INSTRUCTIONS FOR USE ...................................................................................................................................................5

1. CE MARKING..................................................................................................................................................................5

2. WARNINGS.....................................................................................................................................................................5

3. CAUTIONS AND SYMBOLS............................................................................................................................................6

4. STORAGE AND TRANSPORT........................................................................................................................................7

5. TECHNICAL DATA..........................................................................................................................................................8

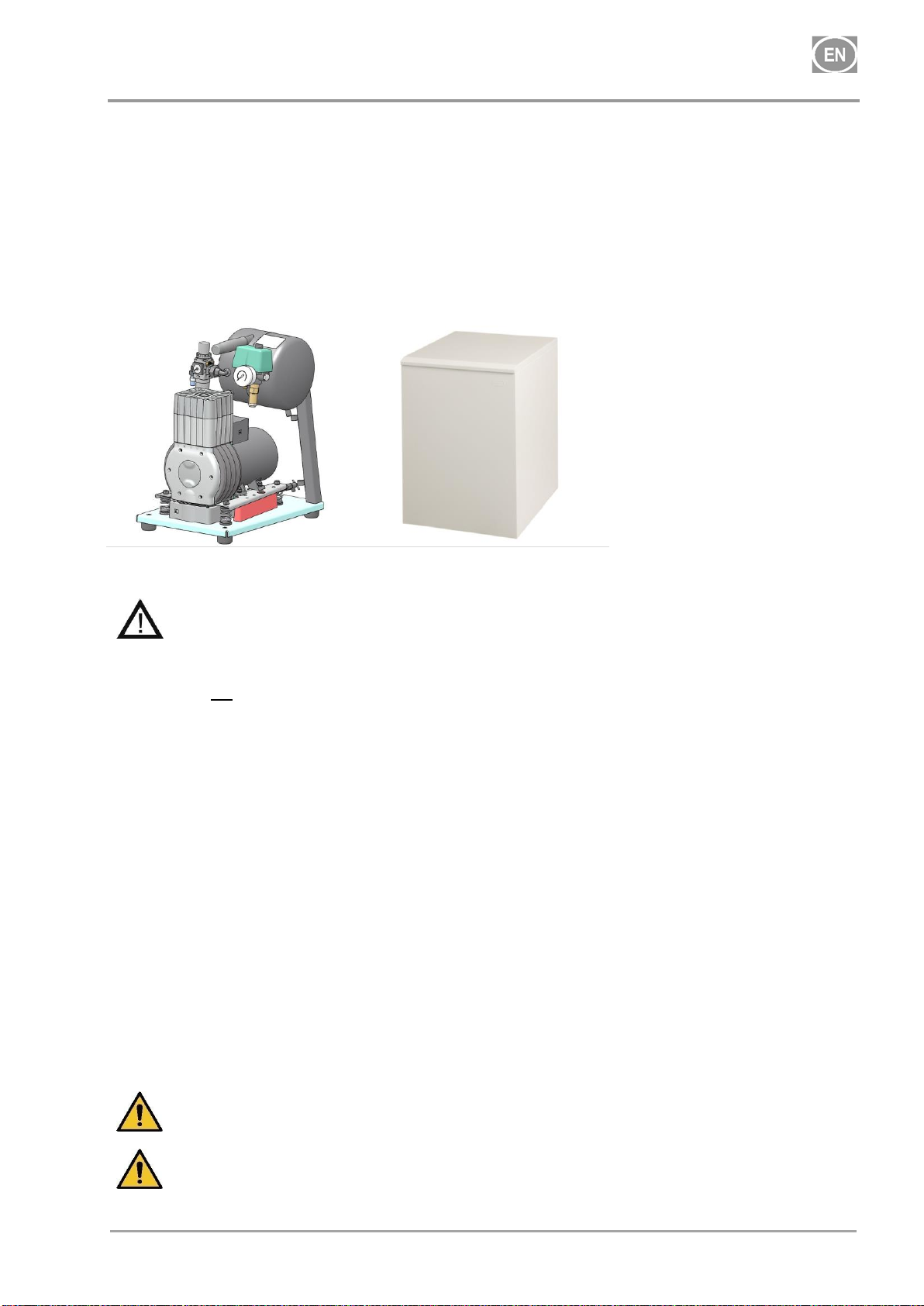

6. PRODUCT DESCRIPTION..............................................................................................................................................9

7. FUNCTION......................................................................................................................................................................9

INSTALLATION...................................................................................................................................................................11

8. USE .............................................................................................................................................................................11

9. INSTALLATION.............................................................................................................................................................11

10. FIRST PUTTING INTO OPERATION ............................................................................................................................13

OPERATION .......................................................................................................................................................................13

11. SWITCHING THE COMPRESSOR ON .........................................................................................................................14

MAINTENANCE...................................................................................................................................................................14

12. MAINTENANCE SCHEDULE ......................................................................................................................................14

13. MAINTENANCE ............................................................................................................................................................15

14. STORAGE.....................................................................................................................................................................16

15. DISPOSING OF THE APPLIANCE................................................................................................................................16

16. REPAIR SERVICE.........................................................................................................................................................16

17. SOLVING PROBLEMS..................................................................................................................................................16

BETRIEBSANWEISUNG......................................................................................................................................18

1. BEZEICHNUNG VON CE..............................................................................................................................................18

2. HINWEISE.....................................................................................................................................................................18

3. WARNHINWEISE UND SYMBOLE ...............................................................................................................................19

4. LAGER- UND TRANSPORTBEDINGUNGEN................................................................................................................20

5. TECHNISCHE DATEN..................................................................................................................................................21

6. PRODUKTBESCHREIBUNG.........................................................................................................................................22

7. FUNKTIONSBESCHREIBUNG......................................................................................................................................22

INSTALLATION...................................................................................................................................................................24

8. NUTZUNGSBEDINGUNGEN ........................................................................................................................................24

9. PRODUKTINSTALLATION............................................................................................................................................24

10. ERSTE INBETRIEBNAHME..........................................................................................................................................26

BEDIENUNG.......................................................................................................................................................................26

11. EINSCHALTEN DES KOMPRESSORS.........................................................................................................................27

WARTUNG..........................................................................................................................................................................27

12. WARTUNGSINTERVALLE............................................................................................................................................27

HINWEIS.............................................................................................................................................................................27

13. WARTUNG....................................................................................................................................................................28

14. ABSTELLEN..................................................................................................................................................................29

15. LIKVIDATION DES GERÄTES......................................................................................................................................29

16. INFORMATIONEN ÜBER DEN REPARATURDIENST..................................................................................................29

17. FEHLERSUCHE UND FEHLERBEHEBUNG.................................................................................................................30

NÁVOD NA POUŽITIE .........................................................................................................................................31

1. OZNAČENIE CE............................................................................................................................................................31

2. UPOZORNENIA............................................................................................................................................................31

3. UPOZORNENIA A SYMBOLY.......................................................................................................................................32

4. SKLADOVACIE A PREPRAVNÉ PODMIENKY .............................................................................................................33

5. TECHNICKÉ ÚDAJE .....................................................................................................................................................34

6. POPIS VÝROBKU .........................................................................................................................................................35

7. POPIS FUNKCIE...........................................................................................................................................................35

INŠTALÁCIA........................................................................................................................................................................37

8. PODMIENKY POUŽITIA................................................................................................................................................37

9. INŠTALOVANIE VÝROBKU ..........................................................................................................................................37

10. PRVÉ UVEDENIE DO PREVÁDZKY .............................................................................................................................39

OBSLUHA ...........................................................................................................................................................................39

11. ZAPNUTIE KOMPRESORA...........................................................................................................................................40

ÚDRŽBA .............................................................................................................................................................................40

12. INTERVALY ÚDRŽBY ...................................................................................................................................................40

POZORNENIE.....................................................................................................................................................................40

13. ÚDRŽBA........................................................................................................................................................................41

14. ODSTAVENIE ...............................................................................................................................................................42

15. LIKVIDÁCIA PRÍSTROJA..............................................................................................................................................42

16. INFORMÁCIE O OPRAVÁRENSKEJ SLUŽBE..............................................................................................................42

17. VYHĽADÁVANIE PORÚCH A ICH ODSTRÁNENIE ..................................................................................................43

SERVICE MANUAL/ WARTUNGSANWEISUNG / SERVISNÝ MANUÁL....................................................................44

18. WIRING DIAGRAMS / SCHALTSCHEMAS / SCHÉMY ZAPOJENIA.........................................................................44

19. SPARE PARTS / VERZEICHNIS DER ERSATZTEILE / ZOZNAM NÁHRADNÝCH DIELOV.........................................46

ANNEX / ANHANG / PRÍLOHA.............................................................................................................................52

20. INSTALLATION RECORD.............................................................................................................................................52

20. INSTALLATIONSPROTOKOLL.....................................................................................................................................53

20. ZÁZNAM O INŠTALÁCII................................................................................................................................................54