ELTRA ELEMENTRAC ONHp2 User manual

© Eltra GmbH, Germany, 42781 Haan, Retsch-Allee 1-5, Germany | 06.10.2021 Version 0005

Operating instructions

ELEMENTRAC ONHp2

Translation

Table of contents

2

Copyright

© Copyright by

Eltra GmbH

Retsch-Allee 1-5

42781 Haan

Germany

Table of contents

3

Table of contents

4

Table of contents

Table of contents............................................................................................................................................. 4

1Additional operating instructions........................................................................................................ 6

1.1 Explanations of signs and symbols ................................................................................................... 6

1.2 Disclaimer.......................................................................................................................................... 6

1.3 Copyright............................................................................................................................................ 6

2Safety...................................................................................................................................................... 7

2.1 Explanations of the safety instructions .............................................................................................. 8

2.2 General safety instructions ................................................................................................................ 9

2.3 Repairs............................................................................................................................................. 10

2.4 Intended use.................................................................................................................................... 10

2.5 Improper use.................................................................................................................................... 10

2.6 Safety symbols on the device.......................................................................................................... 11

2.7 Emergency stop............................................................................................................................... 12

2.8 Remaining safety hazards ............................................................................................................... 12

3Description........................................................................................................................................... 18

3.1 Analyser ONH-p 2............................................................................................................................ 18

3.1.1 Front side..................................................................................................................................... 18

3.1.2 Rear side of the analyser............................................................................................................. 20

3.1.3 Auto cleaner................................................................................................................................. 22

4Installation............................................................................................................................................ 23

4.1 Transport and unpacking................................................................................................................. 23

4.2 Setting up......................................................................................................................................... 25

4.3 Filling the reagent tubes .................................................................................................................. 27

4.4 Providing the gas supply.................................................................................................................. 29

4.5 The cooling water supply is provided .............................................................................................. 30

4.5.1 Connecting the supplied heat exchanger .................................................................................... 30

4.5.2 Connection of a third-party heat exchanger ................................................................................ 31

4.6 Connect the device to the PC.......................................................................................................... 33

4.7 Provide power supply ...................................................................................................................... 33

4.8 Installing the auto cleaner (optional)................................................................................................ 34

5Commissioning.................................................................................................................................... 38

5.1 Commissioning and setting up the ELEMENTRAC ONH-p 2 ......................................................... 38

5.2 Commissioning and setting up the auto cleaner (optional) ............................................................. 38

6Operation of the device ...................................................................................................................... 41

7Technical data...................................................................................................................................... 44

7.1 Technical data ELEMENTRAC ONH-p 2 ........................................................................................ 44

7.2 Name plate ELEMENTRAC ONH-p 2 ............................................................................................. 46

7.3 List of standards............................................................................................................................... 47

8Troubleshooting on the ELEMENTRAC ONH-p 2............................................................................. 48

9Cleaning ............................................................................................................................................... 48

9.1 Exterior cleaning.............................................................................................................................. 48

9.2 Cleaning the dust trap...................................................................................................................... 49

9.2.1 Cleaning the sinter filter............................................................................................................... 49

9.3 Cleaning the furnace area ............................................................................................................... 50

10 Maintenance......................................................................................................................................... 51

10.1 Overview of the maintenance work.................................................................................................. 51

10.2 Removing and installing of reagent tubes ....................................................................................... 53

10.3 Reagents.......................................................................................................................................... 57

10.4 Replacing the reagent tube of the catalyst furnace......................................................................... 58

10.5 Filling of reagent tubes .................................................................................................................... 61

Table of contents

5

10.5.1 Overview of the reagent tubes................................................................................................. 62

10.5.2 Fill the reagent tube of the catalyst.......................................................................................... 63

10.5.3 Fill the reagent tube of the gas processing (thermal conductivity cell, carrier gas)................. 64

10.5.4 Fill the dust trap of the reagent tube........................................................................................ 65

10.5.5 Filling the reagent tube of the water trap................................................................................. 66

10.5.6 Filling the reagent tube of the CO converter............................................................................ 67

10.6 Replacing the O-rings...................................................................................................................... 67

10.7 Maintenance in the furnace area..................................................................................................... 68

10.7.1 Changing the seal of the upper furnace closure...................................................................... 68

10.7.2 Changing the seal of the lower furnace lock............................................................................ 70

10.7.3 Replacing the upper electrode................................................................................................. 71

10.7.3.1 Replacing an electrode.................................................................................................... 71

10.7.3.2 complete electrode replacement, including screws......................................................... 73

10.7.4 Replace lower electrode (graphite tip)..................................................................................... 76

10.8 Replacing the brush of the auto cleaner.......................................................................................... 77

11 Spare parts........................................................................................................................................... 78

11.1 Spare parts Analyser ....................................................................................................................... 78

11.1.1 Front side of the device ........................................................................................................... 78

11.1.2 Front side (Interior view).......................................................................................................... 79

11.1.3 Lower furnace.......................................................................................................................... 81

11.1.4 Upper furnace.......................................................................................................................... 82

11.1.5 Rear side of the device............................................................................................................ 83

11.1.6 Left side of the device.............................................................................................................. 84

11.1.6.1 Left side, DevGate........................................................................................................... 85

11.1.6.2 Left side, inlet valves ....................................................................................................... 86

11.1.6.3 Valve block, compressed air control................................................................................ 87

11.1.7 Right side of the device ........................................................................................................... 88

11.1.8 Upper mounting plate .............................................................................................................. 89

11.2 Auto cleaner spare parts.................................................................................................................. 91

11.3 Fuses............................................................................................................................................... 93

11.4 Consumables................................................................................................................................... 93

11.5 Consumables for auto cleaner......................................................................................................... 93

12 Decommissioning................................................................................................................................ 94

13 Storage ................................................................................................................................................. 94

14 Disposal................................................................................................................................................ 95

Additional operating instructions

6

1 Additional operating instructions

These operating instructions are a technical manual for the safe operation of the device. Please

read these operating instructions carefully before installing, commissioning and operating the

device. Reading and understanding these operating instructions is a prerequisite for the safe and

proper use of the device.

This operating instructions do not include any repair instructions . If anything is unclear or if you

have questions about these instructions or the device as well as in case of any defects or

necessary repairs, please contact your supplier or directly the Eltra GmbH.

For more information about your device, please visit the device-specific pages at www.eltra.com.

Revisions status

The document revision 0005of the operating instructions “ELMENTRAC ONH-p 2” has been

prepared in accordance with the Machinery Directive 2006/42/EC.

1.1 Explanations of signs and symbols

The following signs and symbols are used in these operating instructions:

Signs

Meaning

Additional or further information is

available here..

Further or additional information.

1. First instruction.

2. Following instruction.

Result.

Numbered paragraphs contain sequential

instructions. An instruction may end with a result.

Tab 1: Used signs and symbols

1.2 Disclaimer

Diev orliegende Bedi enungsanleitung wurd emi tg rößter Sorgfalt erst ellt.T echnische Änd erungen sind vorbeh alten.F ür Personensc häden, die aus der Nic htbefolgung der Sicherh eits- und Warnhinweis ei n dieser Bedienungs anleitung resultier en,wi rd keine Haftung über nommen. Für Sac hschäden, die aus der Nich tbefolgung der Hinweis ei n dieser Bedienungs anleitung resultieren, wi rdk eine Haftung übernomm en.

These operating instructions have been prepared with the greatest care. Technical changes

reserved. No liability is assumed for any personal injuries resulting from non-compliance with the

safety instructions and warnings in this operation manual. No liability is assumed for any property

damages resulting from non-compliance with the instructions in this operation manual.

1.3 Copyright

These operating instructions or parts thereof may not be reproduced, distributed, edited or copied

in any form without prior written permission of Eltra GmbH. Any violation may result in claims for

damages.

Safety

7

2 Safety

Safety officer

The operator himself must ensure that the commissioned individuals working on the device

−have taken note of and understood all safety regulations,

−are aware of all the instructions and regulations of the target group relevant to them before

starting any work,

−have easy access to the operating instructions of this device at any time and without any

problems and

−have been made familiar with the safe and intended use of the device before starting any

work on the device, either through a verbal introduction by a competent person and/or

through these operating instructions.

Improper operation may cause personal injury. The operator himself is responsible for his own

safety as well as for the safety of his employees. The operator himself must ensure that no

unauthorised person has access to the device.

Target group

All persons who operate, clean, work with or on the device.

This device is a modern, high-performance product of the Eltra GmbH and was developed

according to the latest state of the art. Operational safety is ensured if this device is used in

accordance with its intended purpose and if the operating instructions provided here are followed.

Persons who are under the influence of intoxicants (medication, drugs, alcohol) or who are

overtired are not allowed to operate the device or work on it.

Safety

8

2.1 Explanations of the safety instructions

The following warnings in this operating instructions indicate potential hazards and damages:

DANGER

D1.0000

Risk of fatal injuries

Source of danger

−Possible consequences if the danger is ignored.

•Instructions and advices on how to avoid the hazard.

Failure to observe the warning “Danger” may result in fatal or serious injuries. There is a very

high risk of a life-threatening accident or permanent injury. The signal word DANGER is

additionally used in the running text or in the handling instructions.

WARNING

W1.0000

Risk of life-threatening or serious injuries

Source of danger

−Possible consequences if the danger is ignored.

•Instructions and advices on how to avoid the hazard.

Failure to observe the warning instruction “Warning” may result in life-threatening or serious

injuries. There is an increased risk of a serious accident or potentially fatal injury. The signal

word WARNING is additionally used in the running text or in the handling instructions.

CAUTION

C1.0000

Risk of injury

Source of danger

−Possible consequences if the danger is ignored.

•Instructions and advices on how to avoid the hazard.

Failure to observe the warning instruction “Caution” may result in moderate of minor injuries.

There is a medium or low risk of accident or personal injury. The signal word CAUTION is

additionally used in the running text or in the handling instructions.

NOTICE

N1.0000

Type of property damage

Source of property damage

−Possible consequences if the notices are not observed.

•Instructions and notices on how to prevent property damage.

Failure to observe the notice may result in property damages. The signal word NOTICE is

additionally used in the running text or in the handling instructions.

Safety

9

2.2 General safety instructions

CAUTION

C2.0002

Risk of injury

Ignorance of the operating instructions

−The operating instructions contain all safety-relevant information. Failure

to observe the operating instructions may therefore cause injuries.

•Please read these operating instructions carefully before operating

the device.

CAUTION

C3.0015

Risk of injury

Improper changes to the device

−Improper changes to the device may cause injuries.

•Do not make any unauthorised changes to the device.

•Use exclusively spare parts and accessories which have been

approved by the company Eltra GmbH!

NOTICE

N2.0012

Changes to the device

Improper modifications

−The conformity to the European directives declared by Eltra GmbH shall

lose its validity through improper modification. Any warranty claims shall

become void.

•Do not make any unauthorised modifications to the device.

•Use exclusively spare parts and accessories which have been

approved by Eltra GmbH.

Safety

10

2.3 Repairs

This operating instructions do not include any repair instructions. For safety reasons, repairs may

only be carried out by Eltra GmbH or an authorised representative as well as by qualified service

technicians.

In case of any repair, please contact…

…the representative of Eltra GmbH in your relevant country,

…your supplier, or

…directly the Eltra GmbH.

Service address:

Eltra GmbH

Retsch-Allee 1-5

42781 Haan

Germany

+49 2104 2333-444

www.eltra.com

2.4 Intended use

This device is used for the thermal digestion and subsequent determination of the

element content of metallic samples. The device may only be used in the laboratory by

appropriately trained and instructed personnel.

2.5 Improper use

Using the device in the private sector as well as for applications other than those mentioned in

Section „Intended use“is not permitted. Any repairs and modifications may only be carried out by

the company Eltra GmbH or an authorised representative and by qualified service technicians.

Safety

11

2.6 Safety symbols on the device

Safety symbols on the ONH-p 2 device warn of potential hazards when operating the device.

The following safety symbols can be found on the analyser:

Figure 1: Safety symbols on the analyser

2

5

4

1

3

6

Safety

12

Position

Component

Description

1,3,6

The warning symbols

1: in the rear area of the cover plate

3: in the upper, central area of the right side

wall

6: On the door at the rear side of the device

there is a warning symbol attached which

means that these covers may only be

opened by qualified personnel.

2

This warning symbol in the area of the

catalyst furnace warns of burns to fingers

and hands.

4, 5

The warning symbols on the furnace

opening warn of burns and the risk of

crushing fingers or hands.

2.7 Emergency stop

The emergency stop is controlled via the main switch of the device.

In case of an emergency, the device can be switched off as follows:

1. Turn the main switch of the analyser to switch position 0.

2.8 Remaining safety hazards

DANGER

D2.0005

Danger to life from electric shock

Exposed electrical contacts –High voltage

−An electric shock can cause severe injuries in the form of burns, cardiac

arrhythmias, respiratory arrest or cardiac arrest.

•Any work on the device may only be carried out by qualified service

personnel.

•Turn the power switch of the analyser to position 0 and pull the

mains plug out of the socket.

WARNING

W2.0015

Danger to life from electric shock

Connection to socket without protective conductor

−When connecting the device to sockets without a protective conductor, life-

threatening injuries from electric shock may occur.

•Operate the device exclusively on sockets with a protective conductor

(PE).

Safety

13

WARNING

W3.0002

Danger to life from electric shock

Damaged power cable

−Operating the device with a damaged power cable or plug can lead to life-

threatening injuries from electric shock.

•Before operating the device, check the power cable and plug for any

damage.

•Never operate the device with a damaged power cable or plug!

WARNING

W4.0017

Risk of injury

Hazardous chemicals

−When working on the device, hazardous chemicals can cause fatal

poisoning or severe skin burns.

•Please observe the safety data sheet in terms of the substances used.

•Please wear your personal protective equipment.

•Never eat or drink within the immediate vicinity of chemicals.

WARNING

W5.0021

Fire hazard / Risk of burns

Hot parts (crucibles, reagents,...) can fall down

−Ignition of tables, floors or any other surface on which the hot parts can fall.

−Ignition of clothing and other materials.

•Set up the device in a fire-proof environment. Please pay particular

attention to the table, the floor and any other surface in the immediate

vicinity of the device.

•Always wear suitable work clothing.

•Keep the work area free from any materials that could catch fire.

Safety

14

WARNING

W6.0000

Danger of poisoning

Toxic combustion gases

−The samples are exposed to high temperatures during analysis. In this

process, harmful gaseous fission products can be released or formed from

reaction processes. These gases can escape from the gas outlet or the

furnace and cause severe poisoning.

•Connect the exhaust air outlet of the device to a suitable ventilation

system.

•Please wear your personal protective equipment.

•Please observe the safety data sheets in terms of the substances

used.

•Carry out a risk analysis regarding the hazard potential of your

samples and implement relevant protective measures.

WARNING

W7.0000

Risk of life-threatening injuries

Falling loads

−The device may only be transported or lifted with suitable aids, such forklift

or crane. Loads can fall down and cause life-threatening injuries.

•Lift and transport the device exclusively by means of suitable aids,

such as forklift or crane.

•Secure the device during transport with suitable safety belts (supplied

straps).

•Please observe the centre of gravity of the device (on the right side of

the device).

•Keep a safe distance during transport.

•Never walk or stand under suspended loads.

WARNING

W8.0003

Danger to life from electric shock

Cleaning of the device

−Any cleaning work with water on the device can lead to life-threatening

injuries from electric shock, if the device is not disconnected from the power

supply.

•Only perform cleaning work with water on the device when the device

is disconnected from the power supply.

Safety

15

CAUTION

C4.0000

Risk of injury

Moving parts

−The furnace closes after user input. Hands in the area of the opening can

be crushed when the furnace closes.

•Never reach into the oven when it is closing.

•Use crucible tongs in order to place crucibles.

CAUTION

C5.0000

Risk of injury

Moving parts

−The lock moves according to user input. Hands in the area of the upper

furnace lock can be crushed when the lock closes.

•Never reach into a moving lock.

CAUTION

C6.0092

Falling device

Incorrect installation or insufficient workplace

–The weight of the device can cause personal injury if it falls down.

•Only operate the device on a sufficiently large, sustainable, slip-

resistant and stable workplace.

•Please ensure that all feet of the device have a secure footing.

CAUTION

C7.0000

Cutting injuries

Broken glass

−Sample tubes and reagent tubes are made of glass and can break. Broken

glass can cause cutting injuries.

•Please check reagent tubes and sample tubes for any damage before

use.

•Please wear protective gloves and goggles when handling with

reagent tubes and sample tubes.

•Replace damaged reagent tubes and sample tubes.

•Do not touch broken glass with unprotected hands.

CAUTION

C8.0000

Risk of injury

Moving parts

−There are fans inside the left side of the analyser. Spinning fans can cause

injuries to fingers.

•Never reach into a rotating fan.

Safety

16

CAUTION

C9.0000

Risk of burns

Hot equipment parts

−Parts of the device can become very hot and cause burns during the

performance of any maintenance work if the waiting time for cooling is not

observed.

•Please wait until the furnace temperatures cooled down to < 40 0C

before performing any maintenance work.

•Check the furnace temperatures in the ELEMENTS software.

CAUTION

C10.0076

Risk of burns

Hot equipment parts

−Some parts of the device can become very hot and cause burns if they are

touched without protective gloves.

•Please wear heat-resistant protective gloves when handling with hot

device parts.

•Never touch hot parts of the device without suitable protective gloves.

CAUTION

C11.0093a

Risk of burns

Hot crucibles

−The crucible can be very hot after the analysis, and it can cause fires and

thus personal injuries if it comes into contact with flammable surfaces.

•Please only use suitable crucible tongs to transport used crucibles.

•Please make sure that there are no flammable materials below the

furnace opening.

•Only open the furnace after a suitable waiting time has elapsed.

•If necessary, adjust the waiting time in the program in such a way that

the sample carrier can cool down sufficiently.

CAUTION

C12.0090

Risk for eye injuries

Chemicals

−When chemicals are replaced, small particles of the chemicals can float in

the air and burn the eyes.

•Please always wear protective goggles when working with chemicals.

•Please observe the safety data sheets in terms of the chemicals used.

Safety

17

CAUTION

C13.0000

Risk of injury

Pressurised system

−The device is pressurised during operation. Removing reagent tubes during

operation may lead to an explosive escape of chemicals or sample material

and can cause injuries.

•Never remove any reagent tubes during operation.

•Use the software in order to put the device into the mode “Replace

reagents” before performing any work on the device.

CAUTION

C14.0094

Risk of burns

Hot catalyst furnace

•The furnace temperature of the catalyst furnace can be up to 800°C

during operation and cause severe burns.

•Please wear heat-resistant protective gloves when handling with the

catalyst furnace.

•Before any maintenance work can be performed, please wait until

the furnace temperature is < 40 0C.

•Check the furnace temperatures in the ELEMENTS software.

•Replace the filling of the catalyst furnace only after a sufficiently

long cooling time.

Caution

C15.0107

Weight:165 kg –The centre of gravity of the device is located on the right side.

Dimensions (WxHxD):56 x 78 x 64 cm

Description

18

3 Description

The ELEMENTRAC ONH-p 2 device is an elemental analyser. By melting samples in a pulse

furnace, the device is able to determine oxygen, nitrogen and hydrogen concentration in inorganic

samples. The gaseous combustion products are measured by infrared and thermal conductivity

cells.

3.1 Analyser ONH-p 2

3.1.1 Front side

The following figure shows the front side of the device:

Figure 2: Front side of the ELEMENTRAC ONHp2

1

2

3

4

5

6

7

8

Description

19

Position

Component

Description

1

Catalyst furnace

Is used for the processing of analysis gases

2

Reagents

Are used for the processing of analysis gases

3

Sample receipt

This is where the sample to be analysed is inserted.

4

Furnace cover

The impulse furnace is located behind the cover.

5

Dust filter

This filter removes particles from the gas flow.

6

Crucible

This is where a crucible must be placed before the

analysis.

7

Crucible carrier

8

Main switch

Position 0: Turns off the device

Position 1: Preheats the device

Position 2: Puts the device ready for analysis

Description

20

3.1.2 Rear side of the analyser

The following figure shows the rear side of the analyser:

Fig. 1: side of the analyser

1

2

3

4

6

7

8

9

10

11

12

13

5

Table of contents

Other ELTRA Measuring Instrument manuals

ELTRA

ELTRA ON-900 User manual

ELTRA

ELTRA Thermostep TGA User manual

ELTRA

ELTRA CS-2000 User manual

ELTRA

ELTRA ON-900 User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA CS-2000 User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA ELEMENTRAC CS-i User manual

ELTRA

ELTRA CS-i User manual

ELTRA

ELTRA CS-800 User manual

Popular Measuring Instrument manuals by other brands

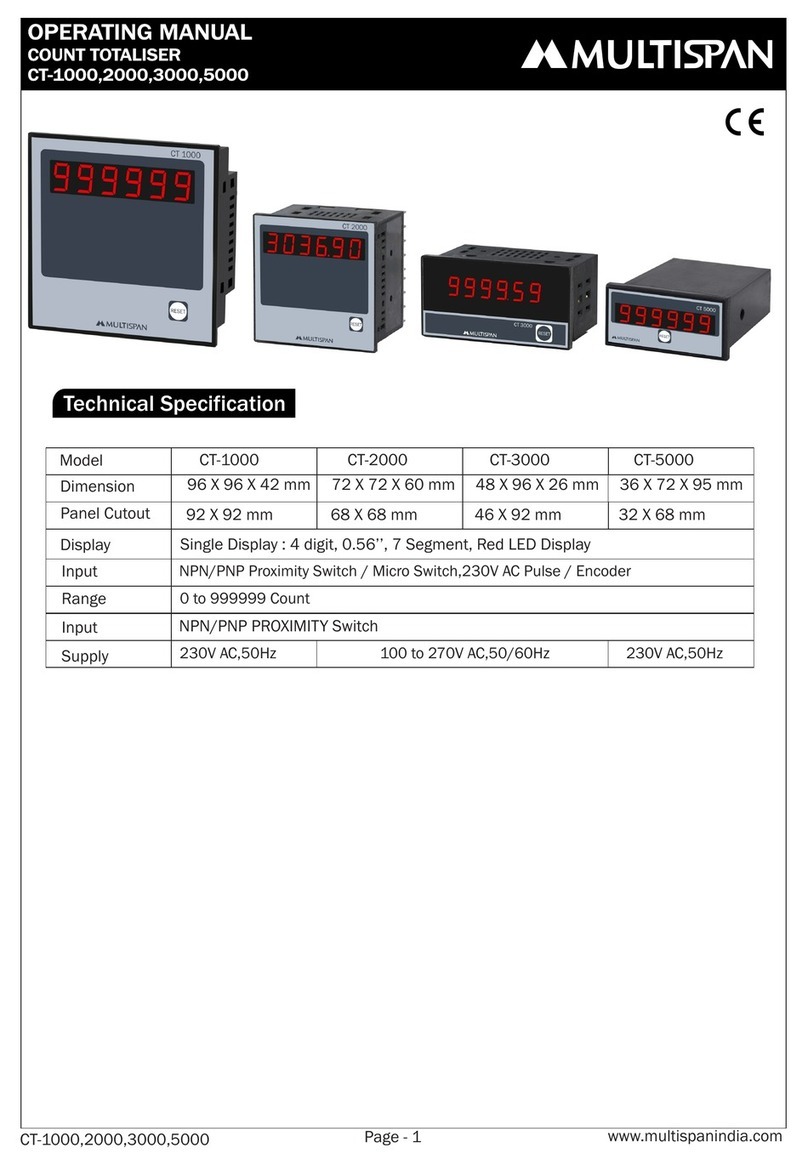

MULTISPAN

MULTISPAN AVH-14 manual

Elenco Electronics

Elenco Electronics TWT-1 instruction manual

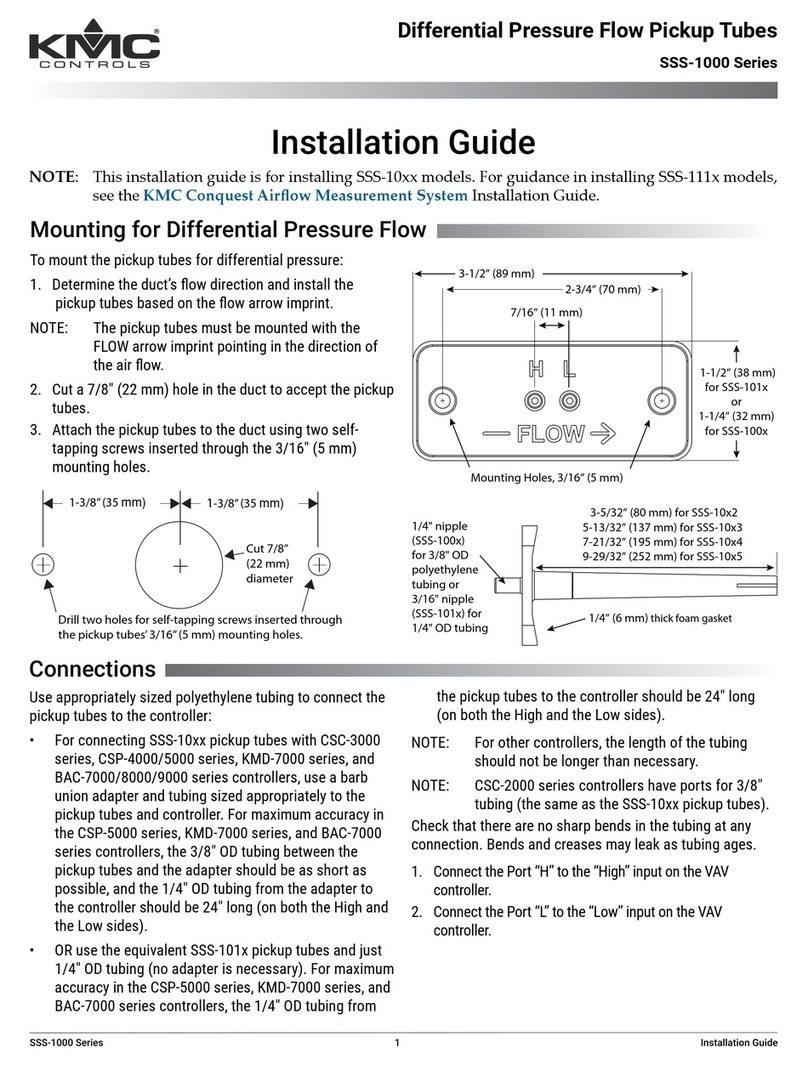

KMC Controls

KMC Controls SSS-1000 Series installation guide

SKF

SKF LINCOLN VP Series operating instructions

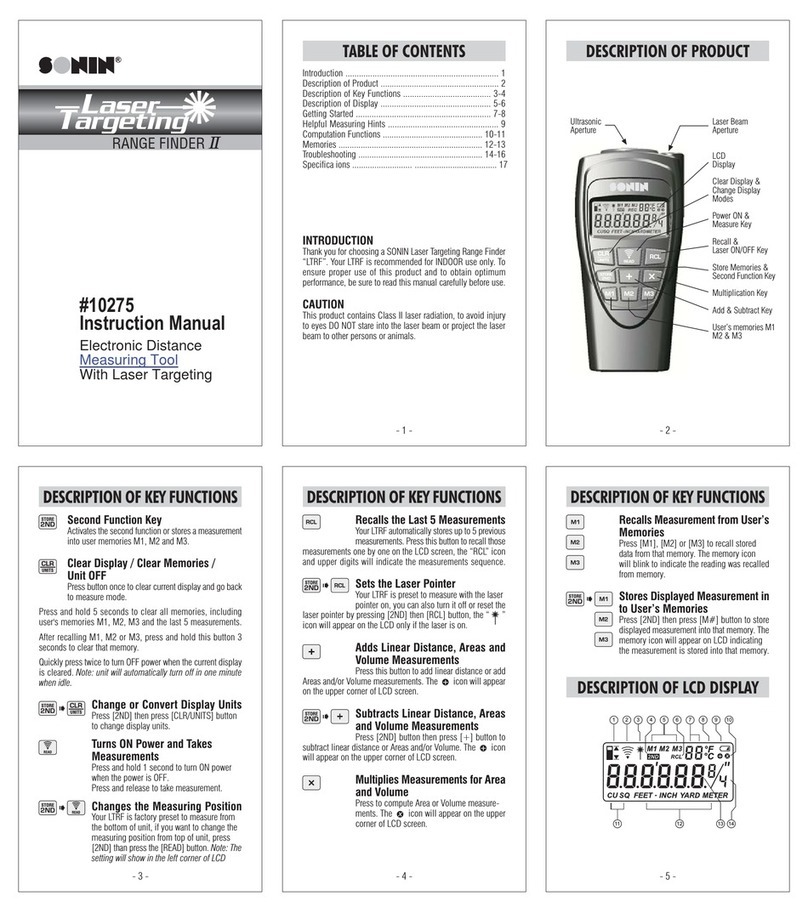

Sonin

Sonin 10275 instruction manual

UWT

UWT NivoRadar NR 7100 Series Technical Information/Instruction manual