Technical Support Line +44 (0)23 9269 6638 2402STE PAK200480 Issue 01H May 2016 Page 3 of 4

I

NSTALLATION

This unit is only suitable for installation as permanently connected equipment. The PSU is NOT SUITABLE for external installation.

This unit must be fed from a mains power source having a separate (approved) disconnect device and fitted with a fuse or other over-current

protection device rated at 3A maximum. Ensure that the disconnect device used has appropriate earth fault protection to the applicable standard.

Where the PSU is used to provide power to a fire alarm circuit, the mains isolation and disconnect device should be provided solely for this

purpose and be suitably marked “FIRE ALARM – DO NOT TURN OFF”. All cabling should meet national and local fire system installation

regulations, e.g. FP200 type cable for high integrity installations.

Where the PSU is used for other applications, it should be installed according to all relevant safety regulations applicable to that application.

Where the PSU Fault and EPS Fault outputs are used, they should only be connected to circuits having voltages less than 60V dc.

Cable Sizing

1) Mains input cable must be to the applicable standard with a 3A or greater current capacity, i.e. 0.5mm

2

nominal conductor area, having a

minimum operating voltage of 300/500 Vac.

2) The low voltage output cable must be sized to carry the rated load current to the devices connected to the PSU.

3) Mains input and low voltage output cables should be routed to use different entry / exit holes in the case. Bushes should be used to

protect cable sheaths from chafing. Ensure that these bushings are correctly sized (i.e. close fitting with respect to cable sizing). Note

that the bushes should meet a minimum flammability specification of UL94 HB.

4) All cabling should be securely fastened in position using a cable tie through the saddles provided.

Mounting

5) Fix to wall or other support structure in correct orientation i.e. with hinge on left hand side, using screws of sufficient size and length

through the mounting holes.

6) PSU should be mounted no further than 10cm from the control and indicating equipment, close coupled by conduit.

7) Knock-outs are provided in the case for mating with external trunking or conduit.

8) Ensure that all unused holes (on the rear of the case) are sealed to prevent the ingress of damp and dust.

C

OMMISSIONING

Mains Power Up

1) With no external connections made to the PSU, connect the mains input wires to the terminal block, ensuring that the mains isolator

(disconnect device) is open. Fasten wiring in place with cable tie to saddle. Note: Equipment must be earthed.

2) Apply mains input. Ensure that the green Mains LED illuminates and that the red Fault LED flashes after approximately 20s (indicating a

disconnected battery).

3) Disconnect the mains power.

Load Output and Remote Signalling

4) Connect the EPS and PSU Fault outputs to the appropriate inputs of control equipment if remote fault monitoring is required.

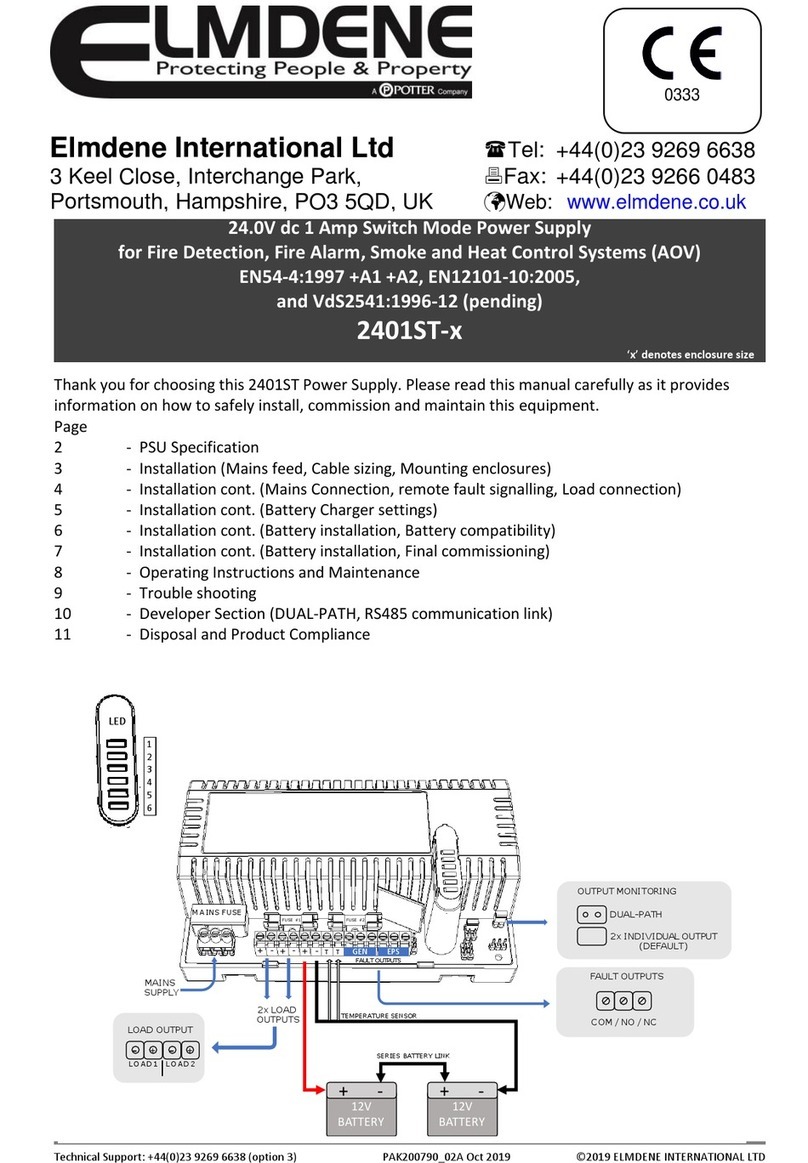

5) Loop the load (output) wiring through the supplied ferrite EMC suppressor as shown in Figure. 1. Cable tie to saddle provided (adjacent

to exit hole).

6) Re-apply mains. Verify that the green Mains LED illuminates and the red

Fault LED flashes after approximately 20s (disconnected battery).

7) If connected, verify that the EPS Fault monitor shows a closed contact

and the PSU Fault monitor shows an open contact.

8)

Perform a full functional test of system including full alarm condition

.

Standby Battery

9)

Mount two 12V 17Ah batteries in lower part of enclosure.

10) Connect the two 12V standby batteries in series using the single cable

provided. Connect the negative of one battery to the positive of the other.

DO NOT CONNECT the other two battery terminals to each other.

11) Connect the free Positive and Negative terminals of the batteries to the

PCB terminals Batt+ and Batt - using the cables provided. See Figure 2.

12) Ensure the temperature sensor and battery connections are made according to figure 2.

13) Verify that the red Fault LED stops flashing after about 20s (battery connection detected). Verify that the remote PSU Fault monitor

shows a closed contact.

14) Disconnect the mains power. Verify that the green Mains LED extinguishes and the red Fault LED starts to pulse (indicating that the

PSU is running from its standby batteries).

15) If connected, verify that the EPS Fault monitor shows an open contact and the PSU Fault monitor shows a closed contact.

16) Perform a full functional test of system including full alarm condition. Verify that the standby batteries can support the system load. Note:

ensure batteries have sufficient charge.

Final

17) Reconnect the mains. Verify that the green Mains LED illuminates and the red Fault LED extinguishes.

18) If connected, verify that the EPS Fault monitor shows a closed contact and the PSU Fault monitor shows a closed contact.

19) Close cover and secure using fastening screws provided.

O

PERATING

I

NSTRUCTIONS

This unit is intended for use by Service Personnel only. There are NO USER SERVICEABLE parts inside.

The green Mains LED will be illuminated whilst the mains supply is present. In the event of a failure, the red Fault LED will flash and the solid

state remote fault output contacts will open.

Figure 1 - Ferrite EMC suppressor

onnection of battery leads

and temp sensor to terminal block.