Elka EST 4004K User manual

©06.03.06ELKA-Torantriebe GmbH & Co. Betriebs KG Seite 1 ED 200, ED 202, ED 350, ED 352

Installation and Operating Instructions

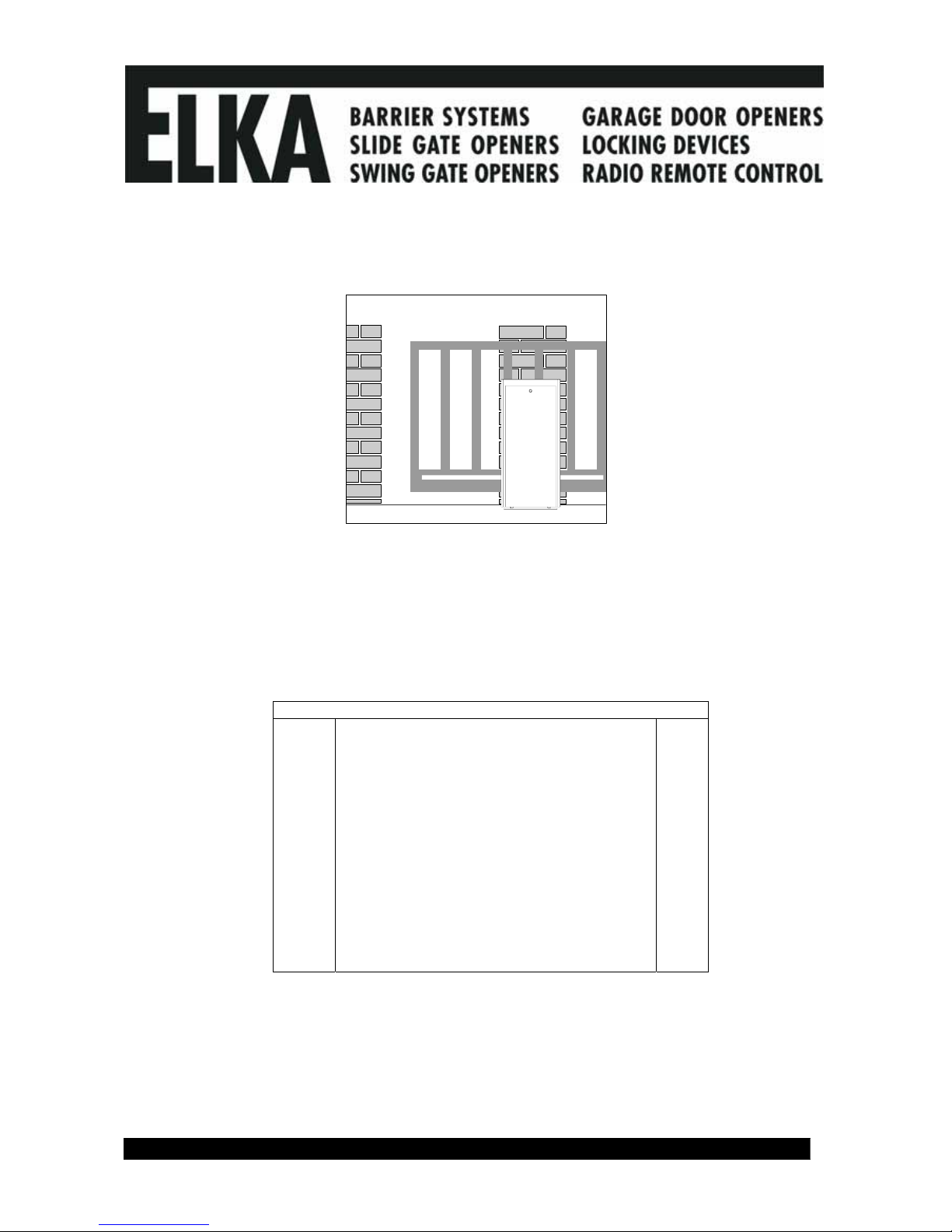

Slide Gate Openers

EST 4004K

Contents Page

1. Usage 2

2. Technical data 2

3. Measurements 2

4. Installation 3

4.1 Emergency release 4

5. Electrical connections 4

6. Connection example 5

7. MO 44-2 Controller 6

7.1. Connections 7

7.2. Operating mode 8

7.3. Programming 11

8. Timer module (optional) 12

9. Fault codes 13

10. Setting personal code 13

11. General notes to safety 14

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 2 EST 4004K

1. Usage

For horizontal moving sliding gates either on rails or as a cantilever, up to the weights stated in the technical

data. Please take note of the valid safety regulations.

2. Technical Data

EST 4004K

Maximum weight 4000 kg

Recommended maximum length 16 m

Self blocking at open and closed positions yes

Approximate speed 0.18 m/s

Rack Module 6

Duty cycle 75%

Temperature range -20°C to +70°C

Emergency release yes

Possible height adjustment 30 mm

Housing H x W x L 800x372x270 mm

Opener weight 68,0 kg

Power supply 400 Vac / 50 Hz

Power consumption 2.2 kW

Control box MO44-2

Electronic brake no

The MO 44-2 control box has among others the following characteristics:

Safety: Four separate reactions to the photo-cell.

Automatic test of the photo-cells before each gate movement can be enabled.

Integrated evaluator for safety contact strips with 8.2 kΩterminating resistors.

Actions: Partial opening (e.g. for pedestrians) can be programmed for any position.

Automatic closure can be set separately for completely open and for partially open.

A dead man’s button can also be set.

Separate inputs for OPEN, STOP and CLOSE commands.

The OPEN button can also be transmitted to a further control box (e.g. for a barrier).

Optional timer card for automatic switching between day and night operation.

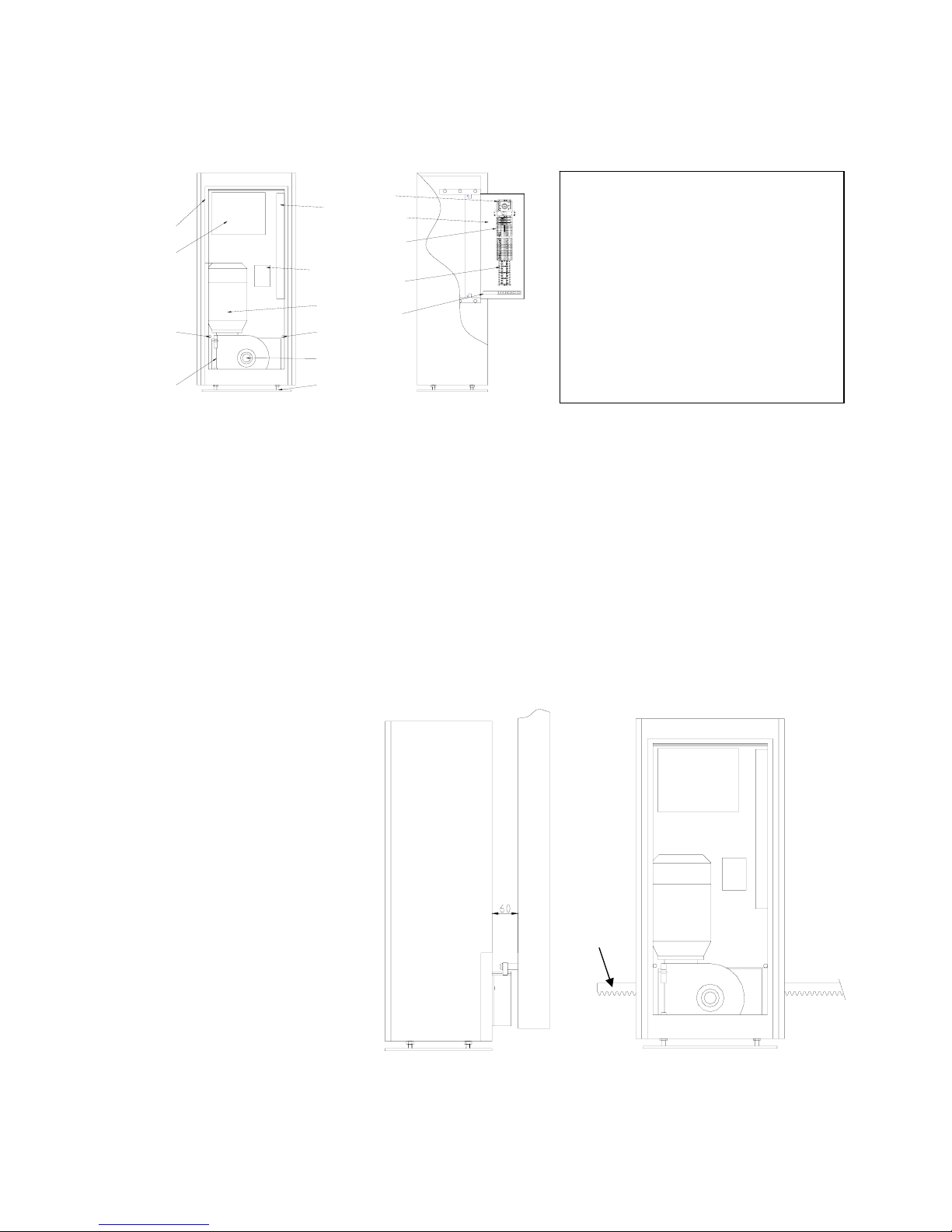

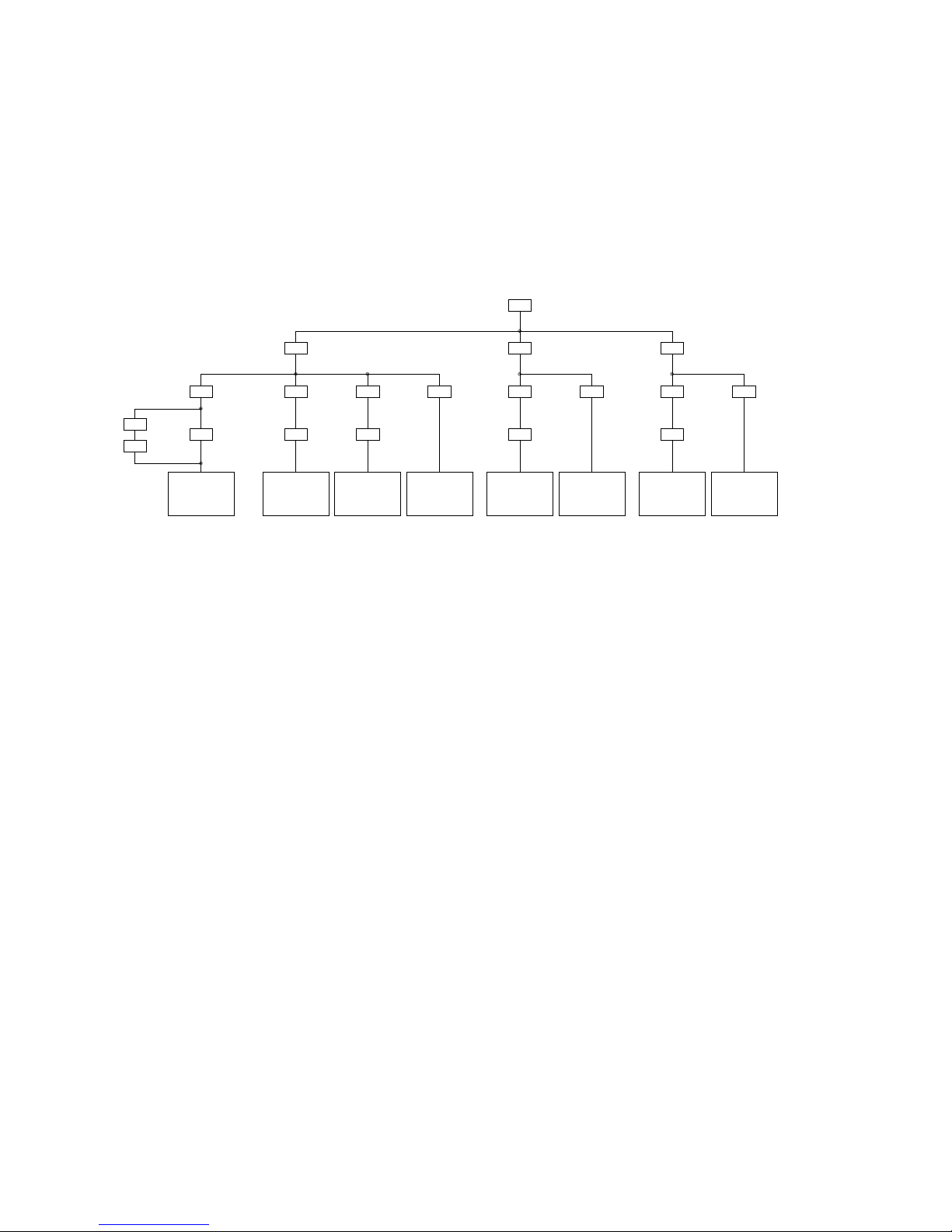

3. Measurements

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 3 EST 4004K

4. Installation

Ensure that the gate is rigid enough, free moving, and suitable for automation (i.e. enough room to

secure the rack on the gate).

Always disconnect the control box before arc welding is carried out.

7

9

5

11

12

1

2

3

4

5

6

10

13NO

14NO

A1

A2

K1

A1 3L2 5L31L1

A2 4T2 6T32T1

5L313NO3L21L1

6T314NO

K2

4T22T1

13

13

8

a) Using the example in section 6 decide which cables are required and where the control box is to be

mounted (near the opener). The cable should enter the control box from the bottom.

b) Make sure sufficient cable conduit or cable is laid into the foundation which should be free from frost.

The very bottom opener should be at least 30 mm higher than the surrounding terrain and should be as

near as possible to the pivoting point of cantilever gates.

c) Open the access panel of the opener and remove the height adjustment plate. You now have access to

the elongated ground fixing holes.

d) Place the opener on the foundation parallel to the gate at a distance of 60 mm. Mark the middle of each

hole on the foundation.

e) Fix the opener, either with plugs and screws (M20), or with heavy duty tie bolts.

e) Decide at what height the rack is to be mounted on the gate. You can use the opener with the height

adjustment plate, or if the rack is to be as low as possible, without the adjustment plate.

g) Using the accompanying tubular “T”-bar disengage the opener (anticlockwise disengages and clockwise

re-engages. See section 4.1.)

h) Mount the rack at the required height on the gate. Don’t use the edges of the gate, always use the pinion

of the opener to determine the

height on the gate.

Lay a length of rack horizontally

on the pinion. Mark the height

of the securing points on the gate

through a hole in the rack. You

may push the gate along while

marking in order to gain a marking

line.

The rack and the pinion should fit

together with minimum play but

enough to ensure that the pinion

does not carry the gate.

1 Aluminium housing

2 MO44-2 Control box

3 Cable clip

4 Terminal block

5 Proximity switch

6 Gear box

7 Power outlet

8 Reversing contactor

9 11 pole socket

10 Motor

11 Emergency release SW22

12 Height adjustment

13 Mounting plate

h)

mark

here

d)

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 4 EST 4004K

i) Drill holes at the appropriate points to secure the rack and then tap an M8 thread. The rack should

protrude 20cm further than the pinion at both limits of gate movement to allow room for the actuators for

open and closed proximity switches.

j) Screw the distance pieces into the gate, which can also be welded in position.

k) Mount the 1 metre lengths of rack. For better results press a third length (with teeth upwards) against the

joints to produce the required distance between lengths.

l) Push the gate completely open and closed and check that it doesn’t jam. If necessary adjust the height

of the rack.

4.1. Emergency release

Open the access panel and using the accompanying tubular “T” bar (SW22) loosen the hex head screw on

the gearbox.

Turning the bar a couple of turns anti-clockwise disengages the gears.

To re-engage the gears, turn the tee wrench clockwise as far as it will go. (see page 3).

5. Electrical Installation

All cables should have at least the suggested cross-sections.

a) Connect the power supply.

b) The opener closes to the left on delivery. The right limit switch (SEZ) stops the movement.

c) If your gate closes to the right swap the motor leads for „open“ and „close“ and swap the leads to the

terminals SEA and SEZ on the control board.

d) Disengage the opener.

e) Close the gate and push the holding plate with magnet along the rack until the

LED SEZ turns off. Fix the holder at this point on the rack so that the magnet

passes the housing at a distance of about 10 mm.

f) Open the gate and push the holding plate with magnet along the rack until the

LED SEA turns off. Fix the holder at this point on the rack so that the magnet

passes the housing at a distance of about 10 mm.

f) Re-engage the opener and carry out a test run with the gate. Use the push

button BT on the controller card which has serial switching OPEN-STOP-

CLOSE-STOP.

Ensure that the LED SEZ turns off when the gate is closed (not SEA)

otherwise you will have malfunctions (e.g. automatic closing becomes

automatic opening).

g) If necessary readjust the actuators for the proximity switches so that the gate

closes exactly.

h) Connect all periphery equipment.

The time required to open or close the door (running time) must be learned.

Caution:

During the learning mode the gate will move automatically several times.

Ensure nobody will enter the gate area.

Learning the running time: (see section 7.3)

Switch the power regulation on with DIP A1 and DIP A2. Choose a low setting, if required it can always be

increased (see section 7.2.).

Press LT for at least 3 seconds The LED DIAG lights.

Press LT twice. The gate closes from any position, opens completely and closes again. Press the LT button

to confirm, the running time and 10 % reserve and the power required are saved.

The opener is ready for use.

Carry on setting operating mode as described in section 7.2.

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 5 EST 4004K

6. Connection example

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 6 EST 4004K

2T1

1L1 1L1

2T114NO6T34T2 A2

13NO

5L33L2

K2

A1

6T34T2 14NO A2

5L33L2

K1

13NO A1

loop

BA1

STOP START

7. MO 44-2 Controller

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 7 EST 4004K

7.1. Connections

PE Ground Power supply

L1 Phase L1 Power supply. 230 V 50Hz. The LED Vp lights if net voltage is present.

N Neutral Power supply

-------

(N) Neutral

APL-RT Red signal, 230 V max. 60 W. The red light is on when the gate is closed and warning prior

opening is not active.

APL-GN Green signal, 230 V max. 60 W. The green light is on when the gate is open and warning

prior closing is not active.

(N) Neutral

WARN Warning light 230 V max. 60 W. The warning light is on every time the gate moves and also

if a warning prior to moving is active.

The warning light can be used also as red if it’s desired that red turns off when the gate is

closed.

Gate status Warning Red Green

Gate closed Off On Off

Gate open Off Off On

Prior warning and movement On Off Off

Gate stopped in any position in between Off Off Off

Gate stopped at pedestrian position Off Off Off

-------

(N) Neutral for motor (Common for both directions)

AUF Motor open - Direction

ZU Motor close - Direction

EXT-AUF Transmission of the signal BA1 to a second control box (n.o.).

The relay EXT-AUF (max. 24V, 100mA) energises if BA1 is pressed, or the corresponding

remote button is used and falls off after about 1 second. The connection EXT-AUF can be

used to transmit the signal to a open-input to a second control box e.g. for a barrier.

-------

BA1 Button to open the gate (n.o.), the signal is transmitted to terminal EXT-AUF. The LED BA

lights if BA1 or the corresponding remote button is pressed. A permanent open signal is

possible.

BA2 Button to open the gate (n.o.), the signal is valid only for this controller. The LED BA lights

when BA2 is pressed. A permanent open signal is possible.

BZ Button to close the gate (n.o.). The LED BZ lights when pressed. Delayed closing is possible

(see operating mode).

LS Photo-cell (n.c.), or a jumper. The LED LS lights when the photo-cell is interrupted. The

controller can react in three different ways (see section 7.2.). The photo-cell can also be

connected to BS and used as a stop button.

NB Toggle between day and night operating mode, works only when the optional timer card is

being used (see section 8.).

SLZ Safety contact strips (n.c.) for direction “gate closed”, or a resistor (8,2kΩ). The LED SLZ

lights whenever the strips are activated. SLZ causes STOP and reversal for a short way.

SLA Safety contact strips (n.c.) for direction “gate open”, or a resistor (8,2kΩ). The LED SLA

lights whenever the strips are activated. SLA causes STOP and reversal for a short way.

SEA Limit switch „gate open“ (n.c.) . The LED SEA turns off when limit switch is pressed.

SEZ Limit switch „gate closed“ (n.c.). The LED SEZ turns off when limit switch is pressed.

BS STOP button (n.c.) or a jumper. The LED BS turns off when BS is pressed. BS stops gate

movement (electronic brake). The gate can only move again when BS is released and a new

signal is given.

BT Push button for serial switching OPEN-STOP-CLOSE-STOP (n.o.). The LED BT lights when

BT or the corresponding remote button is pressed (see automatic closure, too).

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 8 EST 4004K

BTG Button for pedestrian opening (n.o.). The LED BTG lights when BTG or remote button is

pressed. If the gate is not in the pedestrian position, BTG will move it there. If the pedestrian

opening is being used without automatic closure, then BTG works with serial switching

OPEN-STOP-CLOSE-STOP.

If automatic closure is on and the gate is at the pedestrian position, the BTG restarts the time

to stay open.

24 Vdc Power supply for periphery equipment.

12 Vdc Power supply for photo-cells and other external equipment.

Maximum total for both outputs

300 mA

LS-TST Power supply for transmitter. The controller switches the 24 Vdc on terminal LS-TST off.

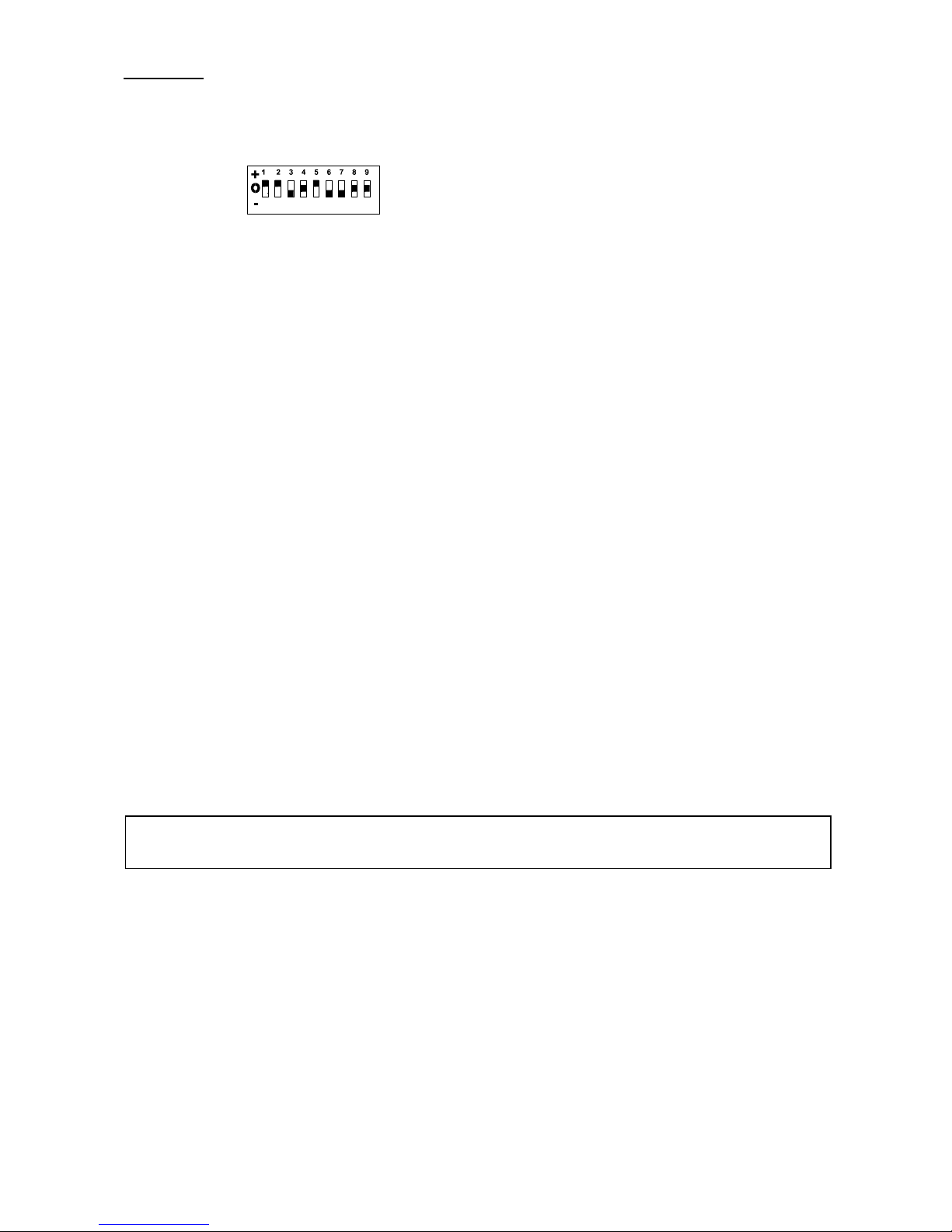

7.2. Operating mode

Motor power (Changes only take effect if the running time is then learned again!)

DIP A1 OFF 100% power.

DIP A2 OFF

DIP A1 OFF 80% power.

DIP A2 ON

DIP A1 ON 70% power.

DIP A2 OFF

DIP A1 ON 60% power.

DIP A2 ON

Photo-cell (Photo-cell connected to BS is stop.)

DIP A3 OFF The opening or closing gate stops when the photo-cell is interrupted and opens when the

DIP A4 OFF photo-cell is free.

DIP A3 OFF The closing gate stops and opens immediately when the photo-cell is interrupted.

DIP A4 ON The opening gate is not effected.

DIP A3 ON The closing gate stops when the photo-cell is interrupted and carries on closing when the

DIP A4 OFF photo-cell is free. The opening gate is not effected.

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 9 EST 4004K

Automatic closure for partial (pedestrian) opening.

DIP A5 OFF Automatic closure is off.

DIP A5 ON Automatic closure for the pedestrian position is enabled.

If the gate is at the pedestrian position, BTG restarts the time to stay open. The gate opens

completely if BA1 or BA2 is pressed. The gate closes immediately if BT or BZ is pressed.

Automatic closure for completely open.

DIP A6 OFF Automatic closure is off.

DIP A6 ON Automatic closure from the open position is enabled.

If the gate is in open position BA1 or BA2 restart the time to stay open. The gate closes

immediately if BT or BZ are pressed when the gate is open. The gate reopens if BT is

pressed during closing.

Warning prior to opening

DIP B1 OFF No warning.

DIP B1 ON The warning light is switched on 4 seconds before the gate opens.

Warning prior to closing

DIP B2 OFF No warning.

DIP B2 ON The warning light is switched on 4 seconds before the gate closes.

Locking relays / Dead man’s button

DIP B3 OFF The control box works with locking relays.

DIP B3 ON BA1, BA2 and BZ are dead man’s buttons. (The opener stops as soon as the button is

released).

Delayed closing

DIP B4 OFF The opening gate closes immediately when BZ is pressed.

DIP B4 ON If the gate is opening and BZ is pressed, the signal is stored until the gate is open and then

carried out.

Three-phase operation

DIP B5 OFF Drive with single-phase motor (with electronic brake)

DIP B5 ON Three-phase motor (with reversing contactor and mechanical brake)

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 10 EST 4004K

Photo-cell testing before gate movement

DIP B6 OFF Photo-cell test is not activated.

DIP B6 ON A photo-cell test occurs before each moving.

Attention: The photo-cell test has to be learnt when programming the controller. Before the

moving of the gate, the photo-cells may be tested.

Max. 6 photo-cells can be connected to the controller MO44-2 and be tested. For the testing

of more than one photo-cell the relay connections of the receivers have to be connected in

series. Parallel to the relay connections a resistor of 1kOhm (+/- 5%) each has to be

connected.

The photo-cell test consists of two parts: The transmitter is taken off the power supply and

then the receiver has to report an obstacle (within max. 2.5 seconds).

The transmitter is connected to the power supply again and then the receiver has to report

that no obstacle is present. If during part one the receiver does not report an obstacle, the

photo-cell is faulty. If during part two the obstacle is still being reported (the controller

assumes a real obstacle being present), the gate will not move. No error code is shown.

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 11 EST 4004K

LT

LT

LT

LT LT

BT

BT BT

BT

BT BT

BTG

BTG BTG

BTGLT

Funk Funk Funk

running time

is stored

all personal

codes are

erased

position for

partial opening

is stored

remote code

for BA1 is

stored

time to stay for

position open

is stored

press 3s

Diag-LED lights

Diag-LED flashes

quickly

Diag-LED lights,

gate opens and

closes, 10 s

reserve are set

Diag flashes

Diag-LED

flashes each

second, set

new reserve

Diag-LED

lights

Diag-LED

lights, BTG is

deadman

button, move

to partial open

position

gate closes

Diag-LED

lights for 3s

Diag-LED

flashes each

second, set

time to stay

open

Diag-LED flashes

quickly

Diag-LED flashes

quickly

Diag-LED

lights for 3s

Diag-LED

lights for 3s

Diag-LED

flashes each

second, set

time to stay

open

remote code

for BT is

stored

time to stay for

partial open is

stored

remote code

for BTG is

stored

7.3. Programming

The minimum to ensure that the opener works correctly is that the running time must be learned. Other

things like automatic closure, or time which the gate should stay open before closing can also be set during

programming.

The following settings can be altered if required:

Time required to open (running time) (0...150 s, default 30 s)

Reserve for the running time (0...10 s, default 10 s)

Time to stay open before automatic closure (0...300 s, default 20 s)

Time to stay open before automatic closure from partial position (0...300 s, default 20 s)

Position for partial opening for pedestrians (any position, default half way)

Remote control codes for BT, BTG and BA1 (default BT -+-+...)

Learning the time for opening (running time) and reserve

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press LERN twice.

The gate closes from any position, opens completely and closes again. The time required and the power

selected (DIP A1 and DIP A2) are then saved. The LED DIAG starts flashing quickly, the running time is

learned. Press LERN if you want to accept the default value for the running time reserve (10 s). The

controller is ready for use.

If you want to change the running time reserve press BT, the LED DIAG flashes in 1 second intervals, press

BT when the required time has elapsed. The controller is ready for use.

The position for partial opening is automatically set to half way when the running time is learned, this means

that any other value for pedestrian opening must be learned after the running time!

Learning partial opening for pedestrians

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press LERN once. The LED DIAG flashes quickly.

The BTG button moves the gate in dead mans mode. When the gate is at the required position press LERN.

The gate closes automatically and the information is stored. The controller is ready for use.

Learning the time to stay open before automatic closure (completely open)

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press BT twice. The LED DIAG flashes in 1 second intervals.

When the time required has elapsed press BT again.

The time is stored and the controller is ready for use. The time is only effective when automatic closure is on

(DIP A6 ON).

Learning the time to stay open before automatic closure (partial opening for pedestrians)

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press BTG twice. The LED DIAG flashes in 1 second intervals.

When the time required has elapsed press BTG again.

The time is stored and the controller is ready for use. The time is only effective when automatic closure is on

(DIP A5 ON).

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 12 EST 4004K

Learning the remote control code for BT

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press BT once. The LED DIAG flashes quickly. Press the appropriate button of your transmitter.

The LED DIAG stays on as long as a signal is received. Release the button. The code is stored and the

controller is ready for use.

Learning the remote control code for BTG

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press BTG once. The LED DIAG flashes quickly. Press the appropriate button of your transmitter.

The LED DIAG stays on as long as a signal is received. Release the button. The code is stored and the

controller is ready for use.

Learning the remote control code for BA1

Press LERN until the LED DIAG lights (approx. 3 seconds).

Press LERN once. The LED DIAG flashes quickly. Press the appropriate button of your transmitter.

The LED DIAG stays on as long as a signal is received. Release the button. The code is stored and the

controller is ready for use.

8. Timer card (optional)

The 7-day-timer can switch between day and night operating.

Day: A continuous signal to open is given in order to hold the sliding gate open. All Signals from BA1 are

sent to EXT-AUF for a further control box.

Night: All signals from BA1 operate the sliding gate and are sent to EXT-AUF for a further control box.

Holidays: The switch NB (night operation) can override the timer. If NB is closed, night operation is active

independent of the status of the timer. The timer has control when NB is open.

Forcing day operation at night: A continuous signal to BA2 opens the sliding gate and keeps it open

independent of the timer status.

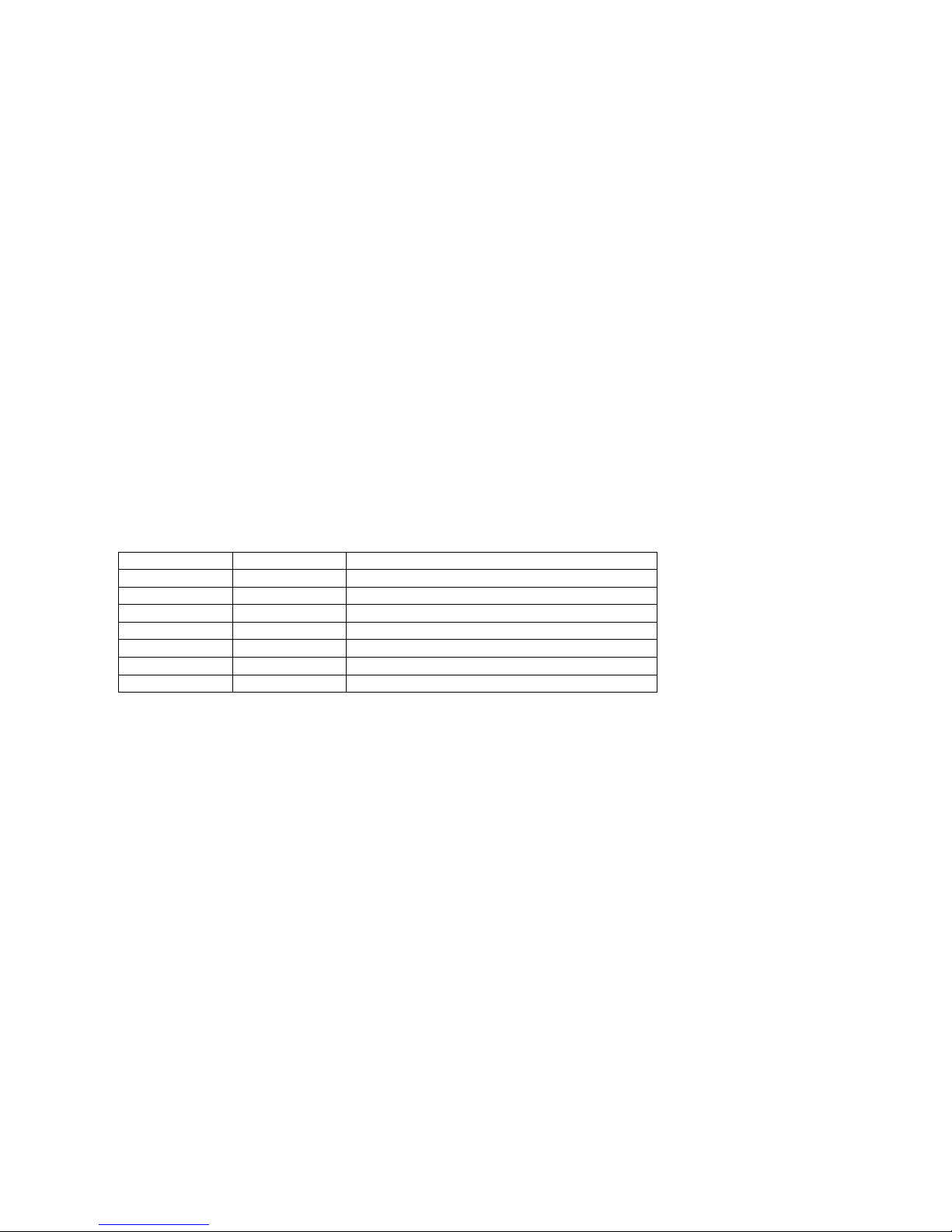

Times NB Gate status

Off Doesn’t matter Does not affect the gate

Switches on Off The gate opens

On Off The gate is held open

Switches off Off The gate closes

On Switches on The gate closes, night operation is forced

On Switches off The gate opens, day operation is continued

Doesn’t matter On Does not affect the gate

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 13 EST 4004K

9. Fault code

The following faults are detected by the controller and reported as a code with

the DIAG and remote control LED:

Code Fault

DIAG 2 flashes Both limit switches are activated. Check the switches and wiring.

DIAG 3 flashes Photo-cell testing unsuccessful.

DIAG 4 flashes Safety contact stripes (SLA) testing unsuccessful.

DIAG 5 flashes Safety contact stripes (SLZ) testing unsuccessful.

DIAG 6 flashes Running time error message. Check the switches or repeat the

learning of the running time.

DIAG 7 flashes The power supply limit for the external equipment 12 V has been

reached. The power source load is too high. The controller is

blocked.

DIAG 8 flashes The power supply limit for the external equipment 24 V has been

reached. The power source load is too high. The controller is

blocked.

DIAG 9 flashes The memory has lost the data. Repeat the learning of the running

time.

DIAG 10 flashes The controller is faulty.

DIAG 11 flashes The controller has detected a fault in the redundant detection of

BS (stop contact). The controller is faulty.

DIAG 12 flashes The controller detects that the TRIAC or one of motor relays is

faulty.

10. Setting personal code in the K Type radio remote control

Example A) Receiver using the code switches on the logic board : MO 33, MO 43 or MO 542

or receiver with code switches in conjunction with the boards : MO 32, MO 42, MO 52Z2, MO 60 or MO

62

Follow the example in the diagram below.

Transmitter SK, SKX and SKI in conjunction with K Type receivers using code switches.

The switches 1 to 7 in transmitter and receiver must have the same settings. The switches 8 and 9 of the

receiver allocate a channel appropriate to the button of the transmitter. The switches 8 and 9 in

multi - channel must be set at 0.

The examples on the right in the diagram above show the allocation of a channel with a one - channel

transmitter using the switches 8 and 9 as in the receiver.

Example B) Receivers without code switches : Logic boards MO 34, MO44 or MO 55

These receivers learn the code from the transmitter as described in the paragraph ‘Learning personal code’

in these installation instructions.

© 27.04.2005 ELKA-Torantriebe GmbH u. Co. Betriebs KG Page 14 EST 4004K

Example C) Combination of examples A and B

A garage door opener with MO 55 and a swing gate opener with either MO 32 or MO 33.

1.) Set the code of the transmitter and receiver for the swing gate opener as described above. Switches 1

to 7 have the same settings in both transmitter and receiver. The switches 8 and 9 set at 0.

The swing gate opener now receives signals from the first button of the transmitter.

2.) You can now allocate the second button to the garage door opener by going through the procedure

described in the installation instructions for the garage door opener in the paragraph ‘Learning

personal code’.

11. General Notes to Safety

These operating instructions must be available on site at all times. It should be read thoroughly by all

persons who use, or service the appliances. Improper usage or servicing or ignoring the operating

instructions can be a source of danger for persons, or result in material damage. If the meaning of any part

of these instructions isn’t clear, then please contact ELKA Torantriebe GmbH & Co. Betriebs KG before you

use the appliance.

This applies to all setup procedures, fault finding, disposal of material, care and servicing of the appliance.

The accident prevention regulations and applicable technical regulations (e.g. safety or electrical) and

environment protection regulations of the country in which the appliance is used also apply.

All repairs on the appliances must be carried out by qualified persons. ELKA Torantriebe GmbH & Co.

Betriebs KG accepts no liability for damage which is caused by using the appliance for purposes other than

those for which it is built.

ELKA Torantriebe GmbH & Co. Betriebs KG cannot recognise every possible source of danger in advance. If

the appliance is used other than in the recommended manner, the user must ascertain that no danger for

himself or others will result from this use. He should also ascertain that the planned use will have no

detrimental effect on the appliance itself. The appliance should only be used when all safety equipment is

available and in working order. All faults which could be a source of danger to the user or to third persons

must be eliminated immediately. All Warning and Safety notices on the appliances must be kept readable.

All electrical periphery equipment which is connected to the appliance must have a CE Mark, which ensures

that it conforms to the relevant EEC regulations. Neither mechanical nor electrical alterations to the

appliance, without explicit agreement of the manufacturer, are allowed. All alterations or extensions to the

appliance must be carried out with parts which ELKA Torantriebe GmbH & Co. Betriebs KG have defined as

suitable for such alterations, and be carried out by qualified personnel.

Any contravention of these conditions revokes the manufacturer’s guarantee and also the CE Mark and the

user is alone responsible for the consequences.

Our service department is available to answer all queries about these conditions and, of course, about our

appliances.

We reserve the right to make technical improvements without prior notice.

The operation of the system within CEN countries must also be conformant with the European safety-

relevant directives and standards.

Table of contents

Other Elka Gate Opener manuals

Popular Gate Opener manuals by other brands

Allmatic

Allmatic IND4000V/T manual

Chamberlain

Chamberlain BG 3100-X1 Installation and operation instructions

Mighty Mule

Mighty Mule FM500 installation manual

SEA

SEA COMPACT 200 CP Fitting and Connection Instructions

tau

tau ARM200 Series Use and maintenance manual

tau

tau R18 series Use and maintenance manual

Daspi

Daspi DS 301 manual

Avidsen

Avidsen STYRKA400 quick start guide

Erreka

Erreka MAGIC Installer manual

Mhouse

Mhouse WG20 Installation instructions and warnings

Dea

Dea REV Series Operating instructions and warnings

Wallace Perimeter Security

Wallace Perimeter Security SPEEDGATE Installation and maintenance manual