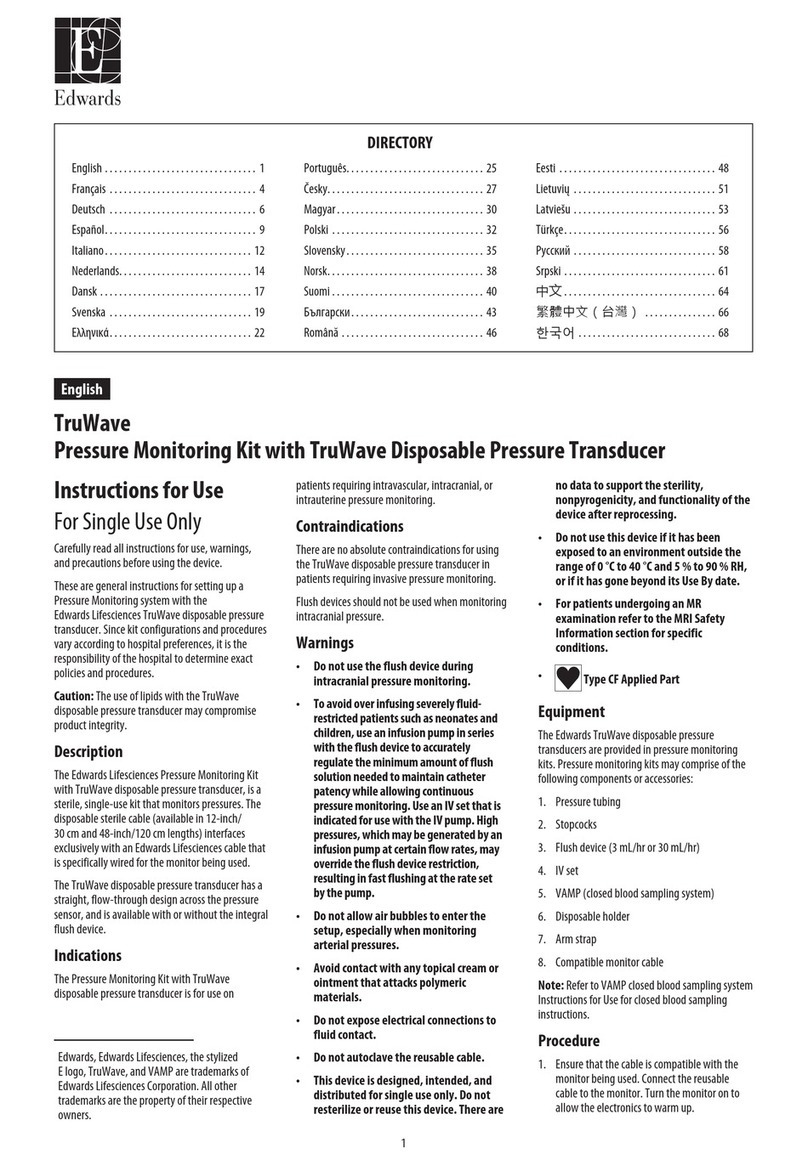

Table of contents

Other Edwards Measuring Instrument manuals

Edwards

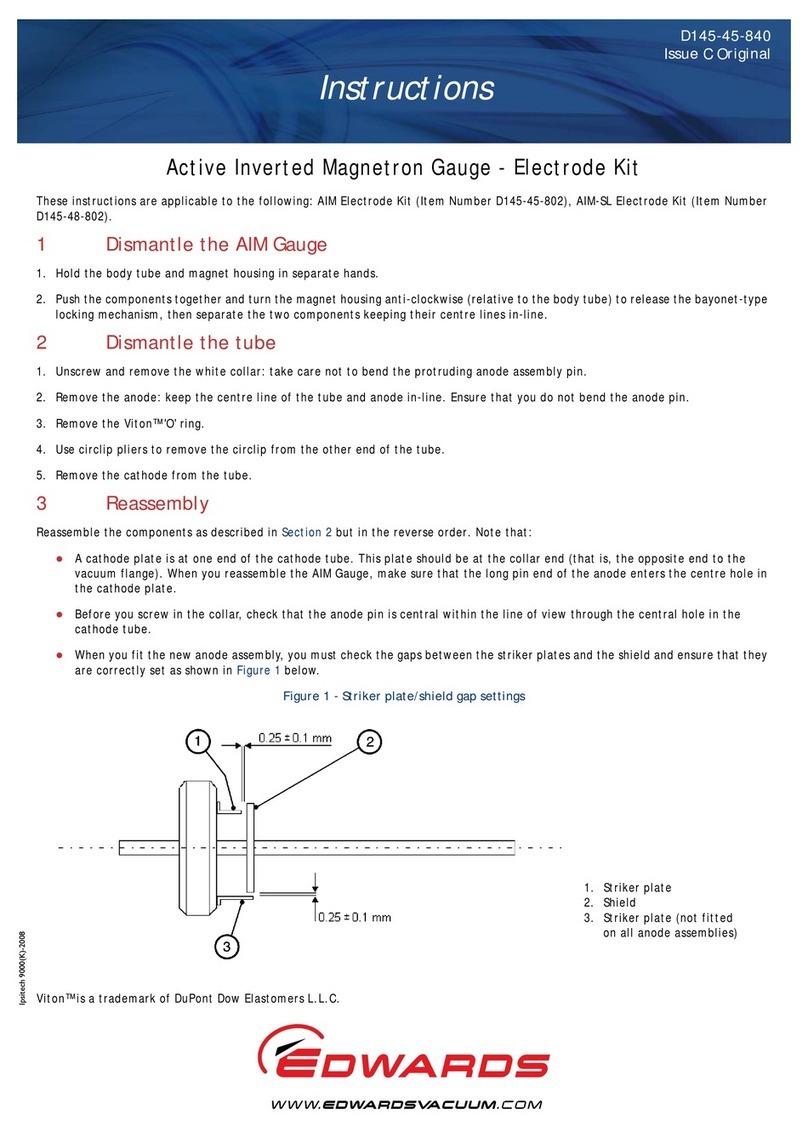

Edwards FSRZI-A Assembly instructions

Edwards

Edwards AIM User manual

Edwards

Edwards Barocel 7045 User manual

Edwards

Edwards PRG20K User manual

Edwards

Edwards APGX-H User manual

Edwards

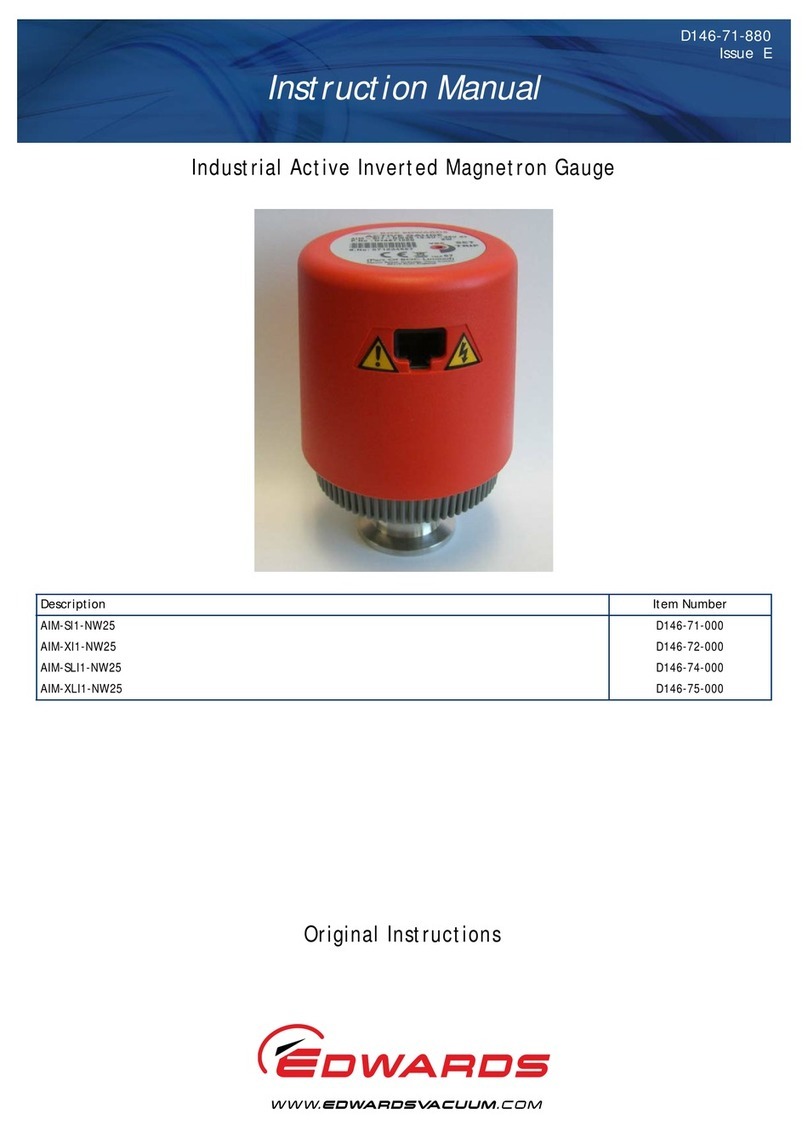

Edwards AIM-SI1-NW25 User manual

Edwards

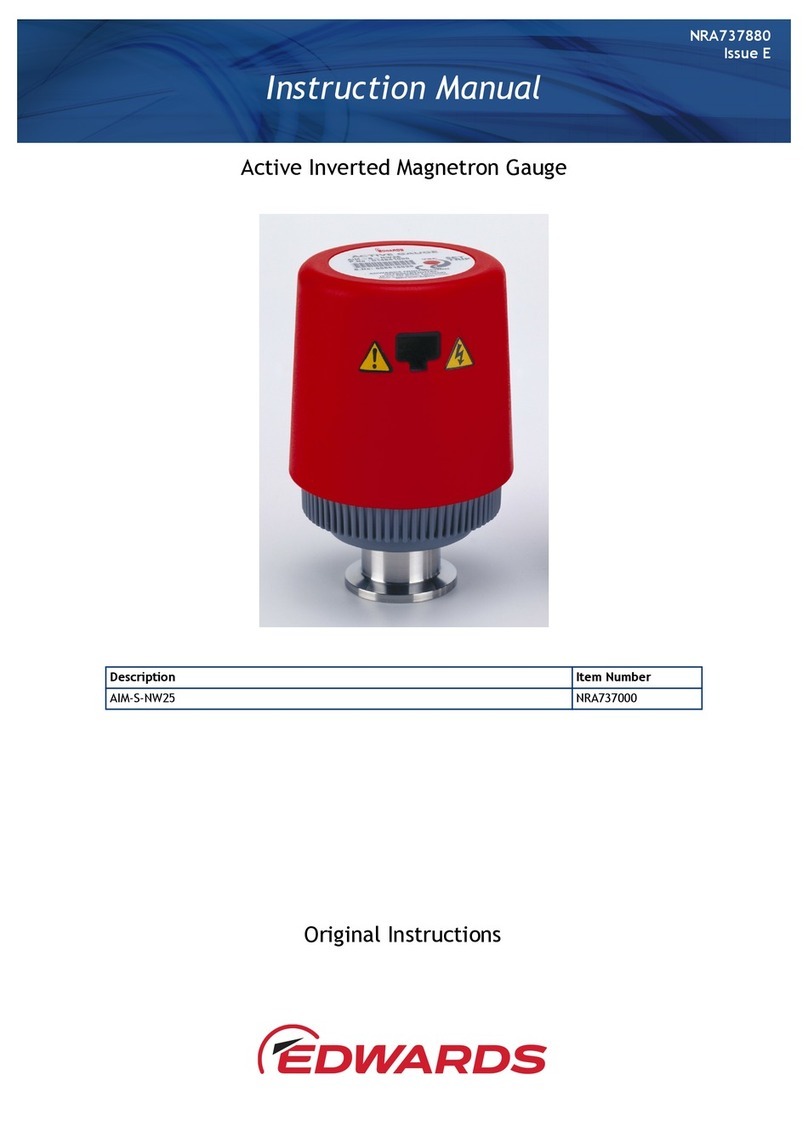

Edwards AIM-S-NW25 User manual

Edwards

Edwards M528-09-160 User manual

Edwards

Edwards OLM100 User manual

Edwards

Edwards APG100 User manual

Popular Measuring Instrument manuals by other brands

Bosch

Bosch GIC 120 C Professional Original instructions

Rinstrum

Rinstrum 400 Series Reference manual

IDEAL

IDEAL niPRO Gbis user guide

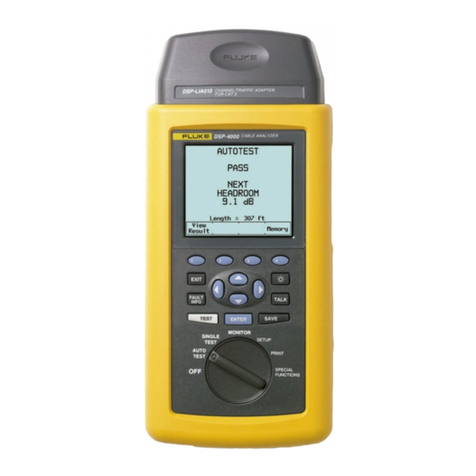

Fluke

Fluke CableAnalyzer DSP-4000 Series Getting started guide

Fieldpiece

Fieldpiece SOX3 Operator's manual

PCE Health and Fitness

PCE Health and Fitness PCE-A-315 instruction manual

Baker Hughes

Baker Hughes Masoneilan 12400 Series Instruction manual & safety guide

Novus

Novus N320 operating manual

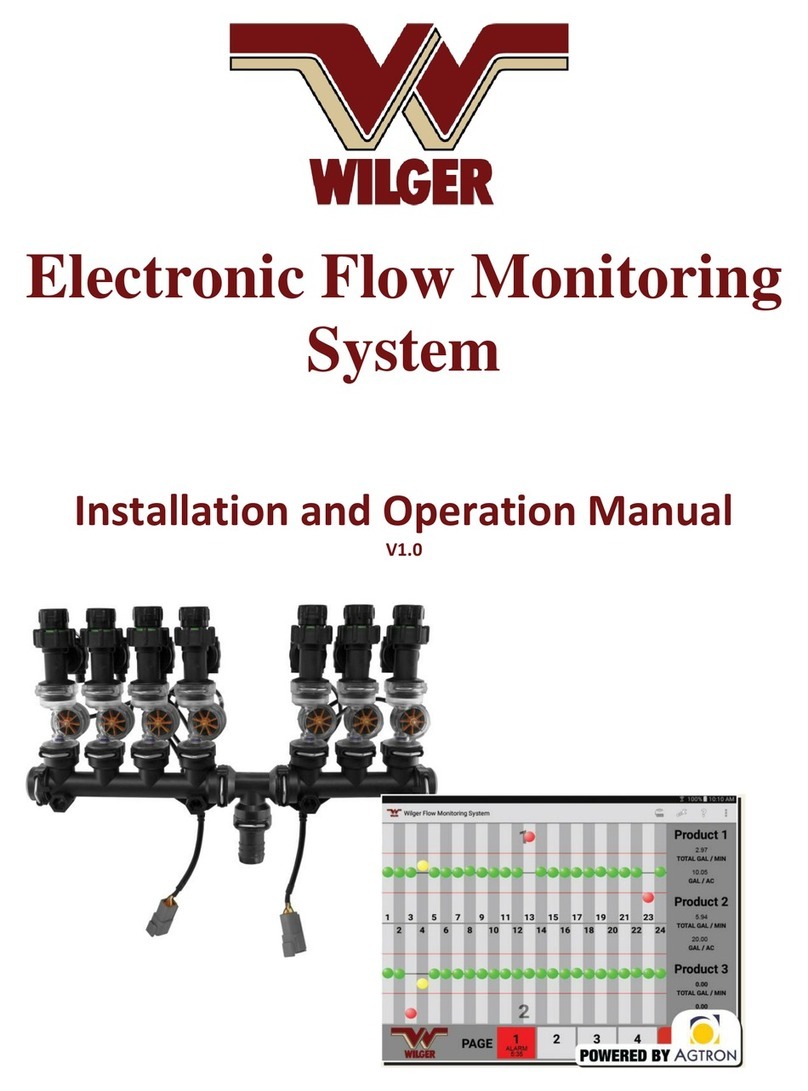

WILGER

WILGER EFMS Installation and operation manual

Endress+Hauser

Endress+Hauser Cerabar PMP51B operating instructions

Hanna Instruments

Hanna Instruments HALO 2 HI9810412 instruction manual

IBS

IBS CPL350 user manual