Important safety instructions

© Elma Schmidbauer GmbH BA_Elmasolvex_VA_EN_Vers.05.2018

Keep the installation area, case and controls dry. Protect

against ingress of moisture. Unplug the mains plug during

filling, maintenance and care of the cleaning machine, suspicion

that liquid has penetrated, operating faults and after use.

The cleaning machine must only be opened by trained staff.

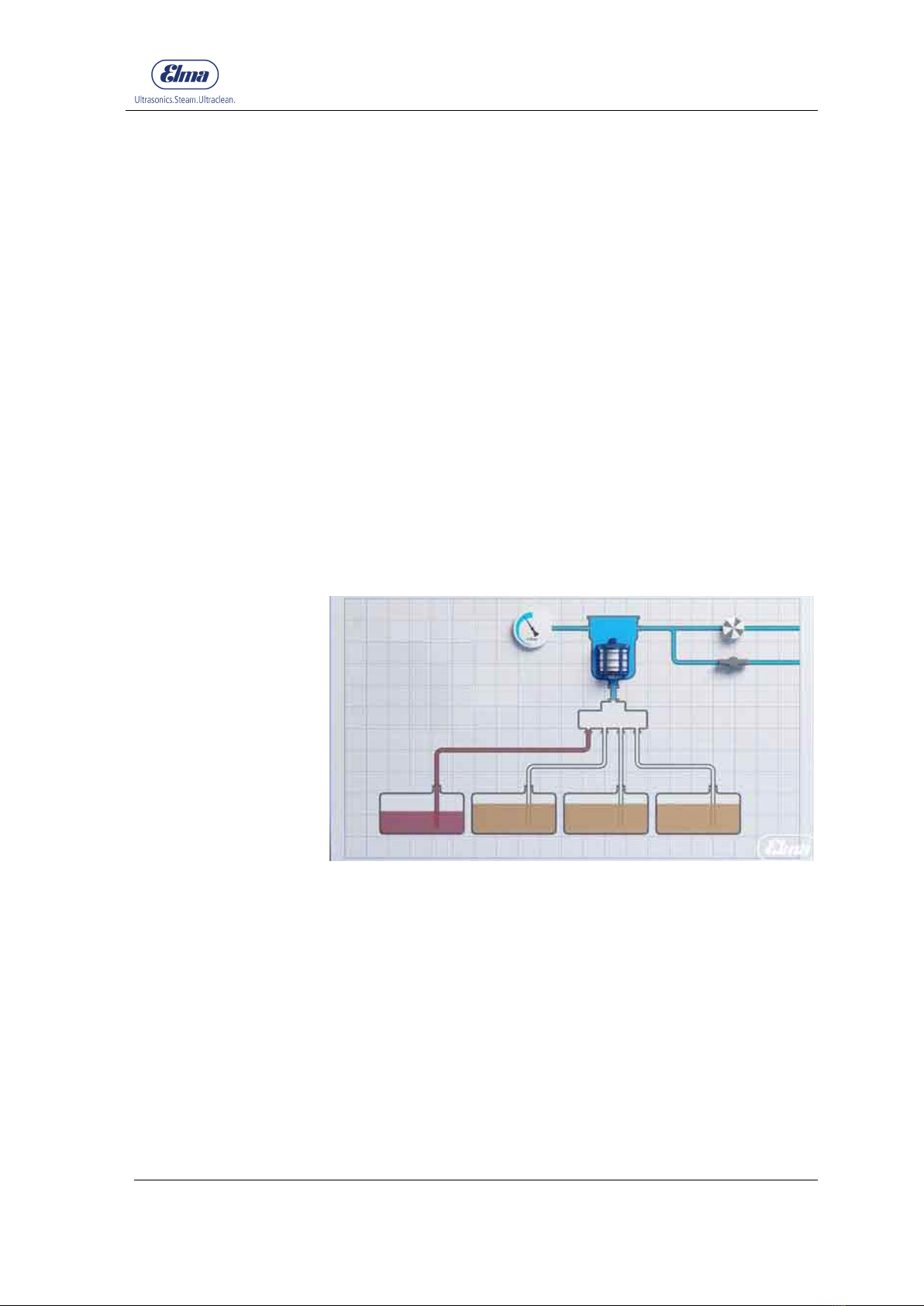

The cleaning machine must be installed at a dry and sufficiently

ventilated place for the extraction of vapours of the cleaning

and rinsing media from the area of the media tanks filled with

these media.

The installation surface must be smooth and flat for application-

related reasons.

The maximum permitted ambient temperature is 30 °C.

The intended exhaust air equipment (exhaust air pipes with

maximum length 5 m or activated carbon unit) for them must be

installed at the ventilation openings (cleaning machine rear

side) before start-up.

Only permitted media must be used in this cleaning machine.

Observe the information in Chapter 8.

The cleaning machine is only permitted to be operated with the

connected and correctly filled 4 original media tanks included in

the scope of delivery (see Chapter 4.4).

Ignitable solvent vapours can escape in the case of improper

operation (without exhaust air connection) and during

replacement of the cleaning and rinsing media.

Smoking and open ignition sources in the cleaning machine

surroundings, particularly in the immediate vicinity of the zone

marked with the appropriate danger symbol are therefore

prohibited.

Strictly observe the safety instructions specified in this manual

to prevent such hazards.

In the event of liquid discharge from the cleaning machine

(amount > droplets), the cleaning machine must no longer be

operated for safety reasons.

Maximum one day's requirement of the solvents used is

permitted to be stored in the surroundings of the cleaning

machine at a minimum distance of 3 m from the cleaning

machine.

Observe the specified safety measures in the safety data

sheets of the respective media used. This also applies with

respect to solvent vapours.

Depending on the operating time of the cleaning machine,

surfaces, particularly the inner wall of the drying chamber, can

become very hot (max. approx. 65 °C).

The black Elma basket holder (Art. No. 105 3905) is delivered

as standard. It is used for attaching electropolished baskets,

baskets made from stainless steel, plastic-coated baskets and

plastic baskets. Only electropolished baskets may be used in

the blue Elma basket holder (Art. No. 105 3162 Accessories).

Prevention of

electrical accidents

Media (cleaning /

rinsing solutions)

Fire and explosion

hazard