4. Do not cause an air inlet blockage.

5. Refer to Technical data on page 60 for liquid handling capacity.

6. Remove the blanking anges, plugs, caps and desiccant bags before you connect

the pipes.

7. The vacuum connecon and discharge pipes must be of correct size and applicable

for the working pressures and temperatures.

8. Do not use frayed, damaged or worn hoses.

9. Distribuon pipes and connecons must be of correct size and applicable for the

working pressures.

10. The inlet air must have no ammable fumes, vapours or parcles (for example,

paint solvents can cause internal re or explosions).

11. The external force on the inlet and outlet connecon is 30 kg. Make sure that there

is no strain on the pipe connecons. Supports must not be installed to the external

body (canopy) of the pump.

12. If a remote control is installed, the pump must have the sign that follows:

"Danger: The machine is remotely controlled and can start without a warning." The

operator must make sure that the machine is stopped and depressurised, the

electrical isolaon switch is open and the electrical isolaon switch is locked with a

temporary warning aached before maintenance and repairs. Persons that use a

remote controlled machine must obey the necessary precauons. When you

operate the machine you must make sure that no one is working on the machine.

13. Air-cooled pump must be installed in such a way that an adequate ow of the

cooling air is available. Make sure that the exhausted air does not recirculate to the

pump air inlet or cooling air inlet.

14. For water-cooled pumps, the cooling water system installed outside the machine

has to be protected by a safety device with set pressure according to the maximum

cooling water inlet pressure.

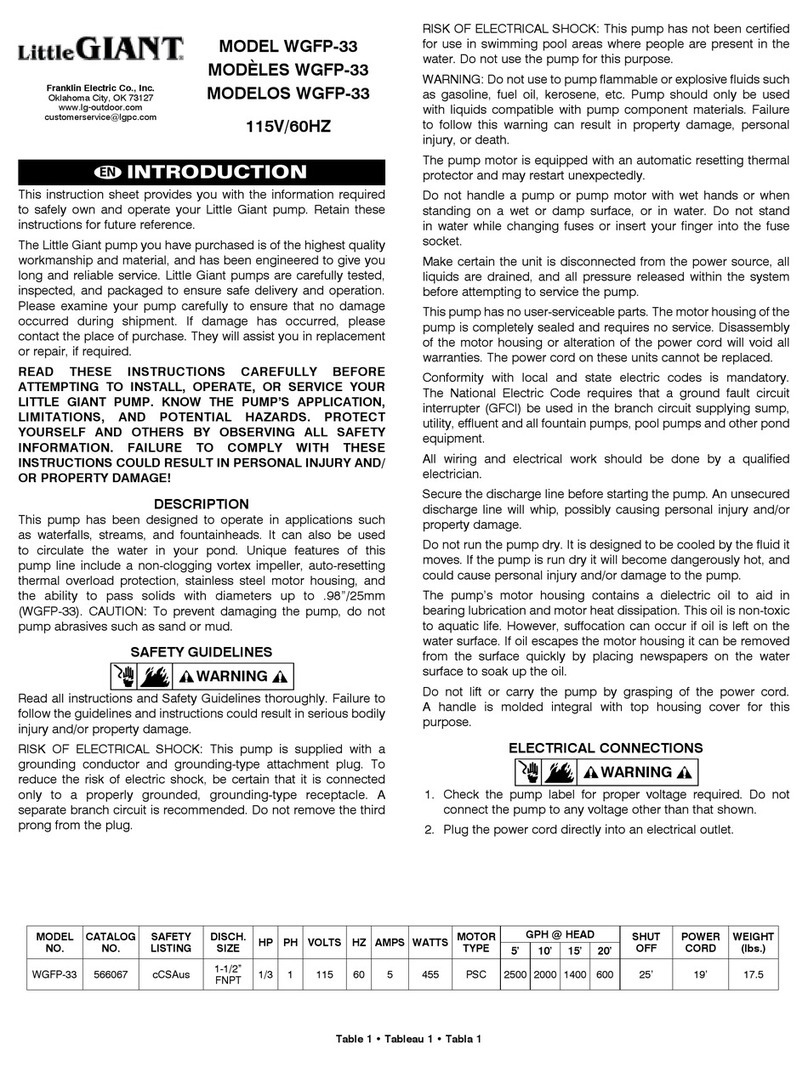

15. The electrical connecons must be same as the applicable codes. Make sure that

the machines are grounded and protected against short circuits by fuses in all

phases. Install a power isolaon switch near the pump. You must be able to lock

the power isolaon switch.

16. The pumps with an automac start/stop system or an Automac Restart Aer

Voltage Failure (ARAVF) funcon must have the sign: "This pump can start without

warning" aached near to the instrument panel.

17. Do not remove or adjust the safety devices, guards or insulaon installed on the

pump.

18. There are pipes and parts with temperatures more than 70 ˚C (158 ˚F). Install

insulaon or guards to prevent contact with hot surfaces. All pipes and parts with

high temperatures must be clearly marked.

19. If the ground is not at or it has slope, contact the manufacturer.

20. Pump outlet air contains traces of oil mist. Make sure that the pump is compable

with the working environment.

21. If a pump is installed in a system with inlet gas‑stream temperatures more than the

maximum temperature permied, contact us. The installaon must be approved

by us before the pump is started.

09/2021 - ©Edwards Limited

Page 96996022910_B

6996022910_B - Safety and compliance