ELTRA CS-800 User manual

© Eltra GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 17.12.2013 0001

Operating Manual

Autoloader CS800/CS2000

Original

2

Copyright

© Copyright by

Eltra GmbH

Haan, Retsch-Allee 1-5

D-42781 Haan

Federal Republic of Germany

3

4

1Operating the machine ..........................................................................................................................5

1.1 General information ........................................................................................................................... 5

1.1.1 Loader models ............................................................................................................................... 5

1.1.2 Space requirements....................................................................................................................... 5

1.1.3 Connecting and disconnecting plastic tubes ................................................................................. 6

1.2 Mechanical connection to the analyzer ............................................................................................. 7

1.3 Chain motor belt adjustment.............................................................................................................. 8

1.4 Chain adjustment............................................................................................................................... 8

1.5 Finger adjustment ............................................................................................................................ 10

1.6 Arm installation ................................................................................................................................ 11

1.7 Electrical and pneumatic connections ............................................................................................. 12

1.8 Up/Down adjustment of the arm ...................................................................................................... 15

1.9 Single step operation for mechanical adjustments .......................................................................... 15

1.10 Vertical laser .................................................................................................................................... 15

1.11 Horizontal laser ................................................................................................................................ 16

1.12 Single step cycles ............................................................................................................................ 18

1.13 Finger position over the pedestal .................................................................................................... 18

1.14 Finger Up/Down speed .................................................................................................................... 18

1.15 Crucible position on the platform ..................................................................................................... 19

1.16 Height of the platform ...................................................................................................................... 19

1.17 Repeating the single step cycle ....................................................................................................... 20

1.18 Non stop cycles ............................................................................................................................... 20

1.19 Error messages ............................................................................................................................... 20

1.20 Final installation after adjusting ....................................................................................................... 21

1.21 Maintenance .................................................................................................................................... 21

1.22 Analysis mode ................................................................................................................................. 21

1.23 Crucibles disposal............................................................................................................................ 22

2Index ......................................................................................................................................................23

Appendix .................................................................................................................................. following page

Operating the machine

5

1 Operating the machine

1.1 General information

The loader is supplied after testing without being completely dismantled. It is only

detached from the analyser and the arm (3) with the fingers (6) (See figure arm

installation) are removed for safety reasons. Therefore, an adjustment after

installation may not be needed however the adjustments are described below.

They may be necessary for accurate readjustment.

1.1.1 Loader models

There are 3 standard loader models available:

130-crucibles version, 104-crucibles version and 36-crucibles version.

The difference between these models is the form of the loader’s platform, i.e. the

size of the loader. There is no difference with regard to loader arm, arm support

and drive, lasers/sensors, chain drive, pneumatics and electronics. Therefore the

adjustments, described in this manual are valid for all models.

1.1.2 Space requirements

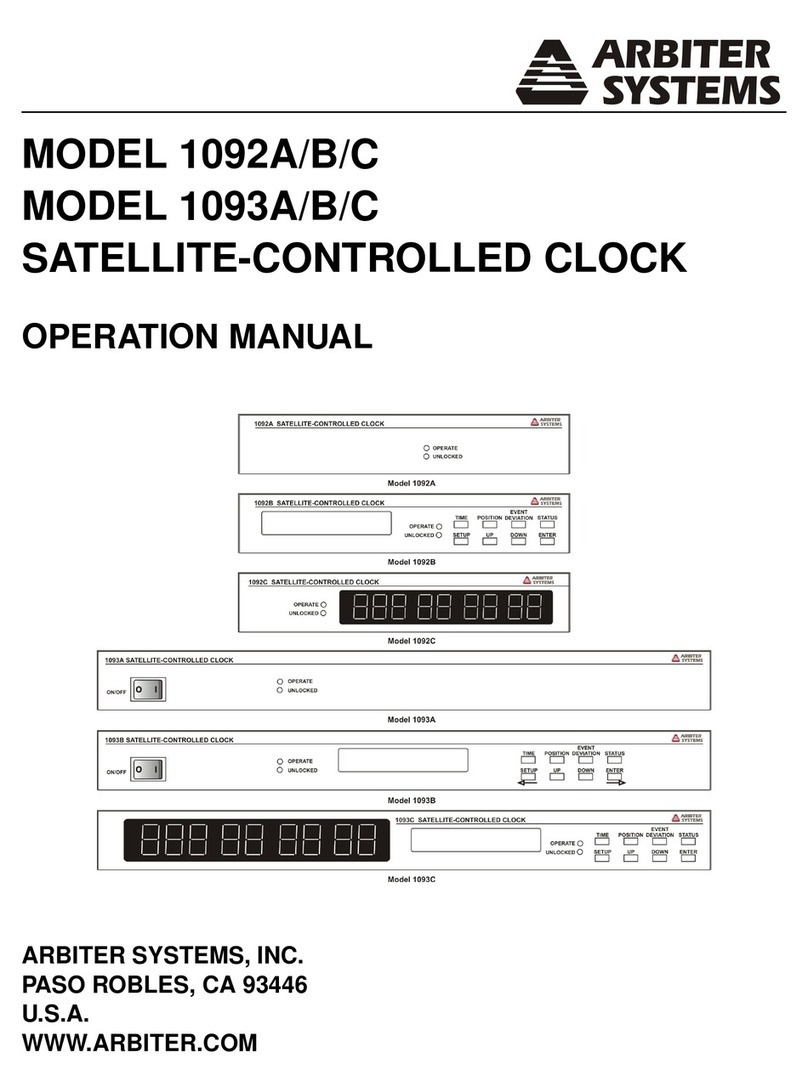

Fig. 1: Loader positioning

Keep sufficient space to the right of the analyzer (minimum 86 cm) to place the

loader.

It is suggested to place the analyser in a position where the front end of the

furnace cover (1) aligns with the front end of the desk (2).

NOTICE

Under no conditions should the analyser and loader be placed in direct sunlight or

be exposed to the wind of air conditioners or to the wind blowing through open

windows and doors.

1

2

A

Operating the machine

6

1.1.3 Connecting and disconnecting plastic tubes

To connect the tube, simply push it into the fitting as far as it would go.

Fig. 2: Plastic tube connecting

To disconnect the tube, first press the plastic ring of the fitting up to the metal ring,

keep it properly pressed and pull the tube.

Fig. 3: Plastic tube disconnecting

To reinstall the loader do this:

•The analyzer is switched off (Mains power switch on position 0).

There is no compressed air supply to the analyser.

Operating the machine

7

1.2 Mechanical connection to the analyzer

Fig. 4: Autoloader reinstallation (Top view)

•Before starting reinstallation take a look at the plastic tubes and bear in mind

the way they are supported with the screw (7). Make sure to lay them the

same way during reinstallation.

•Place the loader to the right of the analyzer. The part (1) is the vertical bar

(profile) of the front right corner of the analyzer’s cabinet (top view of cross

section). For further orientation: The round part (2) is the left front foot of the

loader.

•The loader is positioned in a way that the vertical rod (3) is pushed towards

the cabinet so that the cabinet’s corner rod (1) is inside the vertical rod (3).

•The blade (4) is inserted between the rod (3) and the cabinet rod (1).

•The angle rod (5) is installed and fixed with the screws (6).

•Then the screws (7) are fixed so that a solid, stable mechanical connection

between analyzer and loader is made.

1

2

3

5

4

6

7

Front pane l

B

Operating the machine

8

1.3 Chain motor belt adjustment

Fig. 5: Belt tension check

The toothed belt of the chain motor is located underneath the left-hand section of

the loader’s platform. The mechanical tension of the toothed belt (1) can be

checked by applying the force to the belt, as shown on the picture by the red arrow.

If an adjustment is necessary, loose the two screws (2) push the plate (3) to the

back in order to create an appropriate tension of the belt (1) and drive the screws.

After fixing the screws, check the tension of the belt (1) again.

In case of replacing the belt, the adjustment is made the same way.

1.4 Chain adjustment

Fig. 6: Chain tension adjustment

1467-Horizontal laser

3

4

11111

222

D

5

7

6

14647

Operating the machine

9

Fig. 7: Chain tension adjustment (Bottom view)

The loader is supplied with the adjusted chain tension. If necessary, check the

tension of the chain as follows:

•Press and hold several crucible trays (1) of the rear row on the platform so

that they cannot move.

•Move a few trays (2) of the front row to the left and to the right.

They should move for about 1 mm. If not, loose the screw underneath the

toothed wheel (3) and adjust by moving it back and for.

•Fix the screw (3) and check again.

NOTICE

A too strong tension can lead to a blockage when the crucibles are moved by the

motor. If the chain plays too much, bent elements of the chain can block at the

indicated point (4). Therefore keep about 1 mm play as described above.

•Pull the front part (5) for about one or two millimetres.

The turning point is (6). When you release it, it should return back pressing

the crucible tray, which is at pick up position, to the wheel (7) behind the

tray. This is to make sure that each crucible when at pick up position is

always at the same place.

Fig. 8: Autoloader bottom view

14609-Gear motor

14550-Gear wheel

14559-Gear wheel

70500-Belt for drive

2

1

4

3

C

70500

14609

14550

14559

Operating the machine

10

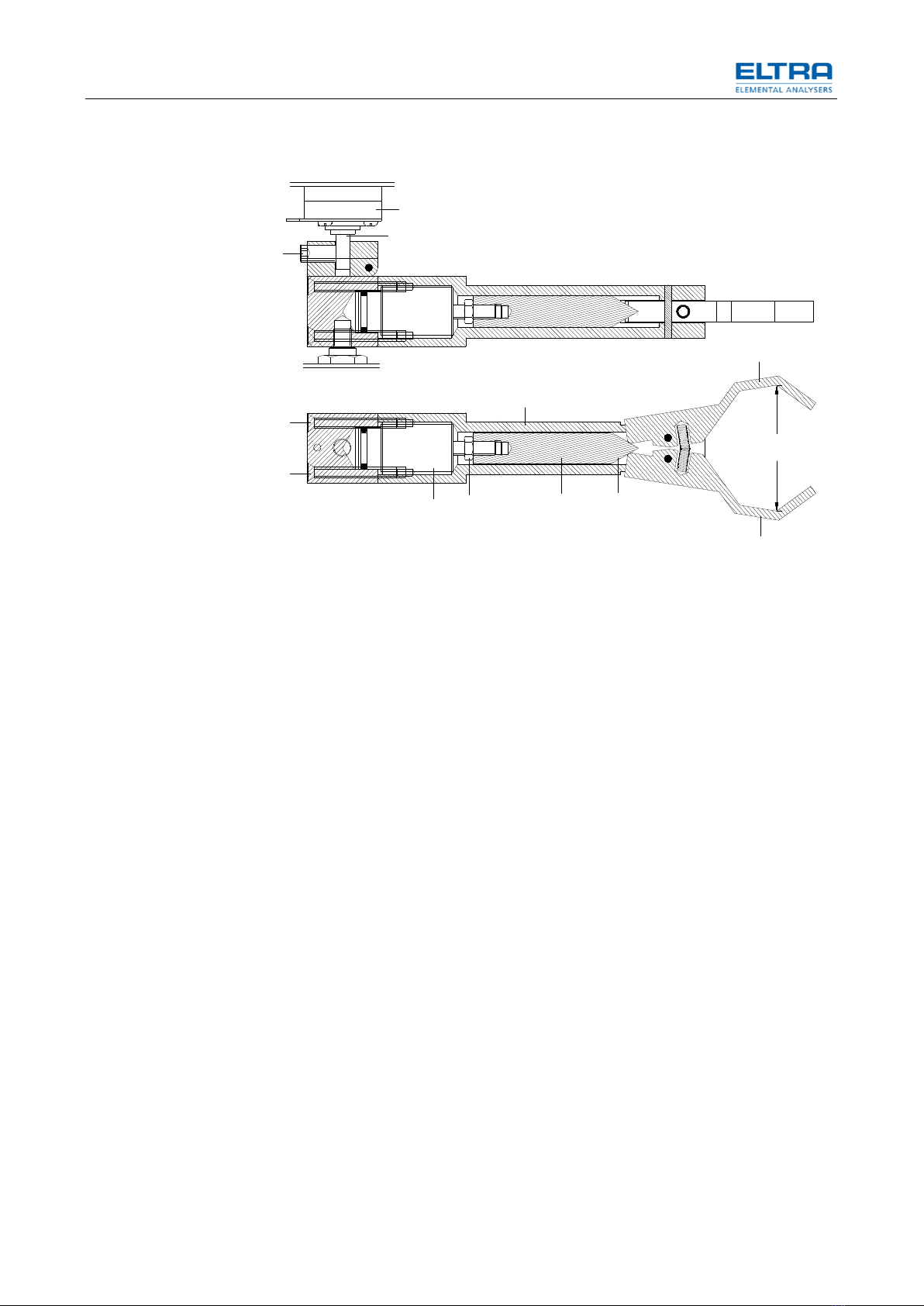

1.5 Finger adjustment

Fig. 9: Finger adjustment

The maximum distance inside the fingers (1) should be about 36 mm.

For adjusting:

•Loose the screw (2).

•Move the assembly (E) down to take it off the shaft (9) of the motor resp. off

the gear box (10).

•Unscrew the four screws (3).

•Remove the piston (4) with the plunger (5).

•Loose the nut (6).

•Screw the plunger (5) to the piston (4) clockwise for making the finger (1)

distance bigger.

•Fix the nut (6) again.

•Unscrew the plunger (5) from the piston (4) (counter clockwise) for reducing

the distance between the fingers (1).

•Fix the nut (6) again.

•Make sure that the plunger (5) is clean.

•Make sure that also the inside surface of the arm (8) is clean from dust,

grease etc.

3

3

57

4

8

29

10

1

1

E

36

6

Operating the machine

11

1.6 Arm installation

Fig. 10: Arm installation

14648-Vertical laser

14795-Finger assembly for Loader CS800/2000

14796 Finger assembly for Loader Helios

14819-Finger motor

•Pass the low end of the spring (8) (see figure pneumatic connections),

through the hole of the cubic support (13) of the arm (3). The upper end of

the spring is already fixed during manufacturing.

•Install the assembly of the arm (3) and the fingers (6) by driving the screw

(17) to fix this assembly on the shaft of the gear motor (14). Handle with care

considering the thin shaft of the gear and the small screw (17) for fixing.

Make sure that the screw will press the flat side of the gear’s shaft.

•Push upwards the plastic tube (15) into the fitting (16).

6

8

1

1

2

2

11

7

5

3

4

F

18

13

16

15

17

10

12

11

10

14648

14795

14796

148 19

9

14

Operating the machine

12

1.7 Electrical and pneumatic connections

Fig. 11: Electrical connection: Motor arm

•Install the 9-pin socket (1)

•Fix with the screws (2).

•Plug in the 9-pin connector (1) of the finger’s motor into the 9-pin socket; see

figure electrical circuit (1).

Fig. 12: Electrical connection: the 25-pin plug

•Locate the electrical cable with a 25-pin plug, coming out of the analyzer.

Plug it in the 25-pin socket, as on the picture above.

1

59

6

Fro nt pane l

1

2

G

Operating the machine

13

Fig. 13: Electrical circuit (14621-6001)

3

4

1

5

6

2

Operating the machine

14

Fig. 14: Pneumatic connections

14016-Sensor holder

14618-Loader board

14795-Finger assembly for Loader CS800/2000

14796-Finger assembly for Loader HELIOS

14819-Finger motor

14820-Finger pneumatic cylinder

60234-Pneumatic valve

60352-Sensor

•Install the magnetic switch (6) at the low end of the pneumatic cylinder as

shown in figure pneumatic connections.

•Connect the 50-pin plug (2) of the loader see figure electrical circuit, to the

50-pin plug (1) on the Loader board.

•Connect the 15-pin plug (5) of the loader; see figure electrical circuit, to the

15-pin plug on the UNI board.

•Connect the compressed air plastic tubes as shown in figure pneumatic

connections.

1

2

4

3

15

Front panel

6

Finger

closing

speed

Arm

up speed

Arm

down speed

8

7

6

14795

14796

60234

14819

14820

14618

60352

14016

I

Operating the machine

15

1.8 Up/Down adjustment of the arm

Fig. 15: Arm installation

•Apply compressed air to the analyzer. The fingers (6) resp. the arm (3) will

go to the UP position.

•Turn the arm (3) manually and position it underneath the wing nut (4).

•Adjust with the screws (9) the height of the arm (3) to be a maximum of only

1 mm underneath the winged nut (4). But even if the arm may touch this nut,

the adjustment is still O.K. The arm will not turn up to the nut (4) when in

operation.

NOTICE

Make sure that the wing nut (4) is properly fixed.

•Check whether the arm (3) is still in proper horizontal position.

•Check and if necessary adjust the position of the fingers (6) to hold the

crucible (7) in coaxial position to the pedestal (8) by readjusting the screws

(9) resp. by moving the arm (3) to the left and to the right and the screws (1)

by moving back and for.

1.9 Single step operation for mechanical adjustments

•Press the adjust button (5) see figure pneumatic connections, and keep it

pressed.

•Turn the mains power switch of the analyzer from position 0 to position 1.

•Release the adjust button immediately after the first beep of the beeper on

the loader’s electronic board.

1.10 Vertical laser

CAUTION

V0075

Eye injury

Laser beam

–Laser beam has high energy and can injure your eyes.

•Don’t look directly into the laser beam.

6

8

1

1

2

2

11

7

5

3

4

F

18

13

16

15

17

10

12

11

10

14648

14795

14796

148 19

9

14

Operating the machine

16

Now the vertical laser (10) for sensing the home position of the arm (3) is

continuously ON. This can be seen by looking at the sensor (11) underneath the

laser (10), see figure arm installation.

If the laser (10) is ON and there is no beeping to hear, it means that the sensor

(11) is sensing the laser beam.

Interrupt the beam between the laser (10) and the sensor (11) to verify the correct

functioning of sensor (11) and beeper.

If the laser (10) is ON and the beeper is beeping, although the beam is not

interrupted, this means that the beam doesn’t hit the sensor (11).The beeper

signalizes this condition. In this case the laser (10) should be mechanically

adjusted so that the beam will be in the middle of the sensor (11). The beeper will

stop beeping.

It is not enough if simply the beeping stops. Make sure that the beam is in the

middle of the sensor.

1.11 Horizontal laser

CAUTION

V0075

Eye injury

Laser beam

–Laser beam has high energy and can injure your eyes.

•Don’t look directly into the laser beam.

Operating the machine

17

Fig. 16: Loader steps

•Press the adjust button (5) of image pneumatic connections again for only

about one second.

Now the horizontal laser (6) for sensing the position of the crucibles (1 to 4) is

continuously ON. This can be seen by looking at the sensor (7) in front of the laser

(6).

CAUTION

Don’t look directly into the laser beam.

If the laser (6) is ON and there is no beeping to hear, it means that the sensor (7) is

sensing the laser beam. For this, make sure that there is no crucible or anything

else between the laser (6) and the sensor (7) preventing the beam from reaching

the sensor (7).

•Interrupt the beam between the laser (6) and the sensor (7) to verify the

correct functioning of detector and beeper.

If the laser (6) is ON and the beeper is beeping, although the beam is not

interrupted, this means that the beam doesn’t hit the detector (7). The beeper

signalises this condition. In this case the laser (6) should be mechanically adjusted

6

7

9

8

1

4

3

J

Home position

Pedestal

Parking

position

Disposal

position

Pickup psition

pick

up

2

Operating the machine

18

so that the beam will be in the middle of the sensor (7). In case of proper

adjustment the beeper will stop beeping.

The adjustment is made by loosing the screws (8) and by turning and moving the

laser (6) until the beeping stops. If necessary, pull up or press down the blade (9)

for vertical adjustment.

NOTICE

It is very essential to adjust the laser for the whole beam to reach the detector. If

you see a part of the beam hitting the aluminium detector housing around the

detector’s hole, readjust until you don’t see any laser radiation on the aluminium

housing.

1.12 Single step cycles

•Place about 10 crucibles into the trays of the chain starting from the left front

tray (1) continuing to the left. (Crucibles 2, 3, 4 etc), see figure loader steps.

•Press the adjust button (5) see image pneumatic connections again for only

approx. one second. This will cause the arm to move to the home position

(vertical laser) and to return back and stay at the parking position.

From now on, after each short pressing of the adjust button, the loader will make

one single step, following the sequence of the steps in analysis mode. The single

step mode gives time for mechanical adjustments.

The sequence of the steps that follow now after each short pressing of the adjust

button (5) of figure pneumatic connections is as follows:

1. The crucibles move so that the first crucible (1) stops at the crucible pick-up

position.

2. The fingers move first to the home position and then to the crucible pick-up

point.

3. The fingers move to the parking position.

4. The fingers (6) move to the position over the pedestal (8), see figure arm

installation.

1.13 Finger position over the pedestal

Now the mechanical adjustment of the position of the fingers (6) can be made.

For better orientation place a crucible (7) on to the pedestal (8). To move the

fingers (6) to the left and to the right, slightly loose the screws (9).The adjustment

of the finger (6) to the direction back and for is done with the screws (1). Take care

to keep the height of the arm (3) as advised before, i.e. about 1 mm underneath to

the wing nut (4).

Fingers down. Now you can adjust the fingers position even more accurately.

1.14 Finger Up/Down speed

The downwards speed of the fingers can be adjusted by the left hand adjustable

restrictor (7) see image pneumatic connections. The upwards speed of the fingers

can be adjusted with the restrictor (8). After adjusting, fix the knurled nuts.

1. Fingers close and take the crucible. If the adjustment of the fingers (6)

position is coaxial to the pedestal (8) resp. to the crucible (7), the crucible will

not move in horizontal direction when the fingers close.

The closing speed of the fingers can be adjusted with the adjustable restrictor (9)

see image pneumatic connections.

2. Fingers up.

3. Fingers turn to the disposal position.

4. The fingers open and the crucible is dropped.

Operating the machine

19

5. The arm goes first to the home position and then it turns back to the pick-up

position

6. Fingers down.

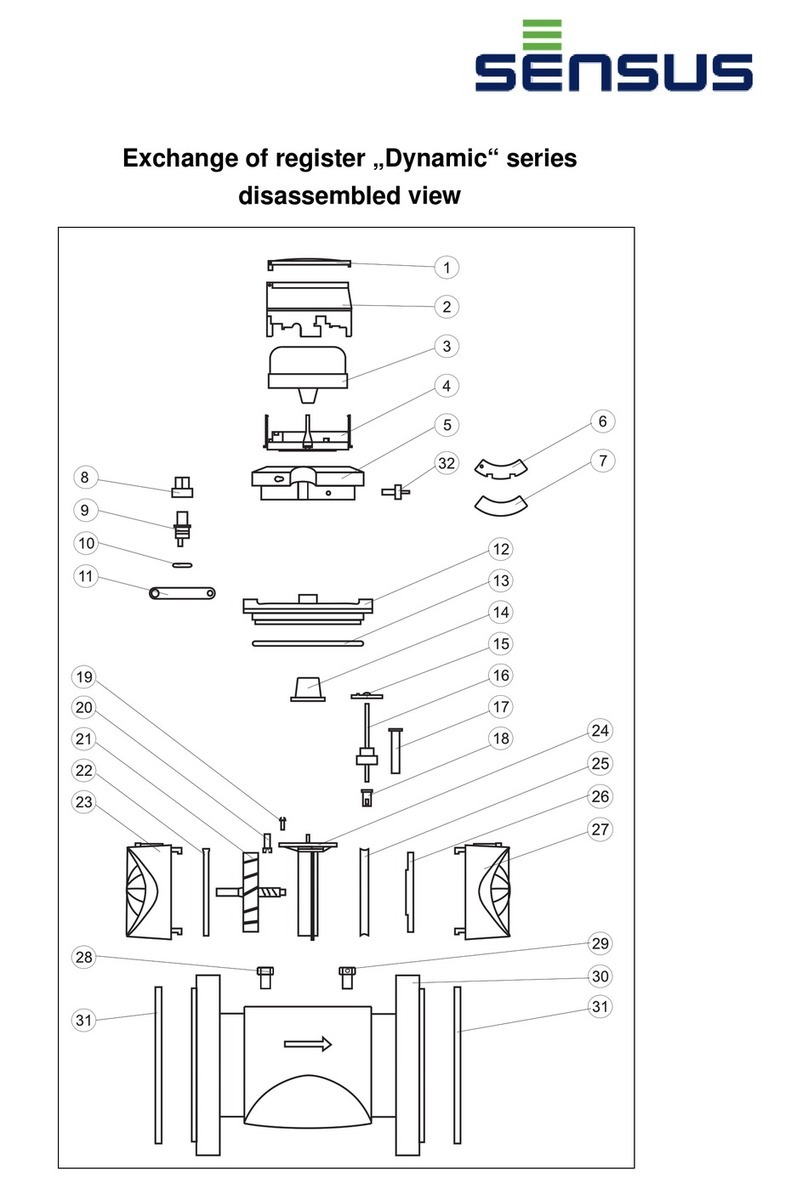

1.15 Crucible position on the platform

Fig. 17: Loader front view

Now the position of the crucible has to be adjusted to be coaxial to the fingers. For

moving the crucible to the left and to the right, slightly loose the screws (1) and (2)

and shift the whole platform (5) accordingly. For moving the platform back and for,

loose the screws (3) and (4).

1. Fingers close. Again, if the crucible doesn’t move when the fingers close, the

crucible is at the right place.

2. Fingers up.

3. Parking position.

1.16 Height of the platform

1. The fingers turn to the pedestal. Check the distance between the top of the

Pedestal and the bottom of the crucible to be 12.5 mm. If it is only approx.

12.5 mm, don’t try to adjust accurately, rather go to the next step.

2. Fingers down. While pressing, watch carefully the crucible. If the height of

the crucibles platform is correct, the crucible should just touch the pedestal.

If the crucible has a distance to the pedestal, the crucibles platform has to be

1

22 4

3

6

7

5

K

Operating the machine

20

lowered by the same distance. If the crucible knocks on the pedestal and the

arm turns up from the horizontal position, the crucibles platform has to be

lifted higher. For moving the platform up and down, loose the screws (1) and

(2) see image autoloader front view. Loose the nut (6) of the foot (7) and turn

the foot by inserting a thin screwdriver or a piece of wire into the hole of the

foot (7). Turn clockwise to lower the platform with the crucible, turn counter

clockwise to move the platform higher. Fix the nut (6) and the screws (1) and

(2).

3. Fingers open.

4. Fingers up.

5. First home and then pick-up position.

6. Parking position.

1.17 Repeating the single step cycle

The next pressing of the adjust button will start the next cycle i.e. the arm will go to

position 1 again. It is advisable to make a couple of cycles with single step to make

sure that the mechanical adjustments described before, are accurate, if not

readjust.

1.18 Non stop cycles

In some cases the automatic repetition of complete cycles is required. For example

in case of a continuous test of the loader by placing 130 empty crucibles for the

loader to run 130 cycles in unattended operation. Also at exhibitions the nonstop

mode without combustion is required. This is obtained by keeping the switch

pressed already before switching on the power, and by keeping it pressed as long

as the cycles have to run.

To do this:

–Place 130 empty crucibles on the loader (or any other required quantity of

crucibles) starting from the left front tray (1) continuing to the left (crucibles 2,

3, 4 etc.) See figure loader steps.

–In order to avoid the need of continuous manual pressing of the button, it

can be mechanically fixed in pressed position before switching on the

analyzer, by mechanically fixing of the button (5) using a rubber ring, see

figure pneumatic connections.

–The analyzer is switched from position 0 to position 1 of the mains power

switch.

–After the last crucible is taken from the platform, the loader will turn the chain

for a while, looking for any more crucibles. If no crucible is found, the chain will

stop turning. The loader electronics will signalize the missing crucibles by triple

beeping. See error messages.

1.19 Error messages

The loader electronic board contains a buzzer for signalizing errors. The number of

beeps in a row specifies the problem according to the table below.

No. of

beeps

Error description

1

The beam of the vertical laser cannot be detected. Defective laser or

detector, dirt in between, arm in between.

2

The beam of the vertical laser is continuously detected. Error of the

finger´s motor.

3

No crucible on the loader although the loader received the command

to load the next crucible.

Other manuals for CS-800

2

This manual suits for next models

1

Table of contents

Other ELTRA Measuring Instrument manuals

ELTRA

ELTRA Thermostep TGA User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA ON-900 User manual

ELTRA

ELTRA CSi/d User manual

ELTRA

ELTRA ELEMENTRAC ONHp2 User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA CS-i User manual

ELTRA

ELTRA CS-800 User manual

ELTRA

ELTRA CS-2000 User manual

ELTRA

ELTRA ELEMENTRAC CS-i User manual

Popular Measuring Instrument manuals by other brands

Autometers Systems

Autometers Systems IC 995 Installation and operating manual

Sokkia

Sokkia 130R Series Operator's manual

MGP Instruments

MGP Instruments DRM-1 OPERATION & CALIBRATION MANUAL

Sensus

Sensus Dynamic Series quick start guide

Atal

Atal ATD-06 instruction manual

Siemens

Siemens SITRANS MAG 5100W instructions