2

48HL: Commissioning Instructions

OPERATING INSTRUCTIONS

•Ensure that this product is suitable for the chosen application.

•Installation, adjustment and maintenance by authorised, trained personnel only.

•When being fitted to an appliance, refer to the appliance manufacturers instructions.

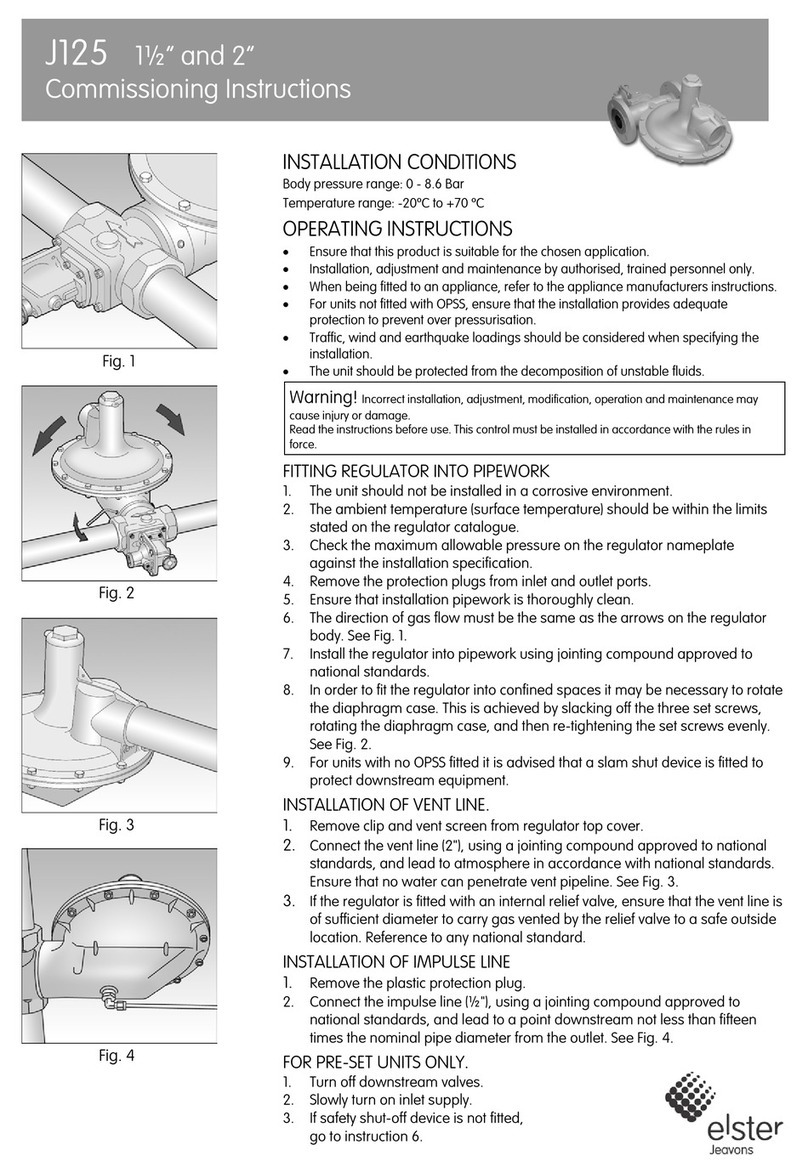

FITTING REGULATOR INTO PIPEWORK (A)

1. The unit should not be installed in a corrosive environment.

2. The ambient temperature (surface temperature) should be within the limits stated on the

regulator catalogue.

3. Check the maximum allowable pressure on the regulator nameplate against the

installation specification.

4. Remove the plastic protection plugs from inlet and outlet (and breather if applicable).

5. Ensure that installation pipework is thoroughly clean.

6. The direction of gas flow must be the same as the arrow(s) on the regulator body.

7. Install the regulator into pipework using a jointing compound approved to national standards.

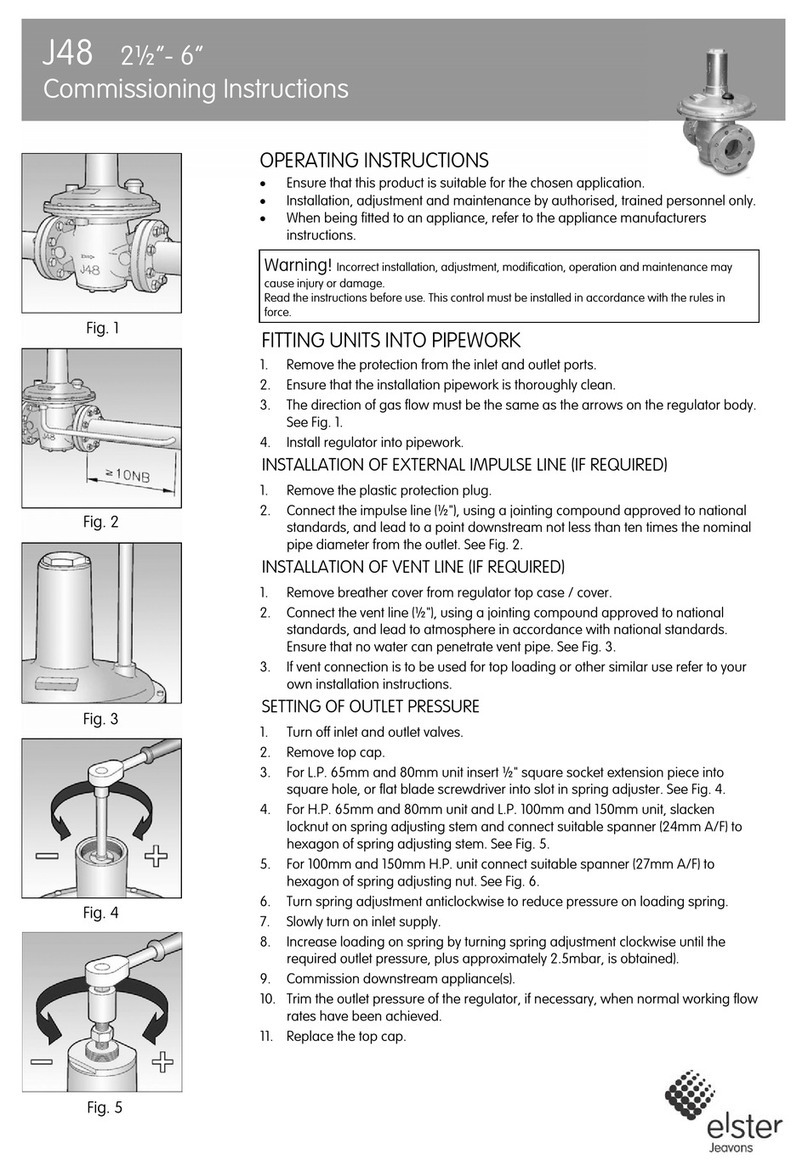

INSTALLATION OF VENT LINE (B) IF REQUIRED

8. Remove the plastic protection plug.

9. Connect the vent line (1/4" connection), using a jointing compound approved to national

standards, and lead to atmosphere in accordance with national standards. Ensure that no

water can penetrate vent pipeline.

INSTALLATION OF EXTERNAL IMPULSE LINE (C) IF REQUIRED

10. Remove the plastic protection plug.

11. Connect the impulse line (1/8” connection), using a jointing compound approved to

national standards, and lead to a point downstream not less than five times the nominal

pipe diameter from the outlet.

FOR PRE - SET REGULATORS

12. Turn off downstream valves.

13. Slowly turn on inlet supply.

14. Commission downstream appliance(s).

SETTING OF OUTLET PRESSURE (D)

15. Turn off downstream valves.

16. Remove the top cap.

17. Insert a flat bladed screwdriver into the slot in the end of the spring adjusting screw.

18. Turn anticlockwise to reduce pressure on the loading spring.

19. Slowly turn on inlet supply.

20. Increase loading on the spring by turning the spring adjusting screw clockwise until the

required outlet pressure, plus approximately 2.5mbar, is obtained.

21. Commission downstream appliance(s).

22. Trim the outlet pressure of the regulator, if necessary, when normal working flow rates

have been achieved.

23. Replace the top cap (and seal if necessary).

IF REQUIRED OUTLET PRESSURE CANNOT BE ACHIEVED WITH SPRING FITTED. (E) & (F).

24. Choose a loading spring from the catalogue that will give the required outlet pressure range.

25. Turn spring adjusting screw anticlockwise (to reduce loading on spring).

26. Carefully lift protruding end of locking lever just clear of adjusting bush (1), whilst in this

position turn (octagon shaped) adjusting bush assembly anticlockwise until disengaged

(2). The adjusting bush assembly can then be removed from the top cover.

27. Remove the loading spring.

28. Insert the new spring - take the label from the spares kit bag and stick it below the

nameplate of the regulator.

29. Screw top spring holder anticlockwise to within 10mm of underside of adjusting bush.

30. Position underside of top spring holder on to loading spring.

31. Align slots in top spring holder with splines in top cover and push adjusting bush

assembly into top cover as far as possible.

32. Turn adjusting bush assembly clockwise until locking lever snaps into any of the three

locking castellations in the top cover.

33. Adjust the outlet pressure, as described above, until the required setting is found.

34. Replace the top cap (and seal if necessary).

Warning! Incorrect installation, adjustment, modification, operation and maintenance may

cause injury or damage.

Read instructions before use. This control must be installed in accordance with the rules in force.