Important safety warnings

© Elma Schmidbauer GmbH BA_ Elmasonic xtra ST 1900S_EN_Vers.04.2019

2.2 Safety instructions for the use of the unit

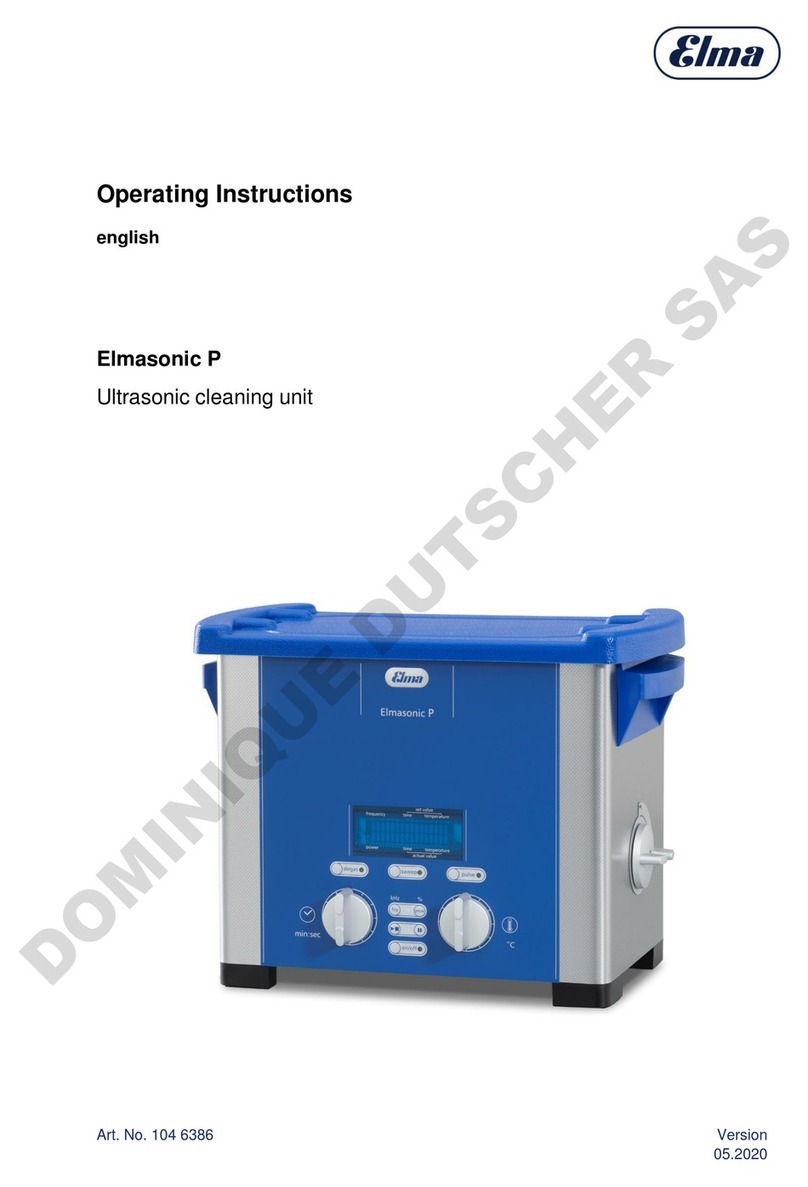

The present ultrasonic cleaning unit has been designed for the

treatment of items immersed in a cleaning liquid only.

It is not intended for the use in areas with potentially explosive

atmosphere.

Operation of the unit by authorized and instructed staff only.

Observe the instructions given in the manual.

Check unit and mains cable for transport damages. Do not

operate the unit in case of visible damages!

For safety reasons, the present unit must be connected to a

correctly grounded socket only. The technical details indicated

on the nameplate must correspond with the available mains

connection details, in particular those of the mains voltage and

current connected value.

Place the unit on a dry surface. The work area must be

sufficiently ventilated to allow any vapours arising from the

cleaning liquid to be carried off. Keep work surface, housing

and operating elements dry.

For operation the unit must be fastened to the delivered support

frame. For reasons of safety the support frame should be

screwed to the floor.

For purposes of filling, maintenance and care of the unit, in

case of suspected humidity inside the unit or in case of

malfunctions and after operation pull the mains plug.

The unit must be opened by authorised specialised personnel

only.

The unit must be operated with aqueous cleaning media only.

Flammable liquids must not be treated by ultrasound directly in

the cleaning tank: risk of fire and explosion!

Risk of burning and scalding! Depending on the operational

period of the unit, unit surfaces, cleaning liquid, basket and

cleaning items can heat up considerably.

During operation with high temperatures inside the cleaning

bath open the unit with care: hot steam can emerge when the

cover is lifted.

Do not move the filled unit, obstacles may cause the unit to tilt

over, or damage the rollers.

Ultrasonic units can produce annoying sounds.

Wear personal ear protection devices when working close to an

ultrasonic unit which is operated without cover.

The use of personal ear protection devices is particularly

recommended for operating the unit at 25 kHz with open cover.

Do not reach inside the cleaning liquid or touch sound-carrying

parts (tank, basket, cleaning items, etc.) during operation.

Prevention of

electrical accidents

emp

Sound transmission

at physical contact