GB

10

the operating instructions to be found in this manual.

All persons who use and service the machine have

to be acquainted with this manual and must be

informed about its potential hazards.

It is also imperative to observe the accident

prevention regulations in force in your area.

The same applies for the general rules of

occupational health and safety.

The manufacturer shall not be liable for any changes

made to the machine nor for any damage resulting

from such changes.

Even when the machine is used as prescribed it is

still impossible to eliminate certain residual risk

factors. The following hazards may arise in

connection with the machineʼs construction and

design:

Contact with the saw blade in the uncovered saw

zone.

Reaching into the running saw blade (cut

injuries).

Kick-back of workpieces and parts of workpieces.

Saw blade fracturing.

Catapulting of faulty carbide tips from the saw

blade.

Damage to hearing if essential ear-muffs are not

worn.

Harmful emissions of wood dust when the

machine is used in closed rooms.

5. Technical data

Weight ca. 7 kg

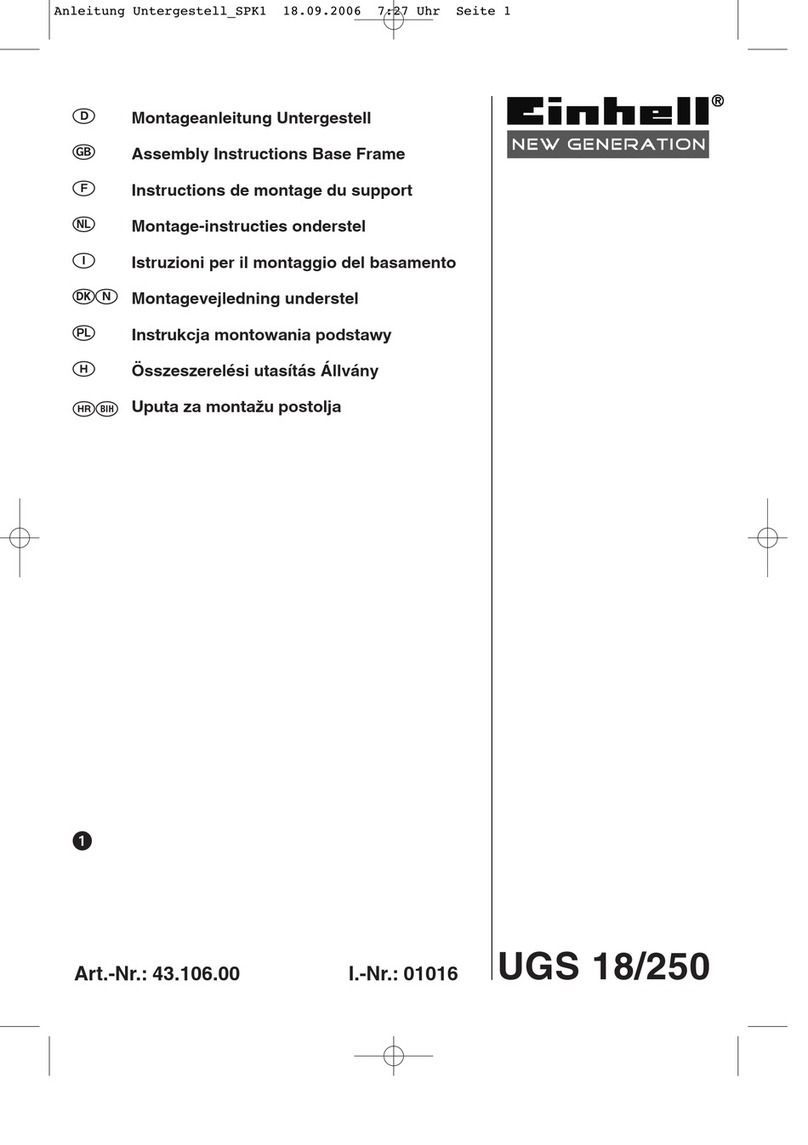

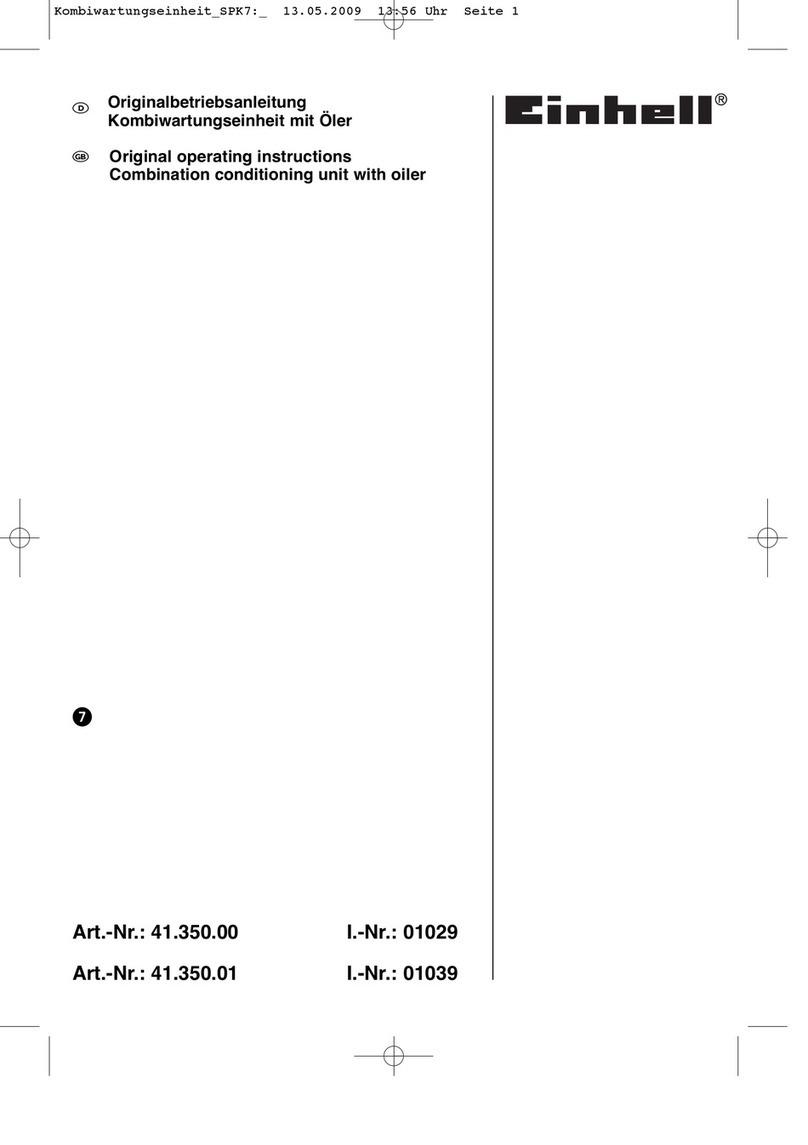

6. Assembling the base frame and

fixing the RT-SM 430 to the base frame

(Figs. 1, 4-14, 15a, 16-18a, 19-21)

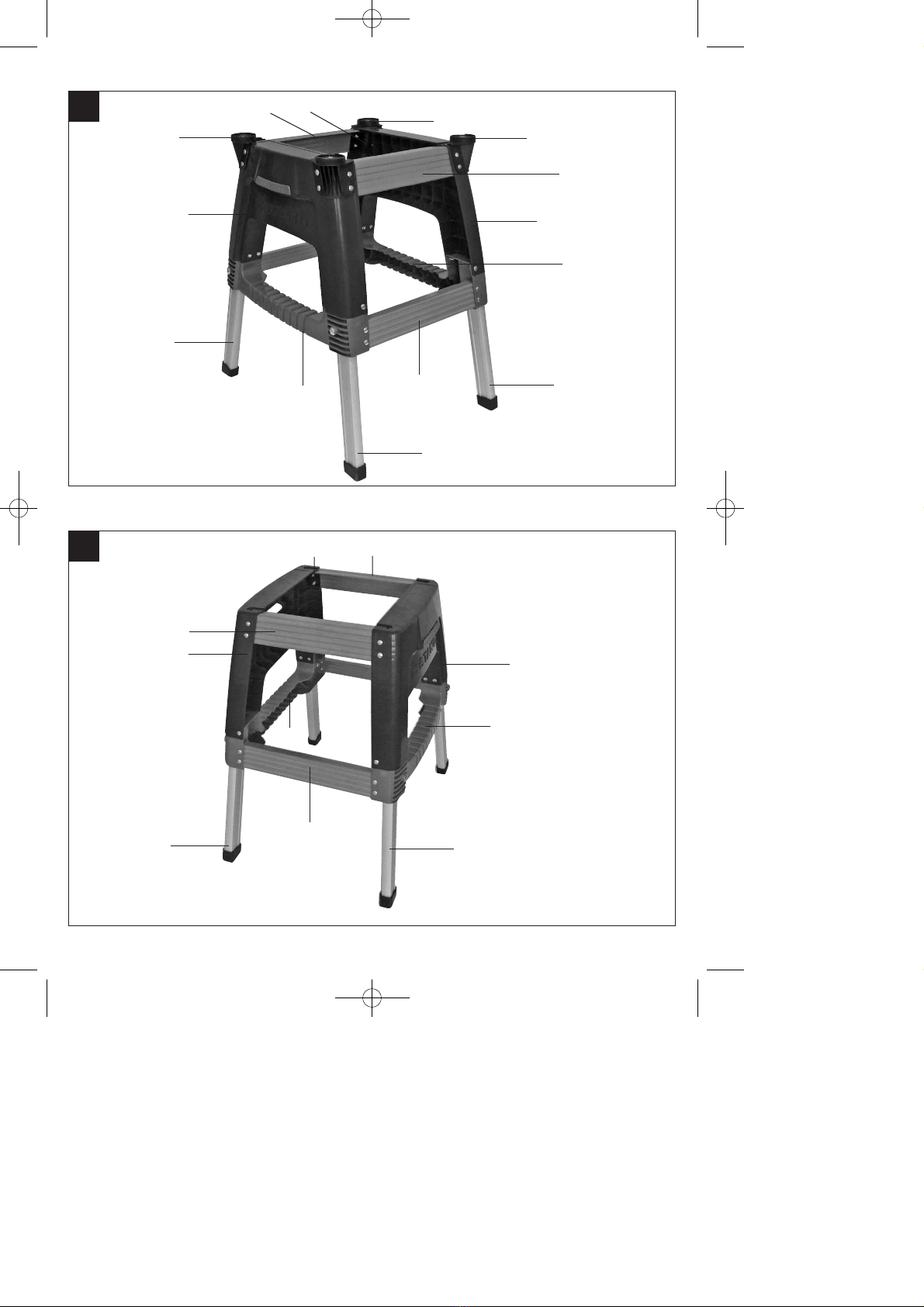

1. Insert the support feet (A) from underneath into

the intermediate struts (C) as shown in Fig. 4.

Ensure that the rubber stoppers on the support

feet (A) are aligned so that their support surfaces

are leveled.

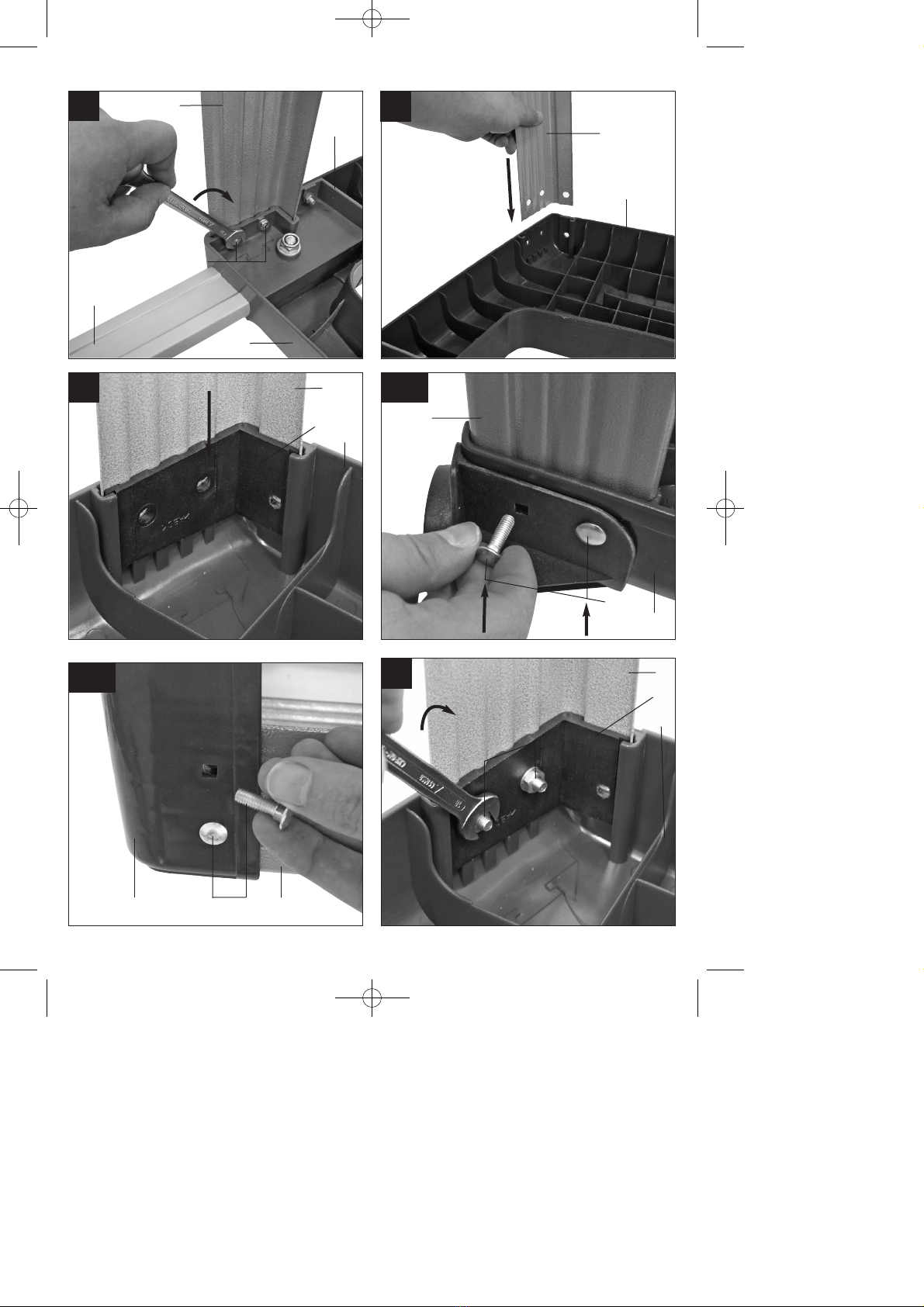

2. Screw the support feet (A) to the intermediate

struts (C) as shown in Figs. 5-6 using the screws

(N), washers (H) and nuts (G).

3. Slide the side part (B) from the top over the

intermediate struts (C) (Fig. 7).

4. Screw the side part (B) to the intermediate struts

(C) using three screws (L), washers (K) and nuts

(I) at each connection point (Figs. 8-9).

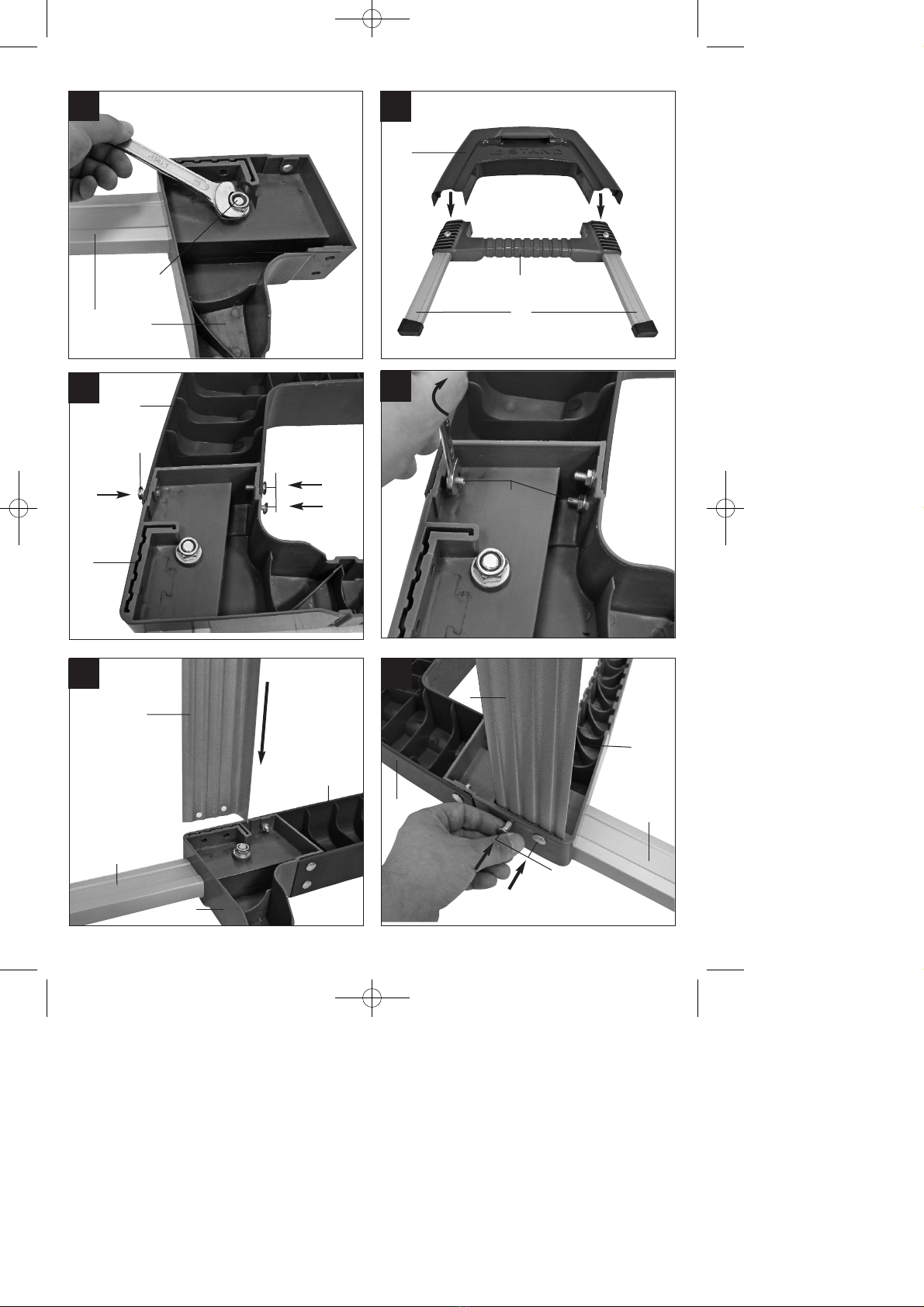

5. Assemble the other part of the base frame as

described above in step 1-4.

6. Take one of the assembled parts (no matter

which one) and insert the two bottom cross struts

(E) as far as possible into the appropriate

openings of the intermediate strut (C)

(Fig. 10). Screw the bottom cross struts (E) to

the intermediate strut (C) using two screws (L),

washers (K) and nuts (I) at each connection

point, as shown in Figs. 11-12.

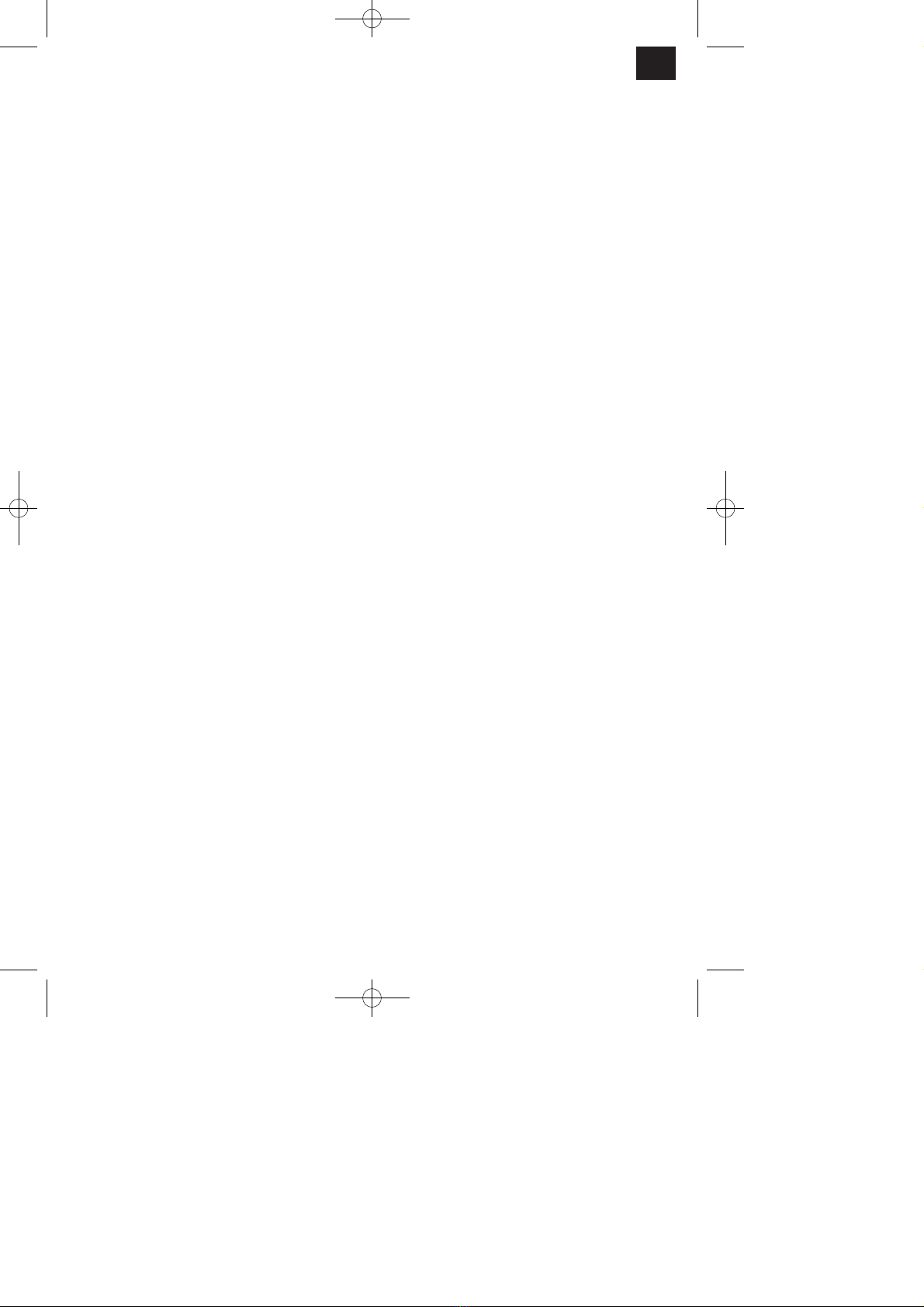

7. On the same part of the base frame, slide the

two top cross struts (F) as far as possible into the

appropriate openings of the side part (B) (Fig.

13). Insert one corner brace (D) into each

opening of the side part (B). Note that the corner

braces (D) only fit one way on the base frame.

This is the case when the holes in the side part

(B), the top cross struts (F) and the corner

braces (D) line up (Fig. 14).

8. Fasten two of the saw mounts (J) onto the same

part of the base frame as shown in Fig. 15a.

Note that the saw mounts (J) only fit one way on

the base frame. This is the case when the holes

in the side part (B), the top cross struts (F), the

corner braces (D) and the saw mounts (J) are

aligned (Fig.15a).

9. Screw the top cross struts (F), corner braces (D),

side part (B) and saw mounts (J) together, as

shown in Figs. 15a-16 using two screws (L),

washers (K) and nuts (I) each time.

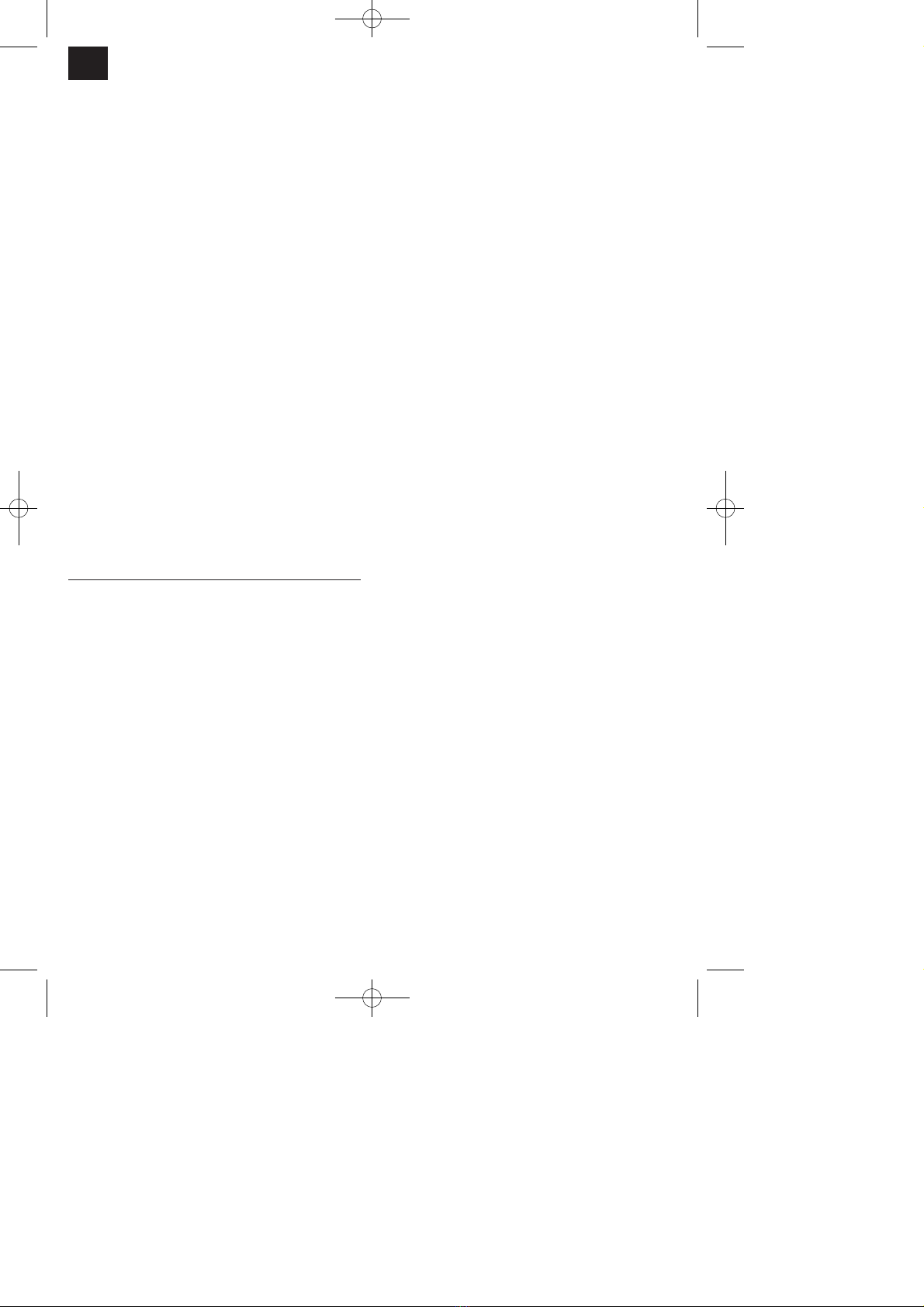

10. Insert the two base frame parts in such a way

that the bottom and top cross struts (E, F) are

positioned in the relevant openings on the side

part (B) and the intermediate strut (C) (Fig. 17).

11. Screw the bottom cross struts (E) to the second

part of the base frame as described in step 6

(Fig. 18a/1.).

12. Screw the top cross struts (F) to the second part

of the base frame as described in step 7 (Fig.

18a/2.).

13. Fasten the other two saw mounts (J) onto the

second part of the base frame as described in

step 8 (Fig. 18a/2.).

14. Pull the four rubber buffers (Z) from the bottom

side of the saw (Fig. 19).

15. Place the saw onto the base frame, align the

holes in which the rubber stops (Z) have been

with the 4 holes on the top side of the saw

mounts (J). Now insert the 4 screws (M) from

above through the saw feet and screw the saw to

the saw mounts (J) (Figs. 20-21).