ELTRA ON-900 User manual

0.1

ELTRA GmbH

Retsch-Allee 1-5

42781 Haan Germany

www.eltra.org

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

0.2-1

0.2 Index OPERATION MANUAL ON - 900

as from serial no. 1550xxxxxx

2TU1 INSTALLATIONU2T

2TU1.1 Setting upU2T

2TU1.2 Front panel illustrationU2T

2TU1.3 Mains power connectionsU2T

2TU1.4 Data interfacesU2T

2TU1.5 Gas connectionsU2T

2TU1.6 Cooling waterU2T

2TU1.7 Filling the cooling waterU2T

2TU1.8 Adjusting the gas flowU2T

2TU2 ANALYSISU2T

2TU2.1 Working procedureU2T

2TU2.2 Work breaksU2T

2TU2.3 Fractional analysisU2T

2TU2.4 ApplicationsU2T

2TU2.5 Gas conservationU2T

2TU3 MAINTENANCEU2T

2TU3.1 General informationU2T

2TU3.2 Installing and removing the reagent tubesU2T

2TU3.3 Filling the reagent tubesU2T

2TU3.4 Replacing the O-ringsU2T

2TU3.5 Cleaning the dust trapU2T

2TU3.6 Cleaning the furnaceU2T

2TU3.7 Replacing the electrodes

2TU4 DESCRIPTION OF FUNCTIONSU2T

2TU4.1 Measuring principleU2T

2TU4.2 Gas flow systemU2T

2TU4.3 Infrared cellU2T

2TU4.4 Thermoconductivity cellU2T

2TU5 MISCELLANEOUSU2T

2TU5.1 Ordering numbersU2T

2TU5.2 PackingU2T

2TU5.3 Trouble shootingU2T

2TU5.4 ON-900 Pre-installation guideU2T

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.1-1

1 INSTALLATION

1.1 Setting up

Since the analyser weighs about 130 kg it should be placed on a suitably stable surface. The

balance should also be placed free of vibration.

The balance can be placed in any position, positioning it to the right of the analyser has

proved to be best suited.

The balance can of course also be placed on a weighing table next to the analyser.

There are no special requirements for setting up the printer and computer; they can be

placed on a normal desk.

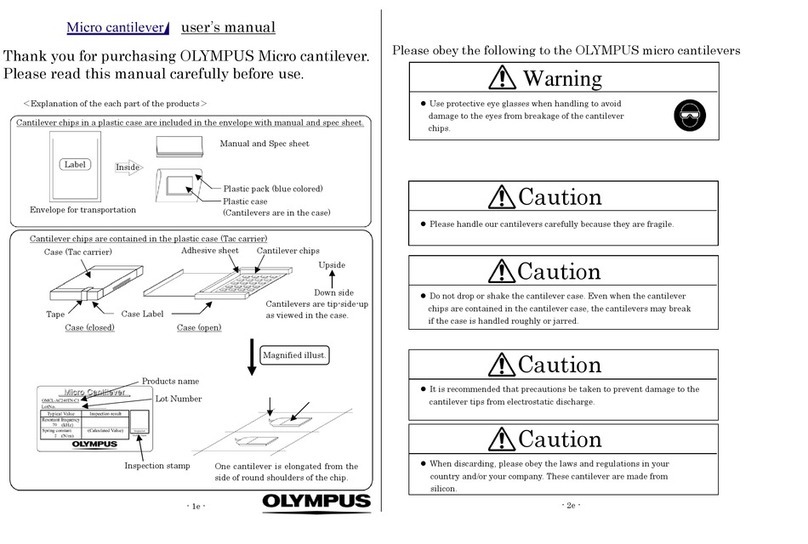

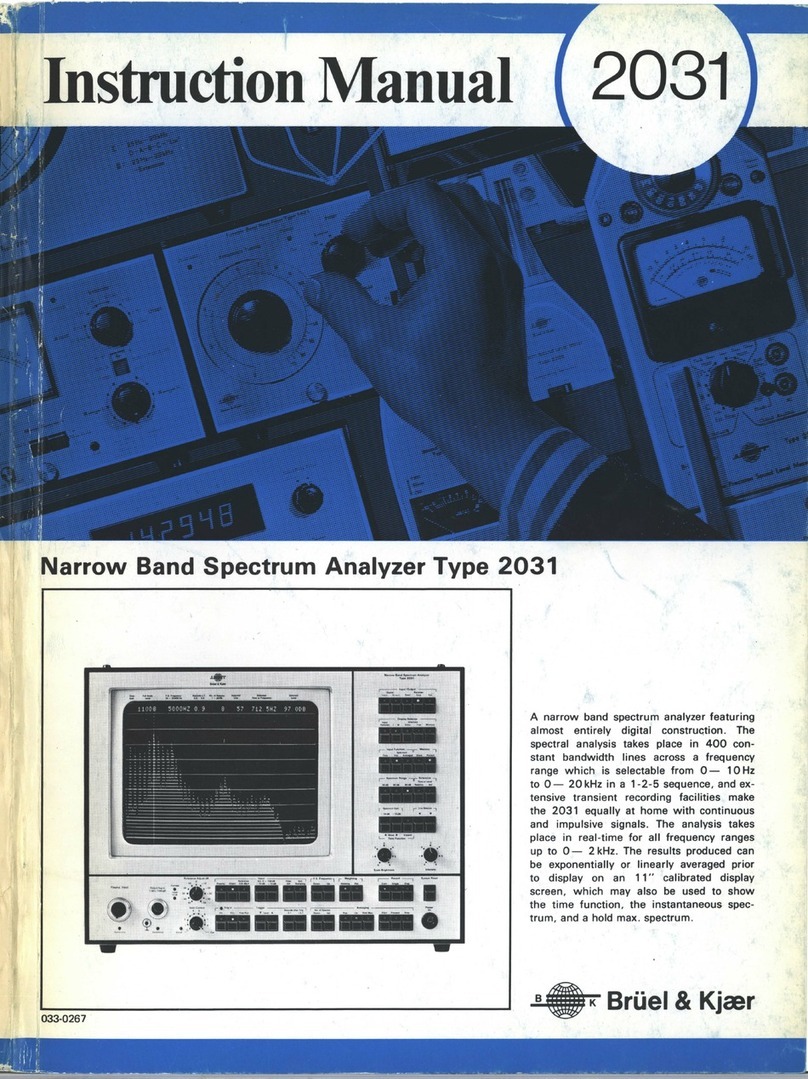

Below is an example in installation:

Although the analyser's operating environment does not necessarily need to be air

conditioned, it is advisable to keep the room temperature between 18°C and 30°C.

Never run the water pump without any water or else it will be damaged!

The pump is activated when the mains switch is set to pos. 2.

First fill up the cooling system with water, according to chapters 2TU1.6U2T and 2TU1.7U0T2T.

Under no conditions should the device be placed in direct sunlight !

Avoid places exposed to the wind of air conditioners or to the wind blowing through

open windows or doors.

TARE

C FI / O F

TARE

sartor ius

C A L

0 20 30 40 50 60 70 80 seconds

10

10.0

9.0

8.0

7.0

6.0

4.0

3.0

5.0

2.0

1.0

0.0

-1.0

MAXDATA

Magic

02-1

0

2

1

ON 900

O xy g e n N i t r og e n D e t er m i n a t o r

A

10

5

4

3

2

0

1

VO LT CR AF T

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.2-1

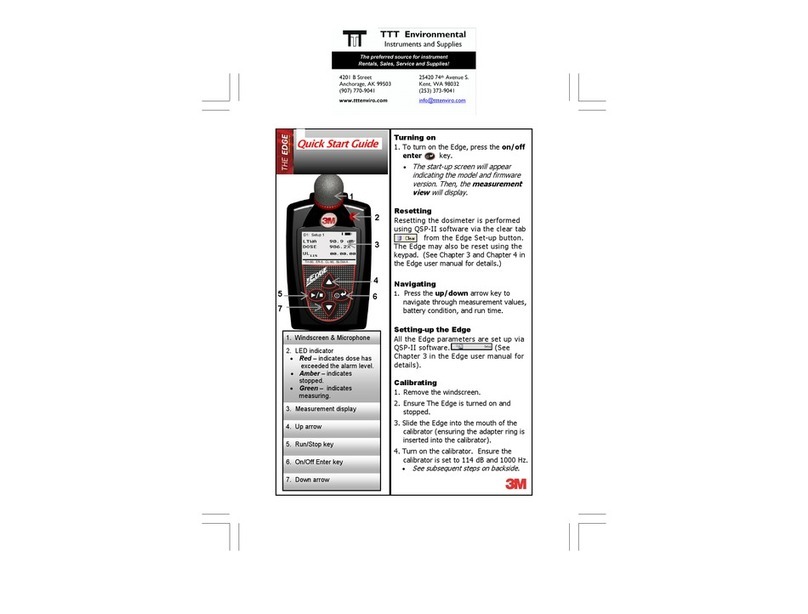

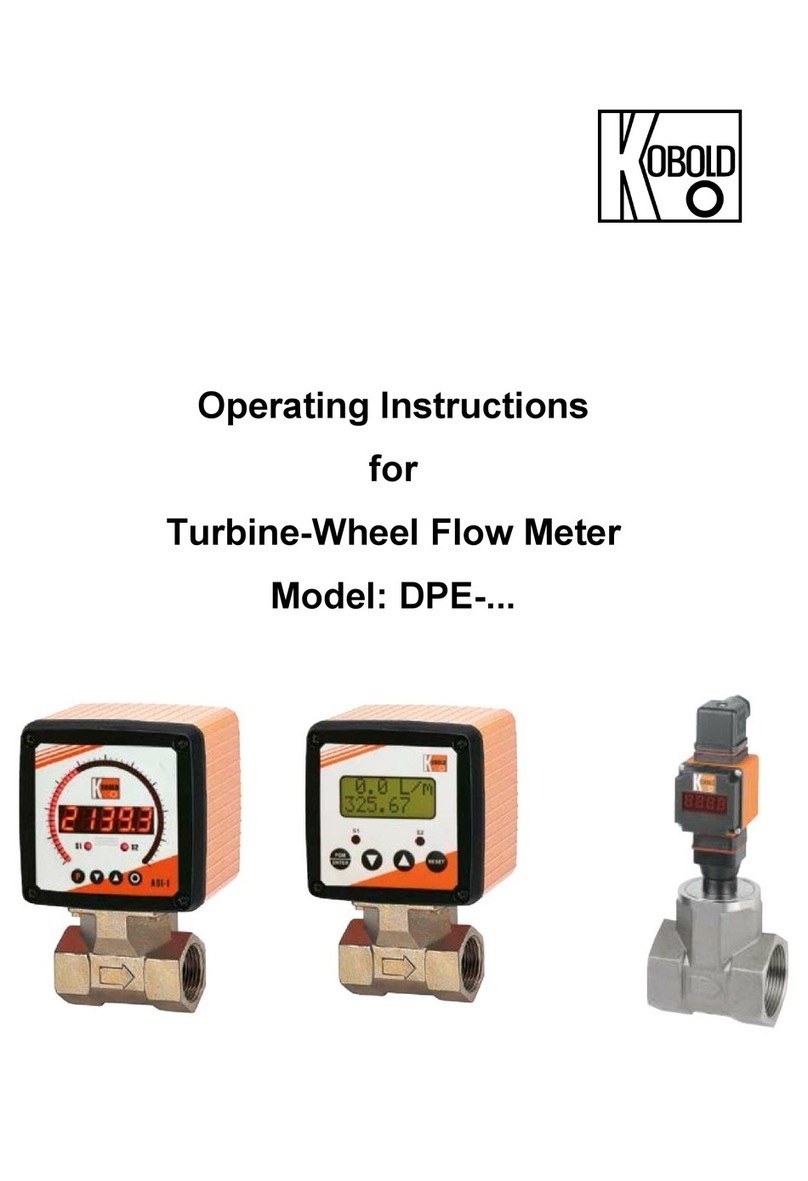

1.2 Front panel illustration

1 Current meter

11 Dust trap

2 Furnace inlet flow

12 Carrier gas pressure gauge

3 Analytical flow (controlled)

13 Compressed air gauge

4 Purge flow regulator

14 Copper oxide catalyst

5 Analysis flow regulator

15 Catalyst furnace

6 Sample drop

16 Mains switch

7 Crucible pedestal

17 Carrier gas pre-cleaning

8 Pneumatic lift

18 CO

R

2

R

/H

R

2

R

O - trap

9 Upper furnace part

19 IR-cell purge pre-cleaning

10 Lower furnace part

100

50

10

130

0

2

1

ON 900

O x yg e n Ni t r o g e n D e t er m i n a t or

16

15

11

12

13

14

23

5

4

A

10

5

4

3

2

0

1

VOLTCRAFT

6

10

8

7

17 19

18

1

9

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.3-1

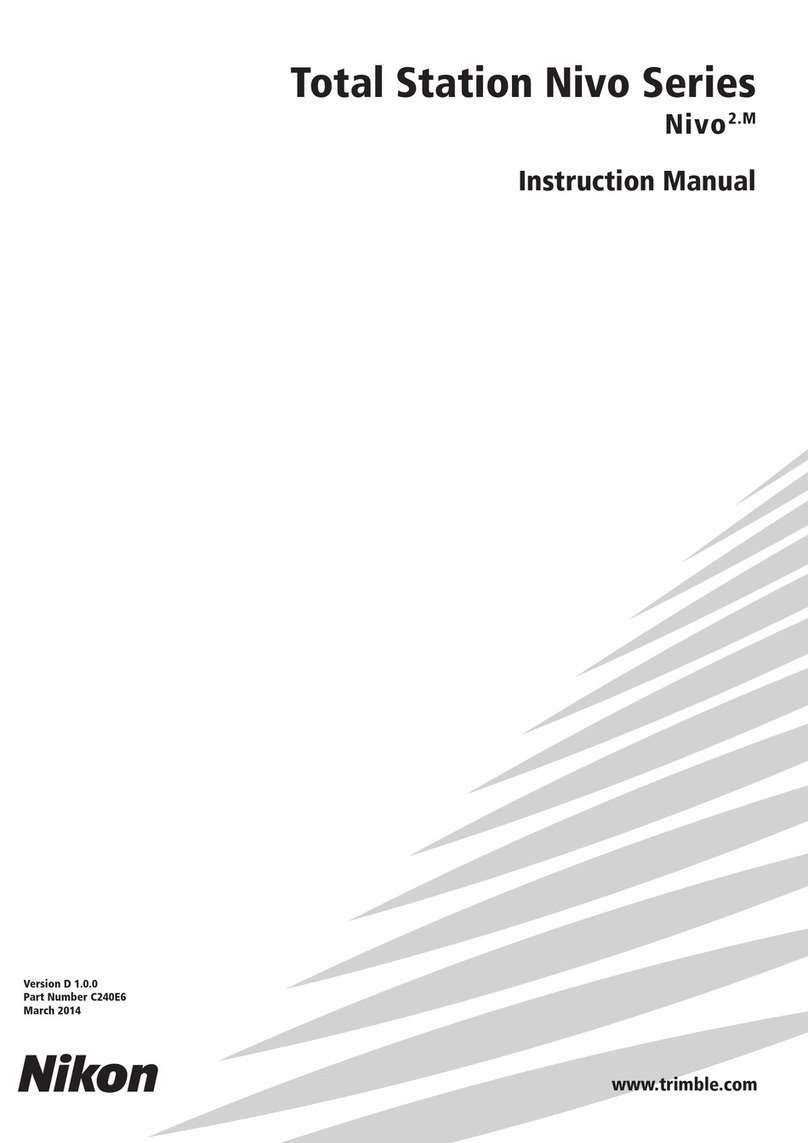

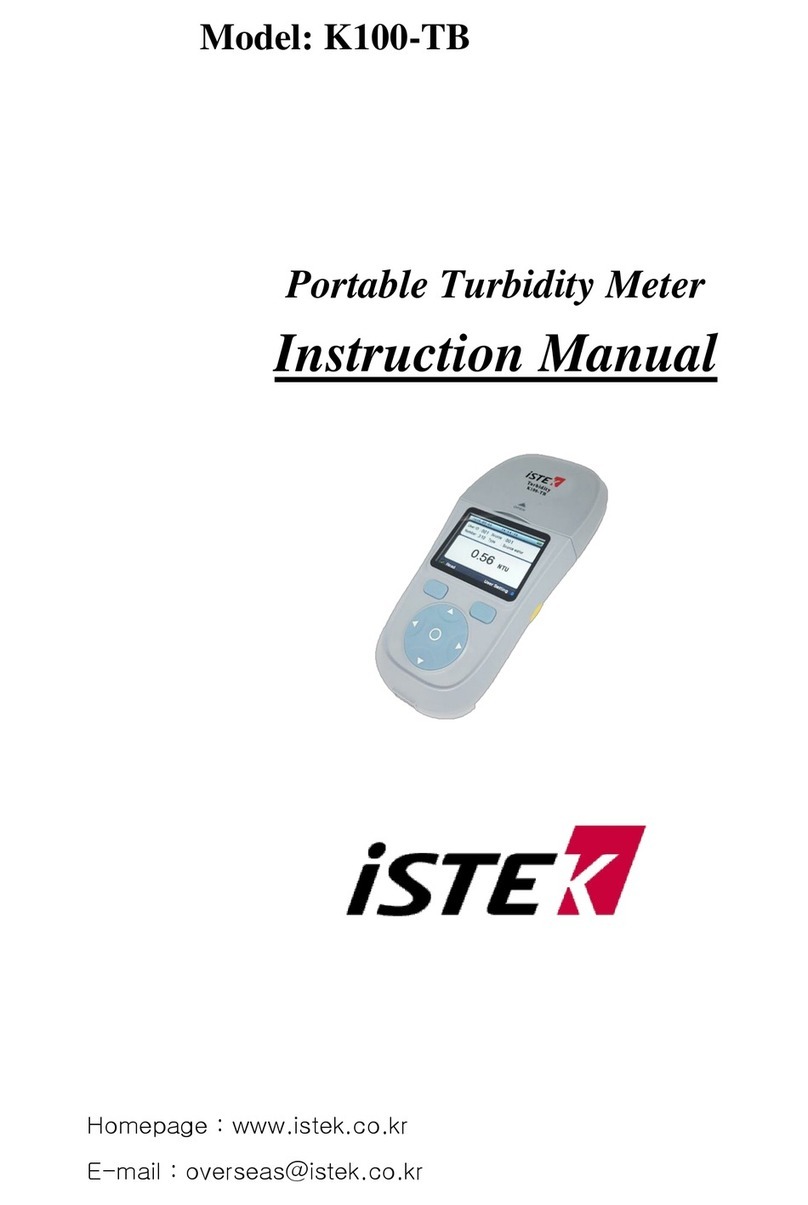

1.3 Mains power connections

Since the infrared cell requires about 1 hour to reach a stable operating temperature, it is

advisable to connect the analyser to the mains power first and switch on before further

installation work is carried out.

This waiting time is only necessary when installing the analyser. Since it is normally not

switched off, and is always in operating temperature.

1 Analyser

2 Computer

3 Monitor

4 Printer

5 Balance

6 Triple plug

7 Analyser mains plug

First connect the analyser to the mains power and switch it on. The switch, located on the

fore side of the analyser, is to be set to position 1.

2-2

34

2

5

7

1

7

6

Model : ON900

SerialNo.: XXXXXXXXXX

VoltsAC:

Amps:30 max.

Watts:10000max.

IP20 1999

madein Germany

ELTRAGmbH

Mainstr.85 Block20 D-41469Neuss Germany

Phone:+(49)213712822 Fax:+(49)213712513

400+/-10%3Ph 50-60Hz

2-4 bar ( 30-60psi)

99,9% pure

Helium inlet

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.4-1

1.4 Data interfaces

Rear side of UNI 1.3 board:

1 Pear serial interface

2 PC connection

3 Analog input/output signals

4 Digital input/output signals

5 Autoloader connection

When all the units are connected to the mains power, then data connections can be made.

The plugs are all different from each other, so that they cannot be interchanged. The required

data cables are included if the additional units are supplied. These are adapted to the

interfaces when the analysers are put into operation in our company.

As the balance transfers the weight to the PC, its serial interface must be programmed.

The computer is already provided with an operating system and software for controlling the

analyser.

UNOTE:UFor all instructions on operating the PC software refer to the Help-function of

the software.

2

345

1

2-3-1

AnalogI/O Digital I/O

Loader

Microcontroller

boardUNI 1.4

Part No.18467

PC

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.5-1

1.5 Gas connections

1 Cooling water outlet

2 Cooling water inlet

3 Outlet water to tank

4 Secondary cycle outlet

5 Water tap inlet

6 Compressed air 4-6 bar

7 Gas outlet

8 Carrier gas inlet 2-4 bar

Two gas connections are necessary for the operation of the analyser. The required tubes are

included in delivery. See above drawing

Tube (8) is for the carrier gas supply, it is soft and transparent.

Tube (6) for the compressed air is harder and opaque.

These are delivered, provided with screw fittings for pressure regulators.

An R¼" inner thread as well as the corresponding copper seals are also provided.

Tube fitting (8) connects the analyser with a helium carrier gas bottle

These connections must be very secure, since the operating pressure in the tube is 2-4 bar

(30 to 60 psi). Gas connection (6) is for the compressed air supply to the pneumatic furnace

lock.

Gas connection (7) is for drawing off outlet gas. It is generally not in use, however, since only

low quantities of CO2and even lower quantities of Nresult from the sample combustion.

When the analyser's mains switch is set to position 2 a valve opens, and the carrier gas

flows through the gas tubes. The flow rate is stabilised after several seconds to 15 l/h and

can be read from the lower flow indicator. At the same time the cooling water pump starts.

5

2-4-1

6

1

3

4

2

78

23 0V A C 1~ N 50 / 60 Hz

ma x. 75 0 0 Wa t ts

40 0V A C 3~ N 50 / 60 Hz

(30-60psi)

pure

F us e

slowblow

4A

Gasoutlet

Com pre ssed A ir

4-6 bar (60- 90psi)

Com pre ssed A ir

4-6 bar (60- 90psi)

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.6-1

1.6 Cooling water

The ELTRA ON-900 has two cooling water circulation systems, a primary and a secondary

system.

The primary system provides furnace cooling, and consists of:

The external barrel.

The internal section of the analyser, which includes water pump, equalising tank and

furnace.

The cooling water circulates from the barrel to the furnace, via the connections (2). It then

returns to the barrel, via the connections (1). Inside the barrel, the water is kept cool by the

inter-cooling coil of the primary system.

The secondary system starts from the drinking water tap, the water is then fed to the water

flow switch, via connections (5). The water then flows to the inter-cooling coil inside the

barrel, via connections (4). Finally, the water flows to the drain, via connection (6)

Connections:

The analyser and the barrel is connected as shown in the above drawing.

It is possible to install the barrel away from the analyser. The barrel should not be installed

more than 5m away and 1m above the instrument. If this is not possible, ask the factory for a

modification.

Tap water drain

3

Ga s out let

Fuse slow blo w

4A

23 0V A C 1~ N 50 / 60 Hz

max. 750 0Watts

40 0V A C 3~ N 50 / 60 Hz

Nit rog en in let

2 - 4 b ar ( 3 0-6 0p si )

99 , 9% pu r e

1

1

4

5

64

2

2

3

Tap water inlet

4-3-3

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.6-2

Water temperature

sensor

2

3

1

6.

Tap water inlet

Tap water

solenoid valve

4

sensor

Furnace

temperature

Tap water drain

Tap water coil

Secondary

water cooling tank

Water pump

5

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.7-2

1.7 Filling the cooling water

Before filling the cooling water, it is necessary to make sure that the analyser is properly

connected to the external barrel, see 2TU1.6U0T2T.

It is absolutely important that the inlet of the water pump inside the instrument, is connected

to the central tap (2) of the external barrel.

Procedures for filling up and bleeding the cooling system:

Open the external barrel and put the additive „COOLING AGENT„ into it. Fill up the

barrel almost completely with water.

Only drink water quality should be used and not any tap water which can pollute or

corrode the cooling system.

Close the barrel.

Open the air bleeder on the water pump.

Pour water into the small plastic water equalising tank above the pump, until some water

starts to exit the air bleeder.

Close the air bleeder.

Place a graphite crucible into the graphite tip.

Make sure that the carrier gas supply is closed, in order to avoid unnecessary gas

consumption during the following steps.

Remove the right side panel of the analyser. UCautionU! Don‘t touch electric

components.

Observe the wheel of the water flow detector on the ON-21 board and switch the mains

switch to pos. 2 for a couple of seconds only and check during this short period if the

water flows.

Set the mains power switch immediately to position 1 if the water wheel doesn’t rotate.

It seams that the shaft of the water pump is jammed.

The pump can be damaged when power is applied and the pump will not rotate.

Reopen the air bleeder and add some more water into the equalising tank. Close the air

bleeder, switch back to pos. 2. Repeat this procedure until the system is completely free

of air.

When the cooling system is inactive or dry for a long period of time, it could occur that the

water pump doesn't start rotating when the mains switch is set to pos. 2

The following instructions will assist you in solving the problems:

Remove the right side panel of the analyser. UCautionU! Don’t touch electric

components.

Remove the screw on the pump’s front place.

The screw that appears next is coaxial to the internal pump shaft, rotate it and the

jammed shaft will be loosened. Up to 10 rotations may be needed to restore back to

working order.

Re-install in reverse order.

Set the mains power switch to position 2.

If the water flow wheel rotates smoothly over a long period of time, the filling-up procedure

is complete.

If the rotation is erratic, then there is still some air in the cooling system.

Switch the mains switch back to pos. 1, reopen the air bleeder and add some more water

into the equalising tank.

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.7-3

Close the air bleeder, switch back to pos. 2. Repeat this procedure until the system is

completely free of air.

Close both side panels.

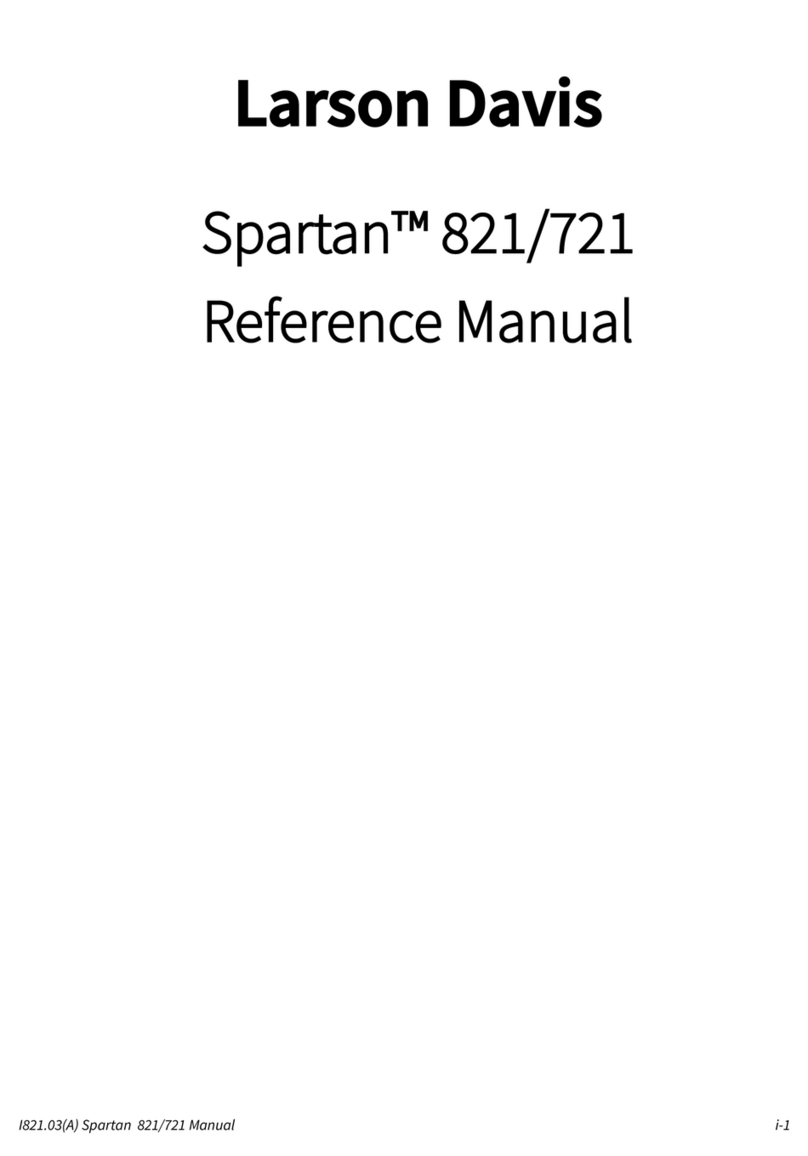

Graphit crucible

Graphitetip

get access to the shaft

Removethisserewto

Water

emalizing

tank

01-06

32480

32480

flow

Water

Pump inlet+dose

Bleeder

Water

flow

wheel

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

1.8-1

1.8 Adjusting the gas flow

There are two different gas flow systems in the

instrument.

Flow meter (B) shows the controlled flow in the

system, which cannot be changed from the front panel.

Flow meter (A) shows the total gas flow in the furnace.

There are two different states, which must be

adjusted.

1. Only a small flow during the analysis or in normal

state with closed furnace.

2. But it needs a higher flow for purging during the

out-gas phase or with an open furnace.

Adjust the gas flow as follows:

Adjust approx. 2 to 4 (30 to 60 psi) on the pressure regulator of the carrier gas/cylinder.

Enable the carrier gas supply to the analyser.

Make sure to have a graphite crucible on the graphite tip.

Set the mains power switch to pos. 2.

Close the furnace by pressing the corresponding button in the software and wait about 10

seconds.

UNOTE:UFor all instructions on operating the PC software refer to the Help-function of

the software.

Adjust the lower flow regulator (D) until the left flow meter (A) shows 30 l/h.

Open the furnace.

Adjust the upper regulator (C) until the same left flow meter (A) shows 50 l/h.

Close the furnace again. If the above settings are unstable, increase both flows by about

10 l/h.

Regarding the flow meter (B), the gas flow is adjusted in our company. This adjustment is

normally not changed. If the blind values of Oand Nare higher than 20ppm, then the gas

flow could be wrong.

UCAUTION:

The furnace should be open only as long as absolutely necessary. If the furnace is

unnecessarily opened to long, you waste purging gas and additionally the electrodes may

oxidise from the air.

D

C

A B

130

100

50

10

10

5

15

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.1-1

2 ANALYSIS

2.1 Working procedure

The ELTRA ON-900 analyser is designed for the analysis of metals. Should other materials

be analysed, take care that the furnace and the gas flow are not contaminated by dust or

other combustion products.

The analysis procedure is described in the following section.

UNOTE:UFor all instructions about operating the PC software refer to the Help-function

of the software.

1. Ensure that the compressed air and the carrier gas are connected. Turn the mains power

switch to position 2. The pump starts working and the gas flow is controlled. It takes a

few minutes until the analyser is ready to work. Put an empty crucible on the lower

electrode and close the furnace.

2. A sample of about 1 gram is weighed. Transfer the sample weight into the PC software

by transferring the value from the connected balance or enter it manually. The sample ID

may be entered as well. Put the sample with clean tongs into the sample drop on top of

the furnace.

3. Start the analysis. From now on the analysis is performed automatically. At the end of the

analysis the results are displayed and all data are saved on the hard disk of the PC.

The analysis procedure consists of several phases following one after another.

Depending on the settings (furnace power mode and sample loading mode) the

sequence is altered. Here, the sequence in ON-OFF-ON furnace power mode and

automatic sample loading mode is described as a basic and only the difference of

other modes is specified.

ON-OFF-ON furnace power and automatic sample loading mode:

1. Outgasing. The graphite crucible itself (without sample) is heated up in the furnace in

order to remove impurities. The carrier gas supply to the furnace is now in the purge

mode. The time for outgasing and the furnace power are adjustable.

2. Purging. The furnace purging is continued after outgasing phase. The furnace is

switched off. The duration is adjustable.

3. Stabilising. The carrier gas supply to the furnace is switched to the analysis mode.

This phase is necessary for stabilizing the base lines of the detectors. The duration is

adjustable.

4. Sample drop. The sample drop mechanism rotates and the sample drops into the

crucible.

5. Analysis. The furnace is switched on, the sample is melted and the signals from the

detectors are processed. The furnace is switched off after the pre-settable time

expires, but the signals processing continues until the comparator level of all detectors

or the maximum analysis time is reached. In order to avoid unnecessary signal

integration from the moment when the furnace is switched on until the moment when

the analytical gas reaches the detectors an integration delay time can be adjusted. All

settings are available in the software.

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.1-2

CONTINUOUS furnace power and automatic sample loading mode:

In this mode, the furnace remains switched on after the outgasing phase and its power level

is set to the analysis power level. The furnace will be switched off only when the comparator

level of all detectors or the maximum analysis time is reached.

ON-OFF-ON furnace power and manual sample loading:

In this mode, the operator is prompted to open the furnace and put the crucible with the

sample into the furnace after the purging phase. After closing the furnace the analysis is

continued.

Please, refer to chapter 2TU2.4U2T for instructions about the settings for making analyses of

different materials.

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.2-1

2.2 Work breaks

UCAUTION:U

Keep the furnace closed to save carrier gas and to avoid oxidation of the electrodes.

Work breaks, e.g. during lunch breaks, the mains switch remains on position 2. During

longer interruptions, e.g. after finishing work for the day, the mains switch is set to position 1

(standby). The analyser's thermostatic control is then still working and no long warm-up time

is needed, when re-starting the analyser. Energy consumption and wear are negligible on

standby.

The mains switch is set to pos.2for about 10-15 minutes before starting the first analysis.

Air, and any moisture which has entered the analyser is expelled by the oxygen flow. The

slight influence which the oxygen flow has on the temperature of the infrared cell is

balanced out. The analyser may only be switched off (pos. 0) when it is not used for several

days or weeks. The analyser is designed for long term use, so that no damage results.

The furnace should always be kept closed during work breaks, so that no moisture can

enter. The furnace only remains open when the analyser is completely switched off. The

mains switch is only set to zero for safety reasons, the crucible lift is then at the bottom

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.3-1

2.3 Fractional analysis

1. Introduction.

In some cases it is useful not to only know the total content of one element in a specific

sample, but also the exact amount of a specific bond or structure.

With the ELTRA ONH-2000 we are able to separate different oxygen and nitrogen phases

in the material to be tested.

It is necessary to separate the different oxides in ores and raw materials, to guarantee

high quality products and to control the production process more efficiently. Together with

the elemental analysis, the engineer obtains information about the iron, silicon, aluminium

and magnesium oxides in row material. It is therefore possible to calculate the alloy

elements and elements in the slag more accurately, before it is melted. The exact amount of

different oxygen and nitrogen phases in a high alloy steel is of vital importance, to

determine the quality of this product.

There are several reasons why fractional analysis is so important. Every time when a

certain process needs to be optimised or when the quality of a product needs some

improvement, there is a demand for more detailed information about the material in use;

more than what the simple elemental analysis can offer.

2. Basics.

It is well documented, that the dissociation of various oxides and nitrides, i.e. the iron

oxides occurs at approximately 1200°C, of silicon oxides at about 1500°C and of

aluminium oxides at 2200°C. It is possible therefore to separate these various oxides, due

to their different dissociation temperature.

There is however one problem:

The oxides don’t discompose exactly at a certain specific temperature, as it happens for

instance when melting a crystal. The velocity of the dissociation increases exponentially with

the temperature. This means that below the specific dissociation temperature, an oxide

discomposes very slowly.

In practice we need mathematical methods to calculate the contents of each oxide. It is not

possible to obtain the oxide value only by temperature analysis. Once the analysis has

delivered precise results, the signals from the oxygen analyser has to be divided.

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.3-2

3. Preparations.

The first step is to calibrate the temperature in the furnace, in accordance to the power

setting of the instrument. This temperature depends on the carrier gas material, the

analytical gas flow, the cooling parameter and the special furnace geometry. Each furnace

must be calibrated individually, because the parameters of the instrument are optimised for

each customer individually.

In combination with the power settings, it is possible to plot a calibration curve which shows

the temperature in relation to the furnace power.

The value of the temperature inside the crucible can be obtained, for instance, by melting

different materials, using the analyser.

Adjust the power of the furnace so that a material of a known melting temperature has

nearly melted.

A satisfactory temperature-power relationship of the instrument, can already be established

by melting a minimum of only three different materials.

4. Detecting the oxygen fractions

First, we need some information about different oxygen fractions in a material. An elemental

analysis with a spectrometer is helpful. We can only get oxides from present elements.

We start by treating the sample with furnace power that increases linearly, to determine

which oxides are present in the sample. A typical pre-selection for furnace power ramp-

function, is from 1.0 kW to 5.0 kW in 200s. The oxygen profile of the tested material is

shown in figure 1

Figure 1

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.3-3

The next step is to separate each oxygen phase, as accurately as possible. We change the

temperature program from a ramp function to a step function. We choose the power setting

of each level in such a way, that the temperature is sufficiently high to discompose just one

oxide, but still too low to brake the next one. The duration of each temperature step should

be between 30 and 60 seconds, depending on the material. The signal of one oxygen

phase should first fall to the lowest level, before the next step can be started. One possible

separation is shown in figure 2.

Figure 2

At the end of this analysis we obtain the total oxygen result. This should be in an acceptable

range, or else the temperature program needs to be modified.

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.3-4

5. Mathematical separation of the peaks.

The optimised signal from each oxygen phase results in a single peak that starts and

finishes at the baseline. We can integrate each peak individually and get perfect results, as

shown in figure 3.

Figure 3

In most cases, nature is not very polite. We cannot separate each oxygen phase well

enough to treat the peak as a unique item. We can only be integrated a peak correctly if it

starts from zero and returns to zero. Unfortunately, very often before one peak has a chance

to return to zero, the next peak starts to rise, causing the reading of the previous peak to be

incomplete. That’s why we need to calculate the first peak as if it actually descended to

zero. We have to mathematically “complete the peak.” See figure 4.

Only this way, it is possible to analyse each oxygen phase. We have to calculate all the

peaks out of our “mountains” of signals.

Figure 4

Copyright 2005 by ELTRA GmbH Germany – January 2005 – Operation Manual ON-900

2.3-1

The typical shape of a peak includes a fast rise, followed by a slow fall, because the

chemicals and volumes of the system must be purged out. We find the same shape for

every peak during the heating period.

Figure 4 includes two diagrams:

1. without mathematical correction, as displayed from the analysis, with the peaks not

returning to zero.

2. with the mathematical correction.

By adding up the signals of the first diagram, we obtain the total contents of oxygen in the

sample.

The integration of each peak area gives the content of the particular oxide. All the oxygen

phases together should represent the total oxygen content. The difference between the

total oxygen content given by the analyser and the sum of the single oxides gives a sign for

the precision of the mathematical procedure. If the difference is too large, then the heating

program needs to be optimised. The mathematical treatment cannot compensate for the

physical errors.

6. Summary.

The separation of different oxygen phases of the temperature profile method, is a way to

obtain more information about a material than with the simple elemental analysis. It is

possible to optimise this method for better temperature programs and better mathematical

methods for the peak calculation. But the limit is imposed by the nature of this analytical

method. With the x-ray diffraction analysis, it is possible to analyse the crystal structure

directly, without destroying the material. The results are more precise, but more time is

needed for sample preparation and analysis.

In most cases it is not necessary to know the exact value of each oxygen phase, it is

sufficient to get a “fingerprint” of the material. It is very useful to compare the fingerprints of

different materials to control or check a production process.

Other manuals for ON-900

1

Other ELTRA Measuring Instrument manuals

ELTRA

ELTRA ON-900 User manual

ELTRA

ELTRA ELEMENTRAC CS-i User manual

ELTRA

ELTRA CS-800 User manual

ELTRA

ELTRA CSi/d User manual

ELTRA

ELTRA ELEMENTRAC ONHp2 User manual

ELTRA

ELTRA CS-800 User manual

ELTRA

ELTRA Thermostep TGA User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA CS-2000 User manual

ELTRA

ELTRA CS-2000 User manual

Popular Measuring Instrument manuals by other brands

Siemens

Siemens FS720 Series Commissioning, Maintenance, Troubleshooting

PCB Piezotronics

PCB Piezotronics 3713B1230G Installation and operating manual

promesstec

promesstec MDW 500 user manual

Cirrus Research

Cirrus Research optimus yellow user manual

Fluke

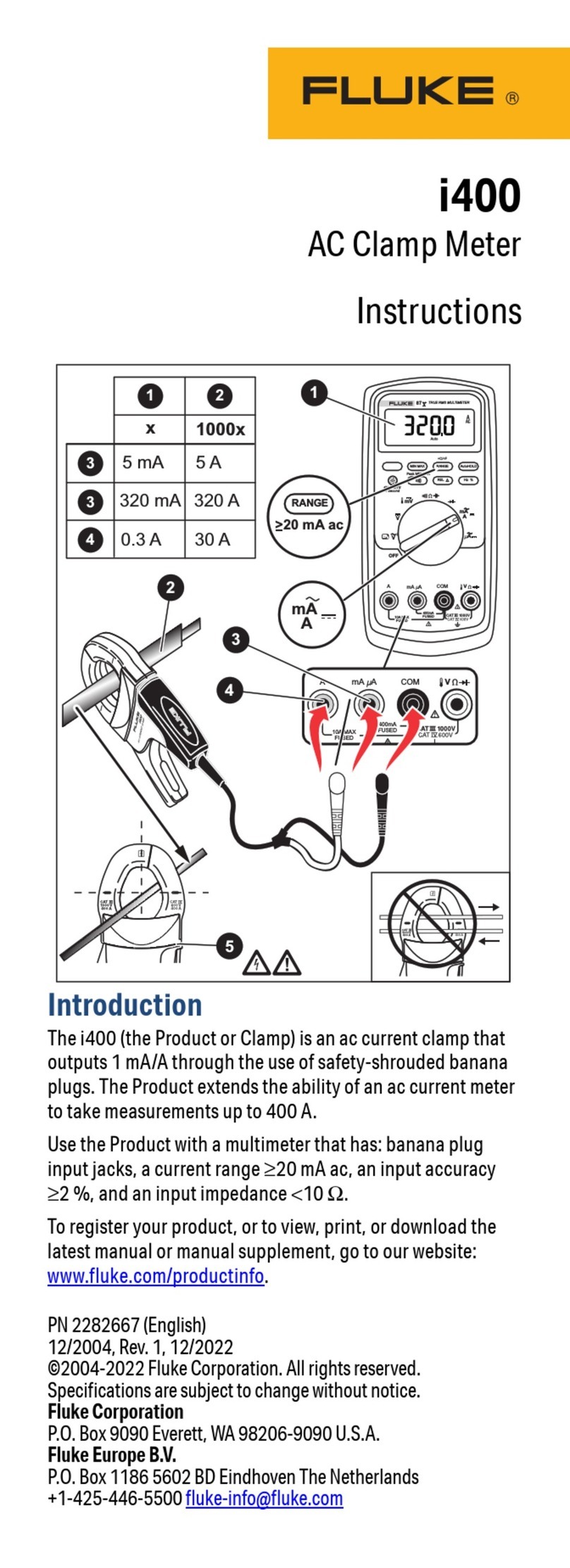

Fluke i400 instructions

LOVATO ELECTRIC

LOVATO ELECTRIC DME D305T2 instruction manual