A301-51-880

Issue T Original

Instruction Manual

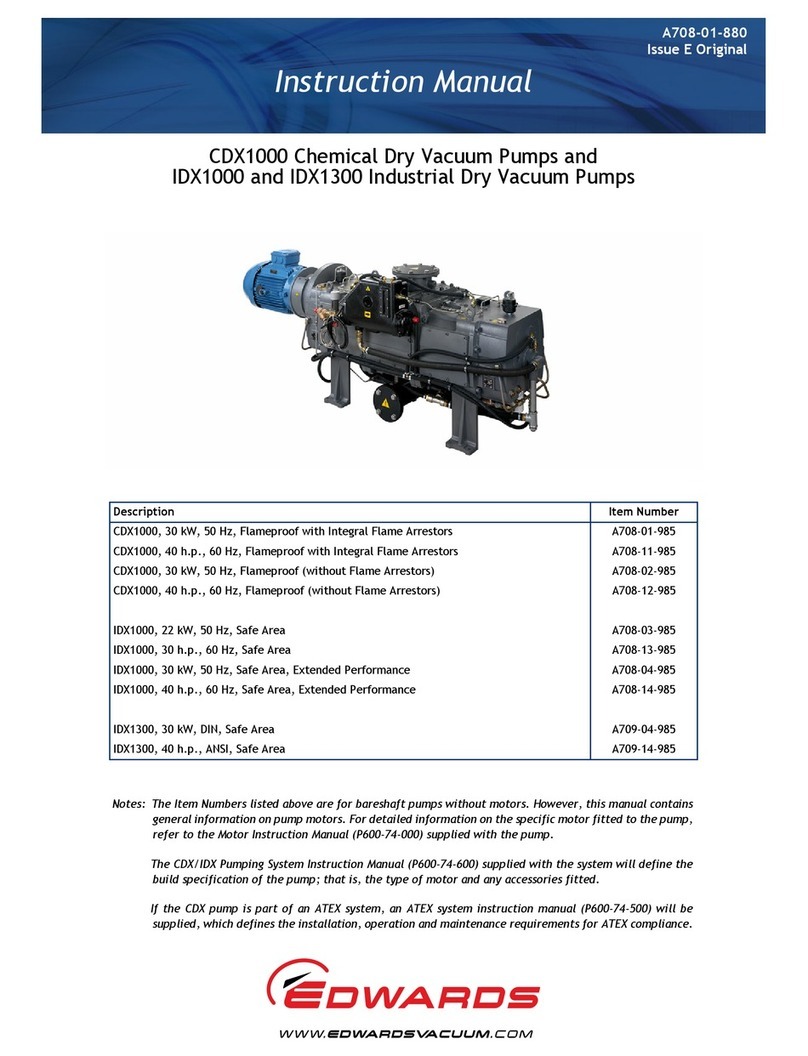

EH Mechanical Booster Pumps

Description Item Number

EH250 2.2kW Safe Area Pumps A301-51-945, A301-52-946

EH250 1.5kW Safe Area Pumps A301-51-935, A301-53-935, A301-52-936, A301-54-936

EH500 1.5kW Safe Area Pumps A302-73-935, A302-74-936

EH500IND 2.2kW Safe Area Pumps A302-71-945, A302-72-946

EH1200 3kW Safe Area Pumps A305-92-935, A305-93-936

EH1200IND 3kW Safe Area Pumps A305-90-935, A305-91-936

EH1200C 3 kW Flame Proof Pump A305-56-982

EH1200 T3/T160/T4 3kW Flame Proof Pump A305-57-900

EH2600 7.5kW Safe Area Pumps A307-51-935, A307-53-935, A307-52-936, A307-54-936

EH2600IND 11kW Safe Area Pumps A307-75-946, A307-76-982

EH2600C 11kW Flame Proof Pump A307-56-982

EH2600 T160/T4 11kW Flame Proof Pump A307-79-900

EH2600T3 11kW Flame Proof Pump A307-41-935

EH4200 7.5kW Safe Area Pumps A309-51-935, A309-53-935, A309-52-936

EH4200IND 11kW Safe Area Pumps A309-75-946, A309-76-982

EH4200C 11kW Flame Proof Pump A309-56-982

EH4200 T160/T4 11kW Flame Proof Pump A309-79-900

EH4200T3 11kW Flame Proof Pump A309-41-935

© Edwards Limited 2007. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

A301-51-880 Issue T

Contents

Section Page

1 Introduction ............. ........................ ......................... ........................ . 1

1.1 Scope and definitions ................................................................................................... 1

1.2 Description ................................................................................................................ 1

1.2.1 Overview .................................................................................................................. 1

1.2.2 General construction .................................................................................................... 5

1.2.3 Principle of operation ................................................................................................... 5

1.2.4 Hydrokinetic drive ....................................................................................................... 5

1.3 Chemical and ATEX compliant EH pumps ............................................................................ 5

1.3.1 Flameproof motors ...................................................................................................... 5

1.3.2 ATEX directive (94/9/EC): Europe only .............................................................................. 6

1.3.3 Temperature classification ............................................................................................. 6

1.3.4 Hydrokinetic drive/gearbox purge .................................................................................... 7

1.3.5 After-cooler ............................................................................................................... 7

1.3.6 Normal operation ........................................................................................................ 7

1.3.7 Abnormal operation ..................................................................................................... 8

1.3.8 Electrostatic charges .................................................................................................... 8

2 Technical Data ... ........................... ......................... .............. ............... 9

2.1 Operating and storage conditions ..................................................................................... 9

2.2 Critical backing pressure ............................................................................................... 9

2.3 Performance .............................................................................................................12

2.4 Mechanical data ......................................................................................................... 12

2.5 Electrical data ........................ ........................... .............................. ......................... . 13

2.6 Lubrication data ......... ........................... ........................... ........................... .............. 14

2.7 Hydrokinetic drive/ge arbox nitrogen supply (EH1200C, EH1200 T3/T160/T4X, EH2600C, EH2600 T3X,

EH2600 T160/T4X, EH4200C, EH4200 T3X, EH4200 T160/T 4X only) 14

2.8 Cooling-water data ............................. ........................................................................14

2.9 Noise and vibration data ... ........................... ......................... ........................... ............. 15

2.10 Connections ..............................................................................................................15

2.11 Materials of construction of components expos ed to pumped gases ...........................................16

2.12 Item Num bers ........................... ........................... ............................ ........................ . 16

3 Installation ....................................................................................... 25

3.1 Safety ..................................................................................................................... 25

3.2 System requirements ....................... ............................ ............................. ................... 25

3.3 Unpack and inspect ..................................................................................................... 26

3.4 Fill the pump with oil .................................................................................................. 27

3.4.1 Hydrokinetic drive/gearbox ........ .......................... ............................ ........................ ..... 27

3.4.2 Shaft-seal reservoir ..................................................................................................... 27

3.4.3 Gear-cover (all EH1200, E H2600 and EH4200 mo del pumps only) ............................................... 28

3.5 Cooling-water connections (all EH1200, EH2600 and EH4200 model pumps only) ............................ 29

3.6 Electrical connections .................................................................................................. 29

3.6.1 Electrical s upply c onfiguration .... ........................... ........................... ........................ ..... 29

3.6.2 Motor connections ...................................................................................................... 30

3.6.3 Connect the motor thermistors (chemical and ATEX co mpliant EH pumps only) ............................. 31

3.7 Check th e direction of pu mp rota tion ........... ........................... ........................... .............. 38

3.8 Connect the hydrokinetic drive/gearbox purge nitrogen supply

(chemical and ATEX compliant EH pumps only) 39

3.9 Connect the pump-inlet and outlet .................................................................................. 40

3.10 External evacuation of hydrokinetic drive/gearbox (optional) .................................................. 41

APT 11/07

A301-51-880 Issue T

Page ii © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

4 Operation ........................................................................................ 43

4.1 Operational safety ......................................................................................................43

4.2 Start-up procedure ..................................................................................................... 43

4.2.1 Pre-start checks ......................................................................................................... 43

4.2.2 Start-up ................................................................................................................. . 44

4.3 Shut-down ................................................................................................................ 44

5 Maintenance ..................................................................................... 45

5.1 Safety information ...................................................................................................... 45

5.2 Maintenance plan ............... ........................ ............................... ........................ ......... 46

5.3 Check th e oil-levels ..... ........................... ............................ ........................... ............. 46

5.4 Inspect the pump connections ............... ......................... ........................... ..................... 46

5.5 Change t he pump oil ........... ........................... ............................ ........................... ...... 47

5.6 Lubricate the rear-bearing (All EH250 and EH500 model pumps only) ......................................... 48

5.7 Overhaul the pump .....................................................................................................49

6 Storage and Disposal ........................................................................... 51

6.1 Storage .... ............................ .............................. ............................ ......................... 5 1

6.2 Disposal ................................ ............................... .................................. .................. 51

7 Service and Spares .............................................................................. 53

7.1 Introduction .............................................................................................................53

7.2 Service .................................................................................................................... 53

7.3 Spares ..................................................................................................................... 5 3

Illustrations

Figure Page

1 All EH250 and EH500 pump variants .................................................................................. 3

2 All EH1200, EH2600 and EH4200 pump variants ..................................................................... 4

3 EH250/EH250IND dimensions (mm)* ................................................................................. 17

4 EH500/EH500IND dimensions (mm)* ................................................................................. 18

5 EH1200/EH1200IND dimensions ( mm) .............................. ............................ ..................... 19

6 EH1200C/EH1200 T3/T160/T4 dimensions (mm) .................................................................. 20

7 EH2600/EH2600IND dimensions ( mm) ........................... .............................. ...................... 2 1

8 EH2600C/EH2600 T3/EH2600 T160/T4 dimensions (mm) . .......................... ..................... ......... 22

9 EH4200/EH4200IND dimensions ( mm) ........................... .............................. ...................... 2 3

10 EH4200C/EH4200 T3/EH4200 T160/T4 dimensions (mm) . .......................... ..................... ......... 24

11 Sight glasses ............................................................................................................. 28

12 Example control circuit ........................ ........................... ........................... .................. 32

13 Electrical supply configuration A ..................................................................................... 34

14 Electrical supply configuration B ..................................................................................... 34

15 Electrical supply configuration C ..................................................................................... 35

16 Electrical supply configuration D ..................................................................................... 35

17 Electrical supply configuration E ..................................................................................... 36

18 Electrical supply configuration F ..................................................................................... 36

19 Electrical supply configuration G ..................................................................................... 37

20 Electrical supply configuration H .....................................................................................37

21 Electrical supply configuration I ......................................................................................38

22 Flange loa ding lim its .................... ........................... ........................... ......................... 4 2

23 Lubricate the rear bearing (EH250, EH500 and EH500IND pumps only) ........................................ 49