3

J125B: Commissioning Instructions

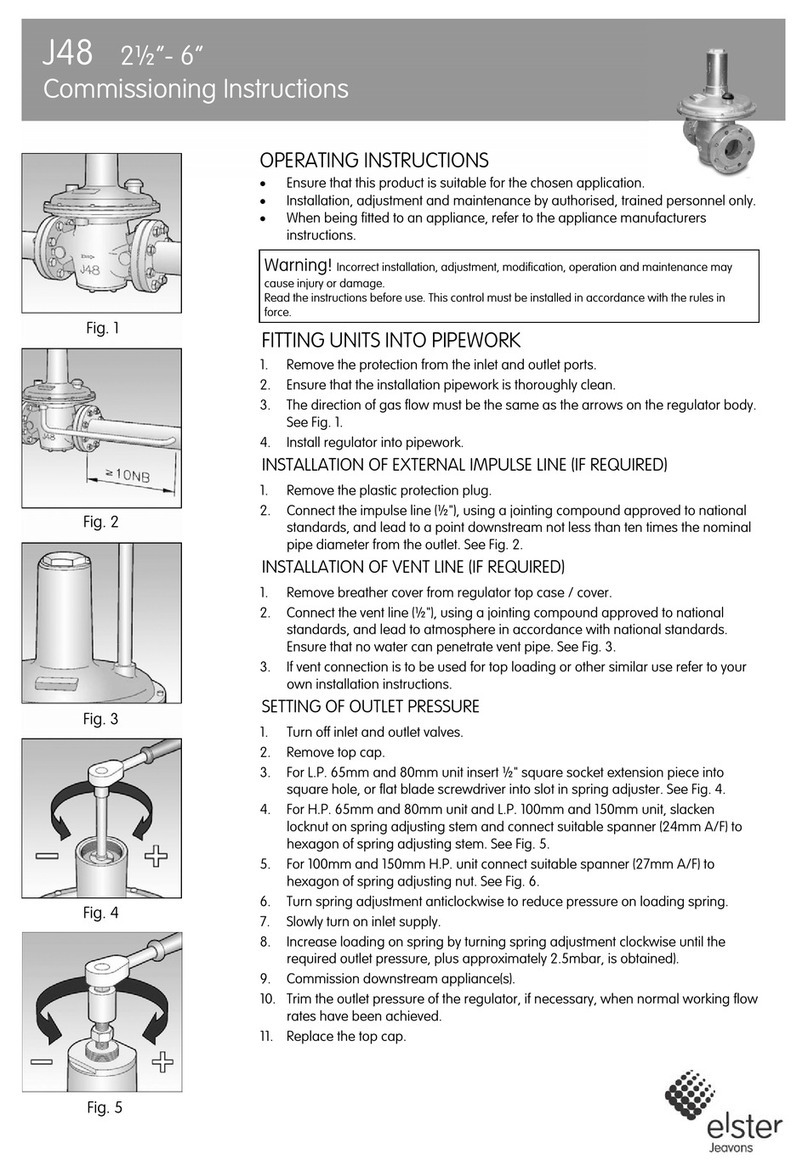

4. If safety shut-off device is fitted unscrew reset spindle end cap and

firmly pull. Hold in this position until the outlet pipework is fully

pressurised, then release reset spindle end cap gently. See Fig. 5.

5. Re-screw reset spindle end cap into body, ensuring not to jam reset

spindle.

6. Commission downstream appliances.

WARNING: DO NOT UNDER ANY CIRCUMSTANCES WEDGE OPEN SAFETY

SHUT-OFF RESET END CAP AS THIS WILL NOT ALLOW THE SAFETY DEVICE(S)

TO FUNCTION IN ADVERSE PRESSURE CONDITIONS.

SETTING THE REGULATOR & SAFETY

SHUT OFF DEVICE PRESSURES.

OPSS = Over Pressure Safety Shut-off.

UPSS = Under Pressure Safety Shut-off.

1. Turn off inlet and outlet valves.

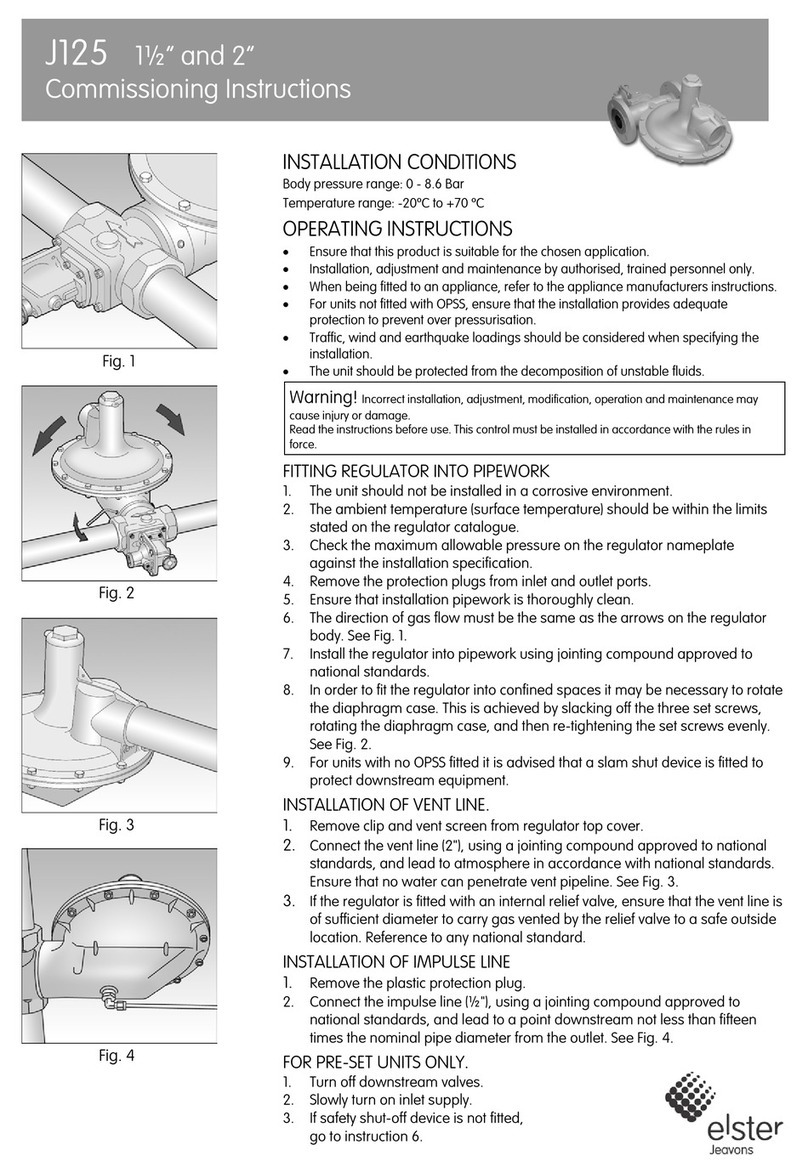

2. Remove top cap from regulator cover.

3. Insert an 11/4" A/F socket over the top of the adjustment screw.

4. Turn anticlockwise (-) to reduce loading on regulator spring to

minimum. See Fig. 6 (If no safety devices are fitted go to instruction 10).

5. Remove top cap from safety shut-off device cover (If UPSS only go to

instruction 8).

6. Insert a flat bladed screwdriver into one of the partial slots on the

OPSS spring holder. See Fig. 7.

7. Turn clockwise (+) to increase loading on OPSS spring to maximum.

8. If UPSS fitted, insert a pozidriv screw driver (No.2 point) into UPSS

adjusting screw in bottom spring holder. See Fig. 8.

9. Turn anticlockwise (-) to reduce loading on UPSS spring, making sure

screw head does not protrude from the bottom spring holder.

10. Slowly open inlet valve(s).

11. If safety device fitted, re-cock by unscrewing reset spindle end cap

and pulling firmly. Hold in this position until the outlet pipework is fully

pressurised, then release reset spindle end cap gently. Re-screw

reset spindle end cap into body. See Fig. 5.

12. Turn regulator adjustment screw clockwise (+) to increase the loading

on the spring until the required outlet pressure, plus approximately

2.5mbar (1"wg) is obtained. (This is an allowance for the regulator

being set with zero flowrate).

If UPSS only go to instruction 20, if no safety device go to instruction 27.

13. Block vent valve opening to prevent relief valve from operating.

14. Apply external pressure source to a suitable point on the outlet

pipework. Increase pressure to that required for OPSS trip-off.

Note: If pressure test point on underside of slam shut unit is used as

external source point, care must be taken to ensure pressures are

equalised across restricted orifice within test point.

15. Slowly turn OPSS spring holder anticlockwise (-) until OPSS device trips

off. See Fig. 7.

16. Reduce external pressure source to level set in instruction 12.

Fig. 5

Fig. 6

Fig. 7