Contents

Contents

1General....................................................................... 3

2Important safety warnings .......................................... 3

2.1 Instructions for the use of the present manual.......... 3

2.2 Instructions for the use of the unit ............................ 4

3Functioning................................................................. 5

3.1 Ultrasonic cleaning factors ....................................... 5

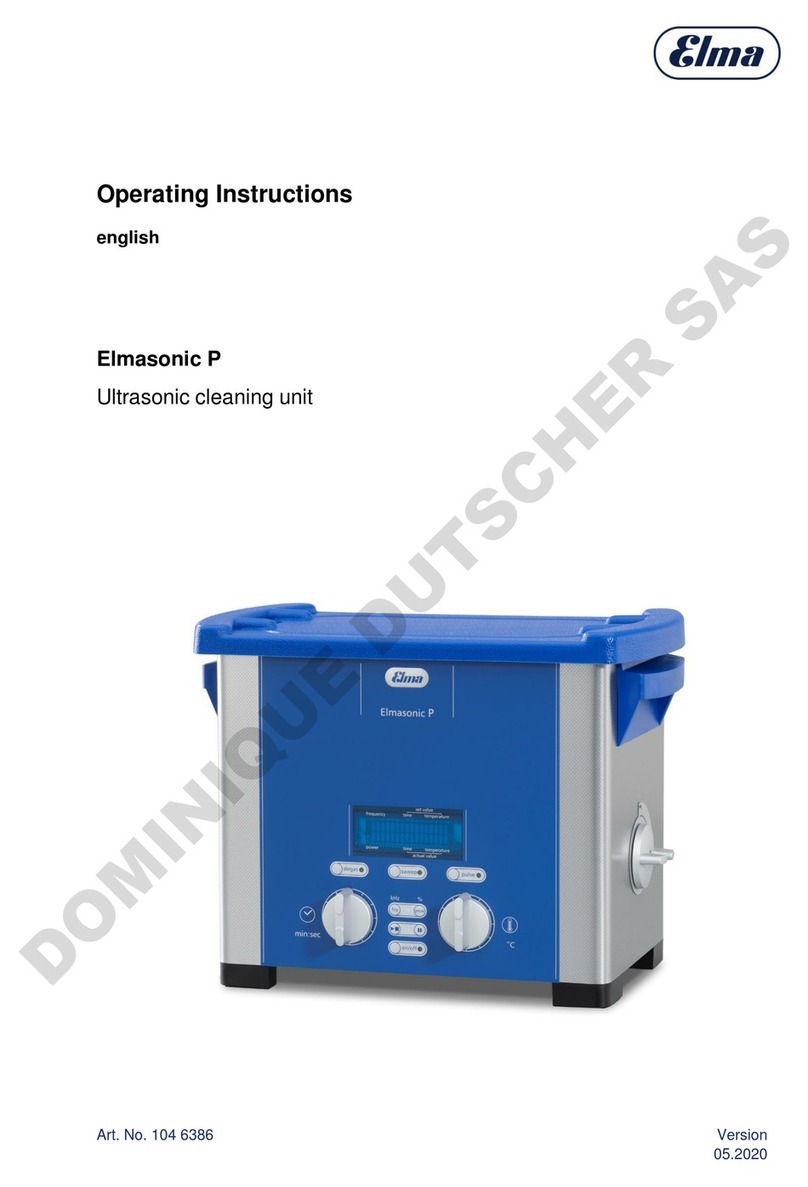

4Product description..................................................... 6

4.1 Elmasonic Denta Pro product features..................... 6

4.2 CE conformity .......................................................... 6

4.3 Delivered equipment ................................................ 6

4.4 Unit font view / side view.......................................... 7

4.5 Unit back view.......................................................... 8

4.6 Turning knob for draining the tank............................ 8

4.7 Description of operating elements............................ 9

4.8 Description cleaning programs................................10

5Initial operation ......................................................... 11

5.1 Set up of the liquid drain .........................................12

5.2 Connecting the unit to the mains.............................12

6Putting unit into operation......................................... 13

6.1 Filling of the unit......................................................13

6.2 Placement of cleaning items ...................................14

7Ultrasonic cleaning process...................................... 15

7.1 Starting the cleaning process manually...................16

7.2 After the cleaning....................................................17

8Cleaning media ........................................................ 18

8.1 Limitations of use of cleaners containing solvents..18

8.2 Limitations on aqueous cleaners.............................19

8.3 List of recommended cleaning media......................19

8.3.1 Dental ..................................................................20

9Maintenance............................................................. 21

9.1 Maintenance / Care.................................................21

9.2 Service life of the transducer tank ...........................21

9.3 Repair .....................................................................22

10 Technical details....................................................... 22

11 Trouble shooting....................................................... 23

12 Putting out of action and waste disposal .................. 24

13 Manufacturer's contact address ............................... 24