Edwards PRG20K User manual

edwardsvacuum.com

PRG20K AND PRG20KCR PASSIVE

PIRANI GAUGE

INSTRUCTION MANUAL

Publication number: D0300020001EN

Issue: A

Original Instructions

This product has been manufactured under a quality management system certified to ISO 9001:2008

07.06.2017, Eastbourne

Declaration of Conformity

We, Edwards,

Innovation Drive,

Burgess Hill,

West Sussex,

RH15 9TW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

•Pirani (PRG) gauges connected to controllers (PGC).

D03000200

PRG20K – NW16 AI

D03000210

PRG20K – DN16CF SS

D03000220

PRG20KCR – NW16 SS

D03000400

PGC201 Pirani/Penning Contr +*

D03000410

PGC202 Pirani/Ion Contr +*

D03000201

PRG cable 5 m

D03000202

PRG cable 10 m

D03000203

PRG cable 20 m

D03000204

PRG cable 30 m

D03000205

PRG cable 50 m

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1:2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use. General Requirements

EN61326-1:2013 Class B,

Industrial Electrical equipment for measurement, control and laboratory

Use. EMC requirements. General requirements

and fulfils all the relevant provisions of

(+) 2014/35/EU Low Voltage Directive

(*) 2014/30/EU Electromagnetic Compatibility (EMC) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

2012/19/EU Waste from Electrical and Electronic Equipment (WEEE) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

Larry Marini, Senior Technical

Date and Place

P200-10-168 Issue A

This page intentionally blank.

Copyright notice

© Edwards Limited 2017. All rights reserved.

Trademark credits

Edwards and the Edwards logo are trademarks of Edwards Limited.

D0300020001EN - Copyright notice

Page 2

D0300020001EN - Contents

Page i

Contents

Safety 1

Symbols used .................................................................................................................... 1

Symbols for residual risks ........................................................................................... 1

Personnel qualifications ................................................................................................... 1

General safety instructions ............................................................................................... 1

Responsibility and warranty ............................................................................................. 2

Description 3

Product identification ....................................................................................................... 3

Validity .............................................................................................................................. 3

Intended use ..................................................................................................................... 3

Unpacking and Checking ................................................................................................... 4

Scope of delivery .............................................................................................................. 4

Technical data 5

PRG20K gauge head NW16 ............................................................................................... 5

PRG20K gauge head DN16CF ............................................................................................ 5

PRG20KCR gauge head NW16 .......................................................................................... 6

Installation 7

Supplied equipment ......................................................................................................... 7

Connection of the gauge head .......................................................................................... 7

Adjustment of the gauge head ......................................................................................... 8

Adjustment of the gauge head in connection with operating units

PGC201 and PGC202 ........................................................................................................ 8

Maintenance 9

Exchanging the sensing cell .............................................................................................. 9

Spare parts and accessories 11

Spares ............................................................................................................................. 11

Accessories ..................................................................................................................... 11

Storing and waste disposal 12

Storage ............................................................................................................................ 12

Disposal ........................................................................................................................... 12

Returning the product 13

Disposal 14

Separating the components ........................................................................................... 14

Contaminated components ............................................................................................ 14

Other components .......................................................................................................... 14

cg/03/17

D0300020001EN - Contents

Page ii

List of Figures

Dimensions ................................................................................................................ 6

Gauge head PRG20K - NW16 Al / PRG20K - DN16CF SS /

PRG20KCR - NW16 SS ................................................................................................ 8

Disassembled PRG20K - NW16 Al / PRG20K - DN16CF SS /

PRG20KCR - NW16 SS gauge head .......................................................................... 10

D0300020001EN - Safety

Page 1

Safety

Symbols used

Symbols for residual risks

Personnel qualifications

All work described in this document may only be carried out by persons who have suitable

technical training and the necessary experience or who have been instructed.

General safety instructions

Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions with the product materials.

Consider possible reactions (for example, explosion) of the process media due to the

heat generated by the product.

Adhere to the applicable regulations and take the necessary precautions for all work

to be performed and consider the safety instructions in this document.

Ensure that all vacuum components have not been contaminated before beginning

any work. If so, adhere to the relevant regulations and take the necessary precautions

when handling contaminated parts.

The PRG heads must only be operated with Edwards PGC201 or PGC202 vacuum gauge

controller instruments.

Communicate the safety instructions to all other users.

WARNING:

Warnings are given where failure to observe the instruction could result in injury or death

to people.

CAUTION:

Cautions are given where failure to observe the instruction could result in damage to the

equipment, associated equipment and process.

Note:

Information on correct handling or use. Disregard can lead to malfunctions or minor

equipment damage.

D0300020001EN - Safety

Page 2

Responsibility and warranty

Edwards will not assume any responsibility or warranty in cases where the operator or third

persons:

Do not observe the information given in this document.

Do not use the product as intended.

Modify the product in any way (conversions, repair work, etc.).

Operate the product with accessories not listed in the corresponding product

documentation.

Subject to technical alterations without prior notice. The figures are not binding.

D0300020001EN - Description

Page 3

Description

The PRG are vacuum gauge heads.

The actual pressure sensing element within the gauge head PRG20K - NW16 is a tungsten

filament.

The PRG gauge heads PRG20K - DN16CF and PRG20KCR - NW16 are made of stainless steel

with a welded ceramics feed-through. The sensing element within the PRG20K - NW16 is a

tungsten filament, whereas the PRG20KCR - NW16 uses a platinum filament.

The gauge heads are supplied fully aligned. Any alignment or recalibration will, if at all

necessary, be required only after a longer period of operation.

The gauge heads are temperature compensated for the range from 0 °C to 40 °C.

The measurement cells can be easily exchanged should this be required. After an exchange

of the sensing cell a recalibration is required by adjusting two potentiometers within in the

gauge head.

Product identification

In all communications with Edwards, please specify the information on the product

nameplate.

Validity

This document applies to products with part numbers

The part number (No:) can be taken from the product nameplate.

Intended use

The PRG gauge heads are vacuum gauge heads which are operated in connection with the

operating units PGC201 and PGC202.

The gauge head is used for the measurement of absolute pressures in the rough and fine

vacuum range in accordance with the technical data.

Product Description Item number

PRG20K NW16 AL D03000200

PRG20K DN16CF SS D03000210

PRG20KCR NW16 SS D03000220

PRG cable 5m D03000201

PRG cable 10m D03000202

PRG cable 20m D03000203

PRG cable 30m D03000204

PRG cable 50m D03000205

D0300020001EN - Description

Page 4

Unpacking and Checking

Unpack the PRG gauge head immediately after delivery, even if it is to be installed at a later

date.

Retain the packaging materials in the event of complaints about damage.

Carefully examine the visually. If any damage is discovered, report it immediately to the

forwarding agent and insurer. If the gauge head has to be replaced, contact the orders

department.

Scope of delivery

PRG gauge head

Securing bow for connection plug

D0300020001EN - Technical data

Page 5

Technical data

PRG20K gauge head NW16

PRG20K gauge head DN16CF

Measurement range 0.5 x 10-4 to 1 x 103mbar

Filament temperature 110 °C

Disruption pressure (Burst pressure)

(absolute)

3 bar

Measurement volume 11 cm3

Connection flange NW16

Filament material Tungsten

Material in contact with the medium Aluminium, glass, Vacon, Tungsten, chrome-nickel

8020, steel nickel-plated, Epoxy adhesive

Operating temperature 0 to 40 °C

Maximum ambient temperature 80 °C

Measurement range 0.5 x 10-4 to 1 x 103mbar

Filament temperature 110 °C

Disruption pressure (Burst pressure)

(absolute)

10 bar

Measurement volume 10 cm3

Connection flange DN 16 CF

Filament material Tungsten

Material in contact with the medium Stainless steel 1.4301, Tungsten, chrome nickel

8020, ceramics Al2O3, NiFe 42

Operating temperature 0 to 40 °C

Maximum ambient temperature 80 °C

D0300020001EN - Technical data

Page 6

PRG20KCR gauge head NW16

Figure 1 Dimensions

Measurement range 0.5 x 10-4 to 1 x 103mbar

Filament temperature 110 °C

Disruption pressure (Burst pressure)

(absolute)

10 bar

Measurement volume 10 cm3

Connection flange NW16

Filament material Platinum

Material in contact with the medium Stainless steel 1.4301, Platinum, chrome nickel

8020, ceramics Al2O3, NiFe 42

Operating temperature 0 to 40 °C

Max. ambient temperature 80 °C

D0300020001EN - Installation

Page 7

Installation

Supplied equipment

PRG gauge head

Securing clip for connector

Operating instructions

Connection of the gauge head

Install the gauge head vertically, i.e. with the flange facing downwards. Dimensional drawing

see Figure 1. The dimensions given with a double asterisk (**) to the PRG20K - DN16CF and

PRG20KCR - NW16 gauge head. Otherwise the dimensions are the same for both gauge

heads.

The maximum permissible ambient temperature for the gauge head is 80 °C. However, at this

temperature the accuracy specified for the gauge head is no longer ensured, as the

temperature compensation is only effective up to 40 °C.

If the gauge head is subjected to strong thermal radiation, it has to be protected by a suitable

thermal screen. In the case that heat is transferred to the gauge head via the connection

cable, a section of the connection cable may be cooled by a cooling spiral.

Any contamination of the sensing cell will impair the accuracy of the pressure readings

obtained. Special care must be taken in the presence of substances which cannot be removed

by solvents.

Suitable orifice plates or bends may be employed to keep any possible sources of

contamination away from the gauge head.

Bent lines should be laid in such a way that no condensate can collect or the vacuum line

cannot become blocked.

The gauge heads are connected to the operating unit via standard gauge head cables.

For the purpose of improved resistance to interference the gauge heads have been equipped

with an additional ground connection (screw terminal) at the housing which is directly linked

to the metal housing of the sensing cell.

Standard gauge head cables are fitted with a ring terminal at each end of the cable. The ring

terminals should be connected to the ground connection (screw terminal) at the housing of

WARNING:

Do not use the PRG for safety critical applications. The PRG is not intended to be fail safe.

WARNING:

Do not use the PRG to measure the pressure of explosive of flammable gasses or mixtures.

The gauge contains a heated filament which can operate at extremely high temperatures

under fault conditions.

Note:

Do not install a vent valve in the immediate vicinity of the gauge head. Sudden changes in air

flow may result in mechanical damage to the filament.

D0300020001EN - Installation

Page 8

the gauge head and the protective earth conductor screw on the rear of the PGC201/PGC202

controller.

Ensure that the correct filament material is selected on the PGC201/PGC202 controller. Refer

to the operating instructions for the PGC201/PGC202 controller.

Ensure the correct filament material is selected (tungsten or platinum) when operating the

gauge head in connection with an operating unit PGC201 and PGC202 (see Operating

Instructions PGC201 and PGC202).

The connecting plug can be safely attached to the gauge via the securing clip. To do so, push

the clip over the connecting pug and let them snap in the provided holes which are in the

shell.

Adjustment of the gauge head

Adjustment is performed as follows:

Remove the caps covering the potentiometers on the gauge head.

Vent vacuum system and set 100% potentiometer (Figure 2 item 1) so that the

controller indicates full scale (atmospheric pressure).

Pump down vacuum system to a pressure below 5 x 10-4 mbar and set "0"

potentiometer (Figure 2 item 2) so that the controller indicates 0.

Vent vacuum system and recheck the 100% adjustment. Correct deviation, if any, by

means of potentiometer.

If a correction of the 100% adjustment was necessary the zero adjustment must be

repeated in any case.

After having completed the adjustment fit the caps to cover the potentiometers.

Figure 2 Gauge head PRG20K - NW16 Al / PRG20K - DN16CF SS / PRG20KCR - NW16 SS

Adjustment of the gauge head in connection with operating units

PGC201 and PGC202

Refer to the operating instructions supplied with the PGC201 or PGC202.

Note:

The ground wire may only be connected if potential equalization between the flange of the

vacuum apparatus and the operating unit is ensured. If necessary install the gauge head so

that it is electrically isolated from the vacuum apparatus.

1 100% potentiometer

2 0% potentiometer

D0300020001EN - Maintenance

Page 9

Maintenance

Exchanging the sensing cell

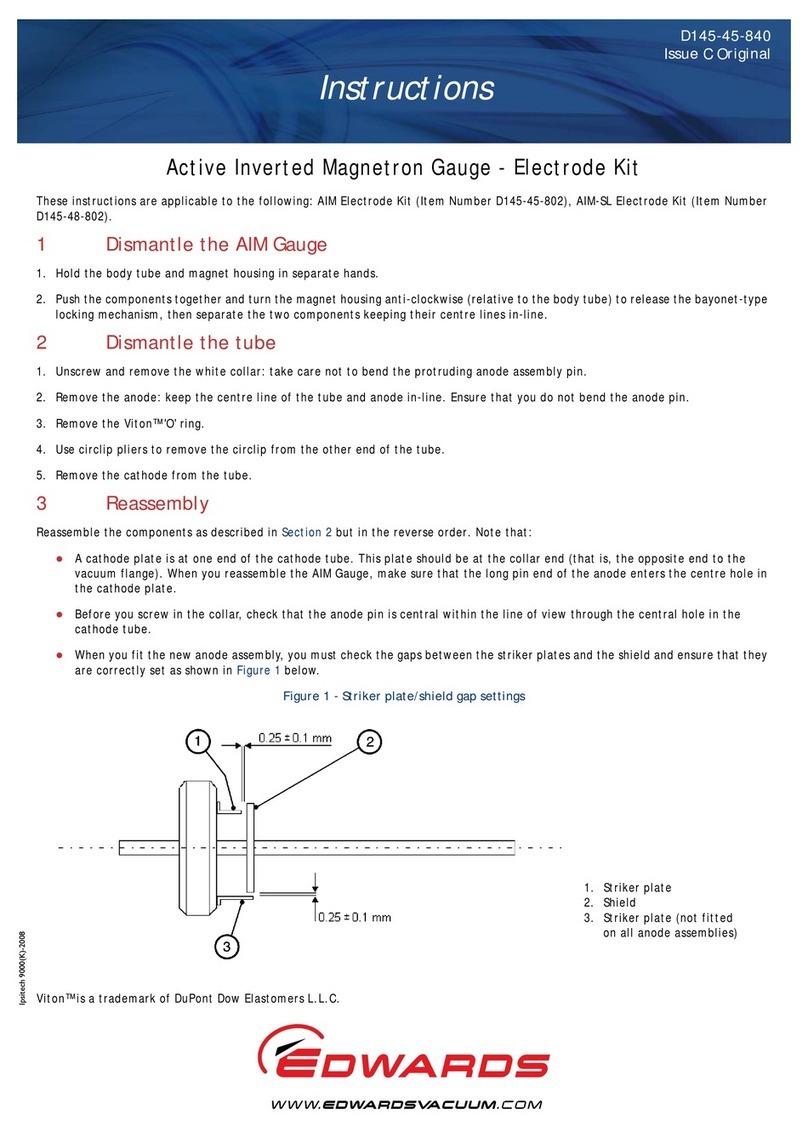

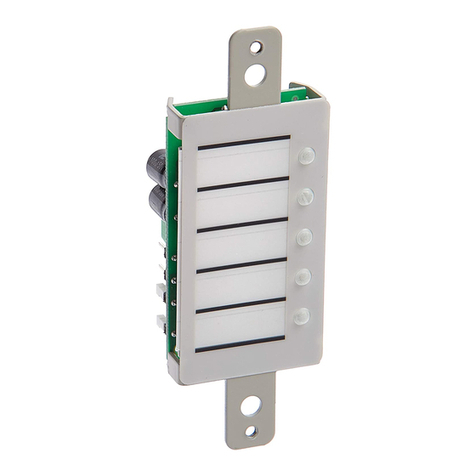

All items in this section refer to Figure 3.

One half of the housing (item 1) is fitted with plastic catches (item 2) which must properly

engage in the slots (item 8) provided in the other half of the housing (item 7) so as to firmly

connect the two halves of the housing (item 1) and (item 7).

Apply a screwdriver to the upper slit on the longer front so as to disengage the plastic catch

(item 2) by pushing it backwards. Simultaneously, pull both halves of the shell (item 1) and

(item 7) apart.

Next apply a screwdriver to the lower slit on the longer front so as to disengage the plastic

catch by pushing it backwards. Simultaneously, pull both halves of the shell apart.

Repeat this for the shorter front.

Detach shell (item 1).

Remove the contact spring (item 4) by loosening the fixing screw (item 3).

Remove the sensing cell (item 11) together with the PCB. and plug (item 6) from the

remaining shell.

Carefully separate the sensing cell (item 11) from the PCB (item 6).

Remove the insulating plate (item 5) from the measurement cell.

Exchange the sensing cell.

Insert insulating plate (item 5) between PCB and measurement cell.

WARNING:

Contaminated parts can be detrimental to health and environment.

Before beginning work, find out whether any parts are contaminated. Adhere to the

relevant regulations and take the necessary precautions when handling contaminated

parts.

CAUTION:

Dirt and damage can impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to ensure cleanliness

and prevent damage.

CAUTION:

Touching the product with bare hands increases the desorption rate.

Always wear clean, lint-free gloves and use clean tools when working in this area.

Note:

The cell can be mounted on the PCB in either orientation.

D0300020001EN - Maintenance

Page 10

During assembly of the gauge head make sure that the holder (item 10) has been placed in

the housing shell and that the temperature sensor is pressed against the sensing cell.

The gauge head is reassembled in the reverse order.

Figure 3 Disassembled PRG20K - NW16 Al / PRG20K - DN16CF SS / PRG20KCR - NW16 SS gauge head

1 One half of the housing with plastic catches

2 Plastic catch

3 Plastic catch

4 Contact spring

5 Insulating plate

6 PCB complete

7 One half of the housing with slots

8 Slots for opening the housing

9 Cap

10 Holder

11 Sensing cell

D0300020001EN - Spare parts and accessories

Page 11

Spare parts and accessories

Spares

When ordering spare parts, always indicate:

All information on the product nameplate.

Description and ordering number according to the spare parts list.

Accessories

Product description Item number

Replacement sensing cell K D03000209

Replacement sensing cell KCR D03000229

Product description Item number

PRG Cable 5m D03000201

PRG Cable 10m D03000202

PRG Cable 20m D03000203

PRG Cable 30m D03000204

PRG Cable 50m D03000205

D0300020001EN - Storing and waste disposal

Page 12

Storing and waste disposal

Storage

Disposal

Dispose of the PRG and any components safely and in accordance with all local and national

safety and environmental requirements.

Alternatively, the PRG and /or cables may be able to be recycled; contact Edwards or supplier

for advice (also see below).

The PRG and associated cables are within the scope of the European Directive on Waste and

Electronic Equipment, 2012/19/EU. Edwards offers customers a recycling service for the

product/cables/associated gauge heads at the end of the product's life. Contact Edwards for

advice on how to return the PRG and/or cables for recycling

CAUTION:

Cover the vacuum ports of the product with protective caps or grease free aluminium foil.

Do not exceed the admissible storage temperature range.

Inappropriate storage leads to an increase in the desorption rate and/or may result in

mechanical damage of the product.

D0300020001EN - Returning the product

Page 13

Returning the product

Products that are not clearly declared as "free of harmful substances" are decontaminated at

the expense of the customer.

Products not accompanied by a duly completed declaration of contamination are returned to

the sender at his own expense.

WARNING:

Products returned to Edwards for service or repair should, if possible, be free of harmful

substances (for example, radioactive, toxic, caustic or microbiological). Otherwise, the

type of contamination must be declared.

Adhere to the forwarding regulations of all involved countries and forwarding companies

and enclose a completed contamination declaration.

D0300020001EN - Disposal

Page 14

Disposal

Separating the components

After disassembling the product, separate its components according to the following criteria:

Contaminated components

Contaminated components (radioactive, toxic, caustic or biological hazard, and so forth) must

be decontaminated in accordance with the relevant national regulations, separated

according to their materials, and disposed of.

Other components

Such components must be separated according to their materials and recycled.

WARNING:

Contaminated parts can be detrimental to health and environment.

Before beginning to work, find out whether any parts are contaminated. Adhere to the

relevant regulations and take the necessary precautions when handling contaminated

parts.

WARNING:

Products returned to Edwards for service or repair should, if possible, be free of harmful

substances (for example, radioactive, toxic, caustic or microbiological). Otherwise, the

type of contamination must be declared.

Adhere to the forwarding regulations of all involved countries and forwarding companies

and enclose a completed contamination declaration.

This manual suits for next models

1

Table of contents

Other Edwards Measuring Instrument manuals

Edwards

Edwards IG40 BA User manual

Edwards

Edwards ATC-E User manual

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards FSRZI-A Assembly instructions

Edwards

Edwards APG100 User manual

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards AIM-S-NW25 User manual

Edwards

Edwards GXS 0-60 SLM User manual

Edwards

Edwards OLM100 User manual

Edwards

Edwards AIM-SI1-NW25 User manual