Keep Working

www.ELITETOOLS.co

10

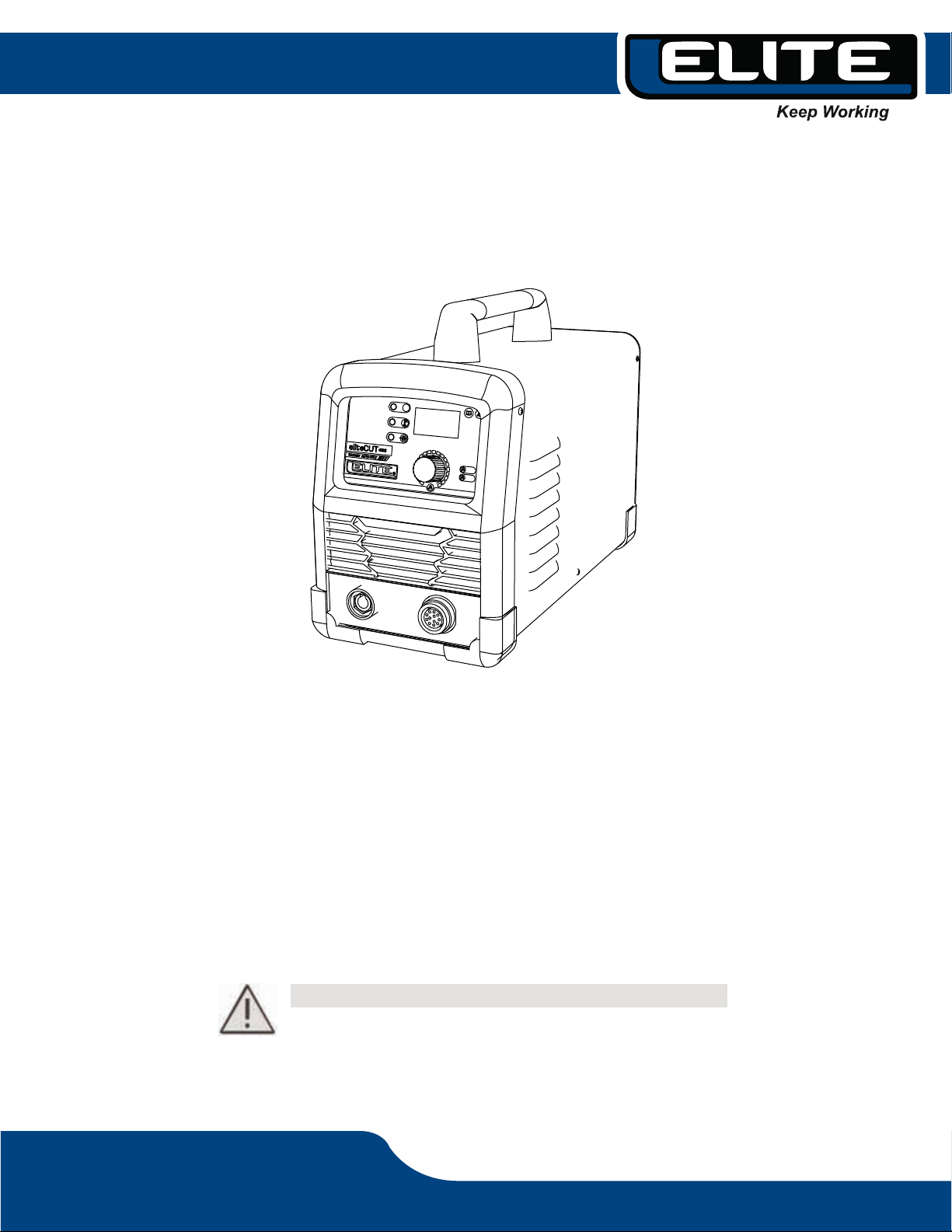

5. MACHINE CHARACTERISTICS INVERTER PLASMA CUTTER

This is a perfectly functioning, high performance and advanced technology digital plasma cutting

machine. The Elite CUT 40 S is an ultra-portable plasma cutting system suitable for a variety of

applications and requirements.

Intended for manual cutting application. The Elite CUT 40 S can cut conductive metal such as

low carbon steel, stainless steel, and aluminum.

The advanced design concept and the application of many modern technologies further protect

the user's investment.

The Elite CUT 40 S plasma cutting machine adopts international leading MUC digital intelligent

control technology, and the main parts are run through software. It is a digital control plasma

cutting machine, improved in many of its functions and performance compared to the traditional

plasma cutting machine.

Advanced digital control mode

Converts AC 50/60 Hz input voltage to DC. Through PWM technology and power IGBT modules,

the machine inverts this DC to a high voltage AC wave with a frequency of 30 to 100 KHz. The

voltage then drops and is rectified to DC output the Power Source for welding. The machine

adopts the switching inverter technology for the power supply, which greatly reduces the volume

and weight of the plasma cutter, and obviously improves the efficiency. The inverter operates at

frequencies higher than audible, which virtually eliminates noise pollution.

Advanced Inverter Technology

We generally speak of inverter machines with analog circuit control, or with analog circuits and

digital circuit control. Performance characteristics are determined by the parameters of various

components. The performance of machines differs because of these parameters, even for

machines of the same brand, their parameters often differ from each other. Also, the performan-

ce of the machine may change to some extent, as the parameters of the components may vary

depending on the environment, such as temperature and humidity, etc. One of the characteris-

tics of digital control is that it is not sensitive to changing parameters; The performance of the

machine will not be affected by changing the parameters of certain parts. Therefore, the consis-

tency and stability of the digital control cutter is better than that of the traditional cutter.

Stable performance and consistency